Professional Documents

Culture Documents

Forklift Pre Start Checklist

Uploaded by

Connie RodriguezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Forklift Pre Start Checklist

Uploaded by

Connie RodriguezCopyright:

Available Formats

Forklift Pre Start Checklist

Pre start checklist is to be completed every day prior to using the equipment. Operator is to initial when

inspected, Supervisor is to review the checklist and sign off at the end of each week.

Seat Belts to be worn where fitted.

Forklift Type............................................................ Forklift Number.......................................................................

Date (Week Commencing Mon).............................

M T W T F S S

Initials of person doing inspection

Tick if item is acceptable, cross if it is not

TYRES – check they are in good condition, intact with rim. Look for visual

wear or damage. Check tyre pressure

FLUIDS – check oil, hydraulics, battery, fuel and coolant for leaks including

hoses under fork lift

STRUCTURE – check for cracks, bends, dents, distortion or broken parts.

Check apron & overhead guards are intact & secure

TINES/FORKS – check they are evenly spread with locking pins in place.

Check there is no sharp edges or distortion

MAST – check chains are level with no obstructions, rams not pitted or

leaking. Check for any wear to lift chains and guides, inspect hydraulic

cylinders, look for any leaks

BATTERY – check it is operational and for any damage

BATTERY CHARGE – discharge meter in full green or 75% after raising forks

(where applicable)

GAS OPERATED FORKS – check gas levels are ok and gas cylinder is not

damaged damage. Check gas cylinder is secure

ENGINE BAY – check it is generally clean?

Hydraulic oil-brake pads and brake fluid (cb machines only).

CONTROLS (pre start) – check seat condition. Check controls are clearly

marked, seat & steering wheel are secure & properly adjusted. Seat belt

(where fitted) works as intended.

CONTROLS (post start) – check controls and pedals are working. No unusual

noises.

CAPACITY/LOAD PLATE – check load-capacity plate if fitted, legible and

correct. What is your safe working load (inc when travelling, tilted & lifting)?

REVERSE BUZZER & HORN – check working

LIGHTS & BEACON – check working

STEERING – check smooth from lock to lock, no binding

BRAKES – check both brake & park brake for proper operation

SAFTEY PEDAL – check the motor cuts out

POWER DISCONNECT – check all electric power cuts out

HYDRAULICS – Operate lift, tilt & reach to full extent of travel

GUARDS – check overhead, load backrest

ATTACHMENTS – check they function correctly, no unusual noises

If any items above are not working, the forklift is to be tagged out and reported to the supervisor for repair.

Description of Issue………………………………………………………………………………………………………………

Date and time tagged out:….…………………… Tagged out by:…………………….. Returned To Service:………….

Weekly Supervisor sign off………………………………………………….

You might also like

- CCO Prep CourseDocument10 pagesCCO Prep CourseJuanCarlosNo ratings yet

- Heavy Equipment Operator: Passbooks Study GuideFrom EverandHeavy Equipment Operator: Passbooks Study GuideNo ratings yet

- Harrington Ner Er Hoist Manual Parts ListDocument143 pagesHarrington Ner Er Hoist Manual Parts ListliftNo ratings yet

- Owner'S Manual: Installation, Operation, Maintenance & PartsDocument152 pagesOwner'S Manual: Installation, Operation, Maintenance & PartsJose RamosNo ratings yet

- Diesel MechanicDocument23 pagesDiesel MechanicAtif MahmoodNo ratings yet

- 2013 Zerostart CatalogDocument96 pages2013 Zerostart CatalogPaulo CardosoNo ratings yet

- Commercial Vehicles Air Brake AdjustmentDocument14 pagesCommercial Vehicles Air Brake Adjustmentarstjunk100% (1)

- 10 Speed Shift PatternDocument1 page10 Speed Shift PatternasdasdNo ratings yet

- Forklift ChecklistDocument4 pagesForklift ChecklistPrabhakar TripathiNo ratings yet

- Operator's ManualDocument144 pagesOperator's ManualCesar MarquesNo ratings yet

- Used Vehicle Inspection ChecklistDocument1 pageUsed Vehicle Inspection ChecklistGloffFordNo ratings yet

- TECE02SM0000Document364 pagesTECE02SM0000Paul MartinNo ratings yet

- Product Recommendation Caterpillar Forklift Trucks, Diesel V225B PDFDocument2 pagesProduct Recommendation Caterpillar Forklift Trucks, Diesel V225B PDFConnie RodriguezNo ratings yet

- Product Recommendation Caterpillar Forklift Trucks, Diesel V225B PDFDocument2 pagesProduct Recommendation Caterpillar Forklift Trucks, Diesel V225B PDFConnie RodriguezNo ratings yet

- How To Implement A Fleet Preventative Maintenance Plan: An Interactive ChecklistDocument3 pagesHow To Implement A Fleet Preventative Maintenance Plan: An Interactive ChecklistJonathan Fox100% (1)

- PG 049-061 PDFDocument13 pagesPG 049-061 PDFfilkeNo ratings yet

- Operator's Manual: ERIES 1000Document40 pagesOperator's Manual: ERIES 1000Mark PhillipsNo ratings yet

- Fifth Wheel Coupling and Uncoupling ProceduresDocument3 pagesFifth Wheel Coupling and Uncoupling ProceduresAbrar HussainNo ratings yet

- 19 Vehicle Checklist & Fault Reporting FormDocument2 pages19 Vehicle Checklist & Fault Reporting Formfirdaus100% (1)

- Articulated Boom Truck Student ManualDocument35 pagesArticulated Boom Truck Student ManualErc Nunez VNo ratings yet

- Heavy Equipment MechanicDocument2 pagesHeavy Equipment Mechanicapi-77182490No ratings yet

- Vehicle Service History RecordsDocument53 pagesVehicle Service History Recordsbetelhem ermiasNo ratings yet

- Vehicle Maintenance Log: Make: KIA Model: PEGAS Year: 2022 Vehicle ID Number: Engine: Total Cost: 0Document2 pagesVehicle Maintenance Log: Make: KIA Model: PEGAS Year: 2022 Vehicle ID Number: Engine: Total Cost: 0sampath sunkojiNo ratings yet

- Air Brake ManualDocument94 pagesAir Brake Manualfreeemeee.now130No ratings yet

- 181 1275 14 PDFDocument32 pages181 1275 14 PDFbleexbloxNo ratings yet

- Safety & Maintenance ProgramDocument36 pagesSafety & Maintenance ProgramRaminder SinghNo ratings yet

- Text Slide: Truck and Trailer Inspection WorkshopDocument39 pagesText Slide: Truck and Trailer Inspection WorkshopFatih D. PrasetioNo ratings yet

- Auto Maintenance Tools - 2Document13 pagesAuto Maintenance Tools - 2eber granados100% (1)

- TYm Tractors Operators Manuals - Team Tractor and Equipment, ArizonaDocument58 pagesTYm Tractors Operators Manuals - Team Tractor and Equipment, ArizonaAnastasiya DorfmanNo ratings yet

- Cranes Hoists Truck CranesDocument26 pagesCranes Hoists Truck Cranesrajesh_jeev100% (1)

- DS350 1319 OperatorsDocument48 pagesDS350 1319 OperatorsHusa Gomez100% (1)

- Avon Manual 320DL 2 StrokeDocument47 pagesAvon Manual 320DL 2 Strokevelocis20360% (1)

- Manual de Parte y Operacion Allanadoras ALLENDocument108 pagesManual de Parte y Operacion Allanadoras ALLENjbarrios960100% (1)

- Trico Product Catalog 2005Document87 pagesTrico Product Catalog 2005efraimmp100% (1)

- Honda GXV 140 - 135cm3Document12 pagesHonda GXV 140 - 135cm3Dejan Brdjovic100% (1)

- 246BDocument16 pages246BNelson Vejar Saez100% (3)

- Allen Bradley Catalog Wiring SystemsDocument189 pagesAllen Bradley Catalog Wiring SystemsAlphaNo ratings yet

- Sample Medium Maintenance PlanDocument20 pagesSample Medium Maintenance PlanPatrick PhoenixNo ratings yet

- 15K psi ES BOP ManualDocument39 pages15K psi ES BOP ManualEl Mundo De Yosed100% (1)

- Checklist Mobil Crane PT NusakuraDocument6 pagesChecklist Mobil Crane PT NusakuraArisNo ratings yet

- DKAKPLDRDocument36 pagesDKAKPLDRCarlos Mezt100% (1)

- Driver Training Strategies: An Educational Webcast Sponsored byDocument54 pagesDriver Training Strategies: An Educational Webcast Sponsored byJunaid QamerNo ratings yet

- Installation & Operational Manual Model D6080 27k Hydraulic Cart LifterDocument45 pagesInstallation & Operational Manual Model D6080 27k Hydraulic Cart Lifterstainless31620039126No ratings yet

- Bradco 625 Trencher ManualDocument107 pagesBradco 625 Trencher ManualAnonymous zSpR5jUdNo ratings yet

- 3.5 to 5.0 ton Gasoline and Diesel Engine Lift TrucksDocument6 pages3.5 to 5.0 ton Gasoline and Diesel Engine Lift TrucksVương HoàngNo ratings yet

- T11 4WD Service Manual PDFDocument40 pagesT11 4WD Service Manual PDFAxlesNo ratings yet

- Model SLT30/35 AC Operator's Manual: Landoll CorporationDocument64 pagesModel SLT30/35 AC Operator's Manual: Landoll CorporationChristian BedoyaNo ratings yet

- Trailer Service Checklist: LightsDocument4 pagesTrailer Service Checklist: LightsYusuf JosephNo ratings yet

- APX Mobile Accessory FinalDocument12 pagesAPX Mobile Accessory FinalbreaserNo ratings yet

- Equipment Lease GoodDocument7 pagesEquipment Lease GoodJaqui Mugge HewettNo ratings yet

- Vehicle Maintenance 6Document26 pagesVehicle Maintenance 6aravNo ratings yet

- Heavy Duty Equipment MechanicsDocument2 pagesHeavy Duty Equipment MechanicsFranco Alberi0% (1)

- Motorcycle Inspection ReportDocument2 pagesMotorcycle Inspection Reportsergiut67% (3)

- SportJet Pump Pinion Location Tools Bulletin No. 2006-21Document2 pagesSportJet Pump Pinion Location Tools Bulletin No. 2006-21Kevin ScogginsNo ratings yet

- Everything You Need to Know About Powerhead Specifications and RepairDocument30 pagesEverything You Need to Know About Powerhead Specifications and RepairBaxter LoachNo ratings yet

- Aeg MotorsDocument62 pagesAeg Motorsndakota1987100% (2)

- Dobdsm971 PDFDocument25 pagesDobdsm971 PDFTecknobites VallenarNo ratings yet

- Pro Torque CatalogDocument230 pagesPro Torque CatalogjitmarineNo ratings yet

- Used Car Inspection Checklist - Driver's Auto MartDocument1 pageUsed Car Inspection Checklist - Driver's Auto MartBleep NewsNo ratings yet

- Electrical and Ignition: Battery, Charging and Starting SystemDocument15 pagesElectrical and Ignition: Battery, Charging and Starting SystemBaxter LoachNo ratings yet

- Al To Standard Clutch CatalogDocument136 pagesAl To Standard Clutch Catalogrobertoperez525No ratings yet

- HOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckDocument3 pagesHOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckRPaivaNo ratings yet

