Professional Documents

Culture Documents

2 08P28 PDF

Uploaded by

Mike2322Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 08P28 PDF

Uploaded by

Mike2322Copyright:

Available Formats

8

Part 28

Temporary Structures for Construction

8

— 2015 —

TABLE OF CONTENTS

Section/Article Description Page

28.1 General ............................................................................... 8-28-2

28.1.1 Scope (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-2

28.1.2 Criteria (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-2

28.1.3 Qualifications (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-2

28.1.4 Responsibility (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-2

28.1.5 Types of Temporary Structures (2015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-3 1

28.1.6 Falsework (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-3

28.2 Information Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-4

28.2.1 Field Surveys and Records (2002) R(2015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-4

28.2.2 Soil Investigation (2002) R(2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-4

28.2.3 Loads (2002) R(2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-4 3

28.2.4 Drainage (2002) R(2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-4

28.2.5 Soil Properties (2002) R(2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-5

28.3 Computation of Lateral Forces (2002) R(2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-5

28.4 Stability (2002) R(2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-5

28.5 Design of Shoring Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-5

28.5.1 Design of Cantilever Sheet Pile Walls (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-5

28.5.2 Design of Anchored Sheet Pile Walls (2002) R(2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-6

28.5.3 Design of Cantilever Soldier Beam and Lagging Walls (2015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-6

28.5.4 Design of Anchored Soldier Beam with Lagging Walls (2015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-7

28.5.5 Design of Braced Excavations (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-9

28.5.6 Design of Cofferdams (2015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-9

28.6 Design of Falsework Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-13

28.6.1 Review and Approval of Falsework Drawings (2015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-13

28.6.2 Design Loads (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-14

28.6.3 Design Stresses, Loadings, and Deflections (2015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-15

28.6.4 Special Conditions (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-16

28.6.5 Falsework Construction (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-17

28.6.6 Removing Falsework (2015) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-17

© 2017, American Railway Engineering and Maintenance-of-Way Association 8-28-1

Concrete Structures and Foundations

TABLE OF CONTENTS (CONT)

Section/Article Description Page

Commentary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-18

LIST OF FIGURES

Figure Description Page

8-1 Apparent Earth Pressure Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28-7

SECTION 28.1 GENERAL

28.1.1 SCOPE (2015)

a. This Part provides a recommended practice for the design of the most commonly used temporary structures. Other

types of temporary structures may be used with the approval of the Engineer. This Part is intended for SERVICE

LOAD DESIGN only.

b. Temporary structures are defined as those structures used to facilitate the construction of a permanent structure. The

temporary structures addressed by this Part are primarily shoring and falsework systems. This Part is intended for

evaluating earth pressure loading, tieback anchor design, wall design, stability considerations and corrosion protection

requirements.

c. All temporary structures anticipated to be in service for more than an 18-month period are not within the scope of this

Part.

d. Temporary bridges to carry railroad traffic shall be designed as permanent structures and are not included in this Part.

28.1.2 CRITERIA (2015)

a. All temporary structures shall be designed and constructed to provide safe support and adequate rigidity for the loads

imposed.

b. All temporary structures shall be constructed with minimal interference to the operating tracks.

28.1.3 QUALIFICATIONS (2015)

The performance of temporary support structures is strongly influenced not only by the methods and materials used but also

the experience of the constructor. The constructor should be able to show sufficient expertise, through past projects and

experience and in addition, be able to demonstrate that proper design capabilities are available and will be used for the project,

as required.

28.1.4 RESPONSIBILITY (2015)

a. The Contractor shall be solely responsible for the design, construction and performance of a temporary structure unless

it is provided by others.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-2 AREMA Manual for Railway Engineering

Temporary Structures for Construction

b. Designs completed by the Contractor shall be submitted to the Engineer, including working drawings and design

calculations for the temporary structures. The drawings and calculations shall be signed and sealed by a Registered

Professional Engineer. The temporary structure(s) shall follow the lines, grades and location as shown on the plans.

The temporary structure(s) shall be designed to conform to the right-of-way and easement restrictions provided and

shall protect facilities and utilities shown on the plans or known to exist.

c. Review by the Engineer of the Contractor’s designs and working drawings shall in no way relieve the Contractor of full

responsibility for the temporary structure, or its effect upon other adjacent facilities.

28.1.5 TYPES OF TEMPORARY STRUCTURES (2015)

28.1.5.1 Shoring Systems

a. A cantilever sheet pile wall is a structure designed to provide lateral support for a soil mass and derives stability from

passive resistance of the soil in which the sheet pile is embedded.

b. An anchored sheet pile wall is a structure designed to provide lateral support for a soil mass and derives stability from

passive resistance of the soil in which the sheet pile is embedded and the tensile resistance of the anchor. Anchors may

be cement-grouted tiebacks or other types of anchors acceptable to the Engineer.

A cantilever soldier beam with lagging wall is a structure designed to provide lateral support for a soil mass and

derives stability from passive resistance of the soil in which the soldier beam is embedded.

c. Soldier beams include steel H-piles, wide flange sections or other fabricated sections that are driven or set in concrete 1

in drilled holes. Lagging refers to the members spanning between soldier beams.

An anchored soldier beam and lagging wall is a structure designed to provide lateral support for a soil mass and derives

stability from passive resistance of the soil in which the soldier beam is embedded and the tensile resistance of the

anchors.

d. Anchored soldier beam with lagging walls are generally designed as flexible structures which have sufficient lateral 3

movement to mobilize active earth pressures and a portion of the passive pressure.

e. A braced excavation is a structure designed to provide lateral support for a soil mass and derives stability from passive

resistance of the soil in which the vertical members are embedded and from the structural capacity of the bracing

members. The vertical members of the braced excavation system include steel sheet piling or soldier beams comprised

of steel H-piles, wide-flange sections, or other fabricated sections that are driven or installed in drilled holes. Wales are

horizontal structural members designed to transfer lateral loads from the vertical members to the struts. Struts are 4

structural compression members that support the lateral loads from the wales.

f. A cofferdam is an enclosed temporary structure used to keep water and soil out of an excavation for a permanent

structure such as a bridge pier or abutment or similar structure. Cofferdams may be constructed of timber, steel,

concrete or a combination of these. This Part considers cofferdams primarily constructed with steel sheet piles.

