Professional Documents

Culture Documents

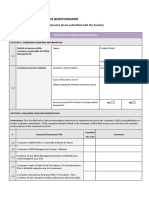

Appendix 2 Hse Screening Questionnaire

Uploaded by

SuadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix 2 Hse Screening Questionnaire

Uploaded by

SuadCopyright:

Available Formats

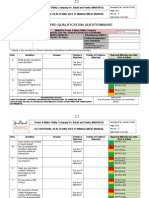

Management of Health, Safety, Environment and Security Questionnaire

1 Leadership & commitment 2 Policy & strategic objectives

1.1 Leadership & commitment 2.1 Policy & strategic objectives

Management of the Company should provide strong, Yes No There is a clearly stated policy and strategic objectives Yes No

visible leadership and commitment, and ensure that which take due account of legislation and industry

this commitment is translated into the necessary practice, includes a commitment to continual

resources, to develop, operate and maintain the HSES improvement, and are communicated and understood

MS and to attain the policy and strategic objectives. by employees and contractors

Do Managers participate in setting safety standards Are policies documented, available in appropriate

1.1.1 and measurable targets, and in establishing 2.1.1 languages, distributed to all concerned and available to

performance measurement systems and procedures? other interested parties?

Are there Plans to manage HSES? Are legal requirements identified and addressed?

1.1.2 2.1.2

Do Managers allocate the necessary resources, such Does the Policy include a commitment for continual

1.1.3 as time and money, to HSES matters? 2.1.3 improvement and prevention of pollution?

Are HSES matters placed high and routinely on the Are Industry standards and other requirements

1.1.4 2.1.4

agenda of meetings, from the Board downwards? recognised and reflected?

Do Managers communicate the importance of HSES Are Policies displayed at each location?

1.1.5 considerations in business decisions? 2.1.5

Do Management goals and objectives include HSES? Are Policies read, discussed and understood by those

1.1.6 2.1.6 affected with the intent that all parties know their

individual obligations?

Do Managers set a personal example in day to day Are Policies implemented?

1.1.7 work and make regular visits to the workplace? 2.1.7

Are Managers actively involved in HSES activities, Are Policies reviewed periodically?

1.1.8 investigations, audits, reviews and corrective actions at 2.1.8

both local and remote sites?

Do Managers have knowledge of HSES management? Are Objectives communicated to relevant personnel

1.1.9 2.1.9

and distilled into a programme to achieve them?

Do Managers follow HSES specialist advice? Are Employees involved in policy development, review

1.1.10 2.1.10

and revision?

Is participation of staff at all levels encouraged, through

1.1.11 seeking views in development and energetically 2.1.11

pursuing suggestions for improvement?

Do Managers promote a company culture conducive to

1.1.12 2.1.12

good HSES performance?

1.1.13 2.1.13

1.1.14 2.1.14

1.1.15 2.1.15

1.1.16 2.1.16

Please provide Evidence as indicated below: Please provide Evidence as indicated below:

Annual Management Review of HSE Performance Corporate HSE Polices

Annual HSE Objectives

Annual HSE Key Performance Indicators

Annual HSE Performance targets

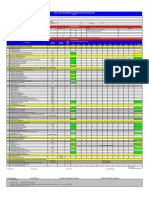

Management of Health, Safety, Environment and Security Questionnaire

Organisation, Resources and Documentation

3 4 Evaluation & risk management

3.1 Organisational structure & responsibilities 4.1 Identification & evaluation of risk

There is Organisational structure in place for HSES Yes No Risks Assessments are carried out to identify and Yes No

management and HSES responsibilities are assess the risks to people, assets and the environment

incorporated into job descriptions and performance arising from operations.

contracts.

Are HSES responsibilities included in individual job Are documented procedures established for the

3.1.1 descriptions? 4.1.1 ongoing identification of hazards, assessment of risk

and implementation of necessary control measures?

Are HSES responsibilities included in working Are documented procedures established and

documents (manuals, procedures, bridging documents) maintained for the ongoing identification of

3.1.2 where appropriate? 4.1.2 environmental impacts (positive and negative impacts)?

Is the principle that HSES is the responsibility of Do evaluations provide a description of measures to

3.1.3 everyone communicated and promoted? 4.1.3 control and monitor the risks?

