Professional Documents

Culture Documents

HIL Testing MPD

Uploaded by

Michael ChandraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIL Testing MPD

Uploaded by

Michael ChandraCopyright:

Available Formats

World Oil

®

Originally appeared in MARCH 2014 issue, pgs 39-42. Posted with permission.

SPECIAL FOCUS: MANAGED PRESSURE DRILLING

Independent HIL testing brings systematic,

effective verification of MPD systems

Independent HIL testing was proven to BACKGROUND

be a systematic, effective method for EC-Drill represents an advance in MPD technology for float-

assessing control system software for MPD ing drilling rigs. It controls downhole pressure accurately, pro-

vides fast detection of influx and losses, and enables the drilling

applications, and served as a key element in

of previously undrillable wells. These advances are made possible

qualifying a new technology. by employing new control system software that manages the mud

level in the riser.

The mud column is the primary safety barrier for drilling,

ŝŝBJØRNAR VIK, Marine Cybernetics; JOHN-MORTEN GODHAVN the secondary being the blowout preventer (BOP). Much focus

and ESPEN HAUGE, Statoil; and ERLEND MJAAVATTEN, AGR has been put on BOP reliability. An example is the minimum

Enhanced Drilling safety integrity level (SIL) defined for BOP functions on the

Norwegian Continental Shelf (NCS), while there are no such

Managed pressure drilling (MPD) systems are becom- requirements for the mud column.¹ The decision not to have

ing more automated, allowing for improved pressure ma- any minimum SIL requirements is explained by arguing that the

nipulation and providing the ability to drill previously BOP can be regarded as the safety system for the mud column,

undrillable wells. and that the impact of the instrumented systems monitoring re-

However, the increased automation and complexity of con- liability of the mud circulation system is marginal.¹ The latter

trol system software means that verification efforts should be argument may have been true, when it was written, but, with

more rigorous. While traditional risk analysis is both useful and increased levels of automation, the MPD software has become

necessary, verification through hardware-in-the-loop (HIL) more critical, as MPD systems automatically control the pres-

testing has the advantage of testing actual running code. A thor- sure exerted by the mud column. This is supported by a recent

ough testing process also increases the knowledge about, and article written by Det Norske Veritas, which has experienced

confidence in, the control system. considerable demand for third-party evaluation of recently in-

This article describes the verification performed during the troduced MPD systems.² This is particularly true, if the mud

development of the new EC-Drill MPD system. EC-Drill, devel- weight is so low that an error in the MPD or rig systems, e.g., a

oped by AGR Enhanced Drilling, is a system with a subsea pump power loss, can lead to an underbalanced situation.

module that was designed to control BHP, by managing the level In the technology qualification prior to the EC-Drill system’s

of the drilling fluid in the riser. The system incorporates new con- use on the NCS, Statoil and AGR Enhanced Drilling agreed to

trol capabilities, and initial usage was planned for first-quarter have a comprehensive third-party verification of the control sys-

2014, in a subsea field offshore Norway. tem software. To this respect, Marine Cybernetics was contracted

to perform HIL testing, to expose the full capability and robust-

The subsea pump module is a central part of the EC-Drill system. ness of the software. This was the first HIL test for an MPD sys-

38 MARCH 2014 / WorldOil.com

MANAGED PRESSURE DRILLING

tem, but Marine Cybernetics has previously tested several drill- relevant documentation is collected, to get an overview of the

ing control systems, BOP control systems, and a large number of system, define interfaces, decide which components to include in

maritime control systems.³, ⁴ the laboratory, and which components to simulate.

The planning phase is followed by the preparations phase,

WHAT IS HIL TESTING? where system analysis and test design are the key activities.

HIL testing is an efficient black-box method for testing and The system analysis is similar to a hazard and operability study

verifying control system software. Instead of being connected to (HAZOP) and Failure Mode and Effects Analysis (FMEA), but

the actual equipment, the control system is connected to an HIL focuses on the control system software. The system analysis is fol-

simulator, with sophisticated models of the equipment being con- lowed by test design, where test cases are created and prioritized,

trolled. This enables systematic, comprehensive testing of control according to a number of factors. Standard systematic testing

system design philosophy, functionality, and failure handling ca- techniques, such as boundary value analysis, equivalence parti-

pability, both in normal and off-design operating conditions. A tioning, error guessing, scenario testing, state transition testing

key advantage is that testing can be performed at an early stage, and stress testing, are used.

