Professional Documents

Culture Documents

LESSONS FROM THE NEW GRP STANDARD EN 13121-3

Uploaded by

alang_business0 ratings0% found this document useful (0 votes)

651 views1 pageThe document discusses key aspects of the European standard EN 13121-3:2016 for GRP chemical equipment. Some of the important features discussed include:

1) The standard introduces limit state design concepts along with a partial factor method to account for uncertainties in material properties and testing.

2) It brings a proper grading of resins, recognizing that the resin, not just the fibers, control durability and serviceability of GRP products.

3) Safety factors indicate the level of uncertainty for different parameters, and are largest for material property testing, showing batch-to-batch variability must be considered in designs.

4) Users must follow all provisions of the standard rigorously to ensure reliability and dur

Original Description:

Lessons to Be Learned - En 13121-3 2016

Original Title

Lessons to Be Learned - En 13121-3 2016

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses key aspects of the European standard EN 13121-3:2016 for GRP chemical equipment. Some of the important features discussed include:

1) The standard introduces limit state design concepts along with a partial factor method to account for uncertainties in material properties and testing.

2) It brings a proper grading of resins, recognizing that the resin, not just the fibers, control durability and serviceability of GRP products.

3) Safety factors indicate the level of uncertainty for different parameters, and are largest for material property testing, showing batch-to-batch variability must be considered in designs.

4) Users must follow all provisions of the standard rigorously to ensure reliability and dur

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

651 views1 pageLESSONS FROM THE NEW GRP STANDARD EN 13121-3

Uploaded by

alang_businessThe document discusses key aspects of the European standard EN 13121-3:2016 for GRP chemical equipment. Some of the important features discussed include:

1) The standard introduces limit state design concepts along with a partial factor method to account for uncertainties in material properties and testing.

2) It brings a proper grading of resins, recognizing that the resin, not just the fibers, control durability and serviceability of GRP products.

3) Safety factors indicate the level of uncertainty for different parameters, and are largest for material property testing, showing batch-to-batch variability must be considered in designs.

4) Users must follow all provisions of the standard rigorously to ensure reliability and dur

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

FROM THE EDITOR’S DESK

LESSONS TO BE LEARNED FROM

EN 13121-3:2016

EN 13121 is the European standard for GRP chemical removed by adopting partial factors for each type of uncertainty.

equipment which replaces BS 4994.In the May issue of this I believe that extensive research might have gone into the

journal, I wrote about the features of this new standard.One formulation of this standard. As I wrote in the last editorial, the

important feature is the introduction of Limit state design standard for the first time brought a proper grading of resins.

concept in conjunction with partial factor method. For the benefit The standard clearly brings out that it is the resin and not the

of readers, a full feature on this design method is presented in fibrethat controls the serviceability and durability. Many believe

this issue.Part of this articlewill be continued in the next issue. that resin is only a bonding medium and any resin will do the

The limit state design concept has been in use since 1974 in job. The standard shows it is not true. Good resin shall be used

European codes for the design of structures made of steel, for creating good products.

aluminium, reinforced concrete, timber and masonry structures.

This method is now used in the 2016 edition of EN 13121-3. The value of partial safety factor is an indication of the level of

Though many more improvements are needed in its use, uncertainty in that parameter. The Factor A1 relating to the test

adoption of this limit state concept for chemical equipment is verification of material properties is the largest among all

certainly a welcome forward step. The standard brings GRP on factors. It indicates the batch to batch property variation that

par with other major engineering construction materials. The exists for fibres and resins. Standard does not recognize test

benefits of design based on this methodology will be better reports prepared before 18 months. When the test report is 18

understood only when the users start using it for practical months' old, the safety factor is 50% more than that of samples

designs. Do not equate GRP with ordinary plastics. prepared just before the design. This means that 50 % more

materials must be used. It is cheaper to test materials and use

I used to emphasize that Composites technology is both the proper value for design rather than add more materials and

“knowledge based and knowledge driven”.Every step of design increase cost. Since it is the purchasers who suffer the financial

and manufacture shall be executedwith proper scientific loss due to premature failure of the product or due to cost of

understanding and decision making.Recognition of this fact is excess materials used, they mustinsist to get the designs made

the reason for the success of composites in aerospace and with proper material properties. Very often design is being done

defense sectors bringingmuch needed weight savings. Such a after making the product for clearing the payment. Purchaser

rigorous knowledge based analysis is costly to be adopted in the must ask for design before the product is made. They must also

industrial and social sectors. Yet, EN 13121 has brought in insist guarantee of service life that they expect from the product.

scientific decision making for selection of fibres, resins, product

wall structure and laminate property evaluation methods. Another tendency seen is to sideline the many stringent

Product is designed for both serviceability requirements during provisions given in the standard. We shall not sideline the

normal operation and structural resistance for overload various provisions of the standard, because the reliability and

conditions. The arbitrariness of selection of safety factor is durability must be lost.Do not get quality certificate for one set of

materials and use other set of materials.

Dr. N.G. NAIR

Honorary Editor

06 COMPOSITES TODAY VOLUME 02 ISSUE 06 JUNE 2017

You might also like

- I S En13121-3-2016Document15 pagesI S En13121-3-2016Vivek ChaurasiaNo ratings yet

- En 13121 GRPDocument9 pagesEn 13121 GRPStephen100% (1)

- 58-0100 FRP - Process - Vessels PDFDocument20 pages58-0100 FRP - Process - Vessels PDFmayukhguha1988No ratings yet

- Case Study of Vessel As Per BS 4994Document4 pagesCase Study of Vessel As Per BS 4994nagarathinam82100% (1)

- FRP Construction With DERAKANE Epoxy Vinylester ResinsDocument65 pagesFRP Construction With DERAKANE Epoxy Vinylester ResinstyNo ratings yet

- Design of FRP Cylindrical Vertical Tank BS4994Document3 pagesDesign of FRP Cylindrical Vertical Tank BS4994Eleazar Mendoza100% (2)

- Design CalculationDocument5 pagesDesign CalculationBrandon Allen60% (5)

- Mechanical Design Calculation of FRP Tank: Project No. - Rev. 02 Document No. 1-074-9/DKP/18 Page 1 of 20Document25 pagesMechanical Design Calculation of FRP Tank: Project No. - Rev. 02 Document No. 1-074-9/DKP/18 Page 1 of 20muchamad yasinNo ratings yet

- Design of HCL FRP Storage TANKDocument21 pagesDesign of HCL FRP Storage TANKEleazar Mendoza86% (7)

- Glass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Document18 pagesGlass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Syed Arsalan Afsar100% (2)

- FRP Vessel Design As Per ASME Sec XDocument6 pagesFRP Vessel Design As Per ASME Sec Xlalitlbw9150% (2)

- Specification For FRP TankDocument10 pagesSpecification For FRP TankKyaw Kyaw Aung75% (4)

- Adriano, A. - Global FRP Standards. A Comparison Between Four Different Design Codes For FRP Vessels - (2014)Document16 pagesAdriano, A. - Global FRP Standards. A Comparison Between Four Different Design Codes For FRP Vessels - (2014)Anonymous q2HC0zyfa2No ratings yet

- FRP Tank Manufacturing MethodsDocument13 pagesFRP Tank Manufacturing Methodsrangabhama9214No ratings yet

- Tank Thickness CalculationDocument1 pageTank Thickness Calculationgovindharajalu100% (6)

- D 6041 - 97 PDFDocument7 pagesD 6041 - 97 PDFlitalomp05No ratings yet

- FRP Vessel CalculationDocument16 pagesFRP Vessel Calculationmukesh75% (16)

- Design Calculation-CYL VERTICAL 1.0mDIA X 1.10m ST HT TankDocument17 pagesDesign Calculation-CYL VERTICAL 1.0mDIA X 1.10m ST HT TankEleazar Mendoza50% (2)

- Design of HCL FRP Storage TANKDocument21 pagesDesign of HCL FRP Storage TANKHaries Bugarin GarciaNo ratings yet

- Anti-corrosion Lining for Concrete PoolsDocument4 pagesAnti-corrosion Lining for Concrete Poolsmuchamad yasinNo ratings yet

- GRP Tank Calculator, Sands Civil Services Estimation To BS 4994Document2 pagesGRP Tank Calculator, Sands Civil Services Estimation To BS 4994Sung Woong Moon100% (1)

- FRP Tanks and VesselsDocument5 pagesFRP Tanks and VesselsManish030119830% (1)

- BS en 13923-2005 PDFDocument44 pagesBS en 13923-2005 PDFBravo Rd50% (4)

- GRP Chemical Storage TanksDocument5 pagesGRP Chemical Storage TanksKarim El ShamashergyNo ratings yet

- Tank Specification - Fiberglass Tanks 0408Document13 pagesTank Specification - Fiberglass Tanks 0408shankarkl100% (2)

- RTP-1 A Standard For FRP Storage TanksDocument32 pagesRTP-1 A Standard For FRP Storage TanksCarlos J Dávila88% (8)

- FRP Fabrication ManualDocument26 pagesFRP Fabrication ManualTanmay Majhi100% (1)

- GRP Tank Calculator BS 4994Document2 pagesGRP Tank Calculator BS 4994vuqar0979100% (2)

- There Are Three Main Groups of Resin:: Polyester ResinsDocument1 pageThere Are Three Main Groups of Resin:: Polyester ResinsmukeshNo ratings yet

- bs4994 Case Study PDFDocument4 pagesbs4994 Case Study PDFA.Subin DasNo ratings yet

- ch26 PDFDocument70 pagesch26 PDFbookppNo ratings yet

- Difference Between Spiral Wound and Simple HDPE TankDocument1 pageDifference Between Spiral Wound and Simple HDPE Tankjokish0% (1)

- Internal Lining of Pressure VesselsDocument21 pagesInternal Lining of Pressure VesselsPattabhi Ramaraju100% (2)

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDocument12 pagesR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- High HDT Superior Vinyl Ester Resin - Crest731Document3 pagesHigh HDT Superior Vinyl Ester Resin - Crest731GautamNo ratings yet

- Tank Design: EN 1993 4 2 Eurocode 3Document31 pagesTank Design: EN 1993 4 2 Eurocode 3אחמד סלאח כאמלNo ratings yet

- FRP ItpDocument2 pagesFRP ItpHrishikesan100% (2)

- Analysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsDocument5 pagesAnalysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- GRP Tank Design Refer-40-KlDocument10 pagesGRP Tank Design Refer-40-KlA.Subin Das100% (1)

- AD 2000 HesapDocument11 pagesAD 2000 HesapBaşarŞenNo ratings yet

- FRP TankDocument3 pagesFRP TankDota Ng100% (1)

- Painting System Guide: SSPC: The Society For Protective CoatingsDocument2 pagesPainting System Guide: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- GRP CalculatorDocument2 pagesGRP Calculatorvuqar0979No ratings yet

- Rectangular Tank CalculationDocument6 pagesRectangular Tank Calculationprince kumarNo ratings yet

- Neoprene Gasket y and M Value Gri-DurlontechnicalhandbookDocument18 pagesNeoprene Gasket y and M Value Gri-DurlontechnicalhandbookpandiangvNo ratings yet

- Asme Sec X 2017Document3 pagesAsme Sec X 2017SARSAN NDTNo ratings yet

- Technical Data - JotunDocument2 pagesTechnical Data - JotunWajid ZiaNo ratings yet

- Tds Derakane Momentum 470-300Document5 pagesTds Derakane Momentum 470-300Joseph Jonathan100% (1)

