Professional Documents

Culture Documents

Distribution Efficiency Measure

Distribution Efficiency Measure

Uploaded by

Franceli Pascual LeonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distribution Efficiency Measure

Distribution Efficiency Measure

Uploaded by

Franceli Pascual LeonCopyright:

Available Formats

Distribution Operational Efficiency

Productos Innovative Competitive

funcionales Products Factors

Supply Chain

Costos

Efficient

Match

Mismatch 1. Calidad

(Lean) 2. Tiempos de entrega

3. Servicios

Service

Supply Chain

Match

Mismatch

Agile

(Agíl) 2. Calidad

2. Costos

2. Tiempos de entrega

Figure 1. Characteristics of supply chains

This work presents a scheme with the purpose of reducing waste in physical distribution to increase efficiency. It is

suggested to begin the waste elimination strategy with the definition of an extended operational efficiency measure, similar

to the one recommended by Nakajima (1988). This paper consists of five sections. Sections one and two are brief reviews

of the literature on lean distribution. Section 3 introduces the concept of distribution efficiency making the Operational

Equipment Effectiveness (OEE) the base measure. Section 4 presents a structure for the value stream mapping. Section 5

gives a description of the scheme utilized to decrease waste. The application of this scheme is undertaken in section 6 and

section 7 presents conclusions.

2. DISTRIBUTION EFFICIENCY MEASURE

As was previously established, the increase of distribution efficiency is achieved through the elimination of waste. This

process is guided by efficiency measures for transportation and warehousing. These measures are derived from the

principles of Operational Equipment Effectiveness (OEE) used to measure the effective utilization of resources in

manufacturing operations, Nakajima (1988). But, as Scott et al., (1998) have pointed out; the gains in OEE are not enough

because machines are not isolated. This insufficiency of the OEE measure has led to modifications to fit a broader

perspective in the manufacturing systems. For instance, Huang, et al., (2003) suggest the use of the Overall Throughput

Effectiveness (OTE) to estimate effectiveness at factory level and Muchiri, et al., (2007) propose the Overall Asset

Effectiveness (OAE) that is used to identify the losses occurring in the overall production process and a framework for

measuring production losses. This framework considers three levels of effectiveness measurement, the equipment level

effectiveness (based on OEE), the operational level effectiveness using the Total Equipment Effectiveness Performance to

include maintenance downtime and the business level effectiveness measured by the (OAE/OPE). The framework can be

further extended one more level upwards to incorporate the supply chain. At this level, the OAE has to be adapted to

consider not only manufacturing plants; but distribution installations such as warehouses and cross-docking points and

transportation assets such as trucks and railroad equipment.

Transport efficiency was originally suggested by Simmons et al.,(2004). They made the measurement with the Overall

Vehicle Effectiveness (OVE). Similar to the estimation of OEE, were calculated the availability, performance and quality

efficiency factors and multiplied to produce an overall OVE percentage rate. This measure converted the OEE losses from

manufacturing to transport operations. The result was the definition of five transport losses or wastes. These are driver

breaks, excess load time, fill loss, speed loss and quality delays. The previous measure has also been modified by Villarreal,

et al., (2010). In this case, the OVE measure is adapted to consider total calendar time as suggested by Jeong et al., (2001).

This is due to the fact that waste identification and elimination is related to the transportation vehicles utilized to move

product. Since vehicles represent a high investment, it is very important to keep them in operation all the time. Figure 2

illustrates the concepts and losses involved in the proposed measure that is called Total Operational Vehicle Effectiveness

and represented by the term TOVE. In summary, four components for the new efficiency measure are suggested;

Administrative or strategic availability, operating availability, performance and quality. The new measure would be

obtained from the product of administrative availability, operating availability, performance and quality efficiency factors.

279

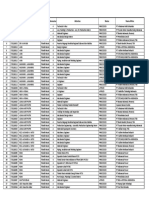

You might also like

- Pizzas Productivity TestDocument4 pagesPizzas Productivity TestJoaquín Amaya García de AcevedoNo ratings yet

- Compiler CAP II Cost AccountingDocument187 pagesCompiler CAP II Cost AccountingEdtech NepalNo ratings yet

- Mahindra Supply ChainDocument14 pagesMahindra Supply ChainDarshak ParikhNo ratings yet

- Chapter 2 Cost Concepts and ClassificationDocument10 pagesChapter 2 Cost Concepts and ClassificationSteffany RoqueNo ratings yet

- Test Bank Chapter 13Document21 pagesTest Bank Chapter 13Jasong75% (4)

- Case Study A Profile of Toyota's Production SystemDocument1 pageCase Study A Profile of Toyota's Production SystemZhen WuNo ratings yet

- MS08 - Activity-Based Costing (Abc) - Total Quality Management (TQM)Document5 pagesMS08 - Activity-Based Costing (Abc) - Total Quality Management (TQM)Elsie GenovaNo ratings yet

- Prasetyaningsih Et Al 2020 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 830 - 032083Document7 pagesPrasetyaningsih Et Al 2020 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 830 - 032083Riezz MauladiNo ratings yet

- Chapter 2 LitratureDocument4 pagesChapter 2 Litraturejondagi85No ratings yet

- Integrated Performance Measurement SystemsDocument7 pagesIntegrated Performance Measurement SystemsFathy TahaNo ratings yet

- Topic 2: Managing Costs - Activity-Based Costing ("ABC") : ACCT2522 Management Accounting For Decision AnalysisDocument58 pagesTopic 2: Managing Costs - Activity-Based Costing ("ABC") : ACCT2522 Management Accounting For Decision AnalysisFreda DengNo ratings yet

- Aalrts Operation, Maintenance and Management Contract Key Performance Indicators (Kpis) ProposalDocument3 pagesAalrts Operation, Maintenance and Management Contract Key Performance Indicators (Kpis) ProposalFNo ratings yet

- Chapter 3Document31 pagesChapter 3mawandeNo ratings yet

- Kpi ObbDocument15 pagesKpi ObbDaniel Aria100% (1)

- Activity Based Costing & Total Quality Management: Topic OutlineDocument12 pagesActivity Based Costing & Total Quality Management: Topic OutlinePrincess Banquil100% (1)

- Estimate of OEE (Overall Equipment Effectiveness) Objective From Classical OEEDocument8 pagesEstimate of OEE (Overall Equipment Effectiveness) Objective From Classical OEEFeliceNo ratings yet

- AF3112 Lec 4 Allocation of Service Department CostsDocument15 pagesAF3112 Lec 4 Allocation of Service Department CostsRoseNo ratings yet

- Volume 4 Issue 3 Paper 1Document10 pagesVolume 4 Issue 3 Paper 1Sabahat SiddiquiNo ratings yet

- Oee PDFDocument5 pagesOee PDFsdvikkiNo ratings yet

- Measuring Performance of SCDocument18 pagesMeasuring Performance of SCKo Gree KyawNo ratings yet

- Experimental Study For Assembly Line Balancing Using Largest Candidate Rule Algorithm in Automoblie Lighting Industries A Case StudyDocument5 pagesExperimental Study For Assembly Line Balancing Using Largest Candidate Rule Algorithm in Automoblie Lighting Industries A Case StudyKenan MuhamedagicNo ratings yet

- Impact of Shift2Rail - A KPI Model For The Entire Railway SystemDocument7 pagesImpact of Shift2Rail - A KPI Model For The Entire Railway SystemKocic GradnjaNo ratings yet

- O & S C M: Recap: The Scope of Operations and Supply Chain Management (OSCM)Document5 pagesO & S C M: Recap: The Scope of Operations and Supply Chain Management (OSCM)Anshul yadavNo ratings yet

- A Framework For Integrating Overall Equipment Effectiveness With Analytic Network Process Method - 2013 - 5p.Document5 pagesA Framework For Integrating Overall Equipment Effectiveness With Analytic Network Process Method - 2013 - 5p.pham ngoc tuanNo ratings yet

- SCM CostsDocument9 pagesSCM CostsArnav VatsNo ratings yet

- Assignment3 ASM Presentation 3 - Vica Putri Nirwanty - 2301982795 - REVIEW PAPERDocument17 pagesAssignment3 ASM Presentation 3 - Vica Putri Nirwanty - 2301982795 - REVIEW PAPERputri999No ratings yet

- Control Charts, Acceptance Sampling Design of Experi-Ments: 1 CRC Press LLCDocument3 pagesControl Charts, Acceptance Sampling Design of Experi-Ments: 1 CRC Press LLCAngie C. JoyaNo ratings yet

- Supply Chain Management:: A Recommended Performance Measurement ScorecardDocument110 pagesSupply Chain Management:: A Recommended Performance Measurement Scorecardsergiobicho1960No ratings yet

- Delivery Performance Measurement in An Integrated Supply Chain Management: Case Study in Batteries Manufacturing FirmDocument16 pagesDelivery Performance Measurement in An Integrated Supply Chain Management: Case Study in Batteries Manufacturing FirmFélicité ramandimbisonNo ratings yet

- A Comprehensive Approach For Maintenance PDFDocument13 pagesA Comprehensive Approach For Maintenance PDFSayed Diab AlsayedNo ratings yet

- Klüberefficiencysupport.: Klüber Lubrication Services - Success For You From One Tool Box!Document16 pagesKlüberefficiencysupport.: Klüber Lubrication Services - Success For You From One Tool Box!Velibor KaranovicNo ratings yet

- Activity-Based Costing Management and Its Implications For Operations Management - M. Gupta, K. Galloway - 2003Document8 pagesActivity-Based Costing Management and Its Implications For Operations Management - M. Gupta, K. Galloway - 2003PacoPicassoNo ratings yet

- Case Study - Supply Chain Management JohDocument9 pagesCase Study - Supply Chain Management JohAzeem AhmadNo ratings yet

- Types of CompetitionDocument15 pagesTypes of Competitionmanojkumar024No ratings yet

- Week 10 S2 LSCM PJJ - Supply Chain PerformanceDocument37 pagesWeek 10 S2 LSCM PJJ - Supply Chain PerformanceI Wayan Cahya PrabawaNo ratings yet

- A Framework To Review Performance Measurement SystemsDocument14 pagesA Framework To Review Performance Measurement SystemsrezasattariNo ratings yet

- Reliability Centred Maintenance For Industrial Use: Significant Advances For The New Millennium J.L. Coetzee and S.J. ClaasenDocument33 pagesReliability Centred Maintenance For Industrial Use: Significant Advances For The New Millennium J.L. Coetzee and S.J. ClaasenManu NascimentoNo ratings yet

- Najmi2005 PDFDocument14 pagesNajmi2005 PDFrezasattariNo ratings yet

- ABC - Food Processing IndustryDocument18 pagesABC - Food Processing IndustryNishant Singh Chauhan100% (1)

- OM Course Handout - 2021-Sec B and FDocument9 pagesOM Course Handout - 2021-Sec B and FLakshmi NairNo ratings yet

- Optimization of Distribution Network With BackhaulDocument9 pagesOptimization of Distribution Network With BackhaulFelix AryaNo ratings yet

- Supplier Evaluation Using AHPDocument62 pagesSupplier Evaluation Using AHPapi-26872269100% (2)

- Ch.2-Evaluating Operational PerformanceDocument21 pagesCh.2-Evaluating Operational PerformanceTiwi PangestiNo ratings yet

- Oee PDFDocument5 pagesOee PDFyuniNo ratings yet

- Measures For Evaluating Supply Chain Performance in Transport LogisticsDocument18 pagesMeasures For Evaluating Supply Chain Performance in Transport LogisticsrezasattariNo ratings yet

- Supply Chain PerformanceDocument38 pagesSupply Chain PerformanceDevie YusdianaNo ratings yet

- 2.2016 Syllabus Paper-15-Oct-2020 Strategic Cost Management - Decision Making Study NotesDocument392 pages2.2016 Syllabus Paper-15-Oct-2020 Strategic Cost Management - Decision Making Study NotesRadhakrishnaraja Ramesh100% (1)

- Evaluation of The Performance AttriDocument6 pagesEvaluation of The Performance AttriPhương Duyên NgôNo ratings yet

- QC2 Paper 06 David Sungkono 2014Document5 pagesQC2 Paper 06 David Sungkono 2014camp bali demakNo ratings yet

- The Applicability of Activity-Based CostingDocument17 pagesThe Applicability of Activity-Based CostingPrasetyoNugrohoNo ratings yet

- QC Benchmarking Report Extract - v88Document12 pagesQC Benchmarking Report Extract - v88Chemist AnnNo ratings yet

- Beneficios y Limitaciones Del Modelo SCOR en AlmacenesDocument6 pagesBeneficios y Limitaciones Del Modelo SCOR en AlmacenesEduardo Cortez OrtegaNo ratings yet

- Integrating Simulation and Optimization Research Into A Graduate Supply Chain Modeling CourseDocument7 pagesIntegrating Simulation and Optimization Research Into A Graduate Supply Chain Modeling CourseChessterNo ratings yet

- ABC Classification Service Levels and Inventory CostsDocument10 pagesABC Classification Service Levels and Inventory CostsFernando GómezNo ratings yet

- The Road To Efficiency and Reliability: ABB Global Consulting and Full ServiceDocument27 pagesThe Road To Efficiency and Reliability: ABB Global Consulting and Full ServiceTeguh PriadiNo ratings yet