28.1.6 FALSEWORK (2015)

a. Falsework is defined in general terms as a temporary construction work on which a main or permanent work is wholly

or partially supported until it becomes self-supporting.

b. Falsework for roll-in/roll-out construction methods is not covered in this Part.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-3

Concrete Structures and Foundations

28.1.6.1 Types of Falsework Systems

a. Conventional falsework typically consists of timber posts and caps, timber bracing, and either timber or steel stringers

and timber joists. Foundation support is usually provided by timber pads or sills set on the surface of the ground,

although poor soil conditions may require the use of concrete footings, or by steel sills designed to distribute the loads

to adequate timber pads or cribbing.

b. Large-diameter, typically 20 inches (500 mm) or more, welded steel pipe columns are occasionally used to support

steel caps and girders. When properly braced, pipe columns may provide an economical design when falsework is tall

and spans are long.

c. Patented steel shoring typically consists of individual components that may be assembled into modular units and

erected in place to make any desired falsework configuration. When erected, the shoring consists of a series of

internally-braced steel towers which, either directly or through a cap system, support the load-carrying members.

d. Depending on load-carrying capacity, steel shoring systems are classified as pipe-frame shoring, heavy-duty shoring or

intermediate strength shoring. For bridge falsework the use of pipe-frame shoring is limited to installations where

tower leg loads do not exceed 11 kips (49 kN). In contrast, a properly designed heavy-duty shoring system will be

capable of supporting loads of 100 kips (445 kN) per tower leg. Intermediate strength shoring will have a load carrying

capacity of up to 25 kips (111 kN) per tower leg. Typically, timber caps and stringers are used with pipe-frame

intermediate strength systems, whereas rolled-beams or welded plate girders will be more economical for the longer

spans which are possible with heavy-duty shoring. Pipe-frame shoring is usually supported on timber pads; however,

the larger leg loads associated with heavy-duty shoring will require, depending on soil conditions, solid timber cribbing

or reinforced concrete footings.

SECTION 28.2 INFORMATION REQUIRED

28.2.1 FIELD SURVEYS AND RECORDS (2002) R(2015)

Sufficient information shall be furnished in the form of profiles and cross sections, or topographical maps to determine general

design and structural requirements. Existing and proposed grades and alignment of tracks and roads shall be indicated together

with records of reference datum, maximum and minimum high water, minimum and mean low water, existing ground water

level, location of utilities, construction history of the area, indication of any conditions which might hamper proper installation

of the piling, soldier beams, ground anchors, depth of scour, allowance for over dredging, and wave heights.

28.2.2 SOIL INVESTIGATION (2002) R(2015)

The characteristics of the foundation soils shall be investigated as indicated in Part 22, this Chapter with the investigation

being done specifically for the temporary structure being designed.

28.2.3 LOADS (2002) R(2015)

Loads shall be as indicated in Part 20, Article 20.2.3, this Chapter.

28.2.4 DRAINAGE (2002) R(2015)

Drainage shall be as indicated in Part 20, Article 20.2.4, this Chapter.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-4 AREMA Manual for Railway Engineering

Temporary Structures for Construction

28.2.5 SOIL PROPERTIES (2002) R(2015)

Soil properties shall be determined and soils classified as indicated in Part 20, Article 20.2.5, this Chapter.

SECTION 28.3 COMPUTATION OF LATERAL FORCES (2002) R(2015)

Computation of lateral forces shall be as indicated in Part 20, Section 20.3, this Chapter.

SECTION 28.4 STABILITY (2002) R(2015)

The stability of the system shall be investigated as indicated in Part 20, Section 20.4, this Chapter or as indicated in

Article 28.5.6.5 for cellular cofferdams.

SECTION 28.5 DESIGN OF SHORING SYSTEMS

1

28.5.1 DESIGN OF CANTILEVER SHEET PILE WALLS (2015)

28.5.1.1 Restrictions on Use1

a. Cantilever sheet pile walls shall not exceed 12 feet (3.7 m) in height and shall be used only in granular soils or stiff

clays. 3

b. If used for shoring adjacent to an operating track the wall should be at least 10 feet (3 m) away from the centerline of

track, and its maximum height should not exceed 10 feet (3 m). Depth of disturbed soil shall not be considered for

passive resistance.

28.5.1.2 Depth of Embedment2

4

a. The total depth of embedment D shall be determined as indicated in Part 20, Section 20.3 of this Chapter. The

coefficient of passive resistance Kp shall be multiplied by 0.66 to provide a factor of safety of 1.5.

b. Conditions such as unrealistically short penetration requirements into relatively strong layers, potential for overall

instability, scour or erosion shall be taken into account, and the depth of embedment increased to not less than the

height of the wall.

28.5.1.3 Maximum Moment (2002)3 R(2015)

Determine the depth at which the shear in the wall is zero by starting from the top of the wall and finding the point at which the

areas of the driving and resisting pressure diagrams are equivalent. Calculate the maximum bending moment at the point of

zero shear.

1

See Commentary

2

See Commentary

3 See Commentary

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-5

Concrete Structures and Foundations

28.5.1.4 Allowable Stresses (2015)

The allowable stresses shall be determined on the following basis:

a. Sheet Pile Section: 2/3 tensile yield strength for new steel. Allowable stresses shall be reduced depending on the extent

of usage for reused material.

b. All other structural material shall comply with applicable parts of this AREMA Manual.

28.5.2 DESIGN OF ANCHORED SHEET PILE WALLS (2002) R(2015)

The design of anchored sheet pile wall systems shall be as indicated in Part 20, this Chapter. Requirements of Article 28.5.4.1,

28.5.4.2, 28.5.4.4, and 28.5.4.5 shall be satisfied as applicable to the anchored sheet pile walls.

28.5.3 DESIGN OF CANTILEVER SOLDIER BEAM AND LAGGING WALLS (2015)

28.5.3.1 Restrictions of Use1

a. Cantilever soldier beam with lagging walls shall not exceed 12 feet (3.7 m) in height and shall be used only in granular

soils or stiff clays.

b. If used for shoring adjacent to an operating track, the wall should be at least 13 feet (4.0 m) away from the centerline of

track, and its maximum height shall not exceed 8 feet (2.4 m).

