Professional Documents

Culture Documents

Lab Manual For Trommel Cit

Uploaded by

Ryle ArbonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Manual For Trommel Cit

Uploaded by

Ryle ArbonCopyright:

Available Formats

CEBU INSTITUTE OF TECHNOLOGY

UNIVERSITY

I. TITLE: ROTARY TROMMEL

II. OBJECTIVE

To determine the theoretical and practical use of trommel screens as devices

for segregating various components from municipal solid waste.

III. THEORY

Trommels, or rotary screens, are an important unit operation in materials

processing. They have a long history in the mineral dressing industry, and are

of particular interest to those concerned with solid waste processing because

of the difficulty of the material processing task. Trommels provide an elegant

screening option with low maintenance and operating costs that could often

justify a higher initial cost.

A trommel is a rotating, cylindrical screen, lying on its side at a small angle

from the horizontal plane. Material is fed at its elevated end, and size-

separation occurs as the material spirals down the drum at an axial speed

governed by the angle of the drum to the horizontal plane. Behavior of the

material normal to the drum axis is governed by the rotational velocity.

The first step in processing municipal solid waste (MSW) for resource recovery

has usually been shredding. However, during the past several years, a

trommel (revolving cylindrical screen) has been investigated as a step to

precede shredding.

IV. EQUIPMENT AND MATERIALS

Rotary Trommel

Pebbles

Cobbles

V. PROCEDURE:

1. Before any experimentation could take place, key output parameters had

to be determined to measure trommel performance

2. The determination of a suitable type of particle involved meeting certain

criteria that would allow for adequate comparison with the analytical

model and be easy enough to work with in the laboratory.

3. The particle had to have consistent density, not be too slippery, exhibit

little rebound upon impact; be close to spherical, but not so close as to

roll on the screen.

4. Once the set-up and preparations are done, rotate the trommel with a

consistent speed since this is done manually.

5. Put the feed inside the trommel and continuously rotate it until there is

no more pebbles and cobbles in the equipment.

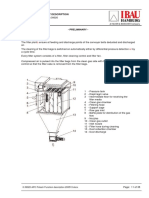

VI. SKETCH/PROCESS FLOW DIAGRAM

You might also like

- Dominos Winning StrategiesDocument185 pagesDominos Winning StrategiesY Ammar IsmailNo ratings yet

- Comminution in Mineral ProcessingDocument23 pagesComminution in Mineral ProcessinggtdomboNo ratings yet

- Development of An AG - SAG Mill Batch Test Methodology (PDFDrive)Document117 pagesDevelopment of An AG - SAG Mill Batch Test Methodology (PDFDrive)W ZuoNo ratings yet

- Test Bank For The Human Body in Health and Disease 7th Edition by PattonDocument11 pagesTest Bank For The Human Body in Health and Disease 7th Edition by PattonLaurence Pence100% (23)

- Punjab University Lahore: Report On PcsirDocument32 pagesPunjab University Lahore: Report On Pcsirone_special89No ratings yet

- Everything You Need to Know About Ball MillsDocument14 pagesEverything You Need to Know About Ball MillsLaxman Kumar100% (1)

- Proposal For The Use of Scaw's Mill Balls in Zambia and DR CongoDocument16 pagesProposal For The Use of Scaw's Mill Balls in Zambia and DR CongoRamoutar (Ken) SeecharranNo ratings yet

- Ball MillDocument23 pagesBall MillSyed Muhammad Saqib BariNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- LP Fuel Gas SystemDocument6 pagesLP Fuel Gas SystemAnonymous QSfDsVxjZNo ratings yet

- Lime Hydrating ProcessDocument24 pagesLime Hydrating ProcessKalai SelvanNo ratings yet

- Air Classifier ArticleDocument16 pagesAir Classifier ArticlePeyman KhNo ratings yet

- Ball Mill Experimental Manual GuideDocument11 pagesBall Mill Experimental Manual GuideShoaib Pathan100% (3)

- 4-The Simplex MethodDocument33 pages4-The Simplex MethodKalai Vani100% (1)

- Influence of Quartz Particles On Wear in Vertical Roller Mills.Document9 pagesInfluence of Quartz Particles On Wear in Vertical Roller Mills.chienhamthepNo ratings yet

- Ball Milling: Understanding the Crushing Action and Factors That Affect CapacityDocument16 pagesBall Milling: Understanding the Crushing Action and Factors That Affect CapacityRodrigo GarcíaNo ratings yet

- Ball Mill Critical SpeedDocument8 pagesBall Mill Critical SpeedDanielito Bonito0% (1)

