Professional Documents

Culture Documents

PTR-390 Hydrostatic Pressure Test

Uploaded by

HUSHIKESHCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTR-390 Hydrostatic Pressure Test

Uploaded by

HUSHIKESHCopyright:

Available Formats

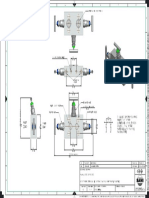

Product Test Report PTR-390

Swagelok Company Ver 05

29500 Solon Road November 2018

Solon, Ohio 44139 U.S.A. Page 1 of 4

TITLE

Hydrostatic Pressure Test of Swagelok® Tube Fittings with 1 Turn and 3/4 Turn of Fitting Nut

Assembly on Normal to Extra-Hard Tubing with Tubing Bottomed and Not Bottomed

PRODUCT TESTED

The following bar stock and forged body Swagelok tube fittings were tested with 316 stainless steel

seamless tubing.

Tubing

Ordering Tubing Hardness

Number Part Form Size HRB

Fractional, in.

SS-400-1-4 Bar stock 81 to 82

1/4 × 0.065 in.

SS-400-9 Forging 100+

SS-600-1-4 Bar stock 83 to 88

3/8 × 0.065 in.

SS-600-9 Forging 100+

SS-600-1-4 Bar stock 78 to 80

3/8 × 0.083 in.

SS-600-9 Forging 100+

SS-810-1-4 Bar stock 86 to 88

1/2 × 0.083 in.

SS-810-9 Forging 98, 100+

Metric, mm

SS-6M0-1-4 Bar stock

6 × 1.5 mm 93

SS-6M0-9 Forging

SS-8M0-1-4 Bar stock

8 × 1.5 mm 88

SS-8M0-9 Forging

SS-10M0-1-4 Bar stock

10 × 2.0 mm 90

SS-10M0-9 Forging

SS-12M0-1-4 Bar stock

12 × 2.0 mm 100+

SS-12M0-9 Forging

PURPOSE

These assemblies were tested to observe the performance of Swagelok tube fittings with advanced

geometry back ferrules when installed at 1 turn and 3/4 turn past finger-tight on normal to extra-

hard tubing under hydrostatic pressure when assembled with tubing both bottomed and not

bottomed on the tube shoulder of the fitting body.

This testing evaluates the tube gripping ability of assembled tube fittings to sustain hydraulic over

pressure, attaining up to 3.5 × working pressure without hydraulic leakage and up to 4.0 × working

pressure without fitting material rupture or tube slippage.

© 2018 Swagelok Company

Product Test Report PTR-390

Swagelok Company Ver 05

29500 Solon Road November 2018

Solon, Ohio 44139 U.S.A. Page 2 of 4

TEST CONDITIONS

Original test date: December 2001

Tube preparation:

Tubing lengths were cut using a tube cutter for 1/2 in. diameter and under. Each tube length

assured a minimum of three diameter lengths between fittings after assembly.

Fitting assembly:

• Each sample tested consisted of one tube length and two test fittings, one bar stock and one

forged body, assembled 1 turn and 3/4 turn past finger-tight.

• Prior to pull-up, assemblies with tubing not bottomed had the tubing withdrawn from the tube

shoulder by 1/16 to 1/8 in. (1.6 to 3.2 mm).

TEST METHOD

The fittings were leak tested using the following controlled laboratory conditions:

1. Each sample was attached to a hydraulic test stand.

2. The tubing was restricted from burst by clamping blocks thereby forcing a failure at the fitting-

to-tubing engagement.

3. Pressure was gradually increased and the pressure was recorded when loss of tube grip, material

rupture or leakage that prevented applying higher pressure occurred, whichever came first.

