Professional Documents

Culture Documents

OBC Risk Assessment

Uploaded by

princeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OBC Risk Assessment

Uploaded by

princeCopyright:

Available Formats

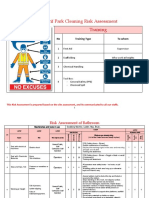

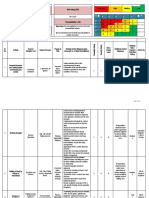

1. Risk Evaluation.

Severity

It is related to the direct impact to persons. Following is the classification of severity assessment.

Severit

Score Definition

y Level

1 Risk Not likely to cause an effect/impact to safety of life and property.

Low 2 Minor – Little potential for harm, easily correctable, clearable

Mediu

3 Moderate – Somewhat harmful, short term loss

m

High 4 Serious – Harmful – difficult to correct but recoverable over a period of time

Very

5 Severe – Fatality / Very harmful to HSE, Complex long-term effect.

High

Frequency of Occurrence

It is related to the number of times it occurs compared to the last incident. Following is the

Score Frequency of Occurrence

5 Very likely – High probability of HSE accident to occur. (daily/weekly/monthly)

Likely – Strong Probability that an HSE impact / dangerous occurrence will occur

4

(quarterly)

Possible – Reasonable probability that an HSE incident / near-miss may occur. (annually)

3

2 Unlikely– Low probability, have heard about this few years / months ago (2-5 years)

1 Rare – Very unlikely (5-10 years)

Assessment Matrix

Frequency RPN score Risk Level

Risk Level 5 4 3 2 1 1≤x≤4 Low (L)

Severit 25 20 15 10

5 5 (M) 5≤x≤9 Medium (M)

y (VH) (VH) (VH) (H)

20

4 16 (H) 12 (H) 8 (M) 4 (L) 10 ≤ x ≤ 16 High (H)

(VH)

3 15 (H) 12 (H) 9 (M) 6 (M) 3 (L) 17 ≤ x ≤ 25 Very High (VH)

2 10 (M) 8 (M) 6 (M) 4 (L) 2 (L)

1 5 (M) 4 (L) 3(L) 2(L) 1(L)

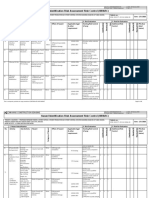

2. Risk Assessment Output

•For every ac vity the Cross Func onal Team (CFT) team should document whether the ac vity is

a Routine (R), Non-Routine (NR).

•Document the associated Hazard/ Aspect and Risk / Impact.

•If Ac vity which has a risk of life or risk of fire or severe environmental impact should be

considered as an Emergency by denoting Yes (Y) in the column Provided.

•For the iden fied ac vity, gather informa on from interested par es. If the ac vity has any

concern with respect to HSE. If any concern is raised, document it as Yes (Y).

•If the ac vity has a legal concern, document as Yes (Y). Examples of Legal concern could be in

the form of: Storage of Hazardous waste, Working at heights

•Evaluate if the Hazard in the work process has a Legal implica on. If yes, indicate by deno ng

“Y” in the cell contained.

•Should there be an instance where any of the columns of Emergency (E), Interested Party

Concern (IPC) / Legal Concern (LC) is applicable and is denoted by “Y” then these concerns will be

an Overriding Criteria and not be evaluated further, But will be identified as a Significant risk by

denoting “S” in the column provided.

•Risks which do not have Emergency / Interested Party Concern (IPC) / Legal Concern (LC) should

be denote by indicating “N” (No)

•Risks where overriding criteria (Interested Party Concern (IPC) / Legal Concern (LC)) are not

applicable, should be considered for Risk Assessment.

•Any ac vity which is having Present / Exis ng controls, should be men oned in column provided.

•The risk criteria for severity and Frequency of occurrence is applied to HSE risks as per the table

provided in appendix and present risk factor is calculated and mentioned in the column provided

here in.

•Any HSE risk having a risk factor above and equal to 5 is considered significant and gradually

lowered to cover all the HSE risks stages such that at one state all risks will be suitably addressed.