28.5.3.2 Depth of Embedment2

a. The total depth of embedment D shall be determined using the guidelines given in Article 28.5.1.2 except that the

pressure distribution on the soldier piles below the excavation elevation shall be adjusted based on their equivalent

width. The equivalent width for passive pressure shall be assumed to equal the width of the soldier pile multiplied by a

factor of 3 for granular soils and a factor of 2 for cohesive soils. The width of the soldier piles shall be taken as the

width of the flange or diameter for driven sections and the diameter of the concrete-filled hole for sections encased in

concrete. Also, when determining the passive pressure distribution on the soldier piles, a depth of 1.5 times the width

of the soldier pile in soil, and a depth of one foot in rock below the excavation elevation, shall not be considered in

providing passive lateral support.

b. For conditions such as unrealistically short penetration requirements into relatively strong layers, the potential for

overall instability, scour or erosion, shall be taken into account and the depth of embedment increased.

28.5.3.3 Maximum Moment

Determine the depth at which the shear in the soldier piles is zero by starting from the top of the wall and finding the point at

which the areas of the driving and resisting pressure diagrams are equivalent. Calculate the maximum bending moment at the

point of zero shear.

28.5.3.4 Allowable Stresses

Allowable stresses shall comply with applicable sections of the AREMA Manual.

1

See Commentary

2 See Commentary

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-6 AREMA Manual for Railway Engineering

Temporary Structures for Construction

28.5.3.5 Lagging

a. The design load on the lagging is the theoretical pressure computed to act on it. When arch action can form in the soil

behind the lagging (i.e., in granular or stiff cohesive soils where there is sufficient space to permit the in-place soil to

arch and the back side of the soldier piles bear directly against the soil) the moment computed based on simple end

supports may be reduced by one third.

b. Well-compacted fill shall be provided behind the lagging.

28.5.4 DESIGN OF ANCHORED SOLDIER BEAM WITH LAGGING WALLS (2015)

28.5.4.1 Design Criteria

a. The lateral earth pressures shall be computed as indicated below:

(1) For single tier anchored walls, lateral earth pressures shall be computed using Part 20, this Chapter.

(2) For earth masses which do not have a history of sliding, the magnitude of lateral pressures on multi-tiered

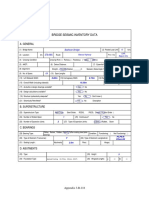

anchored walls shall be computed following the guidelines on Figure 8-28-1.

(3) Refer to Part 20, this Chapter, for the application of live load surcharge.

pa pa pa 1

Ka

Figure 8-28-1. Apparent Earth Pressure Diagrams

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-7

Concrete Structures and Foundations

b. The width of the soldier beam shall be assumed to be equal to the width of the flange for driven sections and the shaft

diameter of the drilled sections. The resultant passive resistance of a soldier beam assumes that passive resistance is

mobilized across an equivalent width described in Article 28.5.3.2, Paragraph a. The effects of backfill compaction and

surcharge loads applied to the surface behind the wall shall be considered in the design earth pressure. The design

stresses shall be in accordance with the current edition of Chapter 15 of the Manual.

c. The unbonded tendon length shall extend beyond the critical failure surface and be a minimum of 15 feet (4.6 m) in

length. The critical failure surface starts at the bottom of the excavation. The wall-anchor system shall be checked for

adequate stability. The overall stability of the earth mass being retained shall be checked and shall have a minimum

factor of safety of 1.3.

28.5.4.2 Submittals

The drawings shall include all details, dimensions, cross-sections, and sequence of construction necessary to construct the

wall. The drawings and calculations shall include, but not be limited to:

a. A description of the tieback installation including drilling, grouting and stressing information;

b. Anchor capacity, type of tendon, anchorage hardware, minimum unbonded lengths, minimum anchor lengths, angle of

installation and tieback locations and spacings;

c. Testing schedule and procedures for tiebacks;

d. A section view indicating the elevation at the top and bottom of the wall and the centerline of track including all

horizontal and vertical dimensions;

e. A plan view of the wall indicating the offset from the construction and track centerlines to the face of the wall at all

changes in horizontal alignment;

f. All details for construction of drainage facilities associated with the wall clearly indicated;

g. The relationship between existing and proposed utilities; and

h. A top of rail monitoring plan.

28.5.4.3 Soldier Beam Installation

a. Soldier beams may be installed by driving with impact or vibration hammers or set in predrilled holes and encased with

concrete below subgrade elevation and with lean concrete backfill above subgrade elevation. Encasement below

subgrade level shall be concrete with a minimum 28-day compressive strength of 3,000 psi (20.7 MPa). Methods and

equipment used for soldier beam installations shall be determined by the Contractor. The effect on existing structures

should be considered.

b. For driven soldier beams, leads or spuds shall be centered in such a manner as to afford freedom of movement to the

hammer and shall be rigged to hold the soldier beam and hammer in alignment during driving. The soldier beam shall

be driven with equipment which will ensure a properly distributed hammer impact on the soldier beam and prevent

damage while driving.

c. For drilled-in soldier beams, side wall stability shall be maintained during drilling. If required by soil and water

conditions, provide casing for hole excavation. Provide casing of sufficient strength to withstand handling stresses,

lean concrete backfill pressure and surrounding earth and/or water pressure. Drilling mud may also be used to maintain

side wall stability of soldier beam holes subject to the approval of the Railroad. Pump water from drill holes.

Contractors may use tremie methods in lieu of pumping water.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-8 AREMA Manual for Railway Engineering

Temporary Structures for Construction

Above subgrade elevation, the soldier beam shall be fully encased in lean concrete backfill after completion of soldier

beam hole excavation. The soldier beam may be set prior to, or after, concrete placement at the option of the

Contractor. Free fall lean concrete backfill may be used. Vibrating of lean concrete backfill mix is not required.

d. Soldier beams may be furnished in full-length sections or may be spliced according to the method of splicing as shown

on the plans. Field welding will be allowed only in accordance with the requirements for welding as specified in AWS

D1.1, except as amended on the plans.

e. Structural welding of steel, steel reinforcement and soldier beams shall be made by personnel qualified to perform the

type of welding involved in accordance with the qualification procedure of AWS D1.1 and D1.4, except as amended on

the plans.

28.5.4.4 Ground Anchors (Tiebacks)

Unless otherwise directed, the Contractor shall select the tieback type and the installation method, and determine the bond

length, anchor length and anchor diameter in accordance with Article 20.5.5 Anchorages, this Chapter.

