Professional Documents

Culture Documents

FMEA Form

FMEA Form

Uploaded by

syedfarazshafeeq0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

FMEA Form.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesFMEA Form

FMEA Form

Uploaded by

syedfarazshafeeqCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

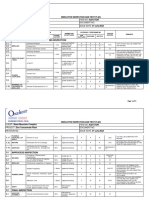

FAILURE MODE & EFFECT ANALYSIS (FMEA)

POTENTIAL FAILURE ANALYSIS (TABLE 1)

Date FMEA Conducted: Prepared by: FMEA Reference # (year-#):

Core Participants in FMEA:

Process for which FMEA was conducted:

Frequency Scale Severity Scale Detectability Scale

10 – Frequent: May happen several times a year 10 – Failure that can result in death or serious harm 10 – Error likely to be discovered < 50% of the time before

7 – Occasional: May happen a few times a year 7 – Failure that can cause non-serious and/or harm significant patient harming/reaching patient

4 – Uncommon: May happen 2 to 5 times a year dissatisfaction and/or resulting in expenditure of money for follow-up care 7 – 50% of the time

1 – Remote: May happen sometimes in 5 to 30 years 4 – Minor event; increased length of stay 4 – 70% of the time

1 – Failure not noticeable or would not affect the delivery of service 1 – > 90% of the time

Potential Failure Mode Potential Effect of Failure Risk Priority

Step or Link in the Process (Identify the potential failures for each Mode Frequency Severity Detect ability

Number (RPN =

(Likeliness Scale 1 – (Potential for (Potential for Rank

(e.g., machine part) component step in process) (Identify the potential outcome Freq. x Sev. x

10) Harm 1 – 10) Discovery 1 -10)

Detect)

can be more than one per step of the failure to patient)

CRITICAL FAILURE ANALYSIS (TABLE 2) FMEA Reference # (year-#): _______________

Critical Failure Action Results

Mode F S D P

Step or Link in Root Causes Tasked to Metrics

(List root causes Proximate Causes Remedial Action r e e R

Process (Identify (Identify Due (Describe applicable Status/

with highest PRN (Brainstorm (Describe action to be e v t N

(copy from Table 1, probable or responsible Date testing & Comment

—see the far right possible causes) taken to “error proof” q e

column 1) critical causes) party) measurement) s

column on Table process) c

1) t

You might also like

- Cümle Atma / Test 3 (40 Adet Soru) Eskişehir YesdđlDocument5 pagesCümle Atma / Test 3 (40 Adet Soru) Eskişehir YesdđlEmircan CesurNo ratings yet

- Unit 6D Mole To Mole CalculationsDocument2 pagesUnit 6D Mole To Mole CalculationsPranav BulusuNo ratings yet

- Print # Rev. FMEA Number: Item: Process Responsibility: Prepared By: Model Year(s) /vehicle(s) Key Date Date (Orig.) Team: Date (Rev.)Document5 pagesPrint # Rev. FMEA Number: Item: Process Responsibility: Prepared By: Model Year(s) /vehicle(s) Key Date Date (Orig.) Team: Date (Rev.)Maida HaqqiNo ratings yet

- Hoarding Install and DismantleDocument5 pagesHoarding Install and Dismantleஅருண்ராஜ் கிருஷ்ணன்சாமி100% (1)

- Fmea PW System 1Document16 pagesFmea PW System 1William Salgado100% (1)

- Faculty of Commerce Bachelor of CommerceDocument28 pagesFaculty of Commerce Bachelor of CommercemawandeNo ratings yet

- There Is Always Hope by Retha McPhersonDocument16 pagesThere Is Always Hope by Retha McPhersonpurifysoul100% (2)

- Failure Modes and Effects Analysis TemplateDocument1 pageFailure Modes and Effects Analysis TemplateElijah JohnNo ratings yet