4. Results were compared to the tubing working pressure.

TEST RESULTS

Swagelok Tube Fittings, 1 Turn Assembly, Normal to Extra-Hard Tubing, Tubing Bottomed

Fractional

Samples Samples Samples

Working Attaining Attaining Attaining

Tubing Tubing Pressure 3.0 × WP 3.5 × WP 4 × WP

Size Hardness Samples (WP) Without Without Without

in. HRB Tested psig (bar) Leakage Leakage Tube Slip

81 to 82 16 10 200 (702) 16 / 16 16 / 16 16 / 16

1/4 × 0.065

100+ 6 10 200 (702) 5 / 6 5/6 5/6

83 to 88 16 6500 (447) 16 / 16 16 / 16 16 / 16

3/8 × 0.065

100+ 6 6500 (447) 6/6 6/6 5/6

78 to 80 24 7500 (516) 24 / 24 24 / 24 24 / 24

3/8 × 0.083

100+ 4 7500 (516) 4/4 4/4 4/4

86 to 88 24 6700 (461) 24 / 24 24 / 24 24 / 24

1/2 × 0.083 98 34 6700 (461) 34 / 34 34 / 34 34 / 34

100+ 18 6700 (461) 18 / 18 17 / 18 16 / 18

Lowest observed was 2.6 × W.P.

© 2018 Swagelok Company

Product Test Report PTR-390

Swagelok Company Ver 05

29500 Solon Road November 2018

Solon, Ohio 44139 U.S.A. Page 3 of 4

TEST RESULTS

Swagelok Tube Fittings, 1 Turn Assembly, Normal to Extra-Hard Tubing, Tubing Bottomed

Metric

Samples Samples Samples

Working Attaining Attaining Attaining

Tubing Tubing Pressure 3.0 × WP 3.5 × WP 4 × WP

Size Hardness Samples (WP) Without Without Without

mm HRB Tested bar (psig) Leakage Leakage Tube Slip

6 × 1.5 93 6 710 (10 304) 6/6 6/6 6/6

8 × 1.5 88 8 520 (7547) 8/8 8/8 8/8

10 × 2.0 90 31 580 (8417) 31 / 31 31 / 31 30 / 30

12 × 2.0 100+ 16 470 (6821) 16 / 16 16 / 16 15 / 16

Swagelok Tube Fittings, 3/4 Turn Assembly, Normal to Extra-Hard Tubing, Tubing Bottomed

Fractional

Samples

Samples Samples Attaining

Working Attaining Attaining 4 × WP

Tubing Tubing Pressure 3.0 × WP 3.5 × WP Without

Size Hardness Samples (WP) Without Without Tube

in. HRB Tested psig (bar) Leakage Leakage Slip

82 4 10 200 (702) 4/4 4/4 4/4

1/4 × 0.065

100+ 4 10 200 (702) 4/4 4/4 4/4

83 4 6500 (447) 4/4 4/4 4/4

3/8 × 0.065

100+ 4 6500 (447) 4/4 4/4 3/4

88 4 6700 (461) 4/4 4/4 4/4

1/2 × 0.083

98 4 6700 (461) 4/4 4/4 4/4

© 2018 Swagelok Company

Product Test Report PTR-390

Swagelok Company Ver 05

29500 Solon Road November 2018

Solon, Ohio 44139 U.S.A. Page 4 of 4

Swagelok Tube Fittings, 1 Turn Assembly, Normal to Extra-Hard Tubing, Tubing Not Bottomed

Fractional

Samples Samples Samples

Working Attaining Attaining Attaining

Tubing Tubing Pressure 3.0 × WP 3.5 × WP 4 × WP

Size Hardness Samples (WP) Without Without Without

in. HRB Tested psig (bar) Leakage Leakage Tube Slip

1/4 × 0.065 81 to 82 12 10 200 (702) 12 / 12 12 / 12 12 / 12

3/8 × 0.065 86 to 88 12 6500 (447) 12 / 12 12 / 12 12 / 12

3/8 × 0.083 100+ 4 7500 (516) 2 / 4 2/4 2/4

86 to 87 20 6700 (461) 20 / 20 20 / 20 19 / 19

1/2 × 0.083

100+ 4 6700 (461) 4/4 3/4 3/4

Lowest observed was 2.8 × W.P.

Metric

Samples Samples Samples

Working Attaining Attaining Attaining

Tubing Tubing Pressure 3.0 × WP 3.5 × WP 4 × WP

Size Hardness Samples (WP) Without Without Without

mm HRB Tested bar (psig) Leakage Leakage Leakage

6 × 1.5 93 4 710 (10 304) 4/4 4/4 4/4

10 × 2.0 90 15 580 (8417) 15 / 15 15 / 15 15 / 15

The tests were conducted beyond the product’s recommended operating parameters and

do not modify the published product ratings.