and in a safe test bed, without risk to personnel, equipment, the However, system analysis can only take you so far, if the docu-

well or the environment. In the automotive, avionics and aero- mentation is not sufficiently complete. In this case, exploratory

space industries, HIL testing has been established as a best prac- testing is used. Exploratory testing relies upon the skills of the tes-

tice, to meet the requirements for performance and reliability. ters, their knowledge of the system and the interpretation of pre-

vious test results. In exploratory testing, new tests are constantly

CONCEPT created and used. These tests can be powerful and efficient,

As seen in Fig. 1, a control system interacts with its sur- because they are based on the tester’s continuously increasing

roundings through a set of Input/Output (I/O) communica- knowledge about the testing target system.

tion channels. Inputs are provided by sensors that measure Herein is another key difference between FMEA and HIL

dynamic states and parameters, as well as inputs from operator testing. The FMEA is a desktop study that reveals possible weak

stations and other control systems. Based on its inputs and in- points in the physical design, and points to critical software func-

ternal models, the system calculates control signals that are then tions that deserve increased attention. This provides important

sent to actuators. input to the HIL testing, which is performed by running the actu-

HIL testing isolates the control system, and its operator sta- al control system code. The insight gained from testing and oper-

tions, from its surroundings, and replaces actual inputs with simu- ating the control system in different scenarios during HIL testing

lated inputs from an HIL simulator. The HIL simulator emulates can provide essential information on the functionality and failure

all the control system surroundings, responds to control signals handling capabilities of the control system software, which may

in a realistic manner, and provides realistic, consistent measure- be included in the FMEA.

ments. The control system cannot sense any difference between

the real world and the virtual world in the HIL simulator. THE MPD SYSTEM: EC-DRILL

In HIL testing, the control system is viewed as a black box, The AGR Enhanced Drilling EC-Drill system is an MPD sys-

meaning no first-hand knowledge of the inner workings of the tem that enables the manipulation of the riser level, by pumping

system is necessary. However, a functional description of the sys- returns from the riser up to the rig. This is done with a subsea

tem is needed to establish a proper test scope. In addition, detailed pump module docked on a specially designed and instrumented

knowledge of the system I/O, and the equipment under control, is riser joint, Fig. 2. In addition to these two, key subsea compo-

necessary to develop a sufficiently accurate simulator. nents, the system has a topside counterpart, which includes a

launch and recovery system; control and operator containers;

TESTING PROCESS and an additional operator position.

In the planning phase of the HIL testing process, the most During drilling, the EC-Drill system greatly reduces the need

to manipulate mud weight. Instead, the mud level in the riser can

Fig. 1. HIL testing conceptual setup. Fig. 2. The EC-Drill subsea pump module, docked on the riser.

Vessel, vessel systems,

Normal operation environment

Control signals

Actuators

Control Dynamic

I/O

system systems

Measurements

Sensors

HIL testing HIL simulator

Control signals Simulated

actuators

Control Simulated

Simulated

I/O

system dynamics

measurements Simulated

sensors

World Oil / MARCH 2014 39

MANAGED PRESSURE DRILLING

be manipulated freely, allowing the BHP to be controlled, Fig. 3. Table 1 shows examples of tests covered by the program.

The system is based on proven technology from AGR Enhanced A good testing program is important for test efficiency and

Drilling’s Riserless Mud Recovery System (RMR) and Cuttings quality, and feedback from stakeholders is very important for a

Transportation System (CTS).⁶ These systems are in continuous good testing program. The testing program was, therefore, sent

operation worldwide, and have been used to drill more than 500 out to all parties for review before testing began, and several itera-

wells. The capabilities of the first version of EC-Drill were shown tions were made before it was finalized.

in the Gulf of Mexico in 2012.⁷, ⁸, ⁹

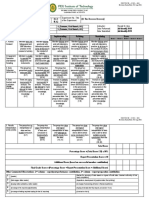

Table 1. Tests covered by the program.

Type of tests Test cases

Fig. 3. Pressure gradients, when drilling with EC-Drill. Functional tests Operational modes, such as manual/auto-

matic modes and change of pressure setpoints

Drilling procedures, such as startup/shut down

of rig pumps, increase/decrease riser level and

tripping in/out

Influx and loss detection

Equipment failures VSD failures

Subsea pump and motor failures

Valve failures

Signal failures Loss of communication

Sensor failures

Loss of power to control system components

Network storm to stress the network

communication

TESTING LAB

An HIL testing lab was built in Trondheim, Norway, and it in-

cluded both topside and subsea control system modules from AGR

Enhanced Drilling, and necessary interface to the Marine Cyber-

STATOIL INVOLVEMENT netics HIL simulator. In this project, the well, riser, drilling equip-

Statoil has, for some years, applied automatic MPD operations ment and subsea pump were included in the HIL simulator, Fig. 4.

successfully in the North Sea on fixed platform rigs, and has a keen An interface and commissioning test was performed, before

interest in supporting development of a viable MPD technology the HIL testing started. The purpose of this test was to verify all

to be used on floating drilling rigs.⁵ The EC-Drill solution was I/O addressing, ensure that all functions in the EC-Drill control

preferred over the backpressure MPD solutions, largely because system could be operated, and verify correct behavior and feed-

of the decrease in rig heave-induced BHP variations; no concern back from the HIL simulator.

regarding riser pressure rating; the use of overbalanced mud den-

sity; and no risk of RCD failure. AGR Enhanced Drilling and Fig. 4. EC-Drill system and the components simulated for the HIL

Statoil have collaborated closely to specify system requirements test.

for the first use of EC-Drill on the NCS, and Statoil has partly

funded this development.

AGR Enhanced Drilling decided to develop a new control sys-

tem to meet the increased requirements for the EC-Drill system,

especially with respect to fault tolerance and redundancy. The

control system is a vital part of EC-Drill, as it governs the BHP

and supervises the volume balance, among other functions.

The new control system has been designed in accordance

with governing industry standards and Statoil’s technical re-

quirements, and AGR Enhanced Drilling and Statoil have veri-

fied the technical solutions in an extensive testing and qualifica-

tion program. In this program, the technology readiness level

is assessed, and a plan is developed to mature the technology.

The HIL testing by a third party was a part of this program, as

it was used to partially qualify the new control system before

going offshore. The idea is to avoid spending rig time to make

the control system work properly, and to increase the system’s

safety level and confidence.

HIL TESTING OF THE EC-DRILL SYSTEM

Good preparations are the key to a successful HIL test. Thor- TEST CONDUCTION

ough system analysis and test design were performed, based on: After initial control system software was downloaded from

documentation from AGR Enhanced Drilling; Statoil require- AGR Enhanced Drilling, to the laboratory, software test 1

ments; standards and guidelines; and risk assessment documents. (SWT1) commenced. The main goal for SWT1 was to verify

40 MARCH 2014 / WorldOil.com

MANAGED PRESSURE DRILLING

the functionality and robustness of the control system soft- provements, based on findings, and in the detailed walk-through

ware, as extensively as possible. During testing, any discrep- of the control system in a safe environment. This, in turn, facili-

ancy from the expected testing result was noted by the test tated constructive discussions between the tester, customer and

operator, and filed as testing observations for further analysis. supplier, ultimately leading to a better, safer control system.

Any issues that were found to require more thorough testing REFERENCES

were noted, and new exploratory tests were created to be run 1. OLF 070, “Recommended guidelines for application of IEC 61508 and IEC 61511 in the Norwegian

petroleum industry,” Norsk Olje og Gass, 2004.

at the end of testing. 2. Handal, A., S. Øie and M. L. Lundteigen, Det Norske Veritas AS, “Risk assessment targets well control

This software test was completed in 10 days, with both AGR functions of MPD operations,” Drilling Contractor, July 2013.

3. Pedersen, T. and Ø. Smogeli, “Experience from Hardware-in-the-loop testing of drilling control sys-

Enhanced Drilling and Statoil present at all times. Every third tems,” SPE paper 163509-MS, SPE/IADC Drilling Conference and Exhibition, Amsterdam, March

day, all parties met for a summary meeting to discuss testing 2013.

4. Pivano, L. and Ø. Smogeli, “Independent HIL testing of DP systems—A life-cycle perspective,” First

observations. In the summary meetings, each recorded test re- Brazilian Conference on Dynamic Positioning, Rio de Janeiro, April 2013.

sult was processed and discussed. The nature of the test result 5. Godhavn, J.-M., “Control requirements for high-end automatic MPD operations,” SPE paper 119442,

SPE/IADC Drilling Conference and Exhibition, Amsterdam, 2009. Journal version: Control require-

was concluded; each software failure was given a severity grade ments for automatic managed pressure drilling system, SPE Drilling & Completion, Vol. 25, No. 3, pp.

and categorized as a finding; and actions for following up each 336-345, September 2010.

6. Stave, R., R. Farestveit, S. Høyland, P. O. Rochmann and N. L. Rolland, “Demonstration and

finding were planned. This included priorities and deadlines for qualification of a riserless dual gradient system,” SPE paper 17665, Offshore Technology Conference,

updates. After testing was completed, a final summary meeting Houston, May 2005.

7. Mir Rajabi, M., K. Toftevag, R. S. Stave and R. Ziegler, “First application of EC-Drill in ultra-deepwa-

was set up to conclude upon all items. ter—Proven subsea managed pressure drilling method, SPE paper 151100, 2012.

8. Ziegler, R., P. Ashley, R. F. Malt, R. Stave and K. R. Toftevåg, “Successful application of deepwater

The second test, software test 2 (SWT2), was started after dual gradient drilling (SPE 164561),” 2013.

AGR Enhanced Drilling finished updating its control system soft- 9. Ziegler, R., M. S. A. Sabri, M. R. B. Idris, R. Malt and R. Stave, “First successful commercial applica-

tion of dual gradient drilling in ultra-deepwater GOM,” SPE paper 166272, 2013.

ware, based on the agreed actions from SWT1. The main objec-

tive of SWT2 was to re-test items found during SWT1, to check BJØRNAR VIK has worked at Marine Cybernetics since

if they had been fixed and were working as intended. Additional 2004, and as a principal engineer since 2007. He also

spot checks were carried out, to verify that system functionality serves as an adjunct associate professor at the

Department of Engineering Cybernetics at the

and robustness were preserved, and to check for any unintended Norwegian University of Science and Technology

consequences from fixing the items after SWT1. (NTNU). He holds MS and doctorate degrees, both from

the Department of Engineering Cybernetics at NTNU.

OUTCOME OF TESTING JOHN-MORTEN GODHAVN joined Statoil in 2001, and

In this project, AGR Enhanced Drilling and Statoil were ac- currently works as an MPD specialist in Houston. He holds

MS and doctorate degrees in engineering cybernetics

tive participants throughout the testing process. In general, the from the Norwegian University of Science and

value of an HIL test is not just seen in the ability to make system Technology (NTNU). Since 2010, Mr. Godhavn has been

improvements, based on findings. The HIL test also: an adjunct professor at the Department of Petroleum

Engineering and Applied Geophysics at NTNU.

• Gives insight and understanding of software barriers, haz-

ards, failure modes and effects ESPEN HAUGE joined Statoil as a senior researcher in

• Helps implement procedures and training, to handle dis- 2013. He works with deepwater drilling, and his research

interests are in MPD and automated drilling. Mr. Hauge

covered software weaknesses holds MS and doctorate degrees in engineering

• Assures that the system operates correctly under certain cybernetics from the Norwegian University of Science

conditions. and Technology (NTNU).

Even though the new control system has gone through ex- ERLEND MJAAVATTEN is AGR Enhanced Drilling’s

tensive testing of a more traditional character, such as Extended control system development manager. He joined the

Factory Acceptance Testing (EFAT) and Site Integration Test- company in 2009, and has a background in subsea

boosting systems, oil spill management systems and

ing, the HIL lab was available at an earlier stage than much of the other marine automation systems. Mr. Mjaavatten holds

equipment required for doing full-scale testing in the workshop. an MS degree from the Department of Engineering

Cybernetics at NTNU.

The schedule for the EC-Drill project was very tight, and the HIL

testing helped bring potential issues and misunderstandings to

the table at an early stage. The test laboratory can be re-used for

new projects, and for the testing of future upgrades to the EC-

Drill system.

CONCLUSIONS

MPD solutions are advancing quickly. New systems, such as

EC-Drill, enable drilling of deeper, more challenging wells, due to

accurate and fast pressure control. However, the new systems also

rely more on control system software, which means that verifica-

tion of the functionality and robustness of this software is critical.

Extensive and early verification is important to reduce rig com-

missioning and non-productive time during operations.

In this project, independent HIL testing has proven to be a

systematic, effective method for assessing the control system soft-

ware, and was key in the technology qualification process. The

main added value from the HIL testing was both in system im-

Article copyright © 2014 by Gulf Publishing Company. All rights reserved. Printed in U.S.A.