- GOLDEN FIRESTONE SAG MILLDocument5 pagesGOLDEN FIRESTONE SAG MILLNovei Almane GorresNo ratings yet

- Grinding The Primary ConditionerDocument18 pagesGrinding The Primary ConditionerAkshay Pookat RammohanNo ratings yet

- 1 - Grinding Media Catalogue PDFDocument14 pages1 - Grinding Media Catalogue PDFmahreza189No ratings yet

- 1 s2.0 S2772275922000144 MainDocument14 pages1 s2.0 S2772275922000144 Mainfaty hdez100% (1)

- Modern Cement Grinding Systems ComparedDocument14 pagesModern Cement Grinding Systems ComparedCao Ngoc AnhNo ratings yet

- Great KilnDocument8 pagesGreat Kilnmbamarketing54No ratings yet

- Duo Dan MillDocument4 pagesDuo Dan Millnhungocbk92_22841857No ratings yet

- Disney's Strategic HRM: Training, Recruitment and HR PlanningDocument9 pagesDisney's Strategic HRM: Training, Recruitment and HR PlanningNgân NgânNo ratings yet

- Britain, Germany and Colonial Violence in South-West Africa, 1884-1919Document238 pagesBritain, Germany and Colonial Violence in South-West Africa, 1884-1919Саша ШестаковаNo ratings yet

- Bag Filter ComponentsDocument6 pagesBag Filter ComponentsAhmad Dagamseh100% (2)

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeNo ratings yet

- Comminution Ore TestingDocument35 pagesComminution Ore TestingHarrison Antonio Mira NiloNo ratings yet

- KHD Tube MillDocument2 pagesKHD Tube MillKeynes de SavaNo ratings yet

- Leaching Section 3Document16 pagesLeaching Section 3EDSON CHENJERAINo ratings yet

- Biochemical Engineering ProblemsDocument22 pagesBiochemical Engineering ProblemsRyle ArbonNo ratings yet

- Bridge Superstructure DesignDocument276 pagesBridge Superstructure Designrenzo wilber bernedo beltranNo ratings yet

- FLS - Ball Mill Liners Brochure - DIGITALDocument9 pagesFLS - Ball Mill Liners Brochure - DIGITALaliNo ratings yet

- 371hw06s (Rapid Mix Tank Design-Sample 1)Document5 pages371hw06s (Rapid Mix Tank Design-Sample 1)Yang Ching HianNo ratings yet

- 371hw06s (Rapid Mix Tank Design-Sample 1)Document5 pages371hw06s (Rapid Mix Tank Design-Sample 1)Yang Ching HianNo ratings yet

- The Selection and Design of Mill LinersDocument11 pagesThe Selection and Design of Mill Linersluis martinezNo ratings yet

- Distance ProtectionDocument21 pagesDistance Protectiondesilvatharindu1No ratings yet

- Lecture 3 Process Engineering of Size ReductionDocument31 pagesLecture 3 Process Engineering of Size ReductionKARABO EMMANUEL NCUBENo ratings yet

- Pamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentDocument12 pagesPamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentKarl Raymundo100% (3)

- Ball MillDocument3 pagesBall MillpassionNo ratings yet

- Cabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"CabletorqthickenerDocument4 pagesCabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"Cabletorqthickenerdgomez686No ratings yet

- Rod and ball mill sizing using Bond Work IndexDocument5 pagesRod and ball mill sizing using Bond Work IndexzicoNo ratings yet

- Grinding and Classifying Technology For Slag: Replacement Factors DryingDocument6 pagesGrinding and Classifying Technology For Slag: Replacement Factors DryingGerman Gabriel Anaya Vega100% (1)

- A Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueDocument3 pagesA Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueVerónica CharresNo ratings yet

- Planetary Ball Mill Process in Aspect of Milling EnergyDocument11 pagesPlanetary Ball Mill Process in Aspect of Milling EnergyJesús IbarraNo ratings yet

- Ball Mill For Cement GrindingDocument5 pagesBall Mill For Cement GrindingNkosilozwelo Sibanda100% (1)

- Chris - Rule - Stirred Milling in The PGM IndustryDocument59 pagesChris - Rule - Stirred Milling in The PGM IndustryJakesNo ratings yet

- Better Grinding Systems with V-Separator and VSK-SeparatorDocument5 pagesBetter Grinding Systems with V-Separator and VSK-SeparatorGerman Gabriel Anaya VegaNo ratings yet

- Grinding 3 Circuit DesignsDocument35 pagesGrinding 3 Circuit DesignsIvan Milanes100% (1)

- Teoria de BondDocument8 pagesTeoria de BondMarcelaChavezNo ratings yet

- Corpare Bond Work Index and Hard GroveDocument15 pagesCorpare Bond Work Index and Hard GroveWaterdrop' 'DewNo ratings yet