These tests were performed to consider a specific set of conditions and should not be considered

valid outside those conditions. Swagelok Company makes no representation or warranties

regarding these selected conditions or the results attained there from. Laboratory tests cannot

duplicate the variety of actual operating conditions. Test results are not offered as statistically

significant. See the product catalog for technical data.

SAFE PRODUCT SELECTION

When selecting a product, the total system design must be considered to ensure safe, trouble-free

performance. Function, material compatibility, adequate ratings, proper installation, operation, and

maintenance are the responsibilities of the system designer and user.

Swagelok—TM Swagelok Company

© 2018 Swagelok Company

You might also like

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyFrom EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyRating: 5 out of 5 stars5/5 (4)

- Swagelok VibrationDocument21 pagesSwagelok VibrationKapil NandwanaNo ratings yet

- Altium PCB Layout Tutorial 2Document31 pagesAltium PCB Layout Tutorial 2oemarbc100% (3)

- Bom 07092018Document47 pagesBom 07092018Tracy GaufoNo ratings yet

- Tube FittingsDocument12 pagesTube FittingsspiritveluNo ratings yet

- What Is VersaFlex® Liner Hanger SystemDocument24 pagesWhat Is VersaFlex® Liner Hanger Systemadvantage025No ratings yet

- UPS Project NewDocument34 pagesUPS Project NewKrishna RajNo ratings yet

- 19.building Movement Control During Construction - Rev.01-17august 2009Document49 pages19.building Movement Control During Construction - Rev.01-17august 2009Syerifaizal Hj. Mustapha100% (1)

- Guidelines Flare Vent Measurement PDFDocument36 pagesGuidelines Flare Vent Measurement PDFVivek JoshiNo ratings yet

- Swagelok CatalogDocument66 pagesSwagelok Catalogfeelmybeat100% (1)

- Tutorial 5Document4 pagesTutorial 5Kumar ShivamNo ratings yet

- 4 Point Mooring SystemDocument26 pages4 Point Mooring SystemGustavo Barreto Sosa100% (2)

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- BS 12385-1 Wire Rope SlingsDocument22 pagesBS 12385-1 Wire Rope SlingsWalid BdeirNo ratings yet

- JDBC JDBC TutorialDocument27 pagesJDBC JDBC Tutorialmanne0504No ratings yet

- Altivar 71Document83 pagesAltivar 71Pablo Pastor AlarconNo ratings yet

- Reporte de Prueba Hidrostatica Racores 1Document3 pagesReporte de Prueba Hidrostatica Racores 1Humberto SERRATO HURTADONo ratings yet

- PTR-4060 Tensile Pull TestDocument3 pagesPTR-4060 Tensile Pull TestHUSHIKESHNo ratings yet

- Tank-Accessories HandholeDocument7 pagesTank-Accessories HandholeAsep DarojatNo ratings yet

- Models 001 002 003A MFCVs WS 0001Document5 pagesModels 001 002 003A MFCVs WS 0001biomed2083No ratings yet

- Wedge Grips - Specification SheetDocument16 pagesWedge Grips - Specification SheetAlexandreinspetorNo ratings yet

- O'Brien - Tracepak MJ Multiple Jacketed TubingsDocument2 pagesO'Brien - Tracepak MJ Multiple Jacketed TubingsMahaveerprabuThangarajNo ratings yet

- Dresser Style 63 Expansion JointDocument1 pageDresser Style 63 Expansion JointAnthonyNo ratings yet

- Restek Gas SamplingDocument4 pagesRestek Gas SamplingtomysetiyadiNo ratings yet

- EstiloDocument2 pagesEstiloJosé EnriqueNo ratings yet

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocument2 pagesStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771No ratings yet

- Reskem Manwaybulletin PDFDocument2 pagesReskem Manwaybulletin PDFTan Chee MingNo ratings yet

- Nylaflow Nylatron 2006Document4 pagesNylaflow Nylatron 2006Miguel GradeNo ratings yet