- Location Thickness Type of LiningDocument7 pagesLocation Thickness Type of LiningPaul PhiliphsNo ratings yet

- RTP 1 A Standard For FRP Storage Tanks PDFDocument32 pagesRTP 1 A Standard For FRP Storage Tanks PDFDaniel Pagliardini100% (2)

- BS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFDocument60 pagesBS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFDavid FonsecaNo ratings yet

- Derakane Momentum 470 300 Epoxy Vinyl Ester ResinDocument14 pagesDerakane Momentum 470 300 Epoxy Vinyl Ester ResinKaren Elias Villegas50% (2)

- CS Raw Water Storage TankDocument18 pagesCS Raw Water Storage Tankmuchamad yasinNo ratings yet

- Assignment 809 - Principle of Material SelectionDocument33 pagesAssignment 809 - Principle of Material SelectionLOTO OLUWASAYO.INo ratings yet

- ConferencePaper AB2019 04 FADocument18 pagesConferencePaper AB2019 04 FAMito ManNo ratings yet

- Sri Venkateshwara College of Engineering Project SynopsisDocument14 pagesSri Venkateshwara College of Engineering Project Synopsisvidyadhar GNo ratings yet

- CCCCCC CCC: C C C C CCDocument5 pagesCCCCCC CCC: C C C C CCShatendra SahuNo ratings yet

- Assessment & Maintenance of Pre-Engineered Buildings: September 2016Document5 pagesAssessment & Maintenance of Pre-Engineered Buildings: September 2016Sukhendu KulkarniNo ratings yet

- Machines: The Insulation For Machines Having A High Lifespan Expectancy, Design, Tests and Acceptance Criteria IssuesDocument34 pagesMachines: The Insulation For Machines Having A High Lifespan Expectancy, Design, Tests and Acceptance Criteria IssuesneomindxNo ratings yet

- Water Systems Report - Part3Document14 pagesWater Systems Report - Part3alang_businessNo ratings yet

- Water Systems Report - Part5Document14 pagesWater Systems Report - Part5alang_businessNo ratings yet

- Water Systems Report - Part4Document14 pagesWater Systems Report - Part4alang_businessNo ratings yet

- Safety Data Sheet: Magnafloc LT25Document9 pagesSafety Data Sheet: Magnafloc LT25alang_businessNo ratings yet

- Water Systems Report - Part2Document14 pagesWater Systems Report - Part2alang_businessNo ratings yet

- Mixing Science and Practice A Reflective View FinalDocument62 pagesMixing Science and Practice A Reflective View Finalalang_businessNo ratings yet

- Biosand Filter CAWST Part7Document10 pagesBiosand Filter CAWST Part7alang_businessNo ratings yet

- Bio-Sand Filtration Mould Construction Guidelines: United Kingdom MadagascarDocument20 pagesBio-Sand Filtration Mould Construction Guidelines: United Kingdom MadagascarjarrydNo ratings yet

- Water Systems Report - Part1Document14 pagesWater Systems Report - Part1alang_businessNo ratings yet

- Appendix G: Filter Construction ChecklistDocument10 pagesAppendix G: Filter Construction Checklistalang_businessNo ratings yet

- Experimental and numerical analysis of horizontal jet flocculatorsDocument6 pagesExperimental and numerical analysis of horizontal jet flocculatorsalang_businessNo ratings yet

- Ghaneeizad (2013)Document25 pagesGhaneeizad (2013)alang_businessNo ratings yet

- Biosand Filter Manual: Design, Construction, Installation, Operation and MaintenanceDocument10 pagesBiosand Filter Manual: Design, Construction, Installation, Operation and Maintenancealang_businessNo ratings yet

- Biosand Filter Manual: Design, Construction, Installation, Operation and MaintenanceDocument94 pagesBiosand Filter Manual: Design, Construction, Installation, Operation and Maintenancealang_businessNo ratings yet

- Biosand Filter CAWST Part6Document10 pagesBiosand Filter CAWST Part6alang_businessNo ratings yet

