Professional Documents

Culture Documents

Home Interior Exterior - Civil Inspector Interview Question and Answer

Uploaded by

ZeeshanAli0 ratings0% found this document useful (0 votes)

55 views5 pagesQC answers

Original Title

Home Interior Exterior- Civil Inspector Interview Question and Answer

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentQC answers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

55 views5 pagesHome Interior Exterior - Civil Inspector Interview Question and Answer

Uploaded by

ZeeshanAliQC answers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

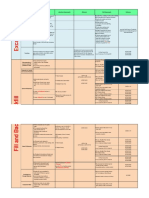

Civil Inspector Interview Question

and Answer

TYPICAL INTERVIEW ANSWER FOR QUALITY

CONTROL CIVIL INSPECTOR

Part One:

1. What are the most important elements of soil classification

(SAES-A-114)

a) Type of soil, Gradation and Atterberg limits. The inspector

should have a general idea how these limits (liquid limit, Plastic limit

and plasticity index) correlate with selecting approved select fill).

2. What’s “CBR” (SAES Q-006)

a) California Bearing Ration (CBR). It’s a laboratory value that

helps determining soil bearing capacity and in classifying soil. It is a

design parameter, however is a requirement by our standard to

verify and check! Not knowing what it is indicates the inspector has

poor soil knowledge and experience.

3. What is the maximum depth of regular fill lift (layer) prior

to compactions (SAES A-114)

a) 200 mm

4. What is the maximum depth of a fill lift (layer) when

manual equipment is used for compaction (SAES A-114)

a) 100 mm

5. What are the project conditions and factors that control

compaction? (Experience & SAES A-114)

a) Proper Moisture Content.

b) Compaction Equipment used and number of rolls.

c) Confinement of soil (for sand) and stepping of layers of marl

and select fill.

d) Type of Soil.

6. What are the different types of laboratory ASTM soil

density test (SAES A-114)? And what are the minimum required

density values for each of the test mention above?

a) Proctor 95%

b) Modified Proctor 90%

c) Relative (for sand) 70%

7. What are the important points to look for in Concrete form

prior to pouring concrete (SAES Q-001, ACI and experience)?

a) Tightness, cleanness, plumpness, steadiness, shoring and

bracing, rebar cover, concrete tip level mark correctness.

b) Also, vapor barrier must be installed prior to pouring on grade.

c) Also, grade must receive termite chemical spray protection

prior to vapor barrier placement.

8. What are the essential elements of concrete placement

(SAES O-001, ACI, and experience)

a) Maximum height of concrete drop is less than or equal to 1

meter.

b) Segregation must be prevented by ensuring transit mixture is

approved, has operating revolution counter, no adding water after

batching, and concrete is placed in such a manner to prevent

segregation (i.e. only shovels can be used to move concrete around

inside the forms-no raking allowed. Vibration should not be used for

that purpose.

c) Pooper vibration must be implemented. (Proper vibrating-

dropping the vibrator under its own weight until it gets to the

desired drop height, then leaving it there for 3-7 seconds pulling at

the count of 3-4 seconds. When vibrating sub-sequent layers,

vibrator must penetrate a centimeter into older layer. ( Any answer

close to this indicate experience)

d) Some labors must be continuously watching the forms in case

a large/high pout to ensure no forms failure takes place. In case a

wall is being poured, proper height (maximum heights) of each

concrete lift must be observed, such as the usual 600 mm stated

normally in projects specifications. Also, tamping on the wall is

necessary to assist in the consolidation process.

e) The concrete temperature and the slump are two strong

indicators of inspector’s knowledge. A slump between 75mm and

125mm is normal for normal pours. If the inspector has no clue as to

even the range, that’s serious! The maximum allowed temperature

for concrete when arriving at project site is 32 degrees Celsius.

9. Tell me structural steel receiving inspection and Structural

Steel Erection (12-SAMMS-007/008 & AISC-American Institute

of Steel Construction, PIPSTS 05130)?

a) This is involved experience in structural steel inspection

against abuse and damage, proper storage, proper sequencing on

job site to minimize damage, etc.

b) An experienced civil inspector must know about erection of

structural steel based on the AISC 9 (American Institute of Steel

Construction) specification for High Strength Bolts A325 & A490.

