Professional Documents

Culture Documents

Hydraulics: Compact Excavators Caterpillar's HP Orenstein & Koppel

Uploaded by

RafiqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulics: Compact Excavators Caterpillar's HP Orenstein & Koppel

Uploaded by

RafiqueCopyright:

Available Formats

Hydraulics

Modern hydraulic excavators come in a wide variety of sizes. The smaller ones are called mini

or compact excavators.[7] For example, Caterpillar's smallest mini-excavator weighs 2,060

pounds (930 kg) and has 13 hp; their largest model is the largest excavator available (a record

previously held by the Orenstein & Koppel RH400), the CAT 6090, which weighs in excess of

2,160,510 pounds (979,990 kg), has 4500 hp, and a bucket as large as 52.0 m³.

Hydraulic excavators usually couple engine power to (commonly) three hydraulic pumps rather

than to mechanical drivetrains. The two main pumps supply oil at high pressure (up to 5000 psi,

345 bar) for the arms, swing motor, track motors and accessories while the third is a lower

pressure (~700 psi, 48 bar) pump for pilot control of the spool valves; this third circuit allows for

reduced physical effort when operating the controls. Generally, the 3 pumps used in excavators

consist of 2 variable displacement piston pumps and a gear pump. The arrangement of the

pumps in the excavator unit changes with different manufacturers using different formats.

The three main sections of an excavator are the undercarriage, the house and the arm (also

boom is used). The undercarriage includes tracks, track frame, and final drives, which have

a hydraulic motor and gearing providing the drive to the individual tracks. Undercarriage can also

have blade similar to that of a bulldozer. The house includes the operator cab, counterweight,

engine, fuel and hydraulic oil tanks. The house attaches to the undercarriage by way of a center

pin. High pressure oil is supplied to the tracks' hydraulic motors through a hydraulic swivel at the

axis of the pin, allowing the machine to slew 360° unhindered and thus provides the left-and-right

movement.[8] The arm provides the up-and-down and closer-and-further (or digging movement)

movements. Arm consist typically of boom, stick and bucket with three joints between them and

the house.

The boom attaches to the house and provides the up and down movement. It can be one of

several different configurations:

Most common are mono booms: these have no movement apart from straight up and down.

Some others have a knuckle boom which can also move left and right in line with the

machine.[clarification needed]

Another option is a hinge at the base of the boom allowing it to hydraulically pivot up to 180°

independent to the house; however, this is generally available only to compact excavators.

Variable angle booms have additional joint in the middle of the boom to change the curvature

of the boom. These are also called triple-articulated booms (TAB) or 3 piece booms.

Attached to the end of the boom is the stick (or dipper arm). The stick provides the digging

movement needed to pull the bucket through the ground. The stick length is optional depending

whether reach (longer stick) or break-out power (shorter stick) is required. Most common is mono

stick but there are also for example telescopic sticks.

On the end of the stick is usually a bucket. A wide, large capacity (mud) bucket with a straight

cutting edge is used for cleanup and levelling or where the material to be dug is soft, and teeth

are not required. A general purpose (GP) bucket is generally smaller, stronger, and has

hardened side cutters and teeth used to break through hard ground and rocks. Buckets have

numerous shapes and sizes for various applications. There are also many other attachments

which are available to be attached to the excavator for boring, ripping, crushing, cutting, lifting,

etc. Attachments can be attached with pins similar to other parts of the arm or with some variety

of quick coupler. Excavators in Scandinavia often feature a tiltrotator which allows attachments

rotate 360 degrees and tilt +/- 45 degrees, in order to increase the flexibility and precision of the

excavator.