•Any ac vi es which are not listed in any regula on and have no exis ng control, the severity is

rated as 3 and the risk is considered as Significant.

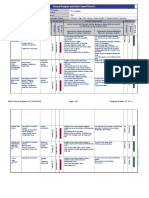

RISK IDENTIFICATION, ASSESSMENT AND CONTROL FORM

OPERATION / SPECIFIC LOCATION DATE:

ACTIVITY

DESCRIPTION:

Frequency

Frequency of Occurrences

Calculated significance

IPC (Interested Party

Activity Type (R / NR)

LC (Legal Concern)

Presentofrisk

Present risk factor

E (emergency)

Final (S/NS)

Severity (S)

Concern)

Severity

Task/equipm Present / Existing Controls added to

(F)

S/N Hazards/aspects Risk/impact

ent controls reduce risks

Occurrences

factor

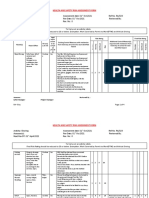

when mixing Cause chemical training, administrative 5 2 10 S the right PPE should be 5 1 5 S

chemicals are burns on skin. controls to insunate the used

exposed to the Damage surfaces. risk of slip trip and fal,

skin, solid metal Cause blindness. use of elastostoic nose

surfaces, eyes, Harm your lungs mask, hand glooves,

inhaled, or and throat if safety boots, SOPs

ingested. inhaled.

When the mixing Be explosive

mixer R Y Y Y

chemicals are under certain

done at conditions.

unfavourable Be fatal if ingested

conditions. slip, trip and fall

Working are height

during operation risk of crushing presence of guards, 5 1 5 S administrative signs as 5 1 5 S

when soap flakes fingers training, SOPs regards safety signages,

Soap 'Roll mill are being produced R Y Y Y update the SOPs

area of the rollers risk of cut and prsence of guards, 5 1 5 S administrative signs as 5 1 5 S

Plodder producing soap crushing fingers R Y Y Y training, SOPs regards safety signages,

worms SOPs

cutting to size and risk of trainings, presently a 5 3 15 S installation of guards, 5 1 5 S

stamping of fingers/limps metal rod is use to administrative signs as

company crest on being cut off or remove clugged soap in regards safety signages,

the soap crushed the area, SOPs Engineer a mechanism

Stampper R Y Y Y to remove clogged soap

the will remove the

frequent human contact

with it, SOPs

during wrapping of risk of burns none 3 3 9 S the presence of Guards 3 1 3 NS

soap with primary for protection, re-activate

packing materil safety devices on the

machine, use of heat

wrapping resistant hand glooves

R Y Y N

Machine when carrying out

maintenace, SOPs

during packaging risk of burns the presence of guards 3 2 6 S in some of the 3 1 3 NS

of product with machines, repair broken

secondary guards, re-activate

packaing material safety devices on the

Bonding machine, use of heat

R Y Y N resistant hand glooves

Machine

when carrying out

maintenace, SOPs

NS

NS

You might also like

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- Csp-Ppm-Asev-01Document2 pagesCsp-Ppm-Asev-01CPP EI DSpNo ratings yet

- Risk Assesment ReportDocument1 pageRisk Assesment Reportsohani WaghelaNo ratings yet

- Cv-f-014 Hasil Hira I2r4Document1 pageCv-f-014 Hasil Hira I2r4Istiqomah SuryaningtyasNo ratings yet

- Risk Assessment of Confined SpaceDocument29 pagesRisk Assessment of Confined Spaceطارق رضوانNo ratings yet

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- Hirac (Piping Installation (Open Cut Trench)Document7 pagesHirac (Piping Installation (Open Cut Trench)tana100% (2)

- Hirac (Piping Installation (Open Cut Trench)Document7 pagesHirac (Piping Installation (Open Cut Trench)tana100% (1)

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana83% (6)

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana100% (1)

- Hirac (Light-Fittings Installation)Document5 pagesHirac (Light-Fittings Installation)tana100% (2)

- Hirac (Manhole Installation)Document7 pagesHirac (Manhole Installation)tanaNo ratings yet

- Hirac (Manhole Installation)Document7 pagesHirac (Manhole Installation)tana50% (2)

- Hirac (Cable Laddertray, Trunking and Conduit Installation)Document9 pagesHirac (Cable Laddertray, Trunking and Conduit Installation)tana67% (6)

- Hirac (LV Cable Installation Work)Document9 pagesHirac (LV Cable Installation Work)tana100% (2)

- Hirac (Busways and Busducts Installation)Document8 pagesHirac (Busways and Busducts Installation)tana100% (3)

- Hirac (Ups and Battery Charger Installation)Document6 pagesHirac (Ups and Battery Charger Installation)tana100% (2)

- Excavation Risk AssessmentsDocument7 pagesExcavation Risk Assessmentshussein aliNo ratings yet

- HIRA For DPP-2 Project in I BlockDocument20 pagesHIRA For DPP-2 Project in I BlockSiddharth PNo ratings yet

- QHS - Risk AssessmentDocument66 pagesQHS - Risk AssessmentMinion Party0% (1)

- Health and Safety Risk Assessment FormDocument4 pagesHealth and Safety Risk Assessment Formbasil aliNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- 14 Risk Assessment of CleaningDocument12 pages14 Risk Assessment of Cleaningطارق رضوان100% (1)

- HIRA MechanicalDocument6 pagesHIRA Mechanicalsufiyan sskNo ratings yet

- Hazard Asessment Summary ReportDocument29 pagesHazard Asessment Summary ReportAnonymous iI88LtNo ratings yet

- Annexure3 HIRA 2Document5 pagesAnnexure3 HIRA 2kanna gNo ratings yet

- RA - Upright Replacement.Document12 pagesRA - Upright Replacement.Christopher FernandezNo ratings yet

- RA For Firefighting (CS Pipe Prefabrication-Sprinklers - Pressure Test and Flashing Painting-001)Document3 pagesRA For Firefighting (CS Pipe Prefabrication-Sprinklers - Pressure Test and Flashing Painting-001)RAMY ABOU AL DAHABNo ratings yet

- Blasting and Painting of Fire Fighting PipingDocument3 pagesBlasting and Painting of Fire Fighting PipingRAMY ABOU AL DAHABNo ratings yet

- Risk Assessment SK GraphiteDocument8 pagesRisk Assessment SK GraphiteWasim KhanNo ratings yet

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Lighting InstallationDocument3 pagesHazard Identification Risk Assessment Risk Control (HIRARC) - Lighting InstallationYasHie PwincsZaNo ratings yet

- RA - HDPE Fire FittingDocument2 pagesRA - HDPE Fire FittingRAMY ABOU AL DAHABNo ratings yet

- 10 HIRA Track Laying WorkDocument16 pages10 HIRA Track Laying WorkSajeen Bensihar100% (2)

- Risk Assessment Manhole CleaningDocument9 pagesRisk Assessment Manhole CleaningShah MuzzamilNo ratings yet

- GIS-RA-4061E-004 Risk Assessment For Road Crossing Area (Rev.00)Document6 pagesGIS-RA-4061E-004 Risk Assessment For Road Crossing Area (Rev.00)Ajas Aju100% (1)

- Risk Assessment Block Work-Revised 13.12.2022Document4 pagesRisk Assessment Block Work-Revised 13.12.2022Ajeet Singh SirohiNo ratings yet

- 5.2.2.9 Laydown Drill Pipes1Document2 pages5.2.2.9 Laydown Drill Pipes1khrayzie bhone100% (1)

- GIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Document6 pagesGIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Ajas AjuNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- Risk Assessment For Installation of Fire Fighting SystemDocument12 pagesRisk Assessment For Installation of Fire Fighting Systemطارق رضوان100% (3)

- HIRA ChemicalDocument1 pageHIRA Chemicalramesh rmNo ratings yet

- Risk Assesment Generic Tender Despatch Electrical DepotDocument10 pagesRisk Assesment Generic Tender Despatch Electrical DepotanishavanloggerenbergNo ratings yet

- Risk Assessment RFP 071 Rev 1Document2 pagesRisk Assessment RFP 071 Rev 1shera laura pykpsbNo ratings yet

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationDocument2 pagesHazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationYasHie PwincsZaNo ratings yet

- Risk Assessment and Control RegisterDocument5 pagesRisk Assessment and Control RegisterMidhunRameshThuvasseryNo ratings yet

- 24.DG Hiradec CDocument2 pages24.DG Hiradec CPankaj PandeyNo ratings yet

- Hirarc 2023Document2 pagesHirarc 2023Ariff ZakariaNo ratings yet

- Hazard Analysis and Risk Control Record: Schlumberger-PrivateDocument2 pagesHazard Analysis and Risk Control Record: Schlumberger-Privatehans vatriolisNo ratings yet

- Department: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJDocument12 pagesDepartment: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJabhrrajjit SANo ratings yet

- RISK ASSESSMENT COVID-19 - Edit - 1645265605593 - Edit - 1645265644305Document11 pagesRISK ASSESSMENT COVID-19 - Edit - 1645265605593 - Edit - 1645265644305Ansar0% (1)

- HIRADC COSHH Antifreeze or CoolantDocument3 pagesHIRADC COSHH Antifreeze or CoolantwisnukerNo ratings yet

- HSE Risk Assessment Form: Risk/significance Evaluation Risk/significance EvaluationDocument1 pageHSE Risk Assessment Form: Risk/significance Evaluation Risk/significance EvaluationSachi AnandNo ratings yet

- HIRADocument7 pagesHIRAAkhilesh DubeyNo ratings yet

- Formation Day 3Document21 pagesFormation Day 3Mokhtar MahboubeNo ratings yet

- HIRAC CraneDocument2 pagesHIRAC CranetaufikNo ratings yet

- Tabel HiracDocument2 pagesTabel HiracAulya Angkasa0% (1)

- Tabel HiracDocument2 pagesTabel HiracAulya AngkasaNo ratings yet

- Risk Assessment of Flag PolesDocument5 pagesRisk Assessment of Flag Polesطارق رضوانNo ratings yet

- Module RCA CAPA Training 19 Oct 2022Document67 pagesModule RCA CAPA Training 19 Oct 2022princeNo ratings yet

- Module BRFT, GDocP & Data Integrity 18 Oct 2022Document55 pagesModule BRFT, GDocP & Data Integrity 18 Oct 2022princeNo ratings yet

- Sample JHADocument3 pagesSample JHAprinceNo ratings yet

- Module QRM Training 17 Oct 2022Document26 pagesModule QRM Training 17 Oct 2022princeNo ratings yet

- Ig2 Risk Assessment Self Evaluation ChecklistDocument2 pagesIg2 Risk Assessment Self Evaluation ChecklistprinceNo ratings yet

- Unit IG2 Risk Assessment Soap Manufacturing FactoryDocument8 pagesUnit IG2 Risk Assessment Soap Manufacturing FactoryprinceNo ratings yet

- Unit IG2 Risk Assessment Warehouse 1Document13 pagesUnit IG2 Risk Assessment Warehouse 1princeNo ratings yet

- 2020 APR GWG Unit IG2 Element 8 v03 S PDFDocument61 pages2020 APR GWG Unit IG2 Element 8 v03 S PDFprinceNo ratings yet

- Fire Emergency Preparedness and Response: 1. ObjectiveDocument8 pagesFire Emergency Preparedness and Response: 1. ObjectiveprinceNo ratings yet

- Forklift Truck/Powered Indutrial Truck: I. ObjectiveDocument4 pagesForklift Truck/Powered Indutrial Truck: I. ObjectiveprinceNo ratings yet

- HSE Management SystemDocument9 pagesHSE Management SystemprinceNo ratings yet

- SOP WASTE MANAGEMENT Revised 2020Document3 pagesSOP WASTE MANAGEMENT Revised 2020princeNo ratings yet

- Opt WorkshopDocument15 pagesOpt WorkshopMhel Daz BabaysonNo ratings yet

- The Right To Die: Pre-ReadingDocument8 pagesThe Right To Die: Pre-ReadingGiovanni EscobarNo ratings yet

- Verify Category B2 Report V6.35 Rev 1.0Document39 pagesVerify Category B2 Report V6.35 Rev 1.0Roger SchulpNo ratings yet

- Supw Project Medicinal PlantsDocument7 pagesSupw Project Medicinal Plantsmehal gupta75% (4)

- How To Get Rid of Panic Attacks Without MedicationDocument20 pagesHow To Get Rid of Panic Attacks Without MedicationmidnightgrNo ratings yet

- NEBOSH IG1 Open Book Mock Examination For Sept. 2022Document5 pagesNEBOSH IG1 Open Book Mock Examination For Sept. 2022m.naNo ratings yet

- Combat StressDocument94 pagesCombat StressClaudia Maria Ivan100% (1)

- CHAPTER 1-Public Health (Environmental Pollution and Control)Document18 pagesCHAPTER 1-Public Health (Environmental Pollution and Control)muhdakmaladnan100% (4)

- SDS 80 Fat Unsalted Butter Lactic AcidDocument8 pagesSDS 80 Fat Unsalted Butter Lactic Acidfiyan maulanaNo ratings yet

- Priyanka Sen Final Practice School Internship ReportDocument35 pagesPriyanka Sen Final Practice School Internship ReportThakur Aditya PratapNo ratings yet

- Sem 2 M.pharm PresentationDocument16 pagesSem 2 M.pharm PresentationPriya ShahNo ratings yet

- Ebook Ebook PDF Personal Stress Management From Surviving To Thriving PDFDocument41 pagesEbook Ebook PDF Personal Stress Management From Surviving To Thriving PDFtina.cousins322100% (37)

- Lesson 1 Physical Fitness and Related ActivitiesDocument31 pagesLesson 1 Physical Fitness and Related ActivitiesKaiNo ratings yet

- Lung Cap DataDocument1 pageLung Cap DataKaren NelsonNo ratings yet

- Phenol - Medical Management Guidelines - Toxic Substance Portal - ATSDR. (N.D.) - Agency ForDocument2 pagesPhenol - Medical Management Guidelines - Toxic Substance Portal - ATSDR. (N.D.) - Agency ForREBEKAH EQUIZNo ratings yet

- Wound Forum 14Document12 pagesWound Forum 14Lia Mar'atush SholihahNo ratings yet

- Qatar Cancer Society in WordsDocument2 pagesQatar Cancer Society in WordsQatarcancersociety QcsNo ratings yet

- Kaelyn Weitzman: Objective: EducationDocument1 pageKaelyn Weitzman: Objective: Educationapi-507319784No ratings yet

- How To Survive Family LifeDocument16 pagesHow To Survive Family LiferoberttNo ratings yet

- Food AdjunctDocument15 pagesFood AdjunctRoby martinus bayaNo ratings yet

- Thesis About Abortion in The PhilippinesDocument8 pagesThesis About Abortion in The PhilippinesBuyingCollegePapersBatonRouge100% (2)

- 002 - 1203 - Ni Wayan Ari Anindita Sari - GalleyDocument5 pages002 - 1203 - Ni Wayan Ari Anindita Sari - GalleyHaningtyas IndahNo ratings yet

- PSC Advert - 14.9.2021 2Document15 pagesPSC Advert - 14.9.2021 2Derrick Ombura NazleyNo ratings yet

- New Grad ResumeDocument1 pageNew Grad Resumeapi-384352990100% (2)

- An Overview of The Role of Nurses and Midwives in Leadership and Management in EuropeDocument44 pagesAn Overview of The Role of Nurses and Midwives in Leadership and Management in EuropeTCNo ratings yet

- 00 - Introduction To PharmacologyDocument19 pages00 - Introduction To PharmacologyChipego NyirendaNo ratings yet

- COVID CertificateDocument1 pageCOVID CertificateshibiranNo ratings yet

- Itr NipDocument2 pagesItr Nipjohnmorts2014No ratings yet

- Q& A DelegationDocument11 pagesQ& A DelegationFilipino Nurses CentralNo ratings yet

- Case Study 2Document12 pagesCase Study 2api-336539272No ratings yet