- Template AMEFDocument10 pagesTemplate AMEFElvis DiazNo ratings yet

- FMEADocument74 pagesFMEAzulfiqarali721No ratings yet

- Copis & FmeaDocument16 pagesCopis & FmeaEXDE601E100% (2)

- 13 Fmea 1Document36 pages13 Fmea 1hello2er.ajayNo ratings yet

- Failure Mode, Effect, and Criticality Analysis (FMECA) WorksheetDocument2 pagesFailure Mode, Effect, and Criticality Analysis (FMECA) WorksheetMaya DamanikNo ratings yet

- Disposal of Old Material HIRADocument3 pagesDisposal of Old Material HIRAAli Al-GhamghamNo ratings yet

- Failure Analysis of FMEA: March 2009Document9 pagesFailure Analysis of FMEA: March 2009swapnil pandeNo ratings yet

- QRM For Water System 18-01-2024Document29 pagesQRM For Water System 18-01-2024anji reddyNo ratings yet

- Free FMEA Failure Modes Effects Analysis Template Excel DownloadDocument9 pagesFree FMEA Failure Modes Effects Analysis Template Excel DownloadReza AgungNo ratings yet

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Failure Modes and Effects Analysis (FMEA) - Risk Assessment MatrixDocument2 pagesFailure Modes and Effects Analysis (FMEA) - Risk Assessment MatrixIoan Mihai ArmăşelNo ratings yet

- FMEA CP Forms Application ManufacturingDocument15 pagesFMEA CP Forms Application ManufacturingCarlo AlvaradoNo ratings yet

- FMEA TrainingDocument30 pagesFMEA Trainingapi-377012184% (19)

- blankPFMEA 4theditionDocument1 pageblankPFMEA 4theditionManopingsoft KrissManoNo ratings yet

- Failure Mode Effects AnalysisDocument11 pagesFailure Mode Effects AnalysisDNo ratings yet

- Pendekatan FMEA Aproach - Rudini MulyaDocument24 pagesPendekatan FMEA Aproach - Rudini MulyaRudini MulyaNo ratings yet

- QMS Risk Planning RegisterDocument34 pagesQMS Risk Planning RegisterKarthi Thiyagarajan100% (1)

- Hazard Identification and Risk Assessment Form: Project ProcessDocument4 pagesHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNo ratings yet

- A Dempster-Shafer Theory-Based Approach To The Failure Mode, Effects andDocument11 pagesA Dempster-Shafer Theory-Based Approach To The Failure Mode, Effects and弘瑞 蒋No ratings yet

- Lean Six Sigma ToolkitDocument63 pagesLean Six Sigma ToolkitLOLIMNo ratings yet

- FMEADocument19 pagesFMEAASHISH KUMAR MAJHINo ratings yet

- FMEA Failure Mode Effect AnalysisDocument61 pagesFMEA Failure Mode Effect AnalysisAbhijeet RandhirNo ratings yet

- FMEA - PZCI TemplateDocument8 pagesFMEA - PZCI TemplateMgr ProdNo ratings yet

- Failure Mode Effect Analysis (FMEA) Training Assessment Questionnaire Total Questions: 10 To Be Attempted: 10 Time Duration: 10 MinutesDocument2 pagesFailure Mode Effect Analysis (FMEA) Training Assessment Questionnaire Total Questions: 10 To Be Attempted: 10 Time Duration: 10 MinutesRishi R SarkarNo ratings yet

- PRN Sevxoccxdet: Failure Mode and Effects AnalysisDocument2 pagesPRN Sevxoccxdet: Failure Mode and Effects AnalysisHelo DixonNo ratings yet

- Failure Mode Design ProjectDocument12 pagesFailure Mode Design ProjectSaddam AbdullahNo ratings yet

- FMEA-template PROSEDUR PENGISIAN FORMDocument1 pageFMEA-template PROSEDUR PENGISIAN FORMAufa Jaya Perkasa LegalityNo ratings yet