You might also like

- BearingsDocument50 pagesBearingsHazim Hazim100% (2)

- Lathe Machine GuideDocument26 pagesLathe Machine GuideHarish Kumar S100% (3)

- Two Stroke EngineDocument16 pagesTwo Stroke EngineRam KarthikNo ratings yet

- Two Stroke EngineDocument13 pagesTwo Stroke EngineAaron PriceNo ratings yet

- A Project Report On Oil Rigs123Document17 pagesA Project Report On Oil Rigs123Somasekhar Koushik Ayalasomayajula100% (1)

- Parts List - Lycoming Engines Numerical Parts HistoryDocument243 pagesParts List - Lycoming Engines Numerical Parts HistoryFernando Servian Dalmas100% (3)

- MST-9000+ User's ManualDocument12 pagesMST-9000+ User's Manualjalvarez_385073No ratings yet

- The Operation, Care, and Repair of Farm MachineryFrom EverandThe Operation, Care, and Repair of Farm MachineryRating: 5 out of 5 stars5/5 (1)

- Projectreport ExcavatorArmDocument41 pagesProjectreport ExcavatorArmVinod Yb0% (1)

- UNIT 3 Tractors and Power TrailersDocument14 pagesUNIT 3 Tractors and Power TrailersVasantha SeelanNo ratings yet

- Drilling Rig Systems OverviewDocument12 pagesDrilling Rig Systems OverviewAhmed AmirNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Lathe Machine and Its ComponentsDocument13 pagesLathe Machine and Its ComponentsEinstein RahatNo ratings yet

- Information For Agitator - Mixer PDFDocument4 pagesInformation For Agitator - Mixer PDFArun GuptaNo ratings yet

- Backhoe LoaderDocument21 pagesBackhoe LoaderBalu Prakash100% (3)

- GS Handy MRP 01 06 23Document7 pagesGS Handy MRP 01 06 23Amit JainNo ratings yet

- Failures in Excavator ArmsDocument8 pagesFailures in Excavator ArmsSonyAcerNo ratings yet

- Scrapers SpecificationDocument12 pagesScrapers SpecificationAmirul HadeeNo ratings yet

- AgitatorDocument10 pagesAgitatorSachin5586No ratings yet

- Literature Review of Motorized Lift TableDocument5 pagesLiterature Review of Motorized Lift Table'Aizat Hafiz'0% (2)

- Android Controlled Arduino Robot Car: Jie HouDocument27 pagesAndroid Controlled Arduino Robot Car: Jie HouRafa S.C.No ratings yet

- Conventional Thickener SystemsDocument13 pagesConventional Thickener SystemslucianotigreNo ratings yet

- Downhole Motors PDFDocument15 pagesDownhole Motors PDFarasquare100% (1)

- SHOP THEORY-Engine Lathe ProcessesDocument54 pagesSHOP THEORY-Engine Lathe ProcessesDaxNo ratings yet

- Dozer PPT (2) .PPT New - PPT 2011Document79 pagesDozer PPT (2) .PPT New - PPT 2011Fayisaa Lamessa100% (1)

- M11W120E171100Document130 pagesM11W120E171100Christie Harris JohnstonNo ratings yet

- OSA 542x 9.5.1 Installation and Commissioning ManualDocument98 pagesOSA 542x 9.5.1 Installation and Commissioning ManualAli Ashkar100% (2)

- Presses and Equipment For SheetMetal DiesDocument153 pagesPresses and Equipment For SheetMetal Diessamurai7_77No ratings yet

- Sucker Rod PumpDocument23 pagesSucker Rod PumpVenkata DineshNo ratings yet

- Excavator Size Classes: Techanical ManualDocument2 pagesExcavator Size Classes: Techanical ManualRafiqueNo ratings yet

- Excavator: TerminologyDocument8 pagesExcavator: TerminologySenna KesavanNo ratings yet

- How Tractor Brakes WorkDocument10 pagesHow Tractor Brakes WorkVengadasubramanianNo ratings yet

- Modern Trailer ComponentsDocument14 pagesModern Trailer Componentspramo_dassNo ratings yet

- Reciprocating Engine For AircraftDocument10 pagesReciprocating Engine For Aircraftعبدالمحسن علي ENo ratings yet

- Sucker Rod PumpDocument23 pagesSucker Rod Pumpbracho08No ratings yet

- Rocker ArmDocument3 pagesRocker ArmAries M. SuarezNo ratings yet

- ExcavatorsDocument12 pagesExcavatorsPrisaca RădășeniNo ratings yet

- Project Report On Hydromechanical CraneDocument16 pagesProject Report On Hydromechanical Cranekml636No ratings yet

- Design and Fabrication of Modern Three Way Dumping Trolley MechanismDocument8 pagesDesign and Fabrication of Modern Three Way Dumping Trolley MechanismvenkataNo ratings yet

- Drilling PetroDocument20 pagesDrilling PetroethanNo ratings yet

- Actuators: Actuators My Notes and CalculationsDocument16 pagesActuators: Actuators My Notes and CalculationsMohamed RashedNo ratings yet

- Vdocument - in Sucker Rod Pump 566f1a30d934aDocument22 pagesVdocument - in Sucker Rod Pump 566f1a30d934aالمصور الدائريNo ratings yet

- Drilling Fluid Drill String Drilling RigDocument2 pagesDrilling Fluid Drill String Drilling RigBethelNo ratings yet

- Rig Components (تم الحفظ تلقائيًا)Document18 pagesRig Components (تم الحفظ تلقائيًا)slymanalb926No ratings yet

- A Drill Is A Tool Fitted With A Cutting Tool Attachment or Driving Tool AttachmentDocument5 pagesA Drill Is A Tool Fitted With A Cutting Tool Attachment or Driving Tool Attachmentsujit_ranjanNo ratings yet

- Lathe Types, Parts, Specification, Operations, PrecautionsDocument15 pagesLathe Types, Parts, Specification, Operations, PrecautionsnNo ratings yet

- BW-500/10 Mud Pump Instruction ManualDocument25 pagesBW-500/10 Mud Pump Instruction ManualameliaNo ratings yet

- Continuous MinerDocument9 pagesContinuous MinergopalNo ratings yet

- Rocker Arm-Final ReportDocument48 pagesRocker Arm-Final ReportKarthi Keyan0% (1)

- Khartoum University drilling report summaryDocument10 pagesKhartoum University drilling report summaryBilly WilsonNo ratings yet

- Tractores Doble TracciónDocument70 pagesTractores Doble TracciónjuanmvazNo ratings yet

- Chapter 2Document44 pagesChapter 2debas dessieNo ratings yet

- Process: Machining Gears Splines Sprockets Milling Machine Cutting ToolDocument31 pagesProcess: Machining Gears Splines Sprockets Milling Machine Cutting ToolSaurabh SinglaNo ratings yet

- A Shock AbsorberDocument5 pagesA Shock Absorberriz2010No ratings yet

- Abogadie - Single Stage Centrifugal PumpDocument13 pagesAbogadie - Single Stage Centrifugal PumpjohnharveytipozoNo ratings yet

- Factors to Consider for Agitator and Mixer DesignDocument4 pagesFactors to Consider for Agitator and Mixer DesignArun GuptaNo ratings yet

- Gear BoxDocument13 pagesGear BoxLoga NathanNo ratings yet

- Transmission (Mechanics) : Navigation Search Gearbox Software Gear TrainDocument9 pagesTransmission (Mechanics) : Navigation Search Gearbox Software Gear TrainbaktinusantaraNo ratings yet

- Lathe MachineDocument12 pagesLathe MachineEmy SyazlindaNo ratings yet

- Two-stroke Basics: How They Work and Their AdvantagesDocument11 pagesTwo-stroke Basics: How They Work and Their AdvantagesAfzal Shams100% (1)

- Transmission Mechanics ExplainedDocument6 pagesTransmission Mechanics ExplainedSelva KumarNo ratings yet

- Training in Tractel Tirfor India PVTDocument106 pagesTraining in Tractel Tirfor India PVTAnonymous QAPuWyDNo ratings yet