- 1 DX450 SCT Leaflet en W3636Document4 pages1 DX450 SCT Leaflet en W3636Jonathan Alexis Quispe HuamaniNo ratings yet

- OSHA ChecklistDocument2 pagesOSHA ChecklistCésar Augusto Quiroga MontenegroNo ratings yet

- Requirements For Checklists Before Putting A Forklift Into UseDocument11 pagesRequirements For Checklists Before Putting A Forklift Into UsekasivisanadhNo ratings yet

- 1081 Tapping A Pipeline (Tap Diameter 2 Inch and Less) Ver 2.2Document3 pages1081 Tapping A Pipeline (Tap Diameter 2 Inch and Less) Ver 2.2Connie RodriguezNo ratings yet

- 0111 Maintain Rectifier Ver 2.2Document4 pages0111 Maintain Rectifier Ver 2.2Connie RodriguezNo ratings yet

- 0601 NDT-Radiographic Ver 2.1Document2 pages0601 NDT-Radiographic Ver 2.1Connie RodriguezNo ratings yet

- 0111 Maintain Rectifier Ver 2.2Document4 pages0111 Maintain Rectifier Ver 2.2Connie RodriguezNo ratings yet

- 0831 Cast-Iron Leak Clamps Ver 2.1Document3 pages0831 Cast-Iron Leak Clamps Ver 2.1Connie RodriguezNo ratings yet

- Offshore and Onshore Pipeline SolutionsDocument11 pagesOffshore and Onshore Pipeline SolutionsVegaGonzalezNo ratings yet

- GasDocument242 pagesGasConnie RodriguezNo ratings yet

- 1291 Locate Underground Pipeline Ver 2.5Document3 pages1291 Locate Underground Pipeline Ver 2.5Connie RodriguezNo ratings yet

- Cat Lift Trucks Daily Inspection ChecklistDocument1 pageCat Lift Trucks Daily Inspection ChecklistConnie RodriguezNo ratings yet

- BoltDocument13 pagesBoltMohd Fakhruddin Basar100% (1)

- Assessment of Quality On Electrofusion Joints: The Stripe Bend TestDocument5 pagesAssessment of Quality On Electrofusion Joints: The Stripe Bend TestConnie RodriguezNo ratings yet

- Calculation of Design Exa of HDPE PenstockDocument29 pagesCalculation of Design Exa of HDPE PenstockZainNo ratings yet

- GAS VALVES AND FITTINGS SPECIALISTDocument49 pagesGAS VALVES AND FITTINGS SPECIALISTConnie RodriguezNo ratings yet

- Teaching of ASME IX Code To Students of GTAW, GMAW/FCAW, SMAW and SAW Welding ProcessesDocument5 pagesTeaching of ASME IX Code To Students of GTAW, GMAW/FCAW, SMAW and SAW Welding ProcessesConnie RodriguezNo ratings yet

- 06 Glenn Allen2 - TWI PDFDocument25 pages06 Glenn Allen2 - TWI PDFConnie RodriguezNo ratings yet

- EY Guia Oil Gas 2017 2018Document136 pagesEY Guia Oil Gas 2017 2018Cristian MedinaNo ratings yet

- 2011-6 TechPresentation SperkoDocument46 pages2011-6 TechPresentation SperkoConnie RodriguezNo ratings yet

- Guidelines For Gas Metal Arc Welding (GMAW)Document20 pagesGuidelines For Gas Metal Arc Welding (GMAW)Dhidic MoE'sanNo ratings yet

- Handbook PDFDocument55 pagesHandbook PDFConnie RodriguezNo ratings yet

- 2011-6 TechPresentation SperkoDocument46 pages2011-6 TechPresentation SperkoConnie RodriguezNo ratings yet

- Recover OmniSwitch from USB in Uboot or MinibootDocument2 pagesRecover OmniSwitch from USB in Uboot or Minibootcuong9550% (1)

- To Study The Hydraulic Bench and Accessories.Document3 pagesTo Study The Hydraulic Bench and Accessories.M Shoaib AfzalNo ratings yet

- PracticalElectronics1967Oct TextDocument84 pagesPracticalElectronics1967Oct Textdonkey slapNo ratings yet

- RS-232 Communications wiring DiagramDocument1 pageRS-232 Communications wiring DiagramwarwarNo ratings yet

- Metalclad Plus™: Range IntroductionDocument3 pagesMetalclad Plus™: Range IntroductionMasterGNo ratings yet

- Ed71-440b (Vkm50-100ga (M) V1) PDFDocument116 pagesEd71-440b (Vkm50-100ga (M) V1) PDFHari GoenawanNo ratings yet

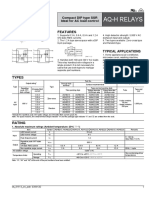

- Aq-H Relays: FeaturesDocument3 pagesAq-H Relays: Featuresmarcio carvalhoNo ratings yet

- Embedded System in PrinterDocument15 pagesEmbedded System in PrinterSuraaj Sakthi Kumar100% (1)

- Shop Practice Number 4Document9 pagesShop Practice Number 4JantzenCaliwliwNo ratings yet

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsNo ratings yet

- IIN ND DU Ussttr Riia ALL: RF HeatingDocument4 pagesIIN ND DU Ussttr Riia ALL: RF Heatingvrozic00No ratings yet

- Nissan Qashqai J11. Instruction - Part 657Document5 pagesNissan Qashqai J11. Instruction - Part 657Schalekis GeorgeNo ratings yet

- GNV1792S DatasheetDocument23 pagesGNV1792S DatasheetSuper ManNo ratings yet

- EEE 1: Essentials of Electrical and Electronics Engineering: Lecture 0: Lab FamiliarizationDocument18 pagesEEE 1: Essentials of Electrical and Electronics Engineering: Lecture 0: Lab FamiliarizationAverly Jerryl EscotoNo ratings yet

- Mono 440 Wp Twin 144 half-cells module analysisDocument1 pageMono 440 Wp Twin 144 half-cells module analysisMAHINDRA CHOUDHARY 18210048No ratings yet

- Tailoring NC II Multiple Choice PracticeDocument13 pagesTailoring NC II Multiple Choice PracticeJe-ann H. GonzalesNo ratings yet

- Room Air Conditioner: Service ManualDocument69 pagesRoom Air Conditioner: Service ManualAnonymous CbrNEsjJNo ratings yet

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocument1 pageChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimNo ratings yet

- Systems Physical Planning GuideDocument42 pagesSystems Physical Planning GuideEugene EzekielNo ratings yet

- Bergamont Workbook LJ AccesoiresDocument3 pagesBergamont Workbook LJ Accesoiresapi-652055634No ratings yet

- FAN7529 (IC601) - Datasheet IIDocument20 pagesFAN7529 (IC601) - Datasheet IIJose BenavidesNo ratings yet

- LP008Document20 pagesLP008Rojas RudyNo ratings yet

- Condensate Recovery Pump: ModelDocument2 pagesCondensate Recovery Pump: ModelCTHNo ratings yet

- 0.5-V Input Digital LDO With 98.7% Current Efficiency and 2.7-ΜA Quiescent Current in 65nm CMOSDocument4 pages0.5-V Input Digital LDO With 98.7% Current Efficiency and 2.7-ΜA Quiescent Current in 65nm CMOSKarim H. MohamedNo ratings yet

- Fact Sheet - VolvoDocument2 pagesFact Sheet - VolvoMihai AncutaNo ratings yet

- Model K-P3 China Models: (Machine Code: G091-69, - 21, - 20)Document118 pagesModel K-P3 China Models: (Machine Code: G091-69, - 21, - 20)william lozadaNo ratings yet