Do individuals have HSES performance goals? Do risk assessments identify and access legal and

3.1.4 4.1.4

other requirements?

Is individual and team HSES performance included in Are evaluations recorded?

3.1.5 staff performance reviews? 4.1.5

Are responsibilities of contractors documented, Are identified actions followed up?

3.1.6 communicated and understood? 4.1.6

Is good HSES performance recognised through merit Are evaluations reviewed at a predetermined time or in

3.1.7 award system/promotion decisions? 4.1.7 a period commensurate with the magnitude of risk and

the frequency of any changes in operation?

Are hazard registers established and maintained?

3.1.8 4.1.8

Are employees involved in the assessment process

3.1.9 4.1.9

and do they have access to hazard information?

3.1.10 4.1.10

3.1.11 4.1.11

3.1.12 4.1.12

3.1.13 4.1.13

3.1.14 4.1.14

3.1.15 4.1.15

3.1.16 4.1.16

Please provide Evidence as indicated below: Please provide Evidence as indicated below:

HSE Organogram Hazard Register

HSE Performance Recognition Scheme Health Case

Safety Case

Environmental Case

Management of Health, Safety, Environment and Security Questionnaire

5 Planning 6 Implementation and Monitoring

5.1 Asset integrity 6.1 Incident reporting & follow-up

Availability and reliability is considered in design and Yes No There is a procedure for incident reporting, and Yes No

operation of facilities and assets. Regular preventative development of corrective action. This system is used

maintenance regimes are in place for key pieces of and performance in incident reporting and investigation

plant. is subject to regular review.

Is a safe working environment maintained? Is there a procedure in place for reporting and

5.1.1 6.1.1 investigation of all accidents and incidents?

Are there appropriate routine inspection and Are all incidents (including near miss reports)

maintenance schedules carried out for all HSES related investigated at a level of detail appropriate for the

5.1.2 equipment? 6.1.2 severity or potential severity of result?

Is all engineering design to the "fail-safe" philosophy as Are all unsafe acts and conditions reported?

5.1.3 a standard? 6.1.3

Is preventative maintenance conducted where Is a logical process followed to identify incident root

5.1.4 6.1.4

appropriate? causes?

Is deviation from approved design practises and Are corrective and preventive action plans set following

5.1.5 standards permitted only after review and approval by 6.1.5 an incident investigation?

designated personnel / authorities?

Are lessons from HSES audits used to improve design Do incident investigations include all personnel involved

5.1.6 and operation? 6.1.6 in the incident?

Is particular emphasis placed on safety in design to Are records regularly reviewed and analysed to identify

5.1.7 eliminate risks at source? 6.1.7 trends and incident frequencies?

Is there regular management review of incident data

5.1.8 6.1.8 leading to continual improvement activities?

Is the effectiveness of actions confirmed through review

5.1.9 6.1.9

of risk assessment?

Are all changes communicated to relevant personnel?

5.1.10 6.1.10

5.1.11 6.1.11

5.1.12 6.1.12

5.1.13 6.1.13

5.1.14 6.1.14

5.1.15 6.1.15

5.1.16 6.1.16

Please provide Evidence as indicated below: Please provide Evidence as indicated below:

Accident Reporting and investigation process

Area Safety Inspection Report

Corrective Action Register

Management of Health, Safety, Environment and Security Questionnaire

7 Auditing & reviewing

7.1 Auditing & reviewing

An plan is in place for audit and review of HSES Yes No

arrangements. Audits and reviews are conducted

according to appropriate standards, to time and with

management participation. Audit reports are generated

and corrective action plans are developed from audit

findings.

Are there procedures in place for the periodic review of

7.1.1 the HSES MS?

Are audits carried out according to a planned

programme and schedule, covering all areas of the

7.1.2 operations and all elements of the HSES MS?

Are auditors independent from the area being audited,

7.1.3 have the necessary expertise to audit and have

specialist advice available?

Do audit findings allow corrective actions to be taken

7.1.4

within an agreed action plan?

Are all actions initiated and completed in a timely

7.1.5 manner and monitored for effective implementation?

Are audit findings published and discussed with

7.1.6 personnel in work area and at safety meetings?