- Understanding CNC Collet ChucksDocument5 pagesUnderstanding CNC Collet ChuckssleonNo ratings yet

- DRLG 6035pDocument24 pagesDRLG 6035pJorge Jiménez100% (2)

- 1 Product GuideDocument24 pages1 Product GuideAprizal AzisNo ratings yet

- Semi Independent SuspensionDocument7 pagesSemi Independent SuspensionAditya TanwarNo ratings yet

- G 962 1188 - BomDocument8 pagesG 962 1188 - BomDibyendu ChakrabortyNo ratings yet

- How to Make a Cardboard Robot That Eats CoinsDocument11 pagesHow to Make a Cardboard Robot That Eats CoinsPaul bayntonNo ratings yet

- COP DetailsDocument98 pagesCOP DetailsGrishma WarkeNo ratings yet

- Design Considerations To Enhance Safety and Reliability For Service Entrance SwitchboardsDocument6 pagesDesign Considerations To Enhance Safety and Reliability For Service Entrance SwitchboardsCA ColeNo ratings yet

- DS400 MultifunctionDocument1 pageDS400 MultifunctionKelvin NgNo ratings yet

- Safety Relief Valves BSV-8: Technical BrochureDocument10 pagesSafety Relief Valves BSV-8: Technical BrochureVasti Diaz AguilarNo ratings yet

- Common Problems and Solutions of EMMC ISP FunctionDocument11 pagesCommon Problems and Solutions of EMMC ISP FunctionVinay BhandariNo ratings yet

- FUJITSU Mainboard D3446-S ATX: Data SheetDocument7 pagesFUJITSU Mainboard D3446-S ATX: Data SheetpziolkoNo ratings yet

- IPD Lab Assignment1 PDFDocument3 pagesIPD Lab Assignment1 PDFViktor IartavNo ratings yet

- 1980 ET 340T 18 PagesDocument18 pages1980 ET 340T 18 PagesTony SleckNo ratings yet

- AVR Unit-1 Cable ScheduleDocument16 pagesAVR Unit-1 Cable ScheduleKamaraj KannanNo ratings yet

- LV Switchboard Technical Data SheetDocument2 pagesLV Switchboard Technical Data SheetjendrikoNo ratings yet

- 6091 Automatic Airventvalve DatasheetDocument1 page6091 Automatic Airventvalve DatasheetlataNo ratings yet

- Categories of ComputersDocument3 pagesCategories of Computersmedina759No ratings yet

- 3412E FlywheelDocument4 pages3412E Flywheelmohammed mostafaNo ratings yet

- BTU &BTA Reference LayoutDocument8 pagesBTU &BTA Reference LayoutMilbert CandelarioNo ratings yet

- P2X1100 circuit descriptionDocument41 pagesP2X1100 circuit descriptionComsa MariusNo ratings yet

- PTC Finned Resistor Heaters: Industrial Thermal ManagementDocument5 pagesPTC Finned Resistor Heaters: Industrial Thermal ManagementDanilNo ratings yet

- 750@10 PPSDocument1 page750@10 PPSCost RootsNo ratings yet

- GD32F103xx Datasheet Rev 2.7Document76 pagesGD32F103xx Datasheet Rev 2.7victor SanmiguelNo ratings yet

- Grindex Lista de PartesDocument28 pagesGrindex Lista de PartesMarco Antonio Cerna HaroNo ratings yet

- 07 - ValvesDocument31 pages07 - ValvesArdanNo ratings yet

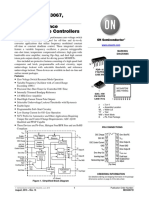

- MC34067, MC33067, NCV33067Document16 pagesMC34067, MC33067, NCV33067Alfredo Valencia Rodriguez100% (1)

- MPMC IV UnitDocument33 pagesMPMC IV UnitVenkatasamy EEENo ratings yet