Professional Documents

Culture Documents

Installation Instruction: Engine Platform PM46

Uploaded by

Maria MarcanoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instruction: Engine Platform PM46

Uploaded by

Maria MarcanoCopyright:

Available Formats

Installation instruction

Wärtsilä Power Plants

06/09/07

Doc. id: DAAB566768

Date: 29-Aug-2007

Page: 1 (19)

Status: Rev. a

Made/Approved: TeKa / AGt

Project: Power Master 46

Name: Installation instructions

Subject: Engine platform PM46

Table of contents

1. Layout of modules

Layout of modules 2

Erection order 3

2. Installation of modules

Module 1 Steel structure assembly 4

Module 2 Steel structure assembly 5

Module 3 Steel structure assembly 6

Module 3 Steel structure assembly 7

Module 4 Steel structure assembly 8

3. Installation of sleeves

Sleeves for handrails 9

4. Installation of handrails

Handrail for module 1 10

Handrail for module 3 11

5. Installation of grating

Fixing clip for grating 12

Map of grating for high level 13

Map of grating for sub level 14

6. Installation of toe boards

Toe board and fixing components 15

Map of toe board 16

Toe board adjusting to engine 17

7. Installation of safety components

Installation of gates 18

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 2 (19)

Handrailings fixing together 19

1. Layout of modules

Engine platforms

1-5 x W18V46/W18V50DF

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 3 (19)

Erection order

Step 1. Erection of feet. See position of feet from general arrangement drawing.

Modules 1, 3, 4 (pages 4-8)

Step 2. Trimming of high-level elevation. Lock by site weld. Modules 1, 3, 4

(pages 4, 6, 8)

Step 3. Mounting of horizontal beams to high-level. Modules 1, 3, 4 (pages 4, 6, 8)

Step 4. Mounting of module 2 (page 5).

Step 5. Trimming of sub-level elevation. Mounting of sub-level horizontal beams.

Modules 1, 3, 4 (pages 4, 6, 8)

Step 6. Mounting of stairs. Adjust right elevation of stairs and drill holes Ø13. Lock

stairs through these holes. Modules 1, 3, 4 (pages 4, 6 – 8).

Step 7. Mounting of all anchor bolts (M12). 2 anchor bolts / foot, 3 anchor bolts /

stairs for high-level and 4 anchor bolts / stairs for sub-level. Modules 1, 3, 4

(pages 4, 6 – 8).

Step 8. Mounting of sleeves. Sleeves to be welded on site, if they are not already

welded on the factory. For correct position of sleeves, see sleeves

arrangement drawing. (Page 9).

Step 9. Mounting of handrailings. Put railing to sleeve and attach it by 2 M12 x 40

screws. See railing arrangement drawing. (Pages 9 – 11)

Step 10. Mounting of gates. Attach steel pipe to sleeve by 2 M12x40 screws. Weld

bended round bar to railing and to Steel pipe. See railings arrangement

drawing. (Page 18)

Step 11. Cleaning and painting all site welding places

Step 12. Mounting of gratings and toeboards. Fixing clips 4 pcs / grating. Adjusting

of gratings and toeboards. See grating arrangement drawing. (Pages 12 –

17)

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 4 (19)

Step 13. Mounting and painting handrailing fixing components. Fix handrailings

together by using threaded rod M8, washers M8, nuts M8 and RHS

25x25x2 or by coupling FinnRasti KP8000. (Page 19)

2. Installation of modules

Module 1. Steel structure assembly

Elevation of frames to be adjusted according to engine 0-Line

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 5 (19)

Module 2. Steel structure assembly

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 6 (19)

Module 3. Steel structure assembly

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 7 (19)

Elevation of frames to be adjusted according to engine 0-Line

Module 3. Steel structure assembly

Fixing of stair (lower level) to be adjusted according to floor level

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 8 (19)

Module 4. Steel structure assembly

Elevation of frames to be adjusted according to engine 0-Line

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 9 (19)

3. Installation of sleeves (see Sleeves arrangement drawing )

Sleeves to be weld on site, if they’re not already welded on the

factory.

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 10 (19)

4. Installation of handrailings

Module 1. Generator end

Module 1. Engine Turbo end

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 11 (19)

Module 3. Engine Turbo end

Module 3. Generator end

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 12 (19)

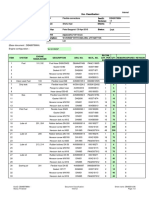

5. Installation of grating

Fixing clips 4pcs / grating

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 13 (19)

Grating map

High-Level (Two engines)

Module 1. Module 2. Module 3. Module 2. Module 4.

