Professional Documents

Culture Documents

Hirac (Piping Installation (Open Cut Trench)

Uploaded by

tanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hirac (Piping Installation (Open Cut Trench)

Uploaded by

tanaCopyright:

Available Formats

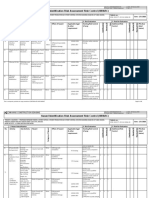

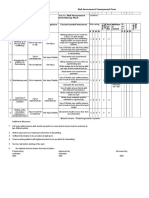

Doc No : NCSB-IMS-SP05-FO-04 Date : 24-February-2020

NAKANO CONSTRUCTION SDN BHD Process Owner : HSE&QA Department Rev : 01

Hazard Identification Risk Assessment Risk Control (HIRARC)

PROJECT / LOCATION : – PROPOSED INFINEON TOWER 11 STOREY OFFICE, 4 STOREY PRODUCTION & 5 STOREY CENTRAL UTILITIES BUILDING (CUB) ON LOT 1604, MUKIM, Update no. : Date :

PRINGGIT DAERAH MELAKA TENGAH HANG TUAH JAYA, MELAKA. NCSB 2019-ITT -CEC-ELE-HIRAC-10

WORK ACTIVITY : PIPING INSTALLATION(OPEN CUT TRENCH) 30/06/2020

1. Hazard Identification 2. Risk Evaluation 3. Risk Re-Evaluation

Likelihood (L)

Severity (S)

Likelihood (L)

Severity (S)

Risk

Residual Risk

Category of Hazard

No. Activity Sub Activity Hazard Effect of hazard Applicable legal Existing Risk Control Additional Risk PIC (Due

& other (if any) Control date/

requirement status)

1) 1)Attend Safety 1)Attend safety 1)Workers are not Minor 1)OHSA 1994 1)Conduct safety induction 2 1 2

Induction induction aware of hazard. 1)Physical injury-bodily 2)FMA 1967 training.

Training. training. injury.

2) 1)Apply Permit To 1)Daily task 1)Wrong type of work Minor 1)Misunderstand work 1)OHSA 1994 1)Conduct Daily toolbox 2 1 2

Work. discussion. permit used. order. 2)FMA 1967 meeting and briefing

2)Improper guidance. 2)Wrong work method. work activities.

2)Safety briefing in daily

toolbox meeting.

3)Apply the right permit to

work.

3) 1)Survey On Site. 1)Marking as per Minor 1) Physical injury-bodily 1)OHSA 1994 1)Safety briefing in daily 2 1 2

1)Miscommunication.

IFC Drawings. injury. 2)FMA 1967 toolbox meeting.

2) People are not

2) Carry out by competent

aware of danger.

person.

3)PPE(refer to work method

statement - NCSB 2019-ITT

-CEC-ELE-WMS-10).

4) 1)Prepare 1)Loading and 1)Ergonomic hazard. Minor 1) Physical injury-bodily 1)OHSA 1994 1)Safety briefing in daily 2 1 2

Material unloading of 2) Material and injury. 2)FMA 1967 toolbox meeting.

Mobilization. material and equipments can fall 2)Material damage. 2)Use lifting tools if need.

equipments. down. 3)Buddy system.

3)Pinching hazard. 4)Make good arrangement.

5) PPE(refer to work method

statement - NCSB 2019-ITT

-CEC-ELE-WMS-10).

5) 1)Display Signage 1)Erecting 1)Tripping hazard. Minor 1)Physical injury-bodily 1)Safety briefing in daily 1 1 1

And Barricade barricade and injury. 1)OHSA 1994 toolbox meeting.

Work Area. display signage. 2)Visual inspection by safety

2)FMA 1967

personnel.

3) PPE(refer to work method

This is computer printed out copy treated as CONTROLLED DOCUMENT Page 1 of 7

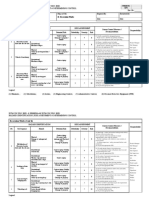

Doc No : NCSB-IMS-SP05-FO-04 Date : 24-February-2020

NAKANO CONSTRUCTION SDN BHD Process Owner : HSE&QA Department Rev : 01

Hazard Identification Risk Assessment Risk Control (HIRARC)

PROJECT / LOCATION : – PROPOSED INFINEON TOWER 11 STOREY OFFICE, 4 STOREY PRODUCTION & 5 STOREY CENTRAL UTILITIES BUILDING (CUB) ON LOT 1604, MUKIM, Update no. : Date :

PRINGGIT DAERAH MELAKA TENGAH HANG TUAH JAYA, MELAKA. NCSB 2019-ITT -CEC-ELE-HIRAC-10

WORK ACTIVITY : PIPING INSTALLATION(OPEN CUT TRENCH) 30/06/2020

1. Hazard Identification 2. Risk Evaluation 3. Risk Re-Evaluation

Likelihood (L)

Severity (S)

Likelihood (L)

Severity (S)

Risk

Residual Risk

Category of Hazard

No. Activity Sub Activity Hazard Effect of hazard Applicable legal Existing Risk Control Additional Risk PIC (Due

& other (if any) Control date/

requirement status)

statement- NCSB 2019-ITT

-CEC-ELE-WMS-10).