28.5.4.5 Allowable Stresses

Allowable stresses shall be in accordance with Article 20.5.7, this Chapter.

28.5.5 DESIGN OF BRACED EXCAVATIONS (2015)

Braced excavations shall be designed using the apparent earth pressure diagram, based on soil type, shown in Figure 8-28-1. 1

28.5.6 DESIGN OF COFFERDAMS (2015)

28.5.6.1 General

a. This section deals primarily with cofferdams constructed with steel sheet piles. This section applies to the case where

the water level lies above the soil or rock level such as in rivers, lakes and bays. 3

b. A single-wall cofferdam consists of a single wall of sheet piling driven in the form of an enclosure. Single-walled

cofferdams shall be designed as flexible sheet pile bulkheads or braced excavations.

c. A double-walled cofferdam consists of two rows of steel sheet piling driven parallel to each other and tied to each other

with anchors and wales. Double wall cofferdams shall be designed similar to single-wall cofferdams. The two rows of

sheet piles shall not be assumed to share equally in resisting the outside pressure unless concrete fill or rigid bracing is

4

used between them. The use of double-wall cofferdams over single-wall cofferdams is usually to provide increased

water tightness.

d. A cellular cofferdam consists of soil-filled interconnected circular or diaphragm cells constructed of steel sheet piling.

Cellular cofferdams are designed as gravity retaining structures.

28.5.6.2 Required Data

The required information about the site includes the following:

•High water elevation

•Velocity of water flow

•Wave height and period

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-9

Concrete Structures and Foundations

•Distance to existing piers and foundation type of existing piers

•Ice conditions

•Scour potential

•Ground line cross-sections and profiles

•Existing soil types, layer thicknesses, and properties

•Properties of backfill materials

•Ground water conditions

•Navigation and lighting requirements

•Vessel impact potential

28.5.6.3 Design Stresses and Factors of Safety1

The maximum stresses for cofferdam materials shall be in accordance with Article 20.5.7, this Chapter. The minimum factors

of safety for stability of cofferdams shall be 1.25. The factors of safety shall be calculated as the sum of the resisting forces or

moments divided by the sum of the applied forces or moments. The factors of safety may be calculated on a unit length of

cofferdam. An analysis shall be conducted to determine the stability of the bottom of the excavation.

28.5.6.4 Applied Forces

In determining the stability of cofferdams, the applied forces shall include the following as applicable:

•Hydrostatic water pressure

•Seepage force

•Stream flow pressure

•Wave forces

•Active earth pressure

•Vessel impact

•Ice forces

28.5.6.5 Design of Cellular Cofferdams

28.5.6.5.1 Equivalent Width

The stability of cellular cofferdams may be determined using an equivalent width. The equivalent width of a cofferdam is

defined as the width of an equivalent rectangular section having an area equal to that of the actual cofferdam.

1 See Commentary

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-10 AREMA Manual for Railway Engineering

Temporary Structures for Construction

28.5.6.5.2 Saturation Line

The location of the line of saturation or phreatic surface within a cofferdam cell may be taken as a straight line sloping

downward from the water surface level on the outboard side to the inboard side. The slope of the saturation line may be

assumed as shown below. A horizontal line representing the average level of saturation may be assumed for stability

calculations.

Cell Fill Material Slope (Horizontal to Vertical)

Free draining coarse-grained 1 to 1

Silty coarse-grained 2 to 1

Fine-grained 3 to 1

28.5.6.5.3 Sliding

Cofferdams shall be investigated for sliding at the base. The resisting forces shall consist of the frictional resistance of the soil

along the bottom of the cofferdam, the passive resistance of soil on the inboard face, and the passive resistance of a berm, if

any, on the inboard face. The unit weight of the soil below the saturation line shall be the submerged unit weight.

28.5.6.5.4 Overturning

Cofferdams shall be investigated for overturning about the inboard toe. The resultant of the applied forces and the cell weight 1

shall lie within the middle one-third of the cofferdam.

28.5.6.5.5 Piling Uplift

Cofferdams shall be investigated for uplift of the outboard piling. The moments shall be summed about the inboard toe. The

resisting moments shall be those due to the frictional forces on the inner and outer surfaces of the outboard sheeting plus the

effective passive resistance of the soil and berm, if any, on the outboard face. The weight of the cell fill shall not be used for 3

resisting moment.

28.5.6.5.6 Vertical Shear

a. Cofferdam cells shall be investigated for vertical shear failure on the centerline of the cells. The total shearing force, Q,

on the neutral plane at the centerline of the cell shall be as follows:

4

Q = 3M/2E

Q = total shearing force per unit length of cofferdam

M = net overturning moment per unit length of cofferdam

E = equivalent width of cofferdam

b. The shearing force, Q, shall be resisted by vertical shear within the cell fill and friction in the interlocks of the sheeting.

In computing the vertical shear resistance of the fill material, the coefficient of earth pressure, K, shall be as follows:

2

coscos 2

K = -----------------------

2 – 2-coscos

2

= angle of internal friction of cell fill

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-11

Concrete Structures and Foundations

c. The total centerline shear force resistance of the cell fill per unit length of cofferdam shall be the resultant lateral force

due to soil fill material multiplied by tan. The frictional resistance of the sheet pile interlocks per unit length of

cofferdam shall be the interlock tension multiplied by the coefficient of friction of the interlocks.

28.5.6.5.7 Horizontal Shear

a. Cofferdam cells shall be investigated for tilting failure through horizontal shear in the cell fill material. The resisting

moments shall be those due to the lateral resistance of the cell fill, the frictional resistance of the sheet pile interlocks,

and the passive resistance of the berm if one is used.

b. The lateral resisting moment, M, of the cell fill about the base of the cofferdam shall be:

(H - Etan) (Etan)2 + (Etan)3

M = γs [ 2 3

]

M = resisting moment per unit length of cofferdam

H = height of cofferdam

E = equivalent width of cofferdam

γs = submerged unit weight of fill material

= angle of internal friction of fill material

c. The resisting moment due to frictional resistance of the interlocks shall be the interlock tension multiplied by the

coefficient of friction of the interlocks multiplied by the equivalent width of the cofferdam.

28.5.6.5.8 Interlock Tension

a. The hoop or interlock forces for circular cells and connecting arcs shall be calculated by the following equation:

T = PR

T = hoop or interlock force

P = maximum lateral pressure from cell fill and water

R = radius of circle or arc

b. The lateral pressure may be taken as maximum at 1/4 the height from the mudline to the top of the cofferdam.

c. The interlock force at the connection of arc to circular cell shall be calculated by the following equation:

Tc = PLsec

Tc = hoop or interlock force at connection

P = maximum lateral pressure from cell fill and water

L = ½ the center-to-center distance of full circular cells

= angle between centerline of cells and a line from center of cell to point on cell

periphery where connecting arc is attached.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-12 AREMA Manual for Railway Engineering

Temporary Structures for Construction

d. The interlock tension shall not exceed the manufacturer's recommended values.

e. The maximum coefficient of friction of steel on steel at the interlocks shall not exceed 0.3.

28.5.6.6 Construction Requirements

a. Cofferdams for foundation construction shall be carried well below the bottom of the excavation or as far below the

bottom of the excavation as conditions will permit and shall be well braced and as watertight as practical. The interior

dimensions of cofferdams shall provide sufficient clearance inside the wales for constructing forms, driving piles,

pumping outside the forms, and inspection.

b. Cofferdams which are tilted or moved out of position by any cause during the process of construction shall be righted

or enlarged as necessary.

c. No bracing which will induce stress, shock, or vibration in the permanent structure will be permitted in cofferdams.

d. Cellular cofferdams with diaphragm walls shall be filled equally on each side of the diaphragm walls to avoid

distortion of the cells.

e. After completion of the construction, the cofferdams with all sheeting and bracing shall be removed as directed by the

Engineer or as shown on the plans. Such removal shall be done in a manner that will not disturb or mar the permanent

structure.

SECTION 28.6 DESIGN OF FALSEWORK SYSTEMS

28.6.1 REVIEW AND APPROVAL OF FALSEWORK DRAWINGS (2015)

a. Falsework design drawings and calculations prepared by, or for an outside agency covering falsework adjacent to or 3

over Railroad's operating tracks shall be certified to be complete and satisfactory to the submitting agency prior to

being submitted to the Railroad.

b. There shall be sufficient detail in the drawings to permit a complete stress analysis. In particular, the drawings shall

show the size of all load-supporting members; all lateral and longitudinal bracing, including connections; the method

of adjustment; and similar design features.

4

c. All design-controlling dimensions shall be shown, including, but not limited to, beam length; beam spacing; post

location and spacing; vertical distance between connectors in diagonal bracing; overall height of falsework bents; and

similar dimensions critical to the analysis.

d. Minimum horizontal and vertical clearances to the centerline of all tracks, tops of rails and adjacent facilities shall be

shown on the plans.

Where cast-in-place concrete will be supported by falsework, a diagram showing the placing sequence and

construction joint locations shall be provided. When a schedule of placing concrete is shown on the contract plans, no

deviation will be permitted without the approval of the design engineer.

e. When footing type foundations are to be used, the Contractor shall determine the bearing value of the soil and shall

show the values assumed in the design of the falsework on the falsework drawings.

f. Anticipated total settlements of the falsework and forms shall be shown on the falsework drawings.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-13

Concrete Structures and Foundations

g. Falsework footings shall be designed to carry the load imposed upon them without exceeding the estimated soil

bearing values and anticipated settlements. Refer to Part 3 of this Chapter for allowable soil pressures of various

material and settlements.

h. When falsework will be supported on pile bents, the required pile capacity and the maximum allowable driving

tolerances shall be shown.

i. The support systems for form panels supporting concrete deck slabs and overhangs on girder bridges shall also be

considered to be falsework and designed as such.

j. The falsework drawings shall show all openings which are required through the falsework. Horizontal and vertical

clearances shall be adequate and be shown on the plans.

k. Temporary bracing shall be provided to all falsework bents adjacent to the operating tracks, and shall be designed to

withstand all imposed loads during erection, construction and removal. Wind loads shall be included in the design of

such bracing.

l. In addition to the falsework drawings, the design engineer shall submit a copy of design calculations. The design

calculations shall show the stresses and deflections of all load-supporting members. Calculations furnished by the

design engineer are for information only, rather than for review and acceptance. Accordingly, design and/or

construction details, which may be shown in the form of sketches with the calculation sheets, shall be shown on the

falsework drawings as well; otherwise the drawings will not be considered complete.

28.6.2 DESIGN LOADS (2015)

a. The design loads for falsework shall consist of the sum of dead and live vertical loads, and the assumed horizontal

load. The minimum total design load for any falsework shall be not less than 100 pounds per square foot (4.8 kPa) for

the combined live and dead load regardless of slab thickness.

b. Dead load shall include the weight of concrete, reinforcing steel, forms and falsework. The weight (mass density) of

concrete, reinforcing steel and forms shall be assumed to be not less than 160 pounds per cubic foot (2600 kg/m3) for

normal concrete.

c. Live loads shall consist of the actual weight of equipment to be supported by the falsework applied as concentrated

loads at the points of contact and a uniform load of not less than 20 pounds per square foot (960 Pa) applied over the

area supported, plus 75 pounds per linear foot (1100 N/m) applied at the outside edge of deck overhangs.

d. The assumed horizontal load to be resisted by the falsework bracing system shall be the sum of the actual horizontal

loads due to equipment, construction sequence or other causes and an allowance for wind, but in no case shall the

assumed horizontal load to be resisted in any direction be less than 2 percent of the total dead load.

e. The falsework shall be designed so that it will have sufficient rigidity to resist the assumed horizontal load without

considering the weight of the supported structure.

f. The minimum horizontal load to be allowed for wind on each heavy-duty steel shore having a vertical load carrying

capacity exceeding 30 kips (133 kN) per leg shall be the sum of the products of the wind impact area, shape factor, and

the applicable wind pressure value for each height zone. The wind impact area is the total projected area of all the

elements in the tower face normal to the applied wind. The shape factor for heavy-duty shoring shall be taken as 2.2.