World Oil / MARCH 2014 41

Not to be distributed in electronic or printed form, or posted on a website, without express written permission of copyright holder.

You might also like

- Custom Pipe Handlers Brochure Feb 27 2013Document6 pagesCustom Pipe Handlers Brochure Feb 27 2013Alejandro Gomez100% (1)

- 01 Bolt Tightening ToolDocument30 pages01 Bolt Tightening ToolabdulfetahNo ratings yet

- Catcus Annual Report 2020 PDFDocument214 pagesCatcus Annual Report 2020 PDFMichael DasNo ratings yet

- 7.0625 10000 Shaffer Bolted Annular Bop Spec SheetDocument1 page7.0625 10000 Shaffer Bolted Annular Bop Spec SheetJoel SNo ratings yet

- Pumptools - BOP CanDocument1 pagePumptools - BOP Cancasda73No ratings yet

- 012 +FMC+Technologies+-+Arno+Vissers PDFDocument21 pages012 +FMC+Technologies+-+Arno+Vissers PDFmalikscribdNo ratings yet

- Shandong Kerui Petrochemical Equipment CO.-business AnalysisDocument1 pageShandong Kerui Petrochemical Equipment CO.-business Analysis911targaNo ratings yet

- Technical Overview and Specification Summary Ps 00232 Data PDFDocument24 pagesTechnical Overview and Specification Summary Ps 00232 Data PDFmmilovanmNo ratings yet

- New Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!Document4 pagesNew Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!Byron LvzNo ratings yet

- Mj-1645-Us Expanding Gate Valve MJDocument16 pagesMj-1645-Us Expanding Gate Valve MJgm_revankar3942No ratings yet

- FEA Analysis of Rectangular Pressure Vessel BoxesDocument13 pagesFEA Analysis of Rectangular Pressure Vessel BoxesIJARSCT JournalNo ratings yet

- Surs PDFDocument27 pagesSurs PDFsaeed65No ratings yet

- Walking SystemDocument2 pagesWalking SystemLuis Eduardo Ferro CotesNo ratings yet

- Motor Standard, IP55, (Ah 180 - 315) - ENDocument60 pagesMotor Standard, IP55, (Ah 180 - 315) - ENkfathi55No ratings yet

- RigSense Enables 99 Uptime Case StudyDocument1 pageRigSense Enables 99 Uptime Case Studymohamed godaNo ratings yet

- Oilfield Processing Measurement and Control Oil and Gas SeparationDocument8 pagesOilfield Processing Measurement and Control Oil and Gas SeparationAnonymous 8te2h1No ratings yet

- Otc20820 - Taking The Gas Lift Valves To A New Level of RealiabilityDocument5 pagesOtc20820 - Taking The Gas Lift Valves To A New Level of Realiabilityomatiaspe2328No ratings yet

- API 6A Gate ValveDocument26 pagesAPI 6A Gate ValveindraNo ratings yet

- Flange DesignDocument4 pagesFlange DesignJilu Easow RajuNo ratings yet

- Knowledge-Based Expert System in Manufacturing Planning - State-Of-The-Art Review PDFDocument26 pagesKnowledge-Based Expert System in Manufacturing Planning - State-Of-The-Art Review PDFprime SEONo ratings yet

- OTC 21226 Roncador P-52 Hybrid Riser Review: Key Concepts, Construction and Installation ChallengesDocument11 pagesOTC 21226 Roncador P-52 Hybrid Riser Review: Key Concepts, Construction and Installation ChallengesRasheed YusufNo ratings yet

- WRT - Maintenance InstructionDocument63 pagesWRT - Maintenance InstructionSon DDarrellNo ratings yet

- Software Development MethodologyDocument31 pagesSoftware Development MethodologyZulfazli BakriNo ratings yet

- Wire LineDocument54 pagesWire LineJOUININo ratings yet

- SH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockDocument7 pagesSH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockCleevh MabialaNo ratings yet

- Hydraulic Power Units ExplainedDocument4 pagesHydraulic Power Units ExplainedJay JayNo ratings yet

- IQ3 RangeDocument44 pagesIQ3 Rangerizky efrinaldoNo ratings yet

- BIW Products Services Brochure 042019 PDFDocument13 pagesBIW Products Services Brochure 042019 PDFJusman Van SitohangNo ratings yet

