Professional Documents

Culture Documents

Toolbox Talk Welding and Metal Work Safety

Uploaded by

Ainnul Dan Aishah0 ratings0% found this document useful (0 votes)

305 views2 pagesN/A

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentN/A

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

305 views2 pagesToolbox Talk Welding and Metal Work Safety

Uploaded by

Ainnul Dan AishahN/A

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Toolbox Safety Talk

Welding & Metal Work Safety

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures, and requires

a correspondingly wide range of skills, processes, and tools. Modern metalworking processes, though diverse and specialized,

can be categorized as forming, cutting or joining processes. Metal working is an essential resource throughout the University,

providing Cornell with infrastructure improvements and opportunities for advanced research. Today's machine shop includes a

number of machine tools capable of creating a precise, useful metal workpiece. Although metal work provides an important

service to the campus, it also provides unique hazards as well.

General Metal Work Safety

• All equipment operators and shop personnel shall be trained on safe operation.

• Operators shall inspect machinery before and after use for any defects.

• Point of Operations Guarding MUST be in place and used at all times.

• Eye protection shall be worn at all times.

• Always wear correct personal protective equipment (PPE) pertaining to the job task.

• Remove or secure jewelry, long hair, and loose clothing.

• Avoid skin contact with metalworking fluids.

• When possible, always use a well mounted vice to grip work.

• Remove all scraps of metal with a brush, NEVER by hand or with an air compressor gun.

• Always receive authorization before working with reactive or harmful emission giving metals.

Welding Safety

When welding outside of a designated welding booth, ensure that a University hot work permit is completed and adequate

safeguards are in place to prevent fire and personal injury. Avoid welding on materials such as galvanized or stainless steel in

order to minimize toxic fume exposure. Always utilize mechanical exhaust ventilation while welding.

Arc Welding Safety

• Make sure the work and /or work table is properly grounded.

• Inspect your work area thoroughly before beginning. DO NOT arc weld if it is damp or substances have a

potential to ignite.

• Turn the arc welder off before removing any grounds from the table or material.

• DO NOT arc weld with skin unprotected. The arc light acts as Ultraviolet light and will cause something

comparable to sunburn.

• Avoid clothing that has pockets, or spaces where hot embers may fall into.

Oxygen Fuel Gas Welding/ Cutting

• All compressed gas cylinders should be clearly marked, and appropriately stored.

• Check all connections and hoses for leaks. Remove defective equipment from service.

• If using acetylene, keep the pressure below 15 pounds.

• Purge your hoses before lighting the torch.

• Never light your torch with a mixture of fuel and oxygen. After purging the lines, light the torch with only the fuel

gas valve open.

• Check valves should be installed on both torch inlets and operating properly. Check valves can stop the reverse

flow of gases, but will not prevent flashbacks.

• To prevent flashbacks, flashback arrestors must be installed on the outlets of both regulators, and/or torch inlets.

For more information on metal working, welding, or machine shop safety, visit www.ehs.cornell.edu or call EH&S at 255-8200.

Environmental Health & Safety

Facilities Safety & Health Section Please return sign-in sheet to

395 Pine Tree Rd. Suite 210 Environmental Health & Safety

Ithaca, NY 14850 for recordkeeping.

607.255.8200

8.29.11

Toolbox Safety Talk

Welding & Metal Work Safety

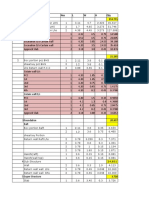

Date:____________________ Start Time: ____________________ End Time: ____________________

Location:_____________________________________________________________________________

Presenter Name:_______________________________________________________________________

PRINT NAME NET ID DEPARTMENT SIGNATURE

Environmental Health & Safety

Facilities Safety & Health Section Please return sign-in sheet to

395 Pine Tree Rd. Suite 210 Environmental Health & Safety

Ithaca, NY 14850 for recordkeeping.