Wind pressure values shall be determined from the following table:

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-14 AREMA Manual for Railway Engineering

Temporary Structures for Construction

WIND PRESSURE

Height Zone Shores Adjacent to At Other Locations

Distance above ground Traffic Openings

0 to 30 ft. (0 to 9 m) 20 psf (960 Pa) 15 psf (720 Pa)

30 to 50 ft. (9 to 16 m) 25 psf (1200 Pa) 20 psf (960 Pa)

50 to 100 ft. (16 to 30 m) 30 psf (1440 Pa) 25 psf (1200 Pa)

Over 100 ft. (30 m) 35 psf (1680 Pa) 30 psf (1440 Pa)

g. The minimum horizontal load to be allowed for wind on all other types of falsework, including falsework supported on

heavy-duty shoring, shall be the sum of the products of the wind impact area and the applicable wind pressure value for

each height zone. The wind impact area is the gross projected area of the falsework and any unrestrained portion of the

permanent structure, excluding the areas between falsework posts or towers where diagonal bracing is not used. Wind

pressure values shall be determined from the following table:

WIND PRESSURE VALUE

Height Zone For Members over and Bents Adjacent to At Other Locations

(Feet above ground) Traffic Openings

0 to 30 (0 to 9 m) 2.0 Q 1.5 Q 1

30 to 50 (9 to 16 m) 2.5 Q 2.0 Q

50 to 100 (16 to 30 m) 3.0 Q 2.5 Q

Over 100 (30 m) 3.5 Q 3.0 Q

The value of Q in the above tabulation shall be determined as follows: 3

Q = 1 + 0.2W psf (Q = 48(1 + .656W) Pa); but shall not be more than 10 psf (480 Pa).

In the preceding formula, W is the width of the falsework system in feet (meters), measured in the direction of the wind

force being considered.

h. The entire superstructure cross-section, except railing, shall be considered to be placed at one time. If the concrete is to 4

be prestressed, the falsework shall be designed to support any increased or readjusted loads caused by the prestressing

forces.

28.6.3 DESIGN STRESSES, LOADINGS, AND DEFLECTIONS (2015)

a. The maximum allowable design stresses and loadings listed are based on the use of undamaged, high-quality structural

grade material. Stresses and loadings shall be reduced by the design engineer if lesser quality materials are to be used.

b. The maximum allowable stresses, loadings and deflections used in the design of the falsework shall be as follows:

28.6.3.1 Timber

a. Allowable stresses shall be in accordance with Chapter 7, Timber Structures, Part 2, Design of Wood Railway Bridges

and Trestles for Railway Loading, or Chapter 7, Appendix 4 - Temporary Structures, of this Manual.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-15

Concrete Structures and Foundations

b. Deflection due to the weight of concrete shall not exceed L/240 of the span irrespective of the fact that the deflection

may be compensated for by camber strips.

c. The maximum modulus of elasticity, E, for timber shall be 1.6 x 106 psi (11.0 x 103 MPa).

d. The maximum loading on timber piles shall be 45 tons (400 kN).

e. Timber connections shall be designed in accordance with the stress and loads allowed in the National Design

Specification of Wood Construction, as published by the National Forest Products Association except that (1)

reductions in allowable loads required therein for high moisture condition of the lumber and service conditions shall

not apply, and (2) the design value of bolts in two member connections (single shear) when used for falsework bracing

shall be 0.75 of the tabulated design value.

28.6.3.2 Steel

a. For identified grades of steel, design stresses shall not exceed those specified in Chapter 15 of this Manual.

When the grade of steel cannot be positively identified, design stresses shall not exceed those specified for ASTM

Designation A36.

b. For compression members L/r shall not exceed 120.

c. For all grades of steel, deflections due to the weight of concrete shall not exceed L/240 irrespective of the fact that the

deflection may be compensated for by camber strips.

d. The modulus of elasticity, E, used for steel shall be 29x106 psi (2.0x103 MPa).

28.6.3.3 Manufactured Assemblies

a. The maximum loadings and deflections used on jacks, brackets, columns, joists and other manufactured devices shall

not exceed the manufacturer's recommendations except that the dead load deflection of such joists used at locations

other than under deck slabs between girders shall not exceed L/240. If requested by the Engineer, the design engineer

shall furnish engineering data from the manufacturer verifying the manufacturer's recommendations or shall perform

tests as necessary to demonstrate the adequacy of any such device proposed for use.

28.6.4 SPECIAL CONDITIONS (2015)

a. In addition to the minimum requirements specified in Section 28.6.2 falsework over or adjacent to the railroad tracks

which are open to traffic shall be protected from impact by motor vehicles and construction equipment. The falsework

design shall include, but not be limited to, the following minimum provisions:

b. The vertical load used for design of falsework posts and towers, but not footings, which support the portion of the

falsework over openings, shall be the greater of the following:

(1) 150 percent of the design load calculated in accordance with the provisions for the design load previously

specified but not including any increased or readjusted loads caused by the prestressing forces, or

(2) The increased or readjusted loads caused by the prestressing forces.

c. Falsework posts adjacent to railroads shall consist of either steel with a minimum section modulus about each axis of

9.5 inches cubed (156,000 mm3) or sound timbers with a minimum section modulus about each axis of 250 inches

cubed (4,100,000 mm3).

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-16 AREMA Manual for Railway Engineering

Temporary Structures for Construction

d. Each falsework post adjacent to railroad shall be mechanically connected to its supporting footing at its base, or

otherwise laterally restrained, so as to withstand a force of not less than 2,000 pounds (8.90 kN) applied at the base of

the post in any direction except toward the railroad track. Such posts also shall be mechanically connected to the

falsework cap or stringer. Such mechanical connection shall be capable of resisting a load in any horizontal direction of

not less than 1,000 pounds (4.45 kN).

e. For falsework spans over railroads all stringers shall be mechanically connected to falsework cap or framing. Such

mechanical connections shall be capable of resisting a load in any direction, including uplift on the stringer, of not less

than 500 pounds (2.22 kN).

f. When timber members are used to brace falsework bents which are located adjacent to railroads, all connections for

such timber bracing shall be bolted type using 5/8 inch (16 mm) diameter or larger bolt.

g. Falsework bents adjacent to tracks shall have a minimum horizontal clearance of 12 feet (3.7 m) from centerline of

track or as required by the Engineer. Falsework shall be sheathed solid on the side adjacent to track between 3 feet (0.9

m) and 17 feet (5.2 m) above the top of rail elevation. Sheathing shall consist of plywood not less than 5/8 inch (16

mm) thick or lumber not less than one inch thick (25 mm), nominal. Bracing on such bents shall be adequate so that the

bent will resist the required assumed horizontal load or 5,000 pounds (22.2 kN) whichever is greater. Collision posts

and sheathing shall not be required if horizontal clearances to falsework is 18 feet (5.5 m) or greater.

h. A minimum vertical clearance of 22'-6" (6.9 m), or as established by the Railroad, above top of higher rail shall be

maintained at all times.

28.6.5 FALSEWORK CONSTRUCTION (2015) 1

a. The falsework shall be constructed to conform to the falsework drawings. The materials used in the falsework

construction shall be of quality necessary to sustain the stress required by the falsework design. The workmanship used

in falsework construction shall be of such quality that the falsework will support the loads imposed on it without

excessive settlement or take-up beyond that shown on the falsework drawings.

b. Falsework shall be founded on solid footings, safe against undermining, protected from softening, and capable of 3

supporting the loads imposed on it. When requested by the Engineer, the Contractor shall demonstrate by suitable load

tests that the soil bearing values assumed for the design of the falsework do not exceed the supporting capacity of the

soil.

c. When falsework is to be supported on piles, the piles shall be driven until the required pile capacity is obtained as

shown on the falsework drawings.

4

d. For falsework over or adjacent railroad tracks, all details of the falsework system which contribute to the horizontal

stability and resistance to impact, except for bolts in bracing, shall be installed at the time each element of the

falsework is erected and shall remain in place until the falsework is removed.

e. Falsework shall be designed to compensate for falsework deflection, vertical alignment and anticipated structure

deflection.

f. Contractor shall provide tell-tales attached to the soffit forms and readable from the ground in enough systematically

placed locations to determine the total settlement of the entire portion of the structure where concrete is being placed.

28.6.6 REMOVING FALSEWORK (2015)

a. Falsework supporting any span of a simple span concrete bridge shall not be released before 10 days after the last

concrete, excluding concrete above the bridge deck, has been placed in that span and in the adjacent portions of each

adjoining span of a length equal to at least ½ the length of the span where falsework is to be released.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-17

Concrete Structures and Foundations

b. Falsework for cast-in-place prestressed portions of structures shall not be removed until after the prestressing tendons

have been tensioned and released.

c. Falsework supporting any span of a continuous or rigid frame bridge shall not be removed until all required

prestressing has been completed in that span and in the adjacent portions of each adjoining span for a length equal to at

least ½ the length of the span where falsework is to be removed.

d. Falsework supporting overhangs, deck slabs between girders and girder stems which slope 45 degrees or more off

vertical shall not be removed before 7 days after the deck concrete has been placed.

e. In addition to the above requirements, no falsework for bridge spans shall be removed until the supported concrete has

attained a compressive strength of 2,600 pounds per square inch (17.9 MPa) or 80 percent of the specified strength,

whichever is higher.

f. When falsework piling are used to support falsework within the limits of the railroad right-of-way, such piling within

this area shall be removed to at least 2 feet (0.6 m) below the finished grades or as required by the Engineer.

g. All debris and refuse resulting from the work shall be removed and the premises left in a neat and presentable

condition.

COMMENTARY

C - SECTION 28.5 DESIGN OF SHORING SYSTEMS

C - 28.5.1 DESIGN OF CANTILEVER SHEET PILE WALLS (2015)

C - 28.5.1.1 Restrictions on Use

A cantilever wall derives support from the passive resistance below the excavation line to support the active pressure from the

soil above excavation elevation without an anchorage. Cantilever walls undergo large lateral deflections, and the member

stresses increase rapidly with height. Therefore, it is important to restrict the maximum height of the wall and require good

quality soil below the excavation line that can provide adequate passive resistance.

C - 28.5.1.2 Depth of Embedment

The large moment and deflections that need to be resisted in cantilever type walls may require quite large penetration depths.

Penetration depths of 2 or more times the height of the wall may be necessary.

C - 28.5.1.3 Maximum Moment (2002) R(2015)

See Steel Sheet Piling Design Manual, US Steel, 1984, for charts that may be used to obtain preliminary values for the depth of

penetration D and the maximum moment for the case of a cantilever sheet pile wall in homogeneous granular soil and in a

cohesive soil with granular soil behind above the excavation elevation. The D values obtained from the charts should be

increased by 20 percent.

C - 28.5.3 DESIGN OF CANTILEVER SOLDIER BEAM AND LAGGING WALLS (2015)

C - 28.5.3.1 Restrictions of Use

A cantilever soldier pile wall behaves similarly to a cantilever sheet pile wall. The active soil pressure and surcharge loadings

are transmitted through the lagging to the soldier piles above the excavation elevation. Below the excavation the soldier piles

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-18 AREMA Manual for Railway Engineering

Temporary Structures for Construction

utilize the soils passive resistance to resist the driving pressures. Due to the rapid increase in deflections and moments with the

wall height, maximum height restrictions needed to be imposed.

C - 28.5.3.2 Depth of Embedment

The depth of embedment of the soldier piles must be sufficient to mobilize the passive resistance. The arching capability of

soils allows the use of an equivalent width for the soldier pile below the excavation.

C - 28.5.6 DESIGN OF COFFERDAMS (2015)

C - 28.5.6.3 Design Stresses and Factors of Safety

Flow nets may be used for this analysis.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 8-28-19

THIS PAGE INTENTIONALLY LEFT BLANK.

© 2017, American Railway Engineering and Maintenance-of-Way Association

8-28-20 AREMA Manual for Railway Engineering

You might also like

- LARSA WJE Solving-For-StabilityDocument39 pagesLARSA WJE Solving-For-StabilityMike2322No ratings yet

- 2021-11-16 - ABCD NEOH - Cross-Frames - ChavelDocument36 pages2021-11-16 - ABCD NEOH - Cross-Frames - ChavelMike2322No ratings yet

- AASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Document8 pagesAASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Mike2322No ratings yet

- Camber Haunch Girder WSDOT A-Dimension RevisionsDocument8 pagesCamber Haunch Girder WSDOT A-Dimension RevisionsMike2322No ratings yet

- Guard Rail On-System Bridge (MASH) Set (4-13-23)Document11 pagesGuard Rail On-System Bridge (MASH) Set (4-13-23)Mike2322No ratings yet

- Seismic Design Bridges For Rural Areas South East AsiaDocument85 pagesSeismic Design Bridges For Rural Areas South East AsiaMike2322No ratings yet