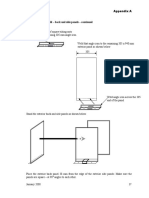

- Interior Side Pieces, Bottom (4 Pieces) : Step 2: Layout and Cut 6.4 MM ( ") Steel PlateDocument10 pagesInterior Side Pieces, Bottom (4 Pieces) : Step 2: Layout and Cut 6.4 MM ( ") Steel Platealang_businessNo ratings yet

- Step 11: Exterior Mold - Back and Side Panels - Continued: Appendix ADocument10 pagesStep 11: Exterior Mold - Back and Side Panels - Continued: Appendix Aalang_businessNo ratings yet

- Step 2 - Greasing and Assembling The Mould:: Bio-Sand Filter Construction Guidelines Page 5 of 10Document4 pagesStep 2 - Greasing and Assembling The Mould:: Bio-Sand Filter Construction Guidelines Page 5 of 10alang_businessNo ratings yet

- Sand Sieve Analysis Field MethodDocument4 pagesSand Sieve Analysis Field Methodalang_businessNo ratings yet

- Biosand Filter CAWST Part2 PDFDocument10 pagesBiosand Filter CAWST Part2 PDFalang_businessNo ratings yet

- Biosand Filter CAWST Part3 PDFDocument10 pagesBiosand Filter CAWST Part3 PDFalang_businessNo ratings yet

- Construction Guidelines, Also Available On: Additional InformationDocument10 pagesConstruction Guidelines, Also Available On: Additional Informationalang_businessNo ratings yet

- Place The Media: Appendix FDocument10 pagesPlace The Media: Appendix Falang_businessNo ratings yet

- Bio-Sand Filtration Mould Construction Guidelines: United Kingdom MadagascarDocument20 pagesBio-Sand Filtration Mould Construction Guidelines: United Kingdom MadagascarjarrydNo ratings yet

- Bio-Sand Filtration Filter Casting Instructions: United Kingdom MadagascarDocument4 pagesBio-Sand Filtration Filter Casting Instructions: United Kingdom Madagascaralang_businessNo ratings yet

- Bio-Sand Filter Construction Guidelines Page 9 of 10Document2 pagesBio-Sand Filter Construction Guidelines Page 9 of 10alang_businessNo ratings yet

- Design Procedures of Improved HafirsDocument8 pagesDesign Procedures of Improved Hafirsalang_businessNo ratings yet

- Bio-Sand Filtration Mould Construction Guidelines: United Kingdom MadagascarDocument20 pagesBio-Sand Filtration Mould Construction Guidelines: United Kingdom MadagascarjarrydNo ratings yet

- Construction Guidelines, Also Available On: Additional InformationDocument10 pagesConstruction Guidelines, Also Available On: Additional Informationalang_businessNo ratings yet

- Technical Guidelines For The Construction and Management of Improved HafirsDocument8 pagesTechnical Guidelines For The Construction and Management of Improved Hafirsalang_businessNo ratings yet

- Sample No 2 499 My22Document27 pagesSample No 2 499 My22rajat guptaNo ratings yet

- Ece-1 2346 ManuscriptDocument12 pagesEce-1 2346 ManuscriptOmer FaridNo ratings yet

- Journal of Cleaner Production: Fabíola Negreiros de Oliveira, Adriana Leiras, Paula CerynoDocument15 pagesJournal of Cleaner Production: Fabíola Negreiros de Oliveira, Adriana Leiras, Paula CerynohbNo ratings yet

- Emergency Department (Ed) Overcrowding: Evidence-Based Answers To Frequently Asked QuestionsDocument7 pagesEmergency Department (Ed) Overcrowding: Evidence-Based Answers To Frequently Asked QuestionsNurul AidaNo ratings yet

- The Tracking Shot in Kapo Serge Daney Senses of CinemaDocument22 pagesThe Tracking Shot in Kapo Serge Daney Senses of CinemaMarcos GonzálezNo ratings yet