607.255.8200

8.29.11

You might also like

- Toolbox Talk - Workshop Safety General RulesDocument3 pagesToolbox Talk - Workshop Safety General Rules260380sdNo ratings yet

- Gas Welding SafetyDocument31 pagesGas Welding SafetyKavipriyan KaviNo ratings yet

- Toolbox Talk CylindersDocument1 pageToolbox Talk CylindersAdel SukerNo ratings yet

- Underwater WeldingDocument5 pagesUnderwater WeldingGourang PaulNo ratings yet

- Welding Oxy A4Document2 pagesWelding Oxy A4LoveNo ratings yet

- ShacklesDocument10 pagesShacklesMuhammad Shahid Mahmood100% (1)

- 11 - Job Safety Analysis ProcedureDocument11 pages11 - Job Safety Analysis ProcedureMohammed MinhajNo ratings yet

- Fire Extinguisher Training: Health, Safety & Environment DeptDocument33 pagesFire Extinguisher Training: Health, Safety & Environment DeptRosano D. ManamtamNo ratings yet

- Opening and closing gas cutting equipmentDocument11 pagesOpening and closing gas cutting equipmentJebaraj VNo ratings yet

- TBTDocument10 pagesTBTSayed Saad ShehataNo ratings yet

- Working at Heights ProcedureDocument26 pagesWorking at Heights ProcedureardodotNo ratings yet

- Oxy Fuel Cutting PDFDocument28 pagesOxy Fuel Cutting PDFruhul01No ratings yet

- Welding Toolbox Talk FinalDocument17 pagesWelding Toolbox Talk FinalAdeAryadewanataNo ratings yet

- Safe Operating Procedure: Pinch PointsDocument1 pageSafe Operating Procedure: Pinch PointsAndri IrawanNo ratings yet

- Asim CVDocument2 pagesAsim CVShahzeb HassanNo ratings yet

- Job Hazard Analysis Welding & Cutting Operations: Reference: OSHA Standard 29 CFR 1926.350, Subpart J, Welding & CuttingDocument1 pageJob Hazard Analysis Welding & Cutting Operations: Reference: OSHA Standard 29 CFR 1926.350, Subpart J, Welding & CuttingRio de MarioNo ratings yet

- Formulation of Accident Prevention ProgrammeDocument24 pagesFormulation of Accident Prevention ProgrammeCHANDUNo ratings yet

- CTS Welder (Welding and Inspection) - NSQFDocument34 pagesCTS Welder (Welding and Inspection) - NSQFgarden00589No ratings yet

- Mechanical Job Hazard Analysis Name of The Job: WELDING JOBDocument1 pageMechanical Job Hazard Analysis Name of The Job: WELDING JOBbrandybuckNo ratings yet

- Tools - Hand and Power: OSHA Office of Training and Education 1Document35 pagesTools - Hand and Power: OSHA Office of Training and Education 1HeatherNo ratings yet

- Aromatics Project: Mobile Telephone PolicyDocument2 pagesAromatics Project: Mobile Telephone Policypl_rajaNo ratings yet

- RFSSB-EHS-P-004 HIRARC Procedure PDFDocument4 pagesRFSSB-EHS-P-004 HIRARC Procedure PDFNajman HamdiNo ratings yet

- JSA Arc WeldingDocument2 pagesJSA Arc WeldinganeshseNo ratings yet

- Cold Work PermitDocument11 pagesCold Work PermitMuneeb Ur Rehman100% (1)

- DCL (Logo) : Hand BookDocument16 pagesDCL (Logo) : Hand BookJahangir ShaNo ratings yet

- Business Procedure: Welding SafetyDocument10 pagesBusiness Procedure: Welding Safetylucky414No ratings yet

- Welding SopDocument7 pagesWelding Sopttdost0% (1)

- Gas Cylinders - Storage and Handling PDFDocument1 pageGas Cylinders - Storage and Handling PDFcityofdarwingisNo ratings yet

- Precautions for Semi-Automatic and Automatic WeldingDocument8 pagesPrecautions for Semi-Automatic and Automatic WeldingFaiz IshakNo ratings yet

- Week 34-Cell Phone PolicyDocument1 pageWeek 34-Cell Phone Policypl_rajaNo ratings yet

- UHP Spec Essentials Rev2 PDFDocument17 pagesUHP Spec Essentials Rev2 PDFfaisal abbasNo ratings yet

- Welding ProcedureDocument7 pagesWelding Proceduredương_thành_28No ratings yet

- GTC Gas Technical GuidelinesDocument36 pagesGTC Gas Technical Guidelinesn67250No ratings yet

- HSE Officer Interview Q & ADocument6 pagesHSE Officer Interview Q & Aတိုး ေဝ ေအာင္No ratings yet

- Crane SafetyDocument2 pagesCrane SafetySayed DarwishNo ratings yet

- Violation Report FormDocument1 pageViolation Report FormEleonor MaderazoNo ratings yet

- Safety Inspections How To Conduct and Document Safety InspectionsDocument14 pagesSafety Inspections How To Conduct and Document Safety InspectionsZaiShinNo ratings yet

- Scaffolding Hazard PreventionDocument2 pagesScaffolding Hazard PreventionRavikant PandeyNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Toolbox EngDocument42 pagesToolbox Engventodelsud83100% (2)

- JSA For KAHSDocument6 pagesJSA For KAHSFrancis Enriquez TanNo ratings yet

- Lightning Brochure18Document2 pagesLightning Brochure18Matt GunnNo ratings yet

- BÖHLER (MSDS) SMAW-AVESTA 2205 E2209-15 Expires 15-12-05Document2 pagesBÖHLER (MSDS) SMAW-AVESTA 2205 E2209-15 Expires 15-12-05PubcrawlNo ratings yet

- Gas Welding and Cutting Safety PDFDocument55 pagesGas Welding and Cutting Safety PDFGnanasekaran MNo ratings yet

- Working From Heights Wooden PolesDocument31 pagesWorking From Heights Wooden PolesJose OrtegaNo ratings yet

- Welding and Gas Cutting - by NRCDocument58 pagesWelding and Gas Cutting - by NRCAshish Patel100% (1)

- JSA Excavation for Sabkha Water Filling StationDocument5 pagesJSA Excavation for Sabkha Water Filling StationDelta akathehuskyNo ratings yet

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDocument18 pagesJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- JHA Arc WeldingDocument2 pagesJHA Arc WeldingechaNo ratings yet

- Welding SequenceDocument8 pagesWelding SequenceErlinawati Bintu SupiyoNo ratings yet

- Safety Do's and Don'tDocument29 pagesSafety Do's and Don'ttulluricharanNo ratings yet

- SAFETY IN GAS WELDING, CUTTINGDocument16 pagesSAFETY IN GAS WELDING, CUTTINGAnonymous dvrhf5No ratings yet

- Learn Oxy-Fuel Cutting FundamentalsDocument14 pagesLearn Oxy-Fuel Cutting Fundamentalskevin mundaNo ratings yet

- Window Cleaning Safety GuidelineDocument4 pagesWindow Cleaning Safety Guidelinejhunvalencia1203No ratings yet

- Oxyacetylene CuttingDocument24 pagesOxyacetylene CuttingTan Chin TeeNo ratings yet

- AEC 200-4C: Solid State Spoolgun & Control Operation and Parts ManualDocument12 pagesAEC 200-4C: Solid State Spoolgun & Control Operation and Parts ManualdzzmikeNo ratings yet

- Industrial Safety Engineering 4.1Document10 pagesIndustrial Safety Engineering 4.1Jayakrishnan JkNo ratings yet

- Tig200ac DCDocument41 pagesTig200ac DCTallerSoldaduraAluminioInoxidableNo ratings yet

- Lincoln CV400 PDFDocument15 pagesLincoln CV400 PDFosamaNo ratings yet

- Motor StirlingDocument15 pagesMotor Stirlingcarlos caizaNo ratings yet

- Hydac Ball ValvesDocument6 pagesHydac Ball ValvesSamad A BakarNo ratings yet

- Dumpschema - LPGP C ENTITYDocument57 pagesDumpschema - LPGP C ENTITYSreenu VasuNo ratings yet

- BroadHop AlarmingAndSNMP QNS5 3 1.1Document56 pagesBroadHop AlarmingAndSNMP QNS5 3 1.1ahmedsabryraghebNo ratings yet

- Mechanical Characterization of 3D Printable Concrete PDFDocument12 pagesMechanical Characterization of 3D Printable Concrete PDFManu K MohanNo ratings yet

- EMCP II Testing and AdjustmentDocument208 pagesEMCP II Testing and AdjustmentAllen AnyayahanNo ratings yet

- K1000 Agent Release NotesDocument6 pagesK1000 Agent Release NotesChail MiNo ratings yet

- A Scheduling Approach For Ship Design Project With Fields Constraint in Tasks and Human ResourcesDocument6 pagesA Scheduling Approach For Ship Design Project With Fields Constraint in Tasks and Human ResourcesavciahmNo ratings yet

- Mitsubishi Lifts BrochureDocument28 pagesMitsubishi Lifts Brochurenaveenarora298040No ratings yet

- Assignment-1 EE-2101: Name:-Hage Nobin Roll no.-B/19/EE/036 Date of Submission-30/10/2020Document4 pagesAssignment-1 EE-2101: Name:-Hage Nobin Roll no.-B/19/EE/036 Date of Submission-30/10/2020x caliber10No ratings yet

- Sizing a Flare Stack and Calculating Flame Distortion from Wind VelocityDocument49 pagesSizing a Flare Stack and Calculating Flame Distortion from Wind VelocityBayu AjipNo ratings yet

- High-performance Bosch Solar Module c-Si P 60Document2 pagesHigh-performance Bosch Solar Module c-Si P 60leo_152842979No ratings yet

- Connection - IDEA StatiCa PDFDocument18 pagesConnection - IDEA StatiCa PDFDaniel TuerosNo ratings yet

- TWS Wheels ENGDocument12 pagesTWS Wheels ENGRaul MorenoNo ratings yet

- Regular Languages and Finite Automata: Lecture Notes OnDocument56 pagesRegular Languages and Finite Automata: Lecture Notes Onchandu903No ratings yet

- Manual-Humdinger Concrete Vibrator 20151126 UKDocument20 pagesManual-Humdinger Concrete Vibrator 20151126 UKValentin NiculaeNo ratings yet

- CSE Application ChecklistDocument4 pagesCSE Application ChecklistArfan HaiderNo ratings yet

- Pre Engineered BLD System PDFDocument104 pagesPre Engineered BLD System PDFSumanthNo ratings yet

- Analysis Based On 15-16 SORDocument195 pagesAnalysis Based On 15-16 SORAjay SaikumarNo ratings yet

- SJ-20100510160815-008-ZXSDR BTS&Node B (V4.09.21) Performance Counter Reference - 325875Document413 pagesSJ-20100510160815-008-ZXSDR BTS&Node B (V4.09.21) Performance Counter Reference - 325875sndi1765100% (1)

- Marine & Offshore Safety ProductsDocument40 pagesMarine & Offshore Safety ProductsJose Manuel Jose ManuelNo ratings yet

- Difusión en Una Partícula Esférica Con Reacción HomogéneaDocument6 pagesDifusión en Una Partícula Esférica Con Reacción HomogéneaCleider Ciniva100% (1)

- SDN and OpenFlow For Beginners With Hands On LabsDocument17 pagesSDN and OpenFlow For Beginners With Hands On LabstiwarigNo ratings yet

- Sr. No. Description Material Grade Length (MM) Weight (KG)Document4 pagesSr. No. Description Material Grade Length (MM) Weight (KG)Shriniwas NaikNo ratings yet

- Alkali Boil OutDocument5 pagesAlkali Boil OutprithwichandraNo ratings yet

- 160 88-CL2Document6 pages160 88-CL2vanthe140591No ratings yet

- Game Console - Graphics Team - Bibliographic ReportDocument42 pagesGame Console - Graphics Team - Bibliographic ReportneslouNo ratings yet

- 10 1 1 130 6862 PDFDocument515 pages10 1 1 130 6862 PDFRahmania NiaphysicsNo ratings yet

- Limiting FactorDocument4 pagesLimiting FactorVanesh Thakur0% (2)

- Scientific American 1962-02-01Document196 pagesScientific American 1962-02-01Ezequiel BrasilNo ratings yet