- Test Plug BrochureDocument4 pagesTest Plug BrochuresitaNo ratings yet

- Sch80ctech SDL80C TDocument9 pagesSch80ctech SDL80C Thumberto.aranguiz2715No ratings yet

- Ifield Products Hoses, Fittings & AccessoriesDocument27 pagesIfield Products Hoses, Fittings & Accessoriesfixture DeptNo ratings yet

- CSA 3.16 Approval GuideDocument16 pagesCSA 3.16 Approval GuideDaniel SanNo ratings yet

- Fig - 3616 TI P160 04 ENDocument4 pagesFig - 3616 TI P160 04 ENAditomo PutrantoNo ratings yet

- Valvulas de Nivel CVBDocument1 pageValvulas de Nivel CVBJean Pierre Villafuerte PastorNo ratings yet

- Tubing Cutter Radial Cutting TorchDocument2 pagesTubing Cutter Radial Cutting Torcharvandi_mahryNo ratings yet

- DX-804 enDocument2 pagesDX-804 enJorge ToroNo ratings yet

- Personalized PDF Catalog: Catalogue Generated April 16, 2019Document2 pagesPersonalized PDF Catalog: Catalogue Generated April 16, 2019ishNo ratings yet

- Velan Valve KatalogDocument22 pagesVelan Valve KatalogAinurizal HilmiNo ratings yet

- Bray Valves Profile I-5000 EL Profile 10 2015 LRDocument17 pagesBray Valves Profile I-5000 EL Profile 10 2015 LRChandravadanNo ratings yet

- Catalogo Hubbell Lineas AereasDocument50 pagesCatalogo Hubbell Lineas AereassalazarjanNo ratings yet

- Stargrip Cat PDFDocument12 pagesStargrip Cat PDFDGWNo ratings yet

- Catalogue - Drill Pipe Protectors PDFDocument3 pagesCatalogue - Drill Pipe Protectors PDFKapil PatwaNo ratings yet

- Bolts FastenerDocument20 pagesBolts FastenerUpadrasta HarishNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- MS 01 177Document8 pagesMS 01 177Fabian Antonio RoldanNo ratings yet

- Nanolub in Caterpillars Cat DEO-ULS 15W-40 ReportDocument6 pagesNanolub in Caterpillars Cat DEO-ULS 15W-40 Reportrosaleshernan1987No ratings yet

- Quick' N Easy Braided Stainless Steel & Nylon Toilet Connectors Specification SheetDocument1 pageQuick' N Easy Braided Stainless Steel & Nylon Toilet Connectors Specification SheetWattsNo ratings yet

- Rva 05 PDFDocument4 pagesRva 05 PDFengp3077No ratings yet

- Your Global Flow Control Partner: International Product ProfileDocument16 pagesYour Global Flow Control Partner: International Product ProfileKevin EsquivelNo ratings yet

- TEKS Self Drilling Fasteners Product Data 334987Document2 pagesTEKS Self Drilling Fasteners Product Data 334987Allan PapionaNo ratings yet

- Local MatsDocument1 pageLocal MatsRhamesh Datchele FulongNo ratings yet

- Abuso Sustancias Tecn DiagDocument4 pagesAbuso Sustancias Tecn DiagalbertuNo ratings yet

- Item # 8LD1000, Formed Sampling Cylinders: Click HereDocument3 pagesItem # 8LD1000, Formed Sampling Cylinders: Click Hereulfah nur khikmahNo ratings yet

- Style 877NDocument7 pagesStyle 877NUmmes AhmedNo ratings yet

- Accesorios CT3Document12 pagesAccesorios CT3Maria Teresa LRNo ratings yet

- 5HR 232 01Document2 pages5HR 232 01Fabian Caballero BernalNo ratings yet

- Flare Identification Chart: Double/SAE 45 Degree FlareDocument2 pagesFlare Identification Chart: Double/SAE 45 Degree Flaredavelance01No ratings yet

- 3M SS Filters Data SheetDocument4 pages3M SS Filters Data SheetbinnisfquoteNo ratings yet

- RJ-SERIES PotablE WatER CaRtS - AeroserviciosDocument34 pagesRJ-SERIES PotablE WatER CaRtS - AeroserviciosKazem QarebeiglooNo ratings yet

- Stainless Steel Seamless Tubing and Tube Suppor T Systems: Fractional, Metric, and Imperial SizesDocument12 pagesStainless Steel Seamless Tubing and Tube Suppor T Systems: Fractional, Metric, and Imperial SizesRizky MuhammadNo ratings yet

- EvolutionTekDatasheet PDFDocument1 pageEvolutionTekDatasheet PDFRobNo ratings yet

- P Series Pipe - Needle Valve CatalogDocument4 pagesP Series Pipe - Needle Valve CatalogHenry PorcoNo ratings yet

- JG JgaDocument4 pagesJG Jgaivan.mehanikNo ratings yet

- Your Choice of Chainsaws, Chains and Guide Bars That Work With Logosol TimberjigDocument6 pagesYour Choice of Chainsaws, Chains and Guide Bars That Work With Logosol TimberjigDiego A Echavarría ANo ratings yet

- You Might Also Like: Currently UnavailableDocument1 pageYou Might Also Like: Currently UnavailableChia Sze KiatNo ratings yet

- Bending Test of Steel BarDocument2 pagesBending Test of Steel Barwajid100% (2)

- 3150cdahhbaa YokogawaDocument1 page3150cdahhbaa YokogawaAlberto Fernández MarínNo ratings yet

- 0427 Kenwood K17SJA09Document36 pages0427 Kenwood K17SJA09nourtal2013No ratings yet

- (Tools, Tips & Tutorials) Entering EDL Mode From Fastboot ModeDocument2 pages(Tools, Tips & Tutorials) Entering EDL Mode From Fastboot ModeAman SinghNo ratings yet

- Ir Pt01 Tu Et 001 IngDocument3 pagesIr Pt01 Tu Et 001 Ingjuliany55964No ratings yet

- Airport ObstructionsDocument32 pagesAirport Obstructionskomal.panchal93No ratings yet

- Info Iec60245-6 (Ed2.0) en D.imgDocument5 pagesInfo Iec60245-6 (Ed2.0) en D.imgRonald Rey SotoNo ratings yet

- Pavel BedrikovetskyDocument1 pagePavel BedrikovetskyMehdi AlizadehNo ratings yet

- Tungaloy - Cutting Tools PDFDocument1,252 pagesTungaloy - Cutting Tools PDFazb00178No ratings yet

- Tuffstuff Apollo 7000 Series BrochureDocument8 pagesTuffstuff Apollo 7000 Series Brochureaamir hussainNo ratings yet

- Asme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel ServiceDocument5 pagesAsme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel Servicelucecita1902No ratings yet

- Natural Iron Oxide Product BrochureDocument4 pagesNatural Iron Oxide Product BrochureNew Riverside Ochre Company, Inc.No ratings yet

- Z Transform 2 of 3Document18 pagesZ Transform 2 of 3Gilbert SigalaNo ratings yet

- PTM Issues Pl2 - Rev01Document37 pagesPTM Issues Pl2 - Rev01Dipak Kumar PatelNo ratings yet

- UTX MTX HVX ManualDocument82 pagesUTX MTX HVX ManualMutahirrasoolNo ratings yet

- Need of SPMDocument3 pagesNeed of SPMranydi0% (2)

- BBMP User ManualDocument135 pagesBBMP User Manualks manjuNo ratings yet

- X1 Meter WiFi Installation GuideDocument2 pagesX1 Meter WiFi Installation GuideVăn ST QuangNo ratings yet

- Sheet Metal ProccessesDocument43 pagesSheet Metal ProccessesisharaNo ratings yet

- Sunflower ThreshingDocument9 pagesSunflower Threshingsanojk_2000No ratings yet

- Manual WPC 4000 5000 7000 9000 15000 12 - 2015Document32 pagesManual WPC 4000 5000 7000 9000 15000 12 - 2015Sabiho GinoNo ratings yet

- Very High Cycle Fatigue - Testing MethodsDocument17 pagesVery High Cycle Fatigue - Testing Methodsالحمد اللهNo ratings yet

- Chapter 1 Introduction and Basic ConceptsDocument26 pagesChapter 1 Introduction and Basic ConceptsZafirahAhmadFauziNo ratings yet