- Media Charge - Optimal Ball SizeDocument6 pagesMedia Charge - Optimal Ball SizeMetalurgia ProcesosNo ratings yet

- A Simulation Model For An Air-Swept Ball Mill Grinding CoalDocument12 pagesA Simulation Model For An Air-Swept Ball Mill Grinding CoalAnonymous NxpnI6jCNo ratings yet

- The Principles of Coal PreparationDocument13 pagesThe Principles of Coal PreparationNdumiso MagaganeNo ratings yet

- A Dynamic Mathematical Model of The Complete Grate/Kiln Iron-Ore Pellet Induration ProcessDocument10 pagesA Dynamic Mathematical Model of The Complete Grate/Kiln Iron-Ore Pellet Induration Processdavibraga8041No ratings yet

- JiggingDocument6 pagesJiggingravimutyamNo ratings yet

- Ball Mill GrindingDocument6 pagesBall Mill GrindingShyanu Udeshika WijerathnaNo ratings yet

- S3 Product Range - EnglishDocument35 pagesS3 Product Range - EnglishJuan Esteban Luque ZegarraNo ratings yet

- Ball Mill Design - CompressDocument6 pagesBall Mill Design - CompressSuresh VedalaNo ratings yet

- Ball Milling Specifications PeruDocument1 pageBall Milling Specifications PerualinoriNo ratings yet

- Power-based comminution calculations using AusgrindDocument13 pagesPower-based comminution calculations using AusgrindMarcos Bueno100% (1)

- Bottle Role TestDocument12 pagesBottle Role TestcemsavantNo ratings yet

- Utkarsh Sankrityayan-Effect of Particle Size Distribution On Grinding Kinetics in Dry and Wet Ball Milling OperationsDocument26 pagesUtkarsh Sankrityayan-Effect of Particle Size Distribution On Grinding Kinetics in Dry and Wet Ball Milling OperationsUtkarsh SankrityayanNo ratings yet

- Caustic Soda From Natural Trona 2014Document5 pagesCaustic Soda From Natural Trona 2014MauRmzNo ratings yet

- Magnetite Standards and Testing ProceduresDocument12 pagesMagnetite Standards and Testing Proceduresmofidhussain100% (1)

- Ball Milling - Final FinalDocument12 pagesBall Milling - Final FinalKrishna TejaNo ratings yet

- SAIL BSBK Visit Docx-15.06. R-1rtfDocument7 pagesSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- Bradken Study SAG LinersDocument2 pagesBradken Study SAG LinersMr29RicardoNo ratings yet

- MAV Comminution TestsDocument16 pagesMAV Comminution TestsNilson Ariel Gálvez OlguinNo ratings yet

- Problem Set 1Document1 pageProblem Set 1Anonymous C06P6LXh9No ratings yet

- CHEMICAL AND HAZARDOUS WASTE MANAGEMENT GUIDEDocument155 pagesCHEMICAL AND HAZARDOUS WASTE MANAGEMENT GUIDERyle ArbonNo ratings yet

- Beef Burger PattyDocument1 pageBeef Burger PattyRyle ArbonNo ratings yet

- Wordsnof HistoryDocument2 pagesWordsnof HistoryRyle ArbonNo ratings yet

- Continuance of Service Form: Do Not Tamper With Any Part of This FormDocument2 pagesContinuance of Service Form: Do Not Tamper With Any Part of This FormRyle ArbonNo ratings yet

- NoteshDocument6 pagesNoteshRyle ArbonNo ratings yet

- Gtky ChiDocument3 pagesGtky ChiRyle ArbonNo ratings yet

- Gtky ChiDocument3 pagesGtky ChiRyle ArbonNo ratings yet

- Nazi Occupied France: AboutDocument3 pagesNazi Occupied France: AboutRyle ArbonNo ratings yet

- 221 04 PDFDocument18 pages221 04 PDFEr Mayur PatilNo ratings yet

- PV NRT: PM RT DRT PDocument19 pagesPV NRT: PM RT DRT PRyle ArbonNo ratings yet

- Advanced Thermodynamics: Volumetric Properties of Pure FluidsDocument36 pagesAdvanced Thermodynamics: Volumetric Properties of Pure FluidsArunodhayam NatarajanNo ratings yet

- Project 1 ProgrammingDocument5 pagesProject 1 ProgrammingRyle ArbonNo ratings yet

- Separation NotesDocument2 pagesSeparation NotesRyle ArbonNo ratings yet

- ReservesDocument2 pagesReservesRyle ArbonNo ratings yet

- OPTIMIZATION (Economic Balance) What, Why, Aims/objectives Essential Features Simple Model, Methods of Solving Application: Insulation EvaporationDocument93 pagesOPTIMIZATION (Economic Balance) What, Why, Aims/objectives Essential Features Simple Model, Methods of Solving Application: Insulation EvaporationRyle Arbon100% (1)

- Chap7 2Document8 pagesChap7 2DharamashiRabariNo ratings yet

- QM Analysis for BusinessDocument6 pagesQM Analysis for BusinessRyle ArbonNo ratings yet

- Solving linear programs with the simplex methodDocument45 pagesSolving linear programs with the simplex methodRyle ArbonNo ratings yet

- Coagulation and Flocculation: Supplementary NotesDocument13 pagesCoagulation and Flocculation: Supplementary NotesRyle ArbonNo ratings yet

- Advanced Thermodynamics: Volumetric Properties of Pure FluidsDocument36 pagesAdvanced Thermodynamics: Volumetric Properties of Pure FluidsArunodhayam NatarajanNo ratings yet

- ThermsDocument2 pagesThermsRyle ArbonNo ratings yet

- Membrane Separation ProcessDocument47 pagesMembrane Separation ProcessRyle ArbonNo ratings yet

- Solved ProblemSetEquipDesisssgn2Document11 pagesSolved ProblemSetEquipDesisssgn2Mailiw AshfordNo ratings yet

- CHE501 Distillation Experiment ReportDocument5 pagesCHE501 Distillation Experiment ReportRyle ArbonNo ratings yet

- Lecture Notes Natural LawDocument52 pagesLecture Notes Natural LawVina EstherNo ratings yet

- ComplexDocument35 pagesComplexKetso MolapoNo ratings yet

- Kaparewetec Farnctbk GbematasDocument37 pagesKaparewetec Farnctbk Gbematasriani antartikaNo ratings yet

- Laser Light PriceDocument5 pagesLaser Light Priceluis palominoNo ratings yet

- Sem 656DDocument1 pageSem 656DCarlos Arturo AcevedoNo ratings yet

- Articol S.brînza, V.stati Pag.96Document154 pagesArticol S.brînza, V.stati Pag.96crina1996No ratings yet

- Chapter 8: Financial Reporting and Management SystemsDocument6 pagesChapter 8: Financial Reporting and Management SystemsKate AlvarezNo ratings yet

- AlumaCore OPGWDocument1 pageAlumaCore OPGWlepouletNo ratings yet

- Atoms and MoleculesDocument4 pagesAtoms and MoleculesShwetaNo ratings yet

- Study of NanofibresDocument237 pagesStudy of NanofibresGerardo ZambranoNo ratings yet

- Tia PortalDocument46 pagesTia PortalAndré GomesNo ratings yet

- Consumer Behavior Quiz (01-16-21)Document3 pagesConsumer Behavior Quiz (01-16-21)litNo ratings yet

- Extending NAS Web App MobileDocument2 pagesExtending NAS Web App MobileD2VNo ratings yet

- The Effect of Dividend Policy On Stock Price: Evidence From The Indian MarketDocument9 pagesThe Effect of Dividend Policy On Stock Price: Evidence From The Indian MarketWilson SimbaNo ratings yet

- Volcanoes, Earthquakes, and Mountain Ranges: What's inDocument3 pagesVolcanoes, Earthquakes, and Mountain Ranges: What's inRuby Jean LagunayNo ratings yet

- Ai, Iot, Big Data & BlockchainDocument19 pagesAi, Iot, Big Data & BlockchainClick GroupNo ratings yet

- Corrosion Rate Measurements in Steel Sheet Pile Walls in A Marine EnvironmentDocument17 pagesCorrosion Rate Measurements in Steel Sheet Pile Walls in A Marine EnvironmentMamoudou SAGNONNo ratings yet

- EN 1090 White Paper17 119019 PDFDocument24 pagesEN 1090 White Paper17 119019 PDFZaza PokumbaNo ratings yet

- Trends in Maternal Mortality: Executive SummaryDocument16 pagesTrends in Maternal Mortality: Executive SummarykansaNo ratings yet

- Communication TasksDocument19 pagesCommunication Taskswaqas08100% (4)

- Chemistry SyllabusDocument9 pagesChemistry Syllabusblessedwithboys0% (1)

- Microsoft MB-210 Exam Dumps With Latest MB-210 PDFDocument10 pagesMicrosoft MB-210 Exam Dumps With Latest MB-210 PDFJamesMartinNo ratings yet

- SCAQMD Method 3.1Document27 pagesSCAQMD Method 3.1Jonathan Aviso MendozaNo ratings yet