Solid knowledge in the Turn-Of-The-Nut method is extremely

essential for proper erection!

10. What is the minimum and maximum acceptable asphalt

temperature range when arriving on site (SAES Q-006 and

AASHTO)?

a) 139 to 163 degree centigrade.

11. What is required compaction density of asphalt (SAES Q-

006 & AASHTO)?

a) 96%

12. What is Prime Coat and where is it applied (SAES Q-006 &

AASHTO)? What is it curing requirement for the Prime Coat?

a) It is asphalt bituminous material that is place on the substrate

prior to placement of the first asphalt mixture (the binder course). It

must be allowed to cure and to soak into capping layer (usually

select fill).

b) 24 hours, a good indication that the material cured is when the

colors turns to pitch black, i.e. the brownness is gone.

13. What is Tack Coat (SAES Q-006 and AASHTO)

a. It is asphalt bituminous material which is applied on existing

concrete or asphalt surfaces to bond the new subsequent asphalt

pavement to them. Tack coat is not necessary to place on new

asphalt before placing the next layer of asphalt, unless it is solid

(dirty).

14. Which is the tolerance requirement of sub-grade asphalt

smoothness prior to placing asphalt (SAESQ-006 & AASHTO)?

a. Using a 3 meter straight edge = 6mm

15. What is requirement of finished asphalt surface

smoothness (SAES Q-006 & AASHTO)?

a. Using a 3 meter straight edge 4mm longitudinally, 3mm

laterally.

You might also like

- QC Inspector Written Test AnswersDocument40 pagesQC Inspector Written Test Answersmohd khajaNo ratings yet

- Civil Engineering Technical Question and AnswersDocument15 pagesCivil Engineering Technical Question and AnswersSudhan100% (1)

- CIVIL KEY POINTSDocument2 pagesCIVIL KEY POINTSMohammed Sadiq100% (3)

- SAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Document5 pagesSAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Nino Celso Astillero100% (1)

- QC CIVIL VOL 2 SS 7aevfrDocument26 pagesQC CIVIL VOL 2 SS 7aevfrSudhanNo ratings yet

- MCQ TestDocument4 pagesMCQ TestPrabhakar Kumar Barnwal0% (1)

- Concrete Batch PlantDocument7 pagesConcrete Batch Plantراجہ شہزاد انورNo ratings yet

- Concrete Works Inspection & TestingDocument9 pagesConcrete Works Inspection & Testingkbldam100% (2)

- SAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Document2 pagesSAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Nino Celso Astillero100% (1)

- Dokumen - Tips 8civil Inspector Questions 100Document27 pagesDokumen - Tips 8civil Inspector Questions 100shamim ahmadNo ratings yet

- Syllabus Civil Qaqc Course Sdlinc 9600162099Document12 pagesSyllabus Civil Qaqc Course Sdlinc 9600162099Sridurgha Lakshmi Inc SDLINC NDT QA QC INSTITUTE100% (1)

- 02225Document6 pages02225uddinnadeemNo ratings yet

- Inspector's Refresher Quiz - Civil - Set1Document2 pagesInspector's Refresher Quiz - Civil - Set1SHAIK ASIMUDDINNo ratings yet

- SAES-A-114 (Excavation and Backfill)Document4 pagesSAES-A-114 (Excavation and Backfill)Nino Celso AstilleroNo ratings yet

- BRITTLE MATERIALSDocument12 pagesBRITTLE MATERIALSShazab Nawaz100% (1)

- Aramco Civil ReviewerDocument10 pagesAramco Civil ReviewerTayyab AchakzaiNo ratings yet

- Civil Test: NameDocument6 pagesCivil Test: NamePrince JoseNo ratings yet

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionDocument2 pagesSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanNo ratings yet

- 5-Notes For Building Related Activities-2Document9 pages5-Notes For Building Related Activities-2Eshaal NoreenNo ratings yet

- Saes Q 001 Saes-Q-006Document5 pagesSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- Civil Inspector Questions TestDocument43 pagesCivil Inspector Questions TestKifayat ullah KhanNo ratings yet