6) 1)Pre-Installation 1) Area of 1)Miscommunication. Major 1)Wrong measurement. 1)OHSA 1994 1)Safety briefing in daily 4 5 20 1)Carried out 2 2 4 1)Site

Checks. excavation to be 2) Hit underground 2) Physical injury-bodily toolbox meeting. underground scanning supervisor.

2)FMA 1967

done the mapping utilities. injury. 2) Monitoring by site test. 2)Safety

3)IFC Drawing

for existing 3) Property supervisor if needed. 2) Check for personnel.

services if damage(underground underground /

applicable. utilities) aboveground services

through metal

detectors.

2) The permit of 1)Wrong type of work Minor 1) Wrong work method. 1)OHSA 1994 1)Conduct Daily toolbox 1 1 1

the area shall be permit used. 2) Misunderstand work meeting and briefing

2)FMA 1967

received and kept 2) Miscommunication order. work activities.

by supervisor. 2)Safety briefing in daily

toolbox meeting.

3)Apply the right permit to

work.

4) Monitoring by site

supervisor if needed

6) 1)Pre-Installation 3) The entire 1)Lack of inspection. Minor 1)Wrong material 1)Project requirement. 1)Follow the sop. 1 1 1

Checks. route shall be specification 2)IFC Drawing 2)Inspect by qualified

inspected to person.

ensure that the

routing is

complete, proper

bending radius to

be consider

7) 1) Planing n 1)selecting the 1)Lack of work skill. Minor 1)Physical injury-bodily 1)Project requirement. 1)Carry out by qualified 1 1 1

preparation for route and 2)Wrong selection of injury. 2)IFC Drawing person.

excavation depth will dig, tools. 2)Monitoring by supervisor

and if needed.

determining 3) PPE(refer to work method

what tools, and statement- NCSB 2019-ITT

This is computer printed out copy treated as CONTROLLED DOCUMENT Page 2 of 7

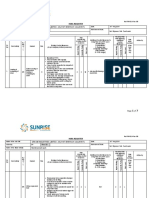

Doc No : NCSB-IMS-SP05-FO-04 Date : 24-February-2020

NAKANO CONSTRUCTION SDN BHD Process Owner : HSE&QA Department Rev : 01

Hazard Identification Risk Assessment Risk Control (HIRARC)

PROJECT / LOCATION : – PROPOSED INFINEON TOWER 11 STOREY OFFICE, 4 STOREY PRODUCTION & 5 STOREY CENTRAL UTILITIES BUILDING (CUB) ON LOT 1604, MUKIM, Update no. : Date :

PRINGGIT DAERAH MELAKA TENGAH HANG TUAH JAYA, MELAKA. NCSB 2019-ITT -CEC-ELE-HIRAC-10

WORK ACTIVITY : PIPING INSTALLATION(OPEN CUT TRENCH) 30/06/2020

1. Hazard Identification 2. Risk Evaluation 3. Risk Re-Evaluation

Likelihood (L)

Severity (S)

Likelihood (L)

Severity (S)

Risk

Residual Risk

Category of Hazard

No. Activity Sub Activity Hazard Effect of hazard Applicable legal Existing Risk Control Additional Risk PIC (Due

& other (if any) Control date/

requirement status)

materials we -CEC-ELE-WMS-10).

will need.

2)Mobilization 1)Struck by moving Major 1)Physical injury-bodily 1)OHSA 1994 1)Monitoring by site 5 4 20 1)Segregate between 2 1 2 1)Site

of excavation or swing machinery. injury. 2)FMA 1967 supervisor or safety vehicle route and supervisor.

machinery 2)Property damage personnel workers walk area. 2)Safety

(excavator) to 2) Carry out by competent 2)Provide designated personnel.

site. operator flagman for assigned

3) PPE(refer to work method movement of

statement- NCSB 2019-ITT machinery.

-CEC-ELE-WMS-10).

7) 1) Planing n 3)Conduct 1)Poor condition of Minor 1) oil spill/hydraulic 1)OHSA 1994 1)Conduct regular 2 2 4

preparation for inspection on machinery hose burst- 2)FMA 1967 preventive maintenance and

excavation excavation Environmental damage check on wear and tear.

machinery 2)Replace or repair the

before start broken hydraulic hose.

excavation 3)Carry out by site safety

works. personnel.

8) 1)Conduct 1) Begin the 1)Miscommunication. Major 1) Physical injury-bodily 1)OHSA 1994 1)Safety briefing in daily 4 5 20 1)Refer the 2 2 4 1)Site

excavation works digging at the 2) Hit underground injury. toolbox meeting. underground scanning supervisor.

2)FMA 1967

making point. utilities. 2) Property 2) Monitoring by site test. 2)Safety

3)IFC Drawing

3) Struck by moving or damage(underground supervisor. 2)Perform pilot hole personnel.

swing machinery. utilities) 3) Carry out by competent before proceed with

operator. excavation work.

4) PPE(refer to work method 2)Provide designated

statement- NCSB 2019-ITT flagman for assigned

-CEC-ELE-WMS-10). movement of

5) Follow the guideline machinery.

excavation safety (NCSB

2020-CEC-ELE-GUIDELINES-

This is computer printed out copy treated as CONTROLLED DOCUMENT Page 3 of 7

Doc No : NCSB-IMS-SP05-FO-04 Date : 24-February-2020

NAKANO CONSTRUCTION SDN BHD Process Owner : HSE&QA Department Rev : 01

Hazard Identification Risk Assessment Risk Control (HIRARC)

PROJECT / LOCATION : – PROPOSED INFINEON TOWER 11 STOREY OFFICE, 4 STOREY PRODUCTION & 5 STOREY CENTRAL UTILITIES BUILDING (CUB) ON LOT 1604, MUKIM, Update no. : Date :

PRINGGIT DAERAH MELAKA TENGAH HANG TUAH JAYA, MELAKA. NCSB 2019-ITT -CEC-ELE-HIRAC-10

WORK ACTIVITY : PIPING INSTALLATION(OPEN CUT TRENCH) 30/06/2020

1. Hazard Identification 2. Risk Evaluation 3. Risk Re-Evaluation

Likelihood (L)

Severity (S)

Likelihood (L)

Severity (S)

Risk

Residual Risk

Category of Hazard

No. Activity Sub Activity Hazard Effect of hazard Applicable legal Existing Risk Control Additional Risk PIC (Due

& other (if any) Control date/

requirement status)

DOSH-EXCAVATION WORKS-

01).

8) 1)Conduct 1) Dig first cut to 1) soil of trench Major 1)Physical injury-bodily 1)Project requirement. 1)Monitoring by supervisor. 4 4 16 1) keep the spoil 1 2 2 4 1)Site

excavation works the depth have collapse. injury. 2)OHSA 1994 2) Carry out by competent meter away from the supervisor.

decided that 2) Collapse of 3)FMA 1967 operator. edge. 2)Safety

enough to serve Excavated soils. 3) Barricade the area 2) . Trench to be personnel.

the ducting. 3) Accidental fall of 4) PPE(refer to work method battered or benched.

equipment. statement- NCSB 2019-ITT 3) Keep the equipment

4)Worker fall down -CEC-ELE-WMS-10). away from the edge of

5) Follow the guideline the trench.

excavation safety (NCSB 3) Install shoring if

2020-CEC-ELE-GUIDELINES- needed.

DOSH-EXCAVATION WORKS- 4)cover with plastic

01). sheet after excavation

work work done.

5)Avoid vehicle

movements away

from the excavation

edge

1)Continue the 1) soil of trench Major 1)Physical injury-bodily 1)Project requirement. 1)Monitoring by supervisor. 4 4 16 1) keep the soil 1 meter 2 2 4 1)Site

digging until the collapse. injury. 2)OHSA 1994 2) Carry out by competent away from the edge. supervisor.

whole trench is 2) Collapse of 3)FMA 1967 operator. 2) . Trench to be 2)Safety

complete. Excavated soils. 3) Barricade the area battered or benched. personnel.

3) Accidental fall of 4) PPE(refer to work method 3) Keep the equipment

equipment. statement- NCSB 2019-ITT away from the edge of

4)Worker fall down -CEC-ELE-WMS-10). the trench.

This is computer printed out copy treated as CONTROLLED DOCUMENT Page 4 of 7

Doc No : NCSB-IMS-SP05-FO-04 Date : 24-February-2020

NAKANO CONSTRUCTION SDN BHD Process Owner : HSE&QA Department Rev : 01

Hazard Identification Risk Assessment Risk Control (HIRARC)

PROJECT / LOCATION : – PROPOSED INFINEON TOWER 11 STOREY OFFICE, 4 STOREY PRODUCTION & 5 STOREY CENTRAL UTILITIES BUILDING (CUB) ON LOT 1604, MUKIM, Update no. : Date :

PRINGGIT DAERAH MELAKA TENGAH HANG TUAH JAYA, MELAKA. NCSB 2019-ITT -CEC-ELE-HIRAC-10

WORK ACTIVITY : PIPING INSTALLATION(OPEN CUT TRENCH) 30/06/2020

1. Hazard Identification 2. Risk Evaluation 3. Risk Re-Evaluation

Likelihood (L)

Severity (S)

Likelihood (L)

Severity (S)

Risk

Residual Risk

Category of Hazard

No. Activity Sub Activity Hazard Effect of hazard Applicable legal Existing Risk Control Additional Risk PIC (Due

& other (if any) Control date/

requirement status)

5) Follow the guideline 3) Install shoring if

excavation safety (NCSB needed.

2020-CEC-ELE-GUIDELINES- 4)cover with plastic

DOSH-EXCAVATION WORKS- sheet after excavation

01). work work done..

5)Avoid vehicle

movements away

from the excavation

edge.

9) 1)In completed 1) Trenches left 1) Worker fall down. Major 1)Physical injury-bodily 1)OHSA 1994 1) Barricade the area 3 5 15 1)Provide proper 2 2 4 1)Site

excavation work. open for injury 2)FMA 1967 2) supervisors monitor site signage, warning lights. supervisor.

continue regularly on excavated 2)safety personnel 2)Safety

excavation work. locations. make sure placed hard personnel.

3) Follow the guideline barricade and proper

excavation safety (NCSB signage before leave the

2020-CEC-ELE-GUIDELINES- site.

DOSH-EXCAVATION

WORKS-01).

10) 1)Dewatering the 1)Dewatering 1) soil of trench Minor 1)Physical injury-bodily 1)OHSA 1994 1)Rotating parts of engine 2 2 4

exaction area. the excavation collapse. injury. 2)FMA 1967 pumps must protected

area, using fuel 2)Pinching hazards with safeguarding.(visual

engine pump for Buddy system.. inspect by safety personnel)

remove the 2) PPE(refer to work method

excess water. statement- NCSB 2019-ITT

( underground -CEC-ELE-WMS-10).

water sources) 3)Monitor by safety

personnel if need.

11) 1) Piping 1)Install the 1)Abrasion hazard. Minor 1)Physical injury-bodily 1)Project requirement. 1)Monitoring by site 1 1 1

installation PN10 Pipe into 2)Ergonomic hazard. injury. 2)IFC Drawing. supervisor.

the trench with 3) Lack of work skill. 2)material damage 2) Carry out by qualified

layers following person.

approved shop 3)Buddy system.

drawing 4) PPE(refer to work method

statement- NCSB 2019-ITT

This is computer printed out copy treated as CONTROLLED DOCUMENT Page 5 of 7

Doc No : NCSB-IMS-SP05-FO-04 Date : 24-February-2020

NAKANO CONSTRUCTION SDN BHD Process Owner : HSE&QA Department Rev : 01

Hazard Identification Risk Assessment Risk Control (HIRARC)

PROJECT / LOCATION : – PROPOSED INFINEON TOWER 11 STOREY OFFICE, 4 STOREY PRODUCTION & 5 STOREY CENTRAL UTILITIES BUILDING (CUB) ON LOT 1604, MUKIM, Update no. : Date :

PRINGGIT DAERAH MELAKA TENGAH HANG TUAH JAYA, MELAKA. NCSB 2019-ITT -CEC-ELE-HIRAC-10

WORK ACTIVITY : PIPING INSTALLATION(OPEN CUT TRENCH) 30/06/2020

1. Hazard Identification 2. Risk Evaluation 3. Risk Re-Evaluation

Likelihood (L)

Severity (S)

Likelihood (L)

Severity (S)

Risk

Residual Risk

Category of Hazard

No. Activity Sub Activity Hazard Effect of hazard Applicable legal Existing Risk Control Additional Risk PIC (Due

& other (if any) Control date/

requirement status)

-CEC-ELE-WMS-10).

2) Connecting 1)Abrasion hazard. Minor 1)Physical injury-bodily 1)Project requirement. 1)Monitoring by site 1 1 1

PN10 pipe with 2)Ergonomic hazard. injury. 2)IFC Drawing. supervisor.

PN10 pipe by 3) Lack of work skill 2)material damage. 2) Carry out by qualified

using socket person.

each 6 meters. 3) Buddy system.

4) PPE(refer to work method

statement- NCSB 2019-ITT

-CEC-ELE-WMS-10).

12) 1)Backfilling the 1) Backfill the 1)Lack of work skill. Major 1)Physical injury-bodily 1)Project requirement. 1)Monitoring by site 4 5 20 1)Conduct safety 2 2 4 1)Site

excavation area trench as follow 2)Miscommunication. injury. 2)OHSA 1994 supervisor. briefing before the start supervisor.

Specification 3)Moving vehicle can 3)FMA 1967 2) Carry out by qualified works. 2)Safety

Drawing. For stuck when move into person. 2) Limit the time spent personnel.

deep trenches, that area. 4) PPE(refer to work method by workers on a

backfilling in 4)Noise hazards. statement- NCSB 2019-ITT vibrating equipment or

lifts (layers) and 5) vibration hazards -CEC-ELE-WMS-10). machinery.(job rotating

compacting the system)

material as it is 3) Avoid continuous

placed . exposure by taking rest

periods.

13) 1)Housekeeping 1)Cleaning/mat 1)Slip and trip falling Minor 1) Physical injury-bodily 1)Project requirement. 1)Conduct daily 1 1 1

. erial hazard. injury. 2)OHSA 1994 (before, during and after).

arrangement 3)FMA 1967 2) Visual check after the

housekeeping.

This is computer printed out copy treated as CONTROLLED DOCUMENT Page 6 of 7

Doc No : NCSB-IMS-SP05-FO-04 Date : 24-February-2020

NAKANO CONSTRUCTION SDN BHD Process Owner : HSE&QA Department Rev : 01

Hazard Identification Risk Assessment Risk Control (HIRARC)

PROJECT / LOCATION : – PROPOSED INFINEON TOWER 11 STOREY OFFICE, 4 STOREY PRODUCTION & 5 STOREY CENTRAL UTILITIES BUILDING (CUB) ON LOT 1604, MUKIM, Update no. : Date :

PRINGGIT DAERAH MELAKA TENGAH HANG TUAH JAYA, MELAKA. NCSB 2019-ITT -CEC-ELE-HIRAC-10

WORK ACTIVITY : PIPING INSTALLATION(OPEN CUT TRENCH) 30/06/2020

1. Hazard Identification 2. Risk Evaluation 3. Risk Re-Evaluation

Likelihood (L)

Severity (S)

Likelihood (L)

Severity (S)

Risk

Residual Risk

Category of Hazard

No. Activity Sub Activity Hazard Effect of hazard Applicable legal Existing Risk Control Additional Risk PIC (Due

& other (if any) Control date/

requirement status)

APPICABLE FOR CEC ELECTRICAL ENGINEERING SDN.BHD

This is computer printed out copy treated as CONTROLLED DOCUMENT Page 7 of 7

You might also like

- Hazard Identification and Risk Control for Cable Ladder InstallationDocument9 pagesHazard Identification and Risk Control for Cable Ladder Installationtana67% (6)

- Hirac (Manhole Installation)Document7 pagesHirac (Manhole Installation)tanaNo ratings yet

- Hirac (Light-Fittings Installation)Document5 pagesHirac (Light-Fittings Installation)tana100% (2)

- Hirac (Ups and Battery Charger Installation)Document6 pagesHirac (Ups and Battery Charger Installation)tana100% (2)

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana100% (1)

- 03 Hirarc Construction o Contiguous Bore Pile BiaxisDocument6 pages03 Hirarc Construction o Contiguous Bore Pile BiaxisRosli Bin Abdul Shukor100% (1)

- Risk Assessment For Plaster WorksDocument2 pagesRisk Assessment For Plaster WorksMuthukumar Jayaveerapandian100% (1)

- Hazard ID risks pile workDocument2 pagesHazard ID risks pile workRafee Pie93% (14)

- Trees Cutting: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 35. Trees CuttingDocument2 pagesTrees Cutting: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 35. Trees CuttingRafee Pie100% (1)

- Hirac (LV Cable Installation Work)Document9 pagesHirac (LV Cable Installation Work)tana100% (2)

- 005 HIRARC Hollow Core Slab InstallationDocument5 pages005 HIRARC Hollow Core Slab Installationbdiey100% (4)

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- Hirarc Plastering WorkDocument3 pagesHirarc Plastering WorkAhmad Afifullah0% (1)

- Hazard risks at construction siteDocument2 pagesHazard risks at construction siteRafee Pie100% (12)

- Hazards Analysis Guide A Reference Manual For Analyzing Safety Hazards On Semiconductor Manufacturing Equipment PDFDocument46 pagesHazards Analysis Guide A Reference Manual For Analyzing Safety Hazards On Semiconductor Manufacturing Equipment PDFdckristantoNo ratings yet

- Guidance Note - Risk AssessmentDocument35 pagesGuidance Note - Risk AssessmentDobrescu CristianNo ratings yet

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie0% (1)

- 011 HIRARC Falsework (EFCO) LiftingDocument5 pages011 HIRARC Falsework (EFCO) Liftingbdiey100% (2)

- HIRARC For Concrete WorkDocument2 pagesHIRARC For Concrete WorkShirako Takamoto80% (5)

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- HIRA - Carpentry Work-018Document8 pagesHIRA - Carpentry Work-018Satya Naidu100% (1)

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana83% (6)

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana83% (6)

- 20 - Roofing WorksDocument2 pages20 - Roofing WorksRafee PieNo ratings yet

- HIRARC Piling WorkDocument4 pagesHIRARC Piling Workhairul89% (9)

- Hazard Identification and Risk Assessment VirtualDocument33 pagesHazard Identification and Risk Assessment VirtualGyanendra Narayan Nayak100% (1)

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocument2 pagesLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanNo ratings yet

- Installation of hoarding risk assessment and controlsDocument1 pageInstallation of hoarding risk assessment and controlsRafee Pie71% (7)

- Hirarc ExcavationDocument6 pagesHirarc ExcavationWeyWeyEnne80% (5)

- HIRADC GGC - BrickworkDocument4 pagesHIRADC GGC - Brickworkfarizal EnterpriseNo ratings yet

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Risk Assessment - Finishing Work (Brick, Plaster, Skim, Tiles, Screeding)Document17 pagesRisk Assessment - Finishing Work (Brick, Plaster, Skim, Tiles, Screeding)Muhd Izzat Iskandar Safarudin100% (3)

- 014 HIRARC Installation of OSD Steel Roof StructureDocument5 pages014 HIRARC Installation of OSD Steel Roof Structurebdiey89% (9)

- Children & Young People's Services RISK ASSESSMENTDocument2 pagesChildren & Young People's Services RISK ASSESSMENThaziq ziqNo ratings yet

- Hazards and Risks Assessment MethodsDocument20 pagesHazards and Risks Assessment Methodsapi-3733731100% (8)

- IHA Fans april 2005 versie 1Document3 pagesIHA Fans april 2005 versie 1Luc Schram100% (1)

- Hirac (Piping Installation (Open Cut Trench)Document7 pagesHirac (Piping Installation (Open Cut Trench)tana100% (1)

- 23 - Steel WorksDocument4 pages23 - Steel WorksRafee PieNo ratings yet

- HIRARC For BrickworkDocument2 pagesHIRARC For BrickworkShirako Takamoto80% (5)

- 8 - Pile Cap WorksDocument3 pages8 - Pile Cap WorksRafee Pie86% (7)

- HIRARC - Front PageDocument2 pagesHIRARC - Front PageRafee Pie0% (1)

- 18 - Aluminum Glazing & Glass WorksDocument1 page18 - Aluminum Glazing & Glass WorksRafee Pie100% (1)

- HIRARC For Plastering WorkDocument2 pagesHIRARC For Plastering WorkShirako Takamoto100% (4)

- 29 - Road WorksDocument4 pages29 - Road WorksRafee Pie100% (2)

- XBCS3103 Plant and Construction SafetyDocument259 pagesXBCS3103 Plant and Construction Safetytana100% (2)

- 007 HIRARC Construction of RC Column (Car Park)Document10 pages007 HIRARC Construction of RC Column (Car Park)bdieyNo ratings yet

- 006 HIRARC Hacking of Pile CapDocument5 pages006 HIRARC Hacking of Pile Capbdiey67% (6)

- Drainage risk assessmentDocument4 pagesDrainage risk assessmentRafee Pie100% (5)

- HIRARC Rock BlastingDocument4 pagesHIRARC Rock BlastingNajman Hamdi100% (13)

- Tiling risk assessmentDocument2 pagesTiling risk assessmentRafee Pie100% (1)

- Hirarc ExcavationDocument6 pagesHirarc ExcavationKalai Arasan100% (1)

- Maintain Load Test (MLT) hazard identification and risk assessmentDocument1 pageMaintain Load Test (MLT) hazard identification and risk assessmentRafee Pie100% (1)

- 28 - Sewerage WorksDocument1 page28 - Sewerage WorksRafee PieNo ratings yet

- RMDJV Pj74 Hiradc Misc 01 (Housekeeping)Document2 pagesRMDJV Pj74 Hiradc Misc 01 (Housekeeping)myn maliQueNo ratings yet

- Hirac (Piping Installation (Open Cut Trench)Document7 pagesHirac (Piping Installation (Open Cut Trench)tana100% (2)

- Excavation Works: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 31. Excavation WorksDocument2 pagesExcavation Works: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 31. Excavation WorksRafee Pie100% (2)

- 04 HIRA For Reinforcement WorkDocument7 pages04 HIRA For Reinforcement WorkMithlesh Singh100% (1)

- HIRARC Risk AssessmentDocument6 pagesHIRARC Risk Assessmentfarizal EnterpriseNo ratings yet

- Health and Safety Manual - Company TemplateDocument22 pagesHealth and Safety Manual - Company TemplateArun VenkatNo ratings yet

- Emergency PlansDocument54 pagesEmergency PlansVasant Kumar VarmaNo ratings yet

- Hazard Risk Assessment Manhole InstallationDocument7 pagesHazard Risk Assessment Manhole Installationtana50% (2)

- Hirac (Busways and Busducts Installation)Document8 pagesHirac (Busways and Busducts Installation)tana100% (3)

- Guide Crane-Lifted Work PlatformsDocument13 pagesGuide Crane-Lifted Work PlatformssheqarayzanNo ratings yet

- General Safety Guide CadetsDocument32 pagesGeneral Safety Guide Cadetsa_macfarlaneNo ratings yet

- HACCP (Coca Cola)Document18 pagesHACCP (Coca Cola)richard.marchant22590% (21)

- C&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFDocument4 pagesC&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFNajman Hamdi100% (3)

- 17 - Painting WorksDocument2 pages17 - Painting WorksRafee Pie50% (4)

- SOPfor Halaland Food Safety Risk AssessmentDocument10 pagesSOPfor Halaland Food Safety Risk AssessmentSRIKANTHNo ratings yet

- Deshuttering WorkDocument2 pagesDeshuttering WorkChandru100% (1)

- Barbending HiracDocument2 pagesBarbending HiracJohn Ha71% (7)

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Turfing works risk assessmentDocument1 pageTurfing works risk assessmentRafee Pie100% (1)

- Industy Code of Practice For Safe Working in A Confined Space 2010Document80 pagesIndusty Code of Practice For Safe Working in A Confined Space 2010Abd Rahim100% (2)

- 32 - Working at HeightDocument2 pages32 - Working at HeightRafee PieNo ratings yet

- Understanding Risk Assessment and Control: Training Course Session 4Document23 pagesUnderstanding Risk Assessment and Control: Training Course Session 4Anonymous iI88LtNo ratings yet

- Risk assessment and control for yarn trolley operationsDocument2 pagesRisk assessment and control for yarn trolley operationsThachnatharen0% (1)

- DNV (2001) - Frequency Analysis of Accidental Oil Releases From Fpso Operations in The Gulf of MexicoDocument155 pagesDNV (2001) - Frequency Analysis of Accidental Oil Releases From Fpso Operations in The Gulf of MexicoHossein Zohdi RadNo ratings yet

- Scaffold Design Approval GuidelinesDocument22 pagesScaffold Design Approval Guidelinesgarych72No ratings yet

- Check List IFS Logistics 2.2 - Eng 250618 - 1Document9 pagesCheck List IFS Logistics 2.2 - Eng 250618 - 1Mariajose MarencoNo ratings yet

- Case For Safety - Bowtie AnalysisDocument23 pagesCase For Safety - Bowtie Analysistrau-nuocNo ratings yet

- Checklist 22000: 2005: PurposeDocument39 pagesChecklist 22000: 2005: PurposestevierayoNo ratings yet

- Conformance Matrix To ISO 9001 2008, IsO 14001 2004, OHSAS 18001 2007 RequirementsDocument7 pagesConformance Matrix To ISO 9001 2008, IsO 14001 2004, OHSAS 18001 2007 Requirementsm_lashin100% (5)

- Nop 177Document2 pagesNop 177tanaNo ratings yet

- ARCOM2014tressintheconstructionindustry Anexplanatorymodel aspublishedbyARCOM2014Document25 pagesARCOM2014tressintheconstructionindustry Anexplanatorymodel aspublishedbyARCOM2014tanaNo ratings yet

- Assignment Sbev 3103 Sem Jan-2022-Tanasilan A.danabaluDocument13 pagesAssignment Sbev 3103 Sem Jan-2022-Tanasilan A.danabalutanaNo ratings yet

- EPA Region 7 EMS Internal Audit ReportDocument13 pagesEPA Region 7 EMS Internal Audit ReporttanaNo ratings yet

- Nop 179Document3 pagesNop 179tanaNo ratings yet

- Nop 180Document2 pagesNop 180tanaNo ratings yet

- WMS Infineon Project Tower (Piping Installation (Open Cut Trench) )Document5 pagesWMS Infineon Project Tower (Piping Installation (Open Cut Trench) )tanaNo ratings yet

- CEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTDocument6 pagesCEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTtanaNo ratings yet

- Nop 178Document2 pagesNop 178tanaNo ratings yet

- WMS Infineon Project Tower (LV Cabling Work) - Rev-1Document8 pagesWMS Infineon Project Tower (LV Cabling Work) - Rev-1tanaNo ratings yet

- CEC Electrical Panel Installation Work Method StatementDocument5 pagesCEC Electrical Panel Installation Work Method StatementtanaNo ratings yet

- Summary 4Document1 pageSummary 4tanaNo ratings yet

- WMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1Document8 pagesWMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1tanaNo ratings yet

- North Building VCB Modification and Cabling WorksDocument10 pagesNorth Building VCB Modification and Cabling WorkstanaNo ratings yet

- WMS INFINEON PROJECT TOWER (11Kv VCB INSTALLATION) - REV-1Document5 pagesWMS INFINEON PROJECT TOWER (11Kv VCB INSTALLATION) - REV-1tana100% (1)

- WMS Infineon Project Tower ( Lifting Activities)Document14 pagesWMS Infineon Project Tower ( Lifting Activities)tanaNo ratings yet

- Wms Infineon Project Tower (Manhole Installation)Document5 pagesWms Infineon Project Tower (Manhole Installation)tanaNo ratings yet

- Light Fitting Lux Measurement Work MethodDocument4 pagesLight Fitting Lux Measurement Work MethodtanaNo ratings yet

- WMS Infineon Project Tower ( Light-Fittings Installation) - Rev-1Document5 pagesWMS Infineon Project Tower ( Light-Fittings Installation) - Rev-1tanaNo ratings yet

- WMS Infineon Project Tower ( Busways and Busducts Installation) - Rev-1Document6 pagesWMS Infineon Project Tower ( Busways and Busducts Installation) - Rev-1tanaNo ratings yet

- Tapak Selamat Buletin Bil3 2015Document22 pagesTapak Selamat Buletin Bil3 2015Nazrul Chermile100% (1)

- Garispanduan 2007 FallDocument68 pagesGarispanduan 2007 FallFrancis WongNo ratings yet

- CSB PM - Thermal Decomposition Incident BP AMOCO PolymersDocument37 pagesCSB PM - Thermal Decomposition Incident BP AMOCO Polymersrieza_fNo ratings yet

- Job Safety Analysis (Jsa) and Risk Assessment Form: WastonoDocument8 pagesJob Safety Analysis (Jsa) and Risk Assessment Form: WastonoPutra FeraNo ratings yet

- Chapter 10 HazopDocument46 pagesChapter 10 HazopNAANo ratings yet

- Chapter 9a - Risk - Management & Accident PreventionDocument31 pagesChapter 9a - Risk - Management & Accident PreventionEng. Ibrahim Abdullah AlruhmiNo ratings yet

- Hazard AnalysisDocument39 pagesHazard AnalysisvishnuNo ratings yet

- 8-Frank Lees - Loss Prevention - Hazard Idenitification, Assessment and Control (Volume 1) - Butterworth-Heinemann (1996) - 250-357Document108 pages8-Frank Lees - Loss Prevention - Hazard Idenitification, Assessment and Control (Volume 1) - Butterworth-Heinemann (1996) - 250-357RafaelNo ratings yet

- Generic Mechanical Workshop Risk AssessmentDocument6 pagesGeneric Mechanical Workshop Risk AssessmentMohammad Abubakar SiddiqNo ratings yet

- Guidelines for Hazard Identification, Risk Assessment and Risk Control (HIRARCDocument34 pagesGuidelines for Hazard Identification, Risk Assessment and Risk Control (HIRARCEncik AhmadNo ratings yet

- Agricultur Products Certification System 2556Document108 pagesAgricultur Products Certification System 2556Nop PiromNo ratings yet

- TOR-2010 (8591) - 18 Mission Assurance Program FrameworkDocument37 pagesTOR-2010 (8591) - 18 Mission Assurance Program FrameworkdpinkleyNo ratings yet

- HIRARC FormDocument43 pagesHIRARC FormFachri Hidayat50% (2)

- Hazard Identification, Risk Assessment, and Controls (HIRACDocument134 pagesHazard Identification, Risk Assessment, and Controls (HIRACJohn Mark DulawanNo ratings yet

- Hirarc ToolsDocument30 pagesHirarc ToolsMikael NaqibNo ratings yet