- Working at Elevated Areas (Scaffolding)Document4 pagesWorking at Elevated Areas (Scaffolding)Ali Al-GhamghamNo ratings yet

- Fmea PW System 1Document15 pagesFmea PW System 1yfermachNo ratings yet

- Template-Organizational Risk AssessmentDocument2 pagesTemplate-Organizational Risk AssessmentVivian Gonzaga JesuraNo ratings yet

- 02 FMEA Training - How To DoDocument45 pages02 FMEA Training - How To DoRamkumar PerumalNo ratings yet

- Experiment 2 - Causal AttributionDocument23 pagesExperiment 2 - Causal AttributionSudisht Narayan MishraNo ratings yet

- Handout - Practical Problem Solving Report ToolsDocument1 pageHandout - Practical Problem Solving Report ToolsSMAKNo ratings yet

- Failure Evaluation RevDocument43 pagesFailure Evaluation RevGahara M. JatiNo ratings yet

- 6.26 Annexe Formsheet FMEADocument6 pages6.26 Annexe Formsheet FMEANDRNo ratings yet

- Root Cause Analysis Presentation (RCA)Document21 pagesRoot Cause Analysis Presentation (RCA)beriNo ratings yet

- Reprioritization of Failures in A System Failure Mode and Effects Analysis by Decision Making Trial and Evaluation Laboratory TechniqueDocument10 pagesReprioritization of Failures in A System Failure Mode and Effects Analysis by Decision Making Trial and Evaluation Laboratory Techniquesumeet0827No ratings yet

- Trigger Control: QRA in Safety Engineering Homework 1Document8 pagesTrigger Control: QRA in Safety Engineering Homework 1mohaned faisalNo ratings yet

- AmefDocument2 pagesAmefAmair Marthz100% (1)

- Risk Management. Hedging and Speculation. Gap ManagementDocument5 pagesRisk Management. Hedging and Speculation. Gap ManagementDaniel Chan Ka LokNo ratings yet

- FMEADocument9 pagesFMEADhivakar S K100% (1)

- Risk Assesment For StudentsDocument20 pagesRisk Assesment For StudentsjjjjjNo ratings yet

- FMEA Rev 4Document25 pagesFMEA Rev 4Vale PazNo ratings yet

- Lowess Notes: Proportion of Individuals Without The Disease Whom Test Is NegativeDocument11 pagesLowess Notes: Proportion of Individuals Without The Disease Whom Test Is NegativeCoffee MochaNo ratings yet

- FMEA Template PDFDocument24 pagesFMEA Template PDFAsghat SuicnoNo ratings yet

- Psychology Statistic NoteDocument13 pagesPsychology Statistic Notechinmengen0928No ratings yet

- Demo of Assignment01 - RMDocument5 pagesDemo of Assignment01 - RMharun or rashidNo ratings yet

- Application - of - The - FMEA IEC 60812 Año 2018 08759874Document12 pagesApplication - of - The - FMEA IEC 60812 Año 2018 08759874jose EscobarNo ratings yet

- OBC Risk AssessmentDocument4 pagesOBC Risk AssessmentprinceNo ratings yet

- FTA Chemical PlantDocument109 pagesFTA Chemical PlantNur AmaninaNo ratings yet

- Incident Report and InvestigationDocument2 pagesIncident Report and InvestigationHerwin Syaid Ibramin HaminataNo ratings yet

- Xiang-Dong Li, Min-Yao Huang, Xin-Dong Zhang, Wei Zhang, Su-Qian Lian and Zhi-Rong WangDocument8 pagesXiang-Dong Li, Min-Yao Huang, Xin-Dong Zhang, Wei Zhang, Su-Qian Lian and Zhi-Rong WangAdyasree AlluruNo ratings yet

- Jsa Mechanical Run TestDocument8 pagesJsa Mechanical Run TestMuhammad YusufNo ratings yet

- Pfmea TemplateDocument2 pagesPfmea TemplateAdetunji Babatunde TaiwoNo ratings yet