Do audits use a variety of enquiry techniques (e.g.

7.1.7 checklists, questionnaires, interviews, measurements

and direct observation)?

Are lessons from audits used to improve design and

7.1.8 operation?

7.1.9

7.1.10

7.1.11

7.1.12

7.1.13

7.1.14

7.1.15

7.1.16

Please provide Evidence as indicated below:

Annual HSE Performance Report

You might also like

- Safety Assessment Questionnaire AppendixDocument26 pagesSafety Assessment Questionnaire AppendixSignam Specialised CoatingsNo ratings yet

- Hsems 8 ElementsDocument86 pagesHsems 8 ElementsIndermohan Mehta100% (2)

- culture of safety A Complete Guide - 2019 EditionFrom Everandculture of safety A Complete Guide - 2019 EditionRating: 5 out of 5 stars5/5 (1)

- Planning and Procedures: Pdo Hse Management System Manual (CP-122)Document10 pagesPlanning and Procedures: Pdo Hse Management System Manual (CP-122)AHMEDNABTNo ratings yet

- HSEDocument5 pagesHSEBlow50% (2)

- HSEQ Questionaire For Contractor EvaluationDocument6 pagesHSEQ Questionaire For Contractor EvaluationNasih Tr100% (1)

- HSE Training Plan-2013Document1 pageHSE Training Plan-2013Abd Zouhier100% (1)

- HSE Management Plan RequirementsDocument5 pagesHSE Management Plan RequirementsMohamed Hadjkacem100% (1)

- HSE Audit ChecklistDocument19 pagesHSE Audit ChecklistOws AnishNo ratings yet

- HSE Action PlanDocument3 pagesHSE Action PlanELANCHELIYANNo ratings yet

- 2013 HSE Annual Report - Web FINAL PDFDocument74 pages2013 HSE Annual Report - Web FINAL PDFarunradNo ratings yet

- Annual Hse ReportDocument8 pagesAnnual Hse Reportbakari hamisiNo ratings yet

- Weekly HSE Report - 20-05-2023Document25 pagesWeekly HSE Report - 20-05-2023abhinav djNo ratings yet

- Apendix 13-HSE Plan ManualDocument50 pagesApendix 13-HSE Plan ManualShahid IqbalNo ratings yet

- SENIOR HSE ENGINEER'S INTERVIEW QUESTIONNAIRE Rev01Document3 pagesSENIOR HSE ENGINEER'S INTERVIEW QUESTIONNAIRE Rev01nazeer_mohdNo ratings yet

- HSE Capability Questionnaire 01-10-2015 v6Document9 pagesHSE Capability Questionnaire 01-10-2015 v6Sayed DarwishNo ratings yet

- HSE Plan DraftDocument5 pagesHSE Plan DraftElang Ishvara Destrian PutraNo ratings yet

- HSE Statistics Presentation ExampleDocument23 pagesHSE Statistics Presentation ExampleKhuda BukshNo ratings yet

- Annexure C HSE QuestionaireDocument8 pagesAnnexure C HSE QuestionaireDie HArdNo ratings yet

- Laydown Yard Safety ChecklistDocument5 pagesLaydown Yard Safety ChecklistTomin ThomasNo ratings yet

- Marine Health, Safety, Quality and Environmental Management: Guide ForDocument56 pagesMarine Health, Safety, Quality and Environmental Management: Guide ForgabelendaNo ratings yet

- 16 How To Monitor Contractor HSE Performance - QatalumDocument17 pages16 How To Monitor Contractor HSE Performance - Qatalumdrmayank10100% (1)

- Marafiq OHSMS Pre-Qualification QuestionnaireDocument17 pagesMarafiq OHSMS Pre-Qualification QuestionnairemedobasNo ratings yet

- 49-JCPDI I-2004 - Contractor Weekly SHE Statistics Report (AutoRecovered)Document2 pages49-JCPDI I-2004 - Contractor Weekly SHE Statistics Report (AutoRecovered)zubair khanNo ratings yet

- 4.4.3.3 Data and Trend AnalysisDocument6 pages4.4.3.3 Data and Trend AnalysisIndermohan MehtaNo ratings yet

- 11-2.3.02 Coshh (Control of Substances Hazardous To Health)Document17 pages11-2.3.02 Coshh (Control of Substances Hazardous To Health)Francisco M. RamosNo ratings yet

- Safe driving rain alertDocument1 pageSafe driving rain alertRanjan PradhanNo ratings yet

- Monthly HSE Report - January 2022Document13 pagesMonthly HSE Report - January 2022adeniyi abiolaNo ratings yet

- HSE MS Audit / Review Document ListDocument4 pagesHSE MS Audit / Review Document ListSteven LeeNo ratings yet

- Contractor Unified HSE PQ Questionnaire (1-3)Document5 pagesContractor Unified HSE PQ Questionnaire (1-3)Shaik Fazlur RahmanNo ratings yet

- Monthly HSE report summaryDocument5 pagesMonthly HSE report summaryNiraNo ratings yet

- WRAL Weekly HSE Report 08-01-2024 To - 14-01-2024Document3 pagesWRAL Weekly HSE Report 08-01-2024 To - 14-01-2024sunday abachaNo ratings yet

- SAFETY Statistics AprDocument1 pageSAFETY Statistics AprSantos RexNo ratings yet

- WEEKLY HSE REPORT HIGHLIGHTSDocument6 pagesWEEKLY HSE REPORT HIGHLIGHTSBrings MotoVlogNo ratings yet

- Hsebooks CatalogueDocument32 pagesHsebooks CatalogueVikas YamagarNo ratings yet

- Hse PolicyDocument1 pageHse PolicysushantvatsaNo ratings yet

- Project HSE Performance Monitoring ProcedureDocument12 pagesProject HSE Performance Monitoring ProcedureWinnie Eldama0% (1)

- HSE Matrix PlanDocument5 pagesHSE Matrix Planवात्सल्य कृतार्थ100% (1)

- Construction Safety Audit ChecklistDocument7 pagesConstruction Safety Audit Checklistamit sikkaNo ratings yet

- HSE AwarenessDocument70 pagesHSE Awarenessعبدالحميد عبدالغفار الدرديري50% (2)

- January HSE Management PlanDocument1 pageJanuary HSE Management PlanMohammed AhmedNo ratings yet

- Appendix B HSE Plan 2019Document1 pageAppendix B HSE Plan 2019aymenmoatazNo ratings yet

- Injury Classification Report Nov 2014-Dec 2015Document18 pagesInjury Classification Report Nov 2014-Dec 2015AbeAu NewNo ratings yet

- Seplat Safe System of Work Scheme: Seplat Petroleum Development CompanyDocument16 pagesSeplat Safe System of Work Scheme: Seplat Petroleum Development CompanySegun Rufai100% (6)

- HSE Auditing ProcedureDocument15 pagesHSE Auditing Proceduresudeesh kumarNo ratings yet

- PJ-RTTS-DI-ERP-009 Rev. B, EMERGENCY RESPONSE PLAN-MNS-1Document17 pagesPJ-RTTS-DI-ERP-009 Rev. B, EMERGENCY RESPONSE PLAN-MNS-1عايض ال سلطان100% (1)

- Code of PracticeDocument26 pagesCode of PracticeS Khan100% (1)

- NorSea Group HSE HandbookDocument23 pagesNorSea Group HSE HandbookAshish TelangNo ratings yet

- Appendix 18 Monthly OSH EHS Proactive Monitoring ProgramDocument1 pageAppendix 18 Monthly OSH EHS Proactive Monitoring ProgramXtreme-DesignsNo ratings yet

- 2 HSE-PlanDocument40 pages2 HSE-Plan09tlionNo ratings yet

- Hse Key Performance Indicator Contractor 2021: Trailling Metric ( )Document1 pageHse Key Performance Indicator Contractor 2021: Trailling Metric ( )Dipendra Satya100% (4)

- Developing HSE ExcellenceDocument26 pagesDeveloping HSE Excellenceantonmp66100% (1)

- Workplace Health, Safety and Environment ChecklistDocument3 pagesWorkplace Health, Safety and Environment ChecklistWaqarAhmedButtNo ratings yet

- Monthly Safety ReportDocument1 pageMonthly Safety Reportsafety.engNo ratings yet

- Hse Team Tour Checklist ProcessDocument2 pagesHse Team Tour Checklist Processf.B100% (1)

- 7c - IOGP 432 Table 1 Draft v3 04062016Document32 pages7c - IOGP 432 Table 1 Draft v3 04062016Idada Ezekiel100% (1)

- Guide Service Station Op PDFDocument18 pagesGuide Service Station Op PDFSuadNo ratings yet

- Access Medical Exp RecordsDocument29 pagesAccess Medical Exp RecordsSuadNo ratings yet

- Interview Evaluation FormDocument8 pagesInterview Evaluation FormSuadNo ratings yet

- 05 - Hole Watch3Document21 pages05 - Hole Watch3SuadNo ratings yet

- 13566822 (1).pptDocument25 pages13566822 (1).pptSuadNo ratings yet

- DOSH - Guidelines On OSH in The OfficeDocument29 pagesDOSH - Guidelines On OSH in The OfficeNur Fadhilah RosliNo ratings yet

- Limit FungsiDocument9 pagesLimit FungsiAnggi SaputraNo ratings yet

- Hsems DemoDocument115 pagesHsems DemoSuadNo ratings yet

- Name: Suad BUS Title Sharrcem Titan GroupDocument13 pagesName: Suad BUS Title Sharrcem Titan GroupSuadNo ratings yet

- Fire Safety 0Document34 pagesFire Safety 0Anonymous iI88LtNo ratings yet

- Electrical Hazard Awareness Study GuideDocument49 pagesElectrical Hazard Awareness Study GuideKARAM ZAKARIANo ratings yet

- Sec 10Document10 pagesSec 10SuadNo ratings yet

- Fire Safety ManaulDocument71 pagesFire Safety ManaulStan MacapiliNo ratings yet

- Workplace Fire SafetyDocument6 pagesWorkplace Fire SafetyazarNo ratings yet

- Quality Excel Stacked Chart TemplatesDocument18 pagesQuality Excel Stacked Chart TemplatesSuadNo ratings yet

- VDZ-Onlinecourse 6 5 enDocument30 pagesVDZ-Onlinecourse 6 5 enSuadNo ratings yet

- Workplace Fire SafetyDocument6 pagesWorkplace Fire SafetyazarNo ratings yet

- WebchDocument2 pagesWebchSuadNo ratings yet

- Quality Excel Stacked Chart TemplatesDocument18 pagesQuality Excel Stacked Chart TemplatesSuadNo ratings yet

- 3D Charts for Quarterly Data VisualizationDocument1 page3D Charts for Quarterly Data VisualizationSuadNo ratings yet

- VDZ-Onlinecourse 6 1 en PDFDocument34 pagesVDZ-Onlinecourse 6 1 en PDFAnonymous iI88LtNo ratings yet

- Sales 2009: Product Sales 2008 Sales 2009 DifferenceDocument2 pagesSales 2009: Product Sales 2008 Sales 2009 DifferenceSuadNo ratings yet

- Ring 1Document2 pagesRing 1SuadNo ratings yet

- Fire Sign Schedule JSBoneDocument3 pagesFire Sign Schedule JSBoneSuadNo ratings yet

- VDZ-Onlinecourse 6 7 enDocument22 pagesVDZ-Onlinecourse 6 7 enAnonymous iI88LtNo ratings yet

- Quality Excel Stacked Chart TemplatesDocument18 pagesQuality Excel Stacked Chart TemplatesSuadNo ratings yet

- Fire SafetyDocument19 pagesFire SafetySuadNo ratings yet

- Certification Dubai 151126082712 Lva1 App6892Document10 pagesCertification Dubai 151126082712 Lva1 App6892SuadNo ratings yet

- IADON Emergency MotionDocument63 pagesIADON Emergency MotionRiley SnyderNo ratings yet

- A. Here Are The Qualifications To Acquire PWD IDDocument9 pagesA. Here Are The Qualifications To Acquire PWD IDMichael James Madrid MalinginNo ratings yet

- Air Transportation GroupDocument10 pagesAir Transportation GroupEm LaurelNo ratings yet

- Guide To Taxation of Employee Disability Benefits: Standard Insurance CompanyDocument26 pagesGuide To Taxation of Employee Disability Benefits: Standard Insurance CompanyJacen BondsNo ratings yet

- Andhra Pradesh Revised Pay Scales 1993Document19 pagesAndhra Pradesh Revised Pay Scales 1993Venkatadurgaprasad GopamNo ratings yet

- PECORARO v. CORRECTIONAL MEDICAL SERVICES Et Al - Document No. 2Document11 pagesPECORARO v. CORRECTIONAL MEDICAL SERVICES Et Al - Document No. 2Justia.comNo ratings yet

- FSSC 22000 Audit TemplateDocument15 pagesFSSC 22000 Audit Templatedakalo8375% (8)

- Inhouse TPA - Claim FormDocument2 pagesInhouse TPA - Claim FormJanarthanan KNo ratings yet

- The Rise and Decline of Cannabis Prohibition.Document88 pagesThe Rise and Decline of Cannabis Prohibition.Descriminalización.orgNo ratings yet

- UntitledDocument2 pagesUntitledSheena De Guzman MorenoNo ratings yet

- Meghalaya Tourism PoliciesDocument9 pagesMeghalaya Tourism PoliciesAmlan KarNo ratings yet

- Access Florida Application Details 810968014Document11 pagesAccess Florida Application Details 810968014Samantha DuffNo ratings yet

- LCPC PresentationDocument31 pagesLCPC PresentationMary Jean Luyahan PanchitoNo ratings yet

- Legalization of Prostitution Sample EssayDocument3 pagesLegalization of Prostitution Sample EssayMuhammad Asyraf Shahran IINo ratings yet

- Corporate Social Responsibility of Zydus Pharma Private LimitedDocument16 pagesCorporate Social Responsibility of Zydus Pharma Private LimitedVishal Vajar100% (1)

- PICQS Membership FormDocument3 pagesPICQS Membership FormIsrael MuhiNo ratings yet

- Oman (Sultanate) : Goods Documents Required Customs Prescriptions RemarksDocument4 pagesOman (Sultanate) : Goods Documents Required Customs Prescriptions RemarksKelz YouknowmynameNo ratings yet

- RJAH NHS FT Supplier Expenditure Jan 2017-Mar 2018Document38 pagesRJAH NHS FT Supplier Expenditure Jan 2017-Mar 2018medhat444444No ratings yet

- A Comparison of EDSA I and EDSA IIDocument4 pagesA Comparison of EDSA I and EDSA IIReymark B. Ibuña100% (2)

- AIDS Foundation of Chicago - Annual Report 2015Document24 pagesAIDS Foundation of Chicago - Annual Report 2015AdamAce VelasquezNo ratings yet

- Namami Gange Programme by Smita SiriDocument7 pagesNamami Gange Programme by Smita Sirigemcap123No ratings yet

- Dental Public HealthDocument116 pagesDental Public Healthyogi_2311100% (1)

- Case LawDocument15 pagesCase LawAshutosh PrasadNo ratings yet

- Impact of Local Government in Rural Area (A Case Study of Etsako West)Document67 pagesImpact of Local Government in Rural Area (A Case Study of Etsako West)Precious KadiriNo ratings yet

- Relevant Provisions of The 1987 ConstitutionDocument4 pagesRelevant Provisions of The 1987 ConstitutionMark Joseph Altura YontingNo ratings yet

- 3M Lapping Film 461X, 462X, 463X, 466X, 468X, 468XY and 468XWDocument2 pages3M Lapping Film 461X, 462X, 463X, 466X, 468X, 468XY and 468XWostogradskiNo ratings yet

- Health Care Ch1Document10 pagesHealth Care Ch1david parker0% (1)

- The Tides of Agencification: Literature Development and Future DirectionsDocument27 pagesThe Tides of Agencification: Literature Development and Future Directionskhalil21No ratings yet

- Zero Traffick - Eliminating Sex Trafficking in India PDFDocument99 pagesZero Traffick - Eliminating Sex Trafficking in India PDFsahil guptaNo ratings yet

- ENV18 Aspects Register Procedure 2014 - UpdatedDocument5 pagesENV18 Aspects Register Procedure 2014 - UpdatedsametggtNo ratings yet