- 02-A Kinetico Owners Manual - Commercial Plus Softener SeriesDocument32 pages02-A Kinetico Owners Manual - Commercial Plus Softener SeriesCastoriadisNo ratings yet

- Product Improvement Notification: Control SystemsDocument2 pagesProduct Improvement Notification: Control SystemscarlosorizabaNo ratings yet

- Horizontalbore: Subsea TreeDocument8 pagesHorizontalbore: Subsea TreeJerome LIKIBINo ratings yet

- @statoil Tr1005Document10 pages@statoil Tr1005Cristian BoselliNo ratings yet

- VGS10 4 1 9 PDFDocument1 pageVGS10 4 1 9 PDFSefa ZumbulNo ratings yet

- Boustead WHCP Esd Catalog With PicturesDocument16 pagesBoustead WHCP Esd Catalog With PicturesbalajiNo ratings yet

- Safety Data Sheet: Martin Decker Fluid W15Document10 pagesSafety Data Sheet: Martin Decker Fluid W15pichet33No ratings yet

- MB Csu 46bbrss1dDocument18 pagesMB Csu 46bbrss1delver sanabriaNo ratings yet

- DHSV TestDocument7 pagesDHSV TestRonald Lucas Silva Lefundes OliveiraNo ratings yet

- VetoDocument4 pagesVetohenry christian wontumiNo ratings yet

- API RP 13C (ISO 13501) - Derrick Equipment CompanyDocument4 pagesAPI RP 13C (ISO 13501) - Derrick Equipment CompanyRai100% (1)

- Hydril Annular BOP1Document2 pagesHydril Annular BOP1Abde EsselamNo ratings yet

- SubSea Controls Inspector DutiesDocument2 pagesSubSea Controls Inspector Dutiesxiexienin23No ratings yet

- Brev Fra Sjøfartdir DNV Rapporter NSA Guidelines PDFDocument122 pagesBrev Fra Sjøfartdir DNV Rapporter NSA Guidelines PDFGiuliano PaoliniNo ratings yet

- Autoclave Subsea Ball ValvesDocument20 pagesAutoclave Subsea Ball Valvesvp989No ratings yet

- FCS Time StampDocument4 pagesFCS Time StampBrijesh Srivastav50% (2)

- Typical Installation of 'SS' (Spacesaver) Compact System: (Running Procedure)Document32 pagesTypical Installation of 'SS' (Spacesaver) Compact System: (Running Procedure)Ricardo Paz SoldanNo ratings yet

- Microsoft Word - Man 2 Chap 11 Well Control EquipmentDocument77 pagesMicrosoft Word - Man 2 Chap 11 Well Control EquipmentЕмиль АббасовNo ratings yet

- Valvulas Compuerta FipDocument15 pagesValvulas Compuerta FipSalvador Espino100% (1)

- BOP Control Unit FlyerDocument2 pagesBOP Control Unit Flyeraliabd1989 alzubidiNo ratings yet

- RigSense Rigsite Information System FlyerDocument2 pagesRigSense Rigsite Information System FlyerAhmed ShaabanNo ratings yet

- Flat PackDocument1 pageFlat PackJansen SaippaNo ratings yet

- Downhole Instrumentation Qualification RPDocument4 pagesDownhole Instrumentation Qualification RPabinadi1230% (1)

- Deepwater Horizon Accident Investigation Report PDFDocument192 pagesDeepwater Horizon Accident Investigation Report PDFgroverableNo ratings yet

- Power Industry - Project Aqcuisition For Sub-Stations ReportDocument84 pagesPower Industry - Project Aqcuisition For Sub-Stations ReportAkhilesh DayalNo ratings yet

- GBA Flare Systems BrochureDocument15 pagesGBA Flare Systems BrochurejpvissottoNo ratings yet

- MS-700 Subsea Wellhead System Nov 11Document108 pagesMS-700 Subsea Wellhead System Nov 11New Auto TV100% (1)

- New Touch Down Zone (TDZ) Solutions For Steel CatenaryDocument52 pagesNew Touch Down Zone (TDZ) Solutions For Steel CatenaryKrixvicNo ratings yet

- Choke Specification - CCI PDFDocument4 pagesChoke Specification - CCI PDFAakashRanjan100% (1)

- 05 Subsea Pipeline Leak Detection - Technology Week For Distribution - tcm14-132674Document16 pages05 Subsea Pipeline Leak Detection - Technology Week For Distribution - tcm14-132674khottabit0433No ratings yet