- A Case Study of A Turnaround PrincipalDocument7 pagesA Case Study of A Turnaround PrincipalReynante Roxas MalanoNo ratings yet

- Kumpulan Berenam Pandu Puteri Tunas 2022Document7 pagesKumpulan Berenam Pandu Puteri Tunas 2022Zi YanNo ratings yet

- Acute cholecystitis pathogenesis, diagnosis and clinical featuresDocument38 pagesAcute cholecystitis pathogenesis, diagnosis and clinical featuresAdrian BăloiNo ratings yet

- Contextual Factors Chart1Document4 pagesContextual Factors Chart1api-213553729No ratings yet

- Type Test Report for AAAC ConductorDocument14 pagesType Test Report for AAAC ConductornigerluvNo ratings yet

- Extended Trumpet Techniques by Cherry Amy KristineDocument321 pagesExtended Trumpet Techniques by Cherry Amy KristineBil Smith100% (12)

- Reference: A Visual Dictionary By: D.K. Ching: ArchitectureDocument75 pagesReference: A Visual Dictionary By: D.K. Ching: ArchitectureRemzskie PaduganaoNo ratings yet

- A Comprehensive Guide To The Asia-Pacific Legal Markets - Part ReportDocument18 pagesA Comprehensive Guide To The Asia-Pacific Legal Markets - Part ReportEstherTan0% (1)

- Elllo Mixer #99 Do You Enjoy CookingDocument2 pagesElllo Mixer #99 Do You Enjoy CookingEnrique GarciaNo ratings yet

- Chapter 2Document16 pagesChapter 2ChuYumNo ratings yet

- 21st Century Literature Grade 11 21st Century Literature Grade 11 21st Century Literature Grade 11 CompressDocument75 pages21st Century Literature Grade 11 21st Century Literature Grade 11 21st Century Literature Grade 11 Compressdesly jane sianoNo ratings yet

- Prabhupada Sannyasa BookDocument221 pagesPrabhupada Sannyasa BookOriol Borràs FerréNo ratings yet

- Cruz Vs Dir. of PrisonDocument3 pagesCruz Vs Dir. of PrisonGeeanNo ratings yet

- Teacher'S Notes: Liter Ature 1ADocument3 pagesTeacher'S Notes: Liter Ature 1AAnne KellyNo ratings yet

- Activity Guide and Evaluation Rubric - Activity 7 - Creating A WIX PageDocument5 pagesActivity Guide and Evaluation Rubric - Activity 7 - Creating A WIX PageLina VergaraNo ratings yet

- Plural NounsDocument3 pagesPlural Nounsapi-440080904No ratings yet

- Consumer Buying Behaviour at Reliance PetroleumDocument4 pagesConsumer Buying Behaviour at Reliance PetroleummohitNo ratings yet

- Linart vs. UgarteDocument1 pageLinart vs. UgarteKristine JoyNo ratings yet

- How To Think Like A Professional TraderDocument7 pagesHow To Think Like A Professional TraderL100% (8)

- Green Building ToolsDocument107 pagesGreen Building ToolsVholts Villa VitugNo ratings yet

- Test Practice 1Document5 pagesTest Practice 1syafwanNo ratings yet

- ShakespeareDocument4 pagesShakespeareVrinda PatilNo ratings yet

- A. Two Subsequences: Codeforces Round #751 (Div. 2)Document4 pagesA. Two Subsequences: Codeforces Round #751 (Div. 2)Trần Nhật KhánhNo ratings yet

- Basic Selectivity - How Oracle Calculates SelectivityDocument7 pagesBasic Selectivity - How Oracle Calculates SelectivityJack WangNo ratings yet

- Book Review of Conceptualising Integration in CLIL and Multilingual EducationDocument5 pagesBook Review of Conceptualising Integration in CLIL and Multilingual EducationAigul AitbaevaNo ratings yet