- Qaqc Inspector QuestionaireDocument4 pagesQaqc Inspector QuestionaireNiño Celso AstilleroNo ratings yet

- S.No. Questions AnswerDocument248 pagesS.No. Questions AnswerSyed Munawar Ali100% (2)

- Interview Questions About Concrete in Gulf CountriesDocument23 pagesInterview Questions About Concrete in Gulf CountriesMd nizamNo ratings yet

- Concrete Batch Plants CommentsDocument2 pagesConcrete Batch Plants CommentsShoaib SafdarNo ratings yet

- Key - QC Buildings TestDocument4 pagesKey - QC Buildings TestKhurram ShehzadNo ratings yet

- Saudi Aramco Concrete Coating ProcedureDocument10 pagesSaudi Aramco Concrete Coating Proceduremoytabura96100% (1)

- South Ghawar Project Inspection Unit (SGPIU) Test For QC Inspector (Earthwork/Paving)Document4 pagesSouth Ghawar Project Inspection Unit (SGPIU) Test For QC Inspector (Earthwork/Paving)Khurram ShehzadNo ratings yet

- Asphalt Pavement Construction: 1. Improved SubgradeDocument4 pagesAsphalt Pavement Construction: 1. Improved Subgrade143No ratings yet

- Saes A 114Document2 pagesSaes A 114Nino Celso AstilleroNo ratings yet

- Back FillDocument3 pagesBack Fillcevhos100% (1)

- Nawaz Khan - Civil InspectorDocument4 pagesNawaz Khan - Civil InspectormlNo ratings yet

- My Notes ConcreteDocument19 pagesMy Notes ConcreteTufail Khan100% (1)

- Concrete ExamDocument26 pagesConcrete ExamKyra AlesonNo ratings yet

- As Soon As The Contract Is Awarded,: Further For PO PlacementDocument9 pagesAs Soon As The Contract Is Awarded,: Further For PO PlacementMohammed SibghatullaNo ratings yet

- Saudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingDocument17 pagesSaudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingUSMAN NAGTHAN100% (2)

- Qa QC Interview QuestionsDocument17 pagesQa QC Interview QuestionsAjin Sharma100% (1)

- Aggregates and Concrete SpecificationsDocument2 pagesAggregates and Concrete SpecificationsNino Celso AstilleroNo ratings yet

- Dcs 1Document12 pagesDcs 1Sai PrintersNo ratings yet

- Concrete Terms and Industry TerminologyDocument12 pagesConcrete Terms and Industry TerminologyNguyen Dang Hanh100% (8)

- Concrete Industry Codes and StandardsDocument5 pagesConcrete Industry Codes and Standardsmohd khajaNo ratings yet

- Method Statement For Approval of Layer Thickness - Rev.01Document9 pagesMethod Statement For Approval of Layer Thickness - Rev.01Jox Biol100% (1)

- Important Points To Remember Practical ThingsDocument2 pagesImportant Points To Remember Practical ThingsricosanojuanNo ratings yet

- SABIC ConcreteDocument14 pagesSABIC ConcreteBasker BaluNo ratings yet

- Project Quality RequirementsDocument8 pagesProject Quality RequirementsSIVANo ratings yet

- Saqib Ali Aramco NotesDocument18 pagesSaqib Ali Aramco NotesAmir Khan0% (1)

- Aramco Standard NotesDocument9 pagesAramco Standard NotesAmir Khan100% (1)

- Chapter 9: Evalua On and Acceptance of Hardened ConcreteDocument9 pagesChapter 9: Evalua On and Acceptance of Hardened ConcreteGaneshNo ratings yet

- TDS Nitomortar TC2000 Saudi ArabiaDocument3 pagesTDS Nitomortar TC2000 Saudi ArabiaHarry BawingNo ratings yet

- Civil CBTDocument3 pagesCivil CBTAris BulaongNo ratings yet

- Asphalt NotesDocument5 pagesAsphalt NotesTufail KhanNo ratings yet

- Concrete Specifications Rev ADocument15 pagesConcrete Specifications Rev ABdteam T2No ratings yet

- Concrete Temp QCS 2014Document1 pageConcrete Temp QCS 2014alden cayagaNo ratings yet