- Guard Rail Special Details MASHDocument11 pagesGuard Rail Special Details MASHMike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 4Document170 pagesSeismic Bridge Design Mitigation Outline Part 4Mike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 5Document398 pagesSeismic Bridge Design Mitigation Outline Part 5Mike2322No ratings yet

- Public Roads Vol 23 Issue 7Document32 pagesPublic Roads Vol 23 Issue 7Mike2322No ratings yet

- Design Spectra Philippines Seismic Part 4Document144 pagesDesign Spectra Philippines Seismic Part 4Mike2322No ratings yet

- Seismic Bridge Design Mitigation Outline Part 3Document156 pagesSeismic Bridge Design Mitigation Outline Part 3Mike2322No ratings yet

- ETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMDocument18 pagesETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMMike2322No ratings yet

- Seismic Design of Bridges in PhilippinesDocument80 pagesSeismic Design of Bridges in PhilippinesMike2322No ratings yet

- Mitigation of Seismic Disasters in Bridges Part 1Document466 pagesMitigation of Seismic Disasters in Bridges Part 1Mike2322No ratings yet

- Mitigation of Seismic Disasters in Bridges Part 1Document291 pagesMitigation of Seismic Disasters in Bridges Part 1Mike2322No ratings yet

- Seismic Design of Bridges South East Asia Part 3Document192 pagesSeismic Design of Bridges South East Asia Part 3Mike2322No ratings yet

- CompositeFloorSystems - ChienRitchie1984 Canada CISCDocument171 pagesCompositeFloorSystems - ChienRitchie1984 Canada CISCMike2322No ratings yet

- Seismic Design of Bridges South East Asia Part 1Document173 pagesSeismic Design of Bridges South East Asia Part 1Mike2322No ratings yet

- Xu - Jian Gong - DissertationDocument341 pagesXu - Jian Gong - DissertationMike2322No ratings yet

- MATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Document195 pagesMATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Mike2322No ratings yet

- ETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMDocument18 pagesETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMMike2322No ratings yet

- AZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFDocument76 pagesAZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFMike2322No ratings yet

- Seismic Design of Bridges Example 7Document62 pagesSeismic Design of Bridges Example 7Mike2322No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Oss Kpi SummaryDocument7 pagesOss Kpi SummaryMohd FaizNo ratings yet

- Clevite Bearing Book EB-40-07Document104 pagesClevite Bearing Book EB-40-07lowelowelNo ratings yet

- Contract 1 ProjectDocument21 pagesContract 1 ProjectAditi BanerjeeNo ratings yet

- Amberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerDocument2 pagesAmberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerJaime SalazarNo ratings yet

- Exam TimetableDocument16 pagesExam Timetablenyarko_eNo ratings yet

- Sample TRM All Series 2020v1 - ShortseDocument40 pagesSample TRM All Series 2020v1 - ShortseSuhail AhmadNo ratings yet

- EceDocument75 pagesEcevignesh16vlsiNo ratings yet

- Development of PBAT Based Bio Filler Masterbatch: A Scientific Research Proposal OnDocument15 pagesDevelopment of PBAT Based Bio Filler Masterbatch: A Scientific Research Proposal OnManmathNo ratings yet

- Perbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota MalangDocument11 pagesPerbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota Malanglely ersilyaNo ratings yet

- Max9924 Max9927Document23 pagesMax9924 Max9927someone elseNo ratings yet

- Volvo HU 803Document8 pagesVolvo HU 803GiegloNo ratings yet

- Chapter 2.2 Quantitative Analysis NewDocument44 pagesChapter 2.2 Quantitative Analysis NewMinase TilayeNo ratings yet

- TOK Assessed Student WorkDocument10 pagesTOK Assessed Student WorkPeter Jun Park100% (1)

- Mortars in Norway From The Middle Ages To The 20th Century: Con-Servation StrategyDocument8 pagesMortars in Norway From The Middle Ages To The 20th Century: Con-Servation StrategyUriel PerezNo ratings yet

- Change LogDocument145 pagesChange LogelhohitoNo ratings yet

- Tournament Rules and MechanicsDocument2 pagesTournament Rules and MechanicsMarkAllenPascualNo ratings yet

- ASM1 ProgramingDocument14 pagesASM1 ProgramingTran Cong Hoang (BTEC HN)No ratings yet

- Video Course NotesDocument18 pagesVideo Course NotesSiyeon YeungNo ratings yet

- Pin Joint en PDFDocument1 pagePin Joint en PDFCicNo ratings yet

- (2016) A Review of The Evaluation, Control and Application Technologies For Drillstring S&V in O&G WellDocument35 pages(2016) A Review of The Evaluation, Control and Application Technologies For Drillstring S&V in O&G WellRoger GuevaraNo ratings yet

- Busbusilak - ResearchPlan 3Document4 pagesBusbusilak - ResearchPlan 3zkcsswddh6No ratings yet

- PERSONAL DEVELOPMENT (What Is Personal Development?)Document37 pagesPERSONAL DEVELOPMENT (What Is Personal Development?)Ronafe Roncal GibaNo ratings yet

- Chapter 3: Verbal Communication SkillsDocument14 pagesChapter 3: Verbal Communication SkillsFares EL DeenNo ratings yet

- Python Cheat Sheet-1Document8 pagesPython Cheat Sheet-1RevathyNo ratings yet

- Unit 1: Power and Responsibility: 1. Important Leadership QualitiesDocument6 pagesUnit 1: Power and Responsibility: 1. Important Leadership QualitiesTrần Thanh MinhNo ratings yet

- Main-A5-Booklet (Spreads) PDFDocument12 pagesMain-A5-Booklet (Spreads) PDFanniyahNo ratings yet

- Ems Speed Sensor Com MotorDocument24 pagesEms Speed Sensor Com MotorKarina RickenNo ratings yet

- The Ins and Outs Indirect OrvinuDocument8 pagesThe Ins and Outs Indirect OrvinusatishNo ratings yet

- Iot Based Garbage and Street Light Monitoring SystemDocument3 pagesIot Based Garbage and Street Light Monitoring SystemHarini VenkatNo ratings yet

- Approximate AnalysisDocument35 pagesApproximate AnalysisSyahir HamidonNo ratings yet