Note:

In this area

grating and kick

plate to be

adjusted on site

Engine 0-Line

To be cut to fit

engine

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 14 (19)

Grating map

Sub-level (One engine)

Engine 0-Line

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 15 (19)

6. Installation of toe boards

High-level engine side

L=2000mm

Fixing components

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 16 (19)

Toe board frame

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 17 (19)

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 18 (19)

7. Installation of safety components

(2 pcs /engine, below of turbo charger)

Print Date 06-Sep-2007 10:22

Wärtsilä Power Plants

Doc id: DAAB566768

Date: 29-Aug-2007

Page: 19 (19)

Handrailings fixing together

FinnRasti KP8000

Print Date 06-Sep-2007 10:22

You might also like

- Caterpillar Cat M313C WHEELED Excavator (Prefix H2A) Service Repair Manual (H2A00001 and Up) PDFDocument27 pagesCaterpillar Cat M313C WHEELED Excavator (Prefix H2A) Service Repair Manual (H2A00001 and Up) PDFfkdmmaNo ratings yet

- Aftercooler - InstallDocument8 pagesAftercooler - Installcarlos moralesNo ratings yet

- Ijet16 08 06 198Document8 pagesIjet16 08 06 198Apm FoumilNo ratings yet

- Caterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)Document28 pagesCaterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)kfsmmeNo ratings yet

- Design Analysis and Weight Optimization of LMV Drive Shaft by Using AL + GF MaterialDocument10 pagesDesign Analysis and Weight Optimization of LMV Drive Shaft by Using AL + GF MaterialIJRASETPublicationsNo ratings yet

- Cat 3304b Disassimble BearingDocument8 pagesCat 3304b Disassimble BearingMahmoud KhattabNo ratings yet

- Counterbalance Valve TravelDocument4 pagesCounterbalance Valve TravelSteven Y.MNo ratings yet

- Circle Drive - Install Installation Procedure: Desarmado y ArmadoDocument5 pagesCircle Drive - Install Installation Procedure: Desarmado y ArmadoTaller HeavytechNo ratings yet

- Project1 - Screw JackDocument23 pagesProject1 - Screw JackKambam TejasreeNo ratings yet

- Design, Analysis and Weight Optimization of Roller Conveyor System by Using Glass Fiber Composite MaterialDocument9 pagesDesign, Analysis and Weight Optimization of Roller Conveyor System by Using Glass Fiber Composite MaterialIJRASETPublicationsNo ratings yet

- Instructions For Installing New Platform Egress Ladder Hardware On Certain 16M, 16M3, and 18M3 Motor Graders M0077168Document14 pagesInstructions For Installing New Platform Egress Ladder Hardware On Certain 16M, 16M3, and 18M3 Motor Graders M0077168isaac989No ratings yet

- IOM Manual: Client: Siemens Job TitleDocument57 pagesIOM Manual: Client: Siemens Job TitleAswindana Ibnu SenaNo ratings yet

- Penang Second Bridge - 20camber - 16.05.2013Document244 pagesPenang Second Bridge - 20camber - 16.05.2013Lengendary PhubrNo ratings yet

- Cylinder Head - InstallDocument7 pagesCylinder Head - InstallJose PichinteNo ratings yet

- 966H Wheel Loader BJ600001-UP (MACHINE) POWERED BY C11 Engine (SEBP5792 - 19) - DocumentationDocument2 pages966H Wheel Loader BJ600001-UP (MACHINE) POWERED BY C11 Engine (SEBP5792 - 19) - DocumentationHari Hara SuthanNo ratings yet

- 966H Wheel Loader BJ600001-UP (MACHINE) POWERED BY C11 Engine (SEBP5792 - 19) - Documentation PDFDocument2 pages966H Wheel Loader BJ600001-UP (MACHINE) POWERED BY C11 Engine (SEBP5792 - 19) - Documentation PDFHari Hara SuthanNo ratings yet

- Fabrication of Solar Sand Screening MachineDocument9 pagesFabrication of Solar Sand Screening MachineIJRASETPublicationsNo ratings yet

- Rotor Stub Shaft - 084637Document4 pagesRotor Stub Shaft - 084637Juan LopezNo ratings yet

- Camshaft - Install: Desarmado y ArmadoDocument4 pagesCamshaft - Install: Desarmado y ArmadoHector VillegasNo ratings yet

- Cylinder Head - Install 3516Document6 pagesCylinder Head - Install 3516CH MUBASHER MAQSOOD ALAM50% (2)

- Caterpillar Cat 336E L Excavator (Prefix KED) Service Repair Manual (KED00001 and Up)Document28 pagesCaterpillar Cat 336E L Excavator (Prefix KED) Service Repair Manual (KED00001 and Up)kfsmmeNo ratings yet

- Caterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB00001-02000) PDFDocument28 pagesCaterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB00001-02000) PDFfkdmmaNo ratings yet

- Cam Shaft InstallDocument4 pagesCam Shaft InstallUn'galluNo ratings yet

- Cylinder Head - Install: Disassembly and AssemblyDocument8 pagesCylinder Head - Install: Disassembly and AssemblyMahmoud AliNo ratings yet

- Base de 3 PilotesDocument27 pagesBase de 3 PilotesnelsonhugoNo ratings yet

- Top Drive PB169 - Blower - Motor - U-Bolt - SupportDocument6 pagesTop Drive PB169 - Blower - Motor - U-Bolt - SupportJoseMi Vacaflor Illanes100% (1)

- Engine Oil Cooler - Install - Engine Oil Cooler With A High Mounted Filter Base (KENR6081-15)Document4 pagesEngine Oil Cooler - Install - Engine Oil Cooler With A High Mounted Filter Base (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Satellite 3Document3 pagesSatellite 3Rohit JangidNo ratings yet

- Cylinder Head Installation Torque SpecificaitionDocument7 pagesCylinder Head Installation Torque SpecificaitionHari Hara SuthanNo ratings yet

- Experimental Investigation of Corn Shelling MachineDocument8 pagesExperimental Investigation of Corn Shelling MachineIJRASETPublicationsNo ratings yet

- Design, Development and Computational Finite Element Analysis (FEA) of An Electric Two-Wheeler FrameDocument16 pagesDesign, Development and Computational Finite Element Analysis (FEA) of An Electric Two-Wheeler FrameIJRASETPublicationsNo ratings yet

- Generator - Align: Shutdown SIS Previous ScreenDocument6 pagesGenerator - Align: Shutdown SIS Previous ScreenNimNo ratings yet

- Manufacturing Directions - PictorialDocument8 pagesManufacturing Directions - PictorialteampsquaredNo ratings yet

- Design of Turbo-Generator Foundations: C.Ravishankar, C. Channakeshava, B. Sreehari Kumar, G V RaoDocument8 pagesDesign of Turbo-Generator Foundations: C.Ravishankar, C. Channakeshava, B. Sreehari Kumar, G V RaoAlastair KerrNo ratings yet

- PUSNES Deck Machinery Installation ProcedureDocument18 pagesPUSNES Deck Machinery Installation ProcedurexatzaraNo ratings yet

- 7.1 Grounding: ResourcesDocument7 pages7.1 Grounding: ResourcesTrần Quang TuyênNo ratings yet

- Design, Analysis and Weight Optimization of LMV Shaft by Using AL + GF CompositeDocument7 pagesDesign, Analysis and Weight Optimization of LMV Shaft by Using AL + GF CompositeIJRASETPublicationsNo ratings yet

- ENMOUNTDocument13 pagesENMOUNTqgfytzvqabzqrxyilmNo ratings yet

- Fatigue Analysis of I-Section and H - Section Connecting Rod Using ANSYS WorkbenchDocument14 pagesFatigue Analysis of I-Section and H - Section Connecting Rod Using ANSYS WorkbenchInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyclic Behaviour of Double Skin Composite Steel Plate Shear Wall Using Shape Memory Alloy With Various Aspect RatiosDocument10 pagesCyclic Behaviour of Double Skin Composite Steel Plate Shear Wall Using Shape Memory Alloy With Various Aspect RatiosIJRASETPublicationsNo ratings yet

- Caterpillar Cat 225D EXCAVATOR Service Repair Manual (2SJ00001 and Up)Document29 pagesCaterpillar Cat 225D EXCAVATOR Service Repair Manual (2SJ00001 and Up)rpoy9396615No ratings yet

- Cam ShaftDocument7 pagesCam ShaftMahmoud AliNo ratings yet

- Gear Group (Front) - Install: Disassembly and AssemblyDocument5 pagesGear Group (Front) - Install: Disassembly and AssemblygustavoNo ratings yet

- Mounting Solar Panels Project PlanningDocument32 pagesMounting Solar Panels Project Planninghimadri.banerji60No ratings yet

- Engine Oil Cooler - Install - Engine Oil Cooler With A Low Mounted Filter Base (KENR6081-15)Document5 pagesEngine Oil Cooler - Install - Engine Oil Cooler With A Low Mounted Filter Base (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Blade - Remove and InstallDocument8 pagesBlade - Remove and InstallJohn GrayNo ratings yet

- Armado de OrbitrolDocument10 pagesArmado de OrbitrolANTONIO CRUZNo ratings yet

- Assembly Procedure VTC 254 TurbochargerDocument16 pagesAssembly Procedure VTC 254 TurbochargerMauricio MUÑOZ100% (1)

- Caterpillar Cat 216B3 SKID STEER LOADER (Prefix CD3) Service Repair Manual (CD300001 and Up) PDFDocument7 pagesCaterpillar Cat 216B3 SKID STEER LOADER (Prefix CD3) Service Repair Manual (CD300001 and Up) PDFfreemanual4480% (1)

- Fuel Injection Lines - (Disassembly and Assembly)Document2 pagesFuel Injection Lines - (Disassembly and Assembly)Ava AddamsNo ratings yet

- d6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Barra Equalizadora - MontarDocument5 pagesd6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Barra Equalizadora - MontarDouglas FernandesNo ratings yet

- Fitting Instruction Fitting Instructions: From ManufacturerDocument2 pagesFitting Instruction Fitting Instructions: From ManufacturerTash LNo ratings yet

- Caterpillar Cat 225B EXCAVATOR (Prefix 2ZD) Service Repair ManualDocument24 pagesCaterpillar Cat 225B EXCAVATOR (Prefix 2ZD) Service Repair Manualrpoy9396615No ratings yet

- BAJA - Chassis Fixture For ManufacturingDocument3 pagesBAJA - Chassis Fixture For ManufacturingIjaems JournalNo ratings yet

- Water Pump Assembly 3500Document9 pagesWater Pump Assembly 3500Gabriel Paco LunaNo ratings yet

- WA1200-3 - Manual de MontagemDocument198 pagesWA1200-3 - Manual de MontagemEduardo GabrielNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Combustion Engines: An Introduction to Their Design, Performance, and SelectionFrom EverandCombustion Engines: An Introduction to Their Design, Performance, and SelectionNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Instructions of Gas Ball ValveDocument5 pagesInstructions of Gas Ball ValveMaria MarcanoNo ratings yet

- Project: Petrosinovensa (4x12V50DF) : System Wise Pipe MaterialDocument2 pagesProject: Petrosinovensa (4x12V50DF) : System Wise Pipe MaterialMaria MarcanoNo ratings yet

- DAAB448550 ADocument1 pageDAAB448550 AMaria MarcanoNo ratings yet

- DBAB078884 - Flexible ConnecDocument2 pagesDBAB078884 - Flexible ConnecMaria MarcanoNo ratings yet

- Dbaa846914 - VjmmrjjjuDocument1 pageDbaa846914 - VjmmrjjjuMaria MarcanoNo ratings yet

- Transistor Darlinton d1414Document3 pagesTransistor Darlinton d1414Maria MarcanoNo ratings yet

- Title: Docid: Revision: Sheets: Draft By: Project: Description: - General Type: Doc. ClassificationDocument2 pagesTitle: Docid: Revision: Sheets: Draft By: Project: Description: - General Type: Doc. ClassificationMaria MarcanoNo ratings yet

- DAAB448549 - C - DAAB448549 Material List - Xls (Extended Bar List) PDFDocument1 pageDAAB448549 - C - DAAB448549 Material List - Xls (Extended Bar List) PDFMaria MarcanoNo ratings yet

- Illumination Level 555Document1 pageIllumination Level 555Maria MarcanoNo ratings yet

- PAAE157415 - Survey ReportDocument1 pagePAAE157415 - Survey ReportMaria MarcanoNo ratings yet

- Manufacturer Conformity Statement 2010Document1 pageManufacturer Conformity Statement 2010Maria MarcanoNo ratings yet

- Test Report For Synchronous MachinesDocument60 pagesTest Report For Synchronous MachinesMaria MarcanoNo ratings yet

- PAAE157417 - Survey ReportDocument1 pagePAAE157417 - Survey ReportMaria MarcanoNo ratings yet

- Declaration of IncorporationDocument1 pageDeclaration of IncorporationMaria MarcanoNo ratings yet

- Test Report PDFDocument60 pagesTest Report PDFMaria Marcano100% (2)

- PAAE157412 Survery ReportDocument1 pagePAAE157412 Survery ReportMaria MarcanoNo ratings yet

- PAAE157415 Test Run ReportDocument14 pagesPAAE157415 Test Run ReportMaria MarcanoNo ratings yet

- PAAE157412 Test Run ReportDocument14 pagesPAAE157412 Test Run ReportMaria MarcanoNo ratings yet

- Fat Test ProtocoloDocument10 pagesFat Test ProtocoloMaria MarcanoNo ratings yet

- PAAE157416 Test Run ReportDocument14 pagesPAAE157416 Test Run ReportMaria MarcanoNo ratings yet

- PAAE157417 Test Run ReportDocument14 pagesPAAE157417 Test Run ReportMaria MarcanoNo ratings yet

- ConclusionDocument1 pageConclusionEvans EjegiNo ratings yet

- Regulatory Documentation PDFDocument21 pagesRegulatory Documentation PDFJohn Mark BordeosNo ratings yet

- Nfpa 72: National Fire Alarm CodeDocument8 pagesNfpa 72: National Fire Alarm CodeSabir NaseerNo ratings yet

- Alfa VapDocument2 pagesAlfa Vapkresimir.mikoc9765No ratings yet

- CIE4160 Textbook February 2019Document371 pagesCIE4160 Textbook February 2019Manank ShahNo ratings yet

- GP170101 Firefighting Equipment PDFDocument26 pagesGP170101 Firefighting Equipment PDFegfernandez21No ratings yet

- Smart2020 United States Report AddendumDocument8 pagesSmart2020 United States Report AddendumL'Usine NouvelleNo ratings yet

- Raw Mix Design by Rashid Jamal (16.02.2017)Document20 pagesRaw Mix Design by Rashid Jamal (16.02.2017)Muhammad AwaisNo ratings yet

- 2014 07 22 Ronnie Flaugh Tips 3DQuickPressDocument37 pages2014 07 22 Ronnie Flaugh Tips 3DQuickPressHarisAvdagićNo ratings yet

- Front Office and Guest Safety and Security PDFDocument11 pagesFront Office and Guest Safety and Security PDFPrabhjot SinghNo ratings yet

- A Comparative Study of Propane Recovery ProcessesDocument15 pagesA Comparative Study of Propane Recovery ProcessesMurali MuthuNo ratings yet

- Lab 1Document25 pagesLab 1Self McNo ratings yet

- Cape Computer Science 2011 Unit 2 P2Document5 pagesCape Computer Science 2011 Unit 2 P2dnitehawk qNo ratings yet

- Aluminum Anodizing ProcessDocument31 pagesAluminum Anodizing ProcessSenthil Kumar100% (2)

- Determination of Hardness of Water (Step-By-Step Plan)Document6 pagesDetermination of Hardness of Water (Step-By-Step Plan)ravenheart90No ratings yet

- Visual Foxpro DOCUMENTDocument98 pagesVisual Foxpro DOCUMENTAndronache Andreea100% (2)

- Barcelo - Computational Intelligence in ArchaeologyDocument437 pagesBarcelo - Computational Intelligence in Archaeologyhristijan_anch100% (1)

- Final Revision Jurnal NCIE - Feby Sanna SibaraniDocument9 pagesFinal Revision Jurnal NCIE - Feby Sanna Sibaranifeby sannaNo ratings yet

- Marine Seawater ValvesDocument8 pagesMarine Seawater ValvesPhornlert WanaNo ratings yet

- Automotive Ethernet Black BookDocument44 pagesAutomotive Ethernet Black BookGrulletto Grullone100% (1)

- Flexiroc T20 R: Atlas Copco Surface Drill RigsDocument4 pagesFlexiroc T20 R: Atlas Copco Surface Drill RigsalmirNo ratings yet

- Del II Vedlegg F-5 - STANAG 3609 (Edition 5)Document135 pagesDel II Vedlegg F-5 - STANAG 3609 (Edition 5)inglevoNo ratings yet

- Telephone: Based On Book - Design For People by Henry DreyfussDocument14 pagesTelephone: Based On Book - Design For People by Henry Dreyfussbhushan manjunathNo ratings yet

- 315 MVA Trafo PDFDocument12 pages315 MVA Trafo PDFzeeshanyg100% (2)

- Solid Short Notes PDFDocument32 pagesSolid Short Notes PDFsanjeet singh kainturaNo ratings yet

- Gcell 4G Nokia 20210419Document667 pagesGcell 4G Nokia 20210419frick tampubolonNo ratings yet

- Microelectronic CapsuleDocument20 pagesMicroelectronic CapsuleMouni BoomiReddyMounikaNo ratings yet

- Breckwell Pellet Stove PartsDocument1 pageBreckwell Pellet Stove PartsHelicon1No ratings yet

- Energy Management SystemDocument33 pagesEnergy Management SystemAnudeep Chittluri100% (2)

- RoboticsinWarehouse PDFDocument35 pagesRoboticsinWarehouse PDFSiva100% (1)