- Sample Size for Analytical Surveys, Using a Pretest-Posttest-Comparison-Group DesignFrom EverandSample Size for Analytical Surveys, Using a Pretest-Posttest-Comparison-Group DesignNo ratings yet

- A Deep Learning Approach For Integrated Production Planning and Predictive MaintenanceDocument21 pagesA Deep Learning Approach For Integrated Production Planning and Predictive MaintenancemawandeNo ratings yet

- Chapter Three David Sos PeterDocument6 pagesChapter Three David Sos PetermawandeNo ratings yet

- Application For A UJ Master's or Doctoral Merit Bursary For 2020Document4 pagesApplication For A UJ Master's or Doctoral Merit Bursary For 2020mawandeNo ratings yet

- Mapsyk360 103Document85 pagesMapsyk360 103mawandeNo ratings yet

- MSC Floor CornelissenDocument46 pagesMSC Floor CornelissenmawandeNo ratings yet

- Arrives: Approaches Four-Way StopDocument2 pagesArrives: Approaches Four-Way StopmawandeNo ratings yet

- Case Study Project EngineerDocument7 pagesCase Study Project EngineermawandeNo ratings yet

- 02 Chapter 2Document54 pages02 Chapter 2mawandeNo ratings yet

- AsylumDocument1 pageAsylummawandeNo ratings yet

- Business Requirements DocumentDocument11 pagesBusiness Requirements DocumentmawandeNo ratings yet

- Edlhodm: The Educator As Leader, Manager and AdministratorDocument3 pagesEdlhodm: The Educator As Leader, Manager and Administratormawande100% (1)

- Using Combinations of Heuristics To Sche PDFDocument8 pagesUsing Combinations of Heuristics To Sche PDFmawandeNo ratings yet

- Years Business Analysis SkillsDocument1 pageYears Business Analysis SkillsmawandeNo ratings yet

- Kopano Letsaba: Personal InformationDocument2 pagesKopano Letsaba: Personal InformationmawandeNo ratings yet

- Cleaning Services Provider: Terms and ConditionsDocument2 pagesCleaning Services Provider: Terms and ConditionsmawandeNo ratings yet

- Capital Budgeting Practice Questions QueDocument9 pagesCapital Budgeting Practice Questions QuemawandeNo ratings yet

- Resource Leveling Vs Resource AllocationDocument7 pagesResource Leveling Vs Resource AllocationmawandeNo ratings yet

- Introduction To Logistics: EctureDocument22 pagesIntroduction To Logistics: EcturemawandeNo ratings yet

- CPM PertDocument31 pagesCPM Pertmawande100% (1)

- Assignments 1 and 2 Engineering Project ManagementDocument70 pagesAssignments 1 and 2 Engineering Project ManagementmawandeNo ratings yet

- Accounts Year Ended 31.03.17Document18 pagesAccounts Year Ended 31.03.17mawandeNo ratings yet

- A Guide To The Project Management Body oDocument19 pagesA Guide To The Project Management Body omawandeNo ratings yet

- Chapter 3Document31 pagesChapter 3mawandeNo ratings yet

- Application For Postgraduate Further Study App Form 2018 2019 V 31 July 2018 For WebDocument12 pagesApplication For Postgraduate Further Study App Form 2018 2019 V 31 July 2018 For WebmawandeNo ratings yet

- LD 1495 "Tax Reform" The Real Facts: Albert A. Dimillo, Jr. Retired Corp Orate Tax Director & CpaDocument30 pagesLD 1495 "Tax Reform" The Real Facts: Albert A. Dimillo, Jr. Retired Corp Orate Tax Director & CpaMelinda JoyceNo ratings yet

- Budd - Chiari (Hepatic VenousDocument43 pagesBudd - Chiari (Hepatic VenousRamy ElbarodyNo ratings yet