- An A LN Implement ChuteDocument6 pagesAn A LN Implement ChuteRieska foni YuniarNo ratings yet

- PDF 18 Dec 12Document8 pagesPDF 18 Dec 12Khtb AshrafNo ratings yet

- Case Study, Optimizing Order Fulfillment in A Global RetailDocument14 pagesCase Study, Optimizing Order Fulfillment in A Global Retailagus ekoNo ratings yet

- Cost OptimizationDocument11 pagesCost Optimizationmexx007No ratings yet

- DVCon Europe 2015 TA1 9 PaperDocument8 pagesDVCon Europe 2015 TA1 9 PaperJon DCNo ratings yet

- Toyota Production SystemDocument2 pagesToyota Production SystemDiwakar BishtNo ratings yet

- Quality in Customer Focused OperationsDocument22 pagesQuality in Customer Focused OperationsQurr'atulaynAlyJaferiNo ratings yet

- How To Select Welded or Seamless Tubing & Pipe, RathGibson, 2010Document0 pagesHow To Select Welded or Seamless Tubing & Pipe, RathGibson, 2010Balamir YasaNo ratings yet

- GMPSADocument6 pagesGMPSAJames TingNo ratings yet

- BJMP2033 Final Ind Assignment Online Questions Oct 2020 Feb 2021Document26 pagesBJMP2033 Final Ind Assignment Online Questions Oct 2020 Feb 2021Carmenn LouNo ratings yet

- Achieving Quality ProductionDocument2 pagesAchieving Quality ProductionOrangess GirlNo ratings yet

- Class 12 Marketing All Chapters CBSE (783) UPDATED September 17-18Document128 pagesClass 12 Marketing All Chapters CBSE (783) UPDATED September 17-18lovellmenezes0% (1)

- Presentation On TPS - JIT KanbanDocument93 pagesPresentation On TPS - JIT KanbanManish RajdevNo ratings yet

- WESCO-NA Program......................Document10 pagesWESCO-NA Program......................kaustubh_dec17No ratings yet

- PM Process Compliance - Self Assessment - v1.0Document4 pagesPM Process Compliance - Self Assessment - v1.0Anuj AhujaNo ratings yet

- No NIM Nama Nama Prodi Semester Aktivitas Status Nama MitraDocument3 pagesNo NIM Nama Nama Prodi Semester Aktivitas Status Nama MitraLoriva Ri avuNo ratings yet

- Centrifugal CastingDocument266 pagesCentrifugal Castinguzairmetallurgist100% (2)

- Bill of MaterialsDocument25 pagesBill of MaterialsIna Pawar100% (1)

- ALPS Application Note - Leak Testing High Speed - Two-Step - Stretch Blow Molded PET Bottles PDFDocument6 pagesALPS Application Note - Leak Testing High Speed - Two-Step - Stretch Blow Molded PET Bottles PDFRafael Calle Napoleon LuisNo ratings yet

- The 5s HousekeepingDocument10 pagesThe 5s HousekeepingdonstonNo ratings yet

- Absorption and Variable Costing Act3Document2 pagesAbsorption and Variable Costing Act3Gill Riguera100% (1)

- Indo German Tool RoomDocument2 pagesIndo German Tool Roomvideopedia tuberNo ratings yet

- EXE Software Outsourcing BrochureDocument4 pagesEXE Software Outsourcing BrochureElena OglindăNo ratings yet

- Applied Economics PPT Module 4Document26 pagesApplied Economics PPT Module 4Jiell Renon VigiliaNo ratings yet

- A C A D e M I C S C I e N C e SDocument4 pagesA C A D e M I C S C I e N C e SEllisaTanNo ratings yet

- Lean ManufacturingDocument26 pagesLean ManufacturingSalim EchbarbiNo ratings yet

- Lean Rolling Stock MaintenanceDocument34 pagesLean Rolling Stock MaintenanceJoaquim Reis100% (1)

- Traceability TrainingDocument62 pagesTraceability TrainingJohnson Gitonga NderiNo ratings yet

- Chapter 6 - Product and Service StrategiesDocument32 pagesChapter 6 - Product and Service StrategiesralphalonzoNo ratings yet

- Cost of Quality in Healthcare: A Case Study in A Clinical LaboratoryDocument14 pagesCost of Quality in Healthcare: A Case Study in A Clinical LaboratoryEllamtouny IhssaneNo ratings yet

- Basic Sample TestDocument20 pagesBasic Sample TestLokesh NarasimhaiahNo ratings yet