- QC Civil Inspector Answer & QuestionDocument11 pagesQC Civil Inspector Answer & Questionengineer bilalNo ratings yet

- Civil Inspector questionnaire guideDocument2 pagesCivil Inspector questionnaire guideNawab Khan Virk100% (1)

- International Standard | Oil & Gas QA/QC - Civil Inspector Qualification Guideline Questions & Answers (VOL-IIDocument26 pagesInternational Standard | Oil & Gas QA/QC - Civil Inspector Qualification Guideline Questions & Answers (VOL-IISyed Munawar Ali100% (3)

- Quality Control Civil InspectorDocument2 pagesQuality Control Civil InspectorNadeem91% (11)

- Aramco Que - Civil InspectorDocument23 pagesAramco Que - Civil InspectorBasker Balu86% (7)

- Table of Contents for Oil Storage Tank Foundation SpecificationDocument6 pagesTable of Contents for Oil Storage Tank Foundation SpecificationUsama AhmedNo ratings yet

- A143Document16 pagesA143Luis Jorge Nahle OrtizNo ratings yet

- Asim Khan 6Document7 pagesAsim Khan 6ZeeshanAliNo ratings yet

- Two Way Simply Support + Slab Beam + Column CautionDesign Excel Sheet 2Document23 pagesTwo Way Simply Support + Slab Beam + Column CautionDesign Excel Sheet 2ZeeshanAliNo ratings yet

- خرسانة مسلحة 4Document12 pagesخرسانة مسلحة 4ZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- SD-SU-746-R00-حديدOFFSET BDocument1 pageSD-SU-746-R00-حديدOFFSET BZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- Business Success Plan PDFDocument8 pagesBusiness Success Plan PDFZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- SD-SU-746-R00-حديدOFFSET BDocument1 pageSD-SU-746-R00-حديدOFFSET BZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST WC 75 R00Document1 pageST WC 75 R00ZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- GE QA QC PlanDocument103 pagesGE QA QC PlanchezzkonsultNo ratings yet

- Post-Tensioned Concrete Design for ACI 318-08Document43 pagesPost-Tensioned Concrete Design for ACI 318-08Duaa Makki100% (3)

- TENSIONING TENDONSDocument11 pagesTENSIONING TENDONSjajun-IchromNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- FACEDocument2 pagesFACEZeeshanAliNo ratings yet

- Post-Tensioned Concrete Design for ACI 318-08Document43 pagesPost-Tensioned Concrete Design for ACI 318-08Duaa Makki100% (3)

- ST-WC-455 B حدادةDocument1 pageST-WC-455 B حدادةZeeshanAliNo ratings yet

- Concrete TolerancesDocument5 pagesConcrete TolerancesVhanNo ratings yet

- de Neef Ha Cut Af En-GbDocument6 pagesde Neef Ha Cut Af En-GbZeeshanAliNo ratings yet

- B.Tech ITDocument42 pagesB.Tech ITHemanth DhanasekaranNo ratings yet

- Is 16415 Product ManualDocument17 pagesIs 16415 Product ManualKumar gsNo ratings yet

- D 3330 - D 3330M - 00 - RdmzmzatmdaDocument5 pagesD 3330 - D 3330M - 00 - RdmzmzatmdaStuartNo ratings yet

- Standard Practice For Condition Monitoring of Used Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry1Document22 pagesStandard Practice For Condition Monitoring of Used Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry1Sergio Gonzalez GuzmanNo ratings yet

- Petrologic Evidence For Boiling To Dryness in The Karaha-Telaga Bodas Geothermal System, IndonesiaDocument10 pagesPetrologic Evidence For Boiling To Dryness in The Karaha-Telaga Bodas Geothermal System, IndonesiaTampan NauliNo ratings yet

- Thermosets: A "Thermoset" Is A Cross-Linked Polymer Formed by An Irreversible Exothermic Chemical ReactionDocument58 pagesThermosets: A "Thermoset" Is A Cross-Linked Polymer Formed by An Irreversible Exothermic Chemical ReactionyigitilgazNo ratings yet

- The Study of Sequence Stratigraphy and Sedimentary System in Muglad BasinDocument4 pagesThe Study of Sequence Stratigraphy and Sedimentary System in Muