0% found this document useful (0 votes)

64 views9 pagesHazardous Chemical Storage Guidelines

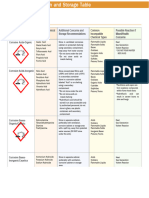

Hazardous chemicals must be properly stored according to their hazard class. Corrosives like acids should be segregated from bases and stored in chemical-resistant trays on low shelves or in corrosive cabinets. Oxidizers such as peroxides should be stored away from flammables and kept cool and dry. Nitric acid requires separate storage due to its reactivity. Plastic tubs are an acceptable substitute for acid cabinets. Personal protective equipment like gloves and safety glasses should be worn when handling hazardous chemicals.

Uploaded by

buattugasmetlitCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

64 views9 pagesHazardous Chemical Storage Guidelines

Hazardous chemicals must be properly stored according to their hazard class. Corrosives like acids should be segregated from bases and stored in chemical-resistant trays on low shelves or in corrosive cabinets. Oxidizers such as peroxides should be stored away from flammables and kept cool and dry. Nitric acid requires separate storage due to its reactivity. Plastic tubs are an acceptable substitute for acid cabinets. Personal protective equipment like gloves and safety glasses should be worn when handling hazardous chemicals.

Uploaded by

buattugasmetlitCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd