Professional Documents

Culture Documents

Slag Blowholes, Which Are Confused With Shrinkage Cavities: Important For Practice

Slag Blowholes, Which Are Confused With Shrinkage Cavities: Important For Practice

Uploaded by

Ranjith RamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slag Blowholes, Which Are Confused With Shrinkage Cavities: Important For Practice

Slag Blowholes, Which Are Confused With Shrinkage Cavities: Important For Practice

Uploaded by

Ranjith RamCopyright:

Available Formats

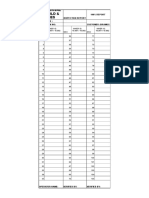

Slag Blowholes, Which Are Confused with

Shrinkage Cavities

IMPORTANT FOR PRACTICE

This does not refer to slag which rises to the surface

during pouring, or into the dirt trap shortly afterwards.

The type of slag to be described separates only during

solidification, whereby very finely emulsified droplets of

slag are forced from the dendrites into the residual melt,

where they become concentrated (Fig. 460). Only then

do the drops float and thrust against the upper wall,

which has already solidified into a thick layer.

This slag porosity is often exposed only with the final

cut during machining, and the castings are then irrecoverably

lost.

Slag porosity is recognized by the fact that the slag

can be detected on close examination. Often it occurs

only as a thin skin (Fig. 461), as slag beads (Fig. 462),

or as larger angular fragments (Fig. 463). Severe cases

are comparatively rare (Fig. 464) but when present they

give a clear indication of their presence (see also

Fig. 465)

You might also like

- GEO - Checklist For Soil DescriptionDocument2 pagesGEO - Checklist For Soil Descriptionraidall0% (1)

- Field Guide Sheet Description of Soil and Rock 2005 PDFDocument2 pagesField Guide Sheet Description of Soil and Rock 2005 PDFparamarthasom1974No ratings yet

- Q'Max Technical Bulletin #9 Mud Rings and Bit BallingDocument4 pagesQ'Max Technical Bulletin #9 Mud Rings and Bit BallingRaul HinojosaNo ratings yet

- Mud Loggers 77 Most Important Questions With AnswersDocument12 pagesMud Loggers 77 Most Important Questions With Answersfadhian_hasbiNo ratings yet

- BS35Document2 pagesBS35maaz siddique100% (1)

- MPBT - Pertemuan 13Document43 pagesMPBT - Pertemuan 13Ardiansyah Ay11No ratings yet

- Defects in The ProductDocument3 pagesDefects in The ProductMohamed Ashraf HindyNo ratings yet

- Shivering: Specific Types of CracksDocument2 pagesShivering: Specific Types of CracksAsad SaeedNo ratings yet

- Chapter 2 - Hole Problem March 2018 PDFDocument60 pagesChapter 2 - Hole Problem March 2018 PDFMohd RafiqNo ratings yet

- Cge578 Chap 2 Oct 20 - Feb 21Document60 pagesCge578 Chap 2 Oct 20 - Feb 21Muhd EizadNo ratings yet

- 2.13. Casting DefectsDocument1 page2.13. Casting Defectsaman chaudharyNo ratings yet

- Formation Damage 2Document21 pagesFormation Damage 2Suleiman Baruni100% (2)

- Double Etching Method For Steel Roll Surfaces: by Henrik KakerDocument12 pagesDouble Etching Method For Steel Roll Surfaces: by Henrik KakerMoinul Haque RiyadNo ratings yet

- Drilling Well PlanDocument105 pagesDrilling Well PlanArshad hassanNo ratings yet

- Jurnal Well ServiceDocument6 pagesJurnal Well ServiceDzaky Sun HajiNo ratings yet

- Drilling Lab. 3 Porosity - Permeability Measurment at LabDocument16 pagesDrilling Lab. 3 Porosity - Permeability Measurment at Labali100% (1)

- Form Scaneline ANODocument2 pagesForm Scaneline ANOyosep_alianduNo ratings yet

- Casting Process IDocument31 pagesCasting Process IArpit JainNo ratings yet

- ChertDocument1 pageChertJuan Carlos Bazán SotomayorNo ratings yet

- Extrusion Guides 06Document6 pagesExtrusion Guides 06ramonaNo ratings yet

- Module C-2: Stresses Around A Borehole - IIDocument39 pagesModule C-2: Stresses Around A Borehole - IIMukhtiar Ahmed LakhanNo ratings yet

- CastingsDocument105 pagesCastingsAhmed MatNo ratings yet

- Dispersed Porosity in Ductile Iron CastingDocument24 pagesDispersed Porosity in Ductile Iron CastingLuis Arturo Ramirez100% (1)

- Slip CastingDocument7 pagesSlip CastingPradyumna PadukoneNo ratings yet

- Casting DefectsDocument2 pagesCasting DefectsLanky IloveuNo ratings yet

- E.1. Rock Properties: PorosityDocument40 pagesE.1. Rock Properties: PorosityDedy DayatNo ratings yet

- Casting DefectsDocument7 pagesCasting DefectsNazrul Abdul LatiffNo ratings yet

- GY403 Structural GeologyDocument17 pagesGY403 Structural GeologyHarly HamadNo ratings yet

- Photo by NASADocument27 pagesPhoto by NASAavinash goswamiNo ratings yet

- Extrusion Guides 08Document4 pagesExtrusion Guides 08ramonaNo ratings yet

- GY403 Structural Geology: Tectonite FabricsDocument25 pagesGY403 Structural Geology: Tectonite FabricstodolopuedoNo ratings yet

- 8 - Rock Mass Characterization (Pg. 7)Document7 pages8 - Rock Mass Characterization (Pg. 7)sudhakarNo ratings yet

- Casting Defects 6Document36 pagesCasting Defects 6AnuskaNo ratings yet

- Basic Petroleum IndustryDocument38 pagesBasic Petroleum IndustryHassan FekiNo ratings yet

- Drilling PblemsDocument48 pagesDrilling PblemsHama RoyaleNo ratings yet

- Soil Description TableDocument1 pageSoil Description Tableaziz fathiryNo ratings yet

- Geofabrics Track Design Guide - 1 PDFDocument12 pagesGeofabrics Track Design Guide - 1 PDFRavi SalimathNo ratings yet

- Soil Descriptions - Figure 1 and 2 Revised ISSMFE - Rev. Oct, 2012Document2 pagesSoil Descriptions - Figure 1 and 2 Revised ISSMFE - Rev. Oct, 2012Terobau111No ratings yet

- Stuck Pipe Mechanisms BookDocument48 pagesStuck Pipe Mechanisms Booksdb158100% (1)

- 1.72 Type IIADocument7 pages1.72 Type IIAMj JjNo ratings yet

- Sand Properties and Casting ProcedureDocument4 pagesSand Properties and Casting ProcedureSADIQUE AZAMNo ratings yet

- Soil and Rock Field GuideDocument2 pagesSoil and Rock Field Guidevickneshj9406No ratings yet

- Wellbore Stability & Clay MineralogyDocument48 pagesWellbore Stability & Clay MineralogySapanNo ratings yet

- Gear Corrosion During The Manufacturing ProcessDocument6 pagesGear Corrosion During The Manufacturing Processluis_dominguezeNo ratings yet

- Wear TypesDocument7 pagesWear Typesmostafa aliNo ratings yet

- Common Hole ProblemsDocument12 pagesCommon Hole ProblemsAlberto Arguea RomeroNo ratings yet

- Module 5 and 6 PetgeoDocument566 pagesModule 5 and 6 PetgeoChristian Rogel De TorresNo ratings yet

- Dental Casting DefectsDocument86 pagesDental Casting DefectsNIDHI SINGHNo ratings yet

- Jenis-Jenis Cacat Pada Dunia PaintingDocument10 pagesJenis-Jenis Cacat Pada Dunia Paintingjoni Mart SitioNo ratings yet

- Plain Bearing FailuresDocument7 pagesPlain Bearing FailuressourajpatelNo ratings yet

- Chapter 4 - Drilling - Problems - UTM-unlockedDocument59 pagesChapter 4 - Drilling - Problems - UTM-unlockedyazidNo ratings yet

- Uartz-Is A Chemical Compound: Ls/minerals/quartz - HTML 8700692.htmlDocument2 pagesUartz-Is A Chemical Compound: Ls/minerals/quartz - HTML 8700692.htmlAyesha Faye BelarminoNo ratings yet

- Glaze Surface DefectsDocument1 pageGlaze Surface DefectsPrakash Panwar100% (1)

- An Introduction To Drilling Fluid 1Document41 pagesAn Introduction To Drilling Fluid 1Kashish MadanNo ratings yet

- Fault Rocks: Mary Rose LicarosDocument23 pagesFault Rocks: Mary Rose LicarosLearn Math by mallowsNo ratings yet

- Crazing: Aniket Raikwar (Sc17M017)Document8 pagesCrazing: Aniket Raikwar (Sc17M017)AniketRaikwarNo ratings yet

- ASTM StandardsDocument1 pageASTM StandardsAhmed AlhosanyNo ratings yet

- SMR RecommendationDocument2 pagesSMR RecommendationSidikNo ratings yet

- Scabs On Rolled Steel ProductsDocument2 pagesScabs On Rolled Steel ProductsCarlos BustamanteNo ratings yet

- Blowholes Which Can Be Confused WithDocument1 pageBlowholes Which Can Be Confused WithRanjith RamNo ratings yet

- Blowholes Which Can Be Confused WithDocument1 pageBlowholes Which Can Be Confused WithRanjith RamNo ratings yet

- The SolidificationDocument1 pageThe SolidificationRanjith RamNo ratings yet

- Fissure Defects: Characteristic FeaturesDocument1 pageFissure Defects: Characteristic FeaturesRanjith RamNo ratings yet

- Report of Graphite MicrostructureDocument1 pageReport of Graphite MicrostructureRanjith RamNo ratings yet

- Burn-On Sand: Characteristic FeaturesDocument1 pageBurn-On Sand: Characteristic FeaturesRanjith RamNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings1Document1 pageEvaluating The Microstructure of Graphite in Iron Castings1Ranjith RamNo ratings yet

- Graphite Cast Iron Keith Millis BrittleDocument1 pageGraphite Cast Iron Keith Millis BrittleRanjith RamNo ratings yet

- FmeaDocument1 pageFmeaRanjith RamNo ratings yet

- Design of Gating SystemDocument1 pageDesign of Gating SystemRanjith RamNo ratings yet

- Manufacturing Technology, Vol. 1 Foundry, Forming and WeldingDocument5 pagesManufacturing Technology, Vol. 1 Foundry, Forming and WeldingRanjith RamNo ratings yet

- Design of Gating SystemDocument1 pageDesign of Gating SystemRanjith RamNo ratings yet

- Manufacturing Technology, Vol. 1 Foundry, Forming and WeldingDocument5 pagesManufacturing Technology, Vol. 1 Foundry, Forming and WeldingRanjith RamNo ratings yet

- Simple Contact List: Last Name First Name Address 1 Address 2 CityDocument3 pagesSimple Contact List: Last Name First Name Address 1 Address 2 CityRanjith RamNo ratings yet

- Universal Mould & Dies: 100% REPORT Inspection ReportDocument3 pagesUniversal Mould & Dies: 100% REPORT Inspection ReportRanjith RamNo ratings yet