- UNIT 5 SPMDocument19 pagesUNIT 5 SPMSumathy Jayaram50% (2)

- Gnpower Dinginin Ltd. Co. Operation and Maintenance Management Electrical Progress ReportDocument4 pagesGnpower Dinginin Ltd. Co. Operation and Maintenance Management Electrical Progress Reportpepenapao1217No ratings yet

- Pze X5 enDocument6 pagesPze X5 enosiel limaNo ratings yet

- Byk-Silclean 3700 TDS (En)Document2 pagesByk-Silclean 3700 TDS (En)feby nurvinandaNo ratings yet

- Installationguide 0005310Document28 pagesInstallationguide 0005310miculinicNo ratings yet

- A Study On Area, Production and Marketing of Apples in KashmirDocument5 pagesA Study On Area, Production and Marketing of Apples in KashmirEditor IJTSRD0% (1)

- Defender 90 1993 1995 3.9L 4.2LDocument131 pagesDefender 90 1993 1995 3.9L 4.2LJuan QuispeNo ratings yet

- Chapter 37Document112 pagesChapter 37Arcanos2312No ratings yet

- IEEE Recommended Practice For Sizing Nic-2Document6 pagesIEEE Recommended Practice For Sizing Nic-2Hamza AHMED SAADINo ratings yet

- Ufap - Usmle Step 1 Study GuideDocument8 pagesUfap - Usmle Step 1 Study GuideWade BullockNo ratings yet

- Raw Material & Bought Out Items InspectionDocument3 pagesRaw Material & Bought Out Items InspectionSuraj ShettyNo ratings yet

- Maintenance Management Impact On Hospital Energy ConsumptionDocument6 pagesMaintenance Management Impact On Hospital Energy ConsumptionLutfie HidayatullahNo ratings yet

- Data Sheet - Provolt Dual Relay Multi-Tech Occupancy Sensor (O2C05 O2C10 O2C20-MDW)Document4 pagesData Sheet - Provolt Dual Relay Multi-Tech Occupancy Sensor (O2C05 O2C10 O2C20-MDW)Elkin Bautista RomeroNo ratings yet

- Chemistry Project ReportDocument14 pagesChemistry Project ReportSonam Aggarwal54% (13)

- Cargo Space InspectionDocument7 pagesCargo Space InspectionNizza Claire BusaNo ratings yet

- Humanae Vitae PowerpointDocument15 pagesHumanae Vitae PowerpointPaula Andrea García75% (4)

- The Added Value of A Second Read by Pediatric Radiologists For OutsideDocument7 pagesThe Added Value of A Second Read by Pediatric Radiologists For OutsideSkander GharbiNo ratings yet

- Identity and RespectDocument10 pagesIdentity and RespectUlisesRochaNo ratings yet

- Richard P Feynman-Surely Youre Joking MR Feynman v5Document3 pagesRichard P Feynman-Surely Youre Joking MR Feynman v5Anonymous Nayak0% (1)

- Agra Report Final TermDocument87 pagesAgra Report Final TermRafael AdanNo ratings yet

- Estimate North Side NoyyalDocument58 pagesEstimate North Side NoyyalRaj DharmaNo ratings yet

- Schreiber Engineering: Model No. 400 ACDocument4 pagesSchreiber Engineering: Model No. 400 ACcarlo jose cortez montano0% (1)

- Format:: PUBH1001/Introduction To Environmental, Health and Safety 45% Weighted TestDocument3 pagesFormat:: PUBH1001/Introduction To Environmental, Health and Safety 45% Weighted TestViswa VittalNo ratings yet

- The Maintanence of The Performance Hydraulic Servo Drive: Optimized Pressure and Flow Control AlgorithmDocument7 pagesThe Maintanence of The Performance Hydraulic Servo Drive: Optimized Pressure and Flow Control AlgorithmDavid MuniveNo ratings yet

- Probor DatasheetDocument6 pagesProbor DatasheetDanka FocoNo ratings yet