- 980 Catwalk Broch 2014 v10 FINALDocument6 pages980 Catwalk Broch 2014 v10 FINALtictacalNo ratings yet

- White Paper Lambda Tuning As A Promising Controller Tuning Method For Refinery Pss en 67720Document10 pagesWhite Paper Lambda Tuning As A Promising Controller Tuning Method For Refinery Pss en 67720Anish ShahNo ratings yet

- Sales & Distribution - User Exit DetailsDocument36 pagesSales & Distribution - User Exit DetailsSudipto100% (11)

- 1185190Document16 pages1185190Syed Abdul HafeezNo ratings yet

- Project CharterDocument7 pagesProject CharterNishant GambhirNo ratings yet

- Project Assumptions and Risks PDFDocument2 pagesProject Assumptions and Risks PDFbrujhito100% (1)

- Alfa Range BrochureDocument14 pagesAlfa Range BrochureJohn SpencerNo ratings yet

- OpenScape DECT Phone S5 On OpenScape Cordless Enterprise User GuideDocument85 pagesOpenScape DECT Phone S5 On OpenScape Cordless Enterprise User GuideDaniel LuisNo ratings yet

- GeM Bidding 2919836Document12 pagesGeM Bidding 2919836Hussain ShaikhNo ratings yet

- 2010FA01Document10 pages2010FA01ALEJONo ratings yet

- A Framework For Analysis of Aircraft ManeuverabilityDocument13 pagesA Framework For Analysis of Aircraft ManeuverabilityJeff BeckNo ratings yet

- Casr 139Document467 pagesCasr 139Achmad MunifNo ratings yet

- ResumeatbapujiDocument2 pagesResumeatbapujiEllur AnandNo ratings yet

- Company Profile @MRF TyresDocument8 pagesCompany Profile @MRF TyresAnkur Dubey40% (5)

- 3698 8a2fgDocument3 pages3698 8a2fgJampaNo ratings yet

- MG6851 Principles of Management Question Bank PDFDocument9 pagesMG6851 Principles of Management Question Bank PDFthangalakshmipr9728No ratings yet

- Review Work Done So FarDocument177 pagesReview Work Done So FargoodynomailNo ratings yet

- CV Over 33 Years HVAC ExperienceDocument3 pagesCV Over 33 Years HVAC ExperienceReuben SimonNo ratings yet

- Weld Filler WireDocument37 pagesWeld Filler WireSiva Raman MurugesanNo ratings yet

- City of Boerne Building RequirementsDocument20 pagesCity of Boerne Building Requirementsurfriend77No ratings yet

- Radio Power ConsumptionDocument436 pagesRadio Power ConsumptionMustafa QaizarNo ratings yet

- Procedure System of Site Quality Record ControlDocument5 pagesProcedure System of Site Quality Record ControlImtiyaz AkhtarNo ratings yet

- CV KhairulUmmah2012 InggrisDocument3 pagesCV KhairulUmmah2012 InggrisMuhammad Al FarabiNo ratings yet

- Ismail Thesis CarbuncleDocument269 pagesIsmail Thesis CarbuncleTudorel AfilipoaeNo ratings yet

- Review On Implementation of Six Sigma DMAIC Methodology in Manufacturing IndustriesDocument4 pagesReview On Implementation of Six Sigma DMAIC Methodology in Manufacturing IndustriesIJSTENo ratings yet

- Laboratory Report Cover & Score SheetDocument2 pagesLaboratory Report Cover & Score SheetCarlo TabalanzaNo ratings yet

- Colorscope IncDocument14 pagesColorscope IncRajeev Gulrajani25% (4)

- SriLankan Airlines Annual Report Highlights ImprovementDocument92 pagesSriLankan Airlines Annual Report Highlights ImprovementChandu De Silva100% (2)

- Lean Six Sigma and Innovation PDFDocument19 pagesLean Six Sigma and Innovation PDFFrancis ParedesNo ratings yet

- MERITOR 9 10 Platform G Transmission PDFDocument115 pagesMERITOR 9 10 Platform G Transmission PDFemmanuelNo ratings yet

- Cast vs. Calendered Vinyl: Which is BestDocument4 pagesCast vs. Calendered Vinyl: Which is BestbaanaadiNo ratings yet

- Meralco CommentDocument241 pagesMeralco CommentThe Supreme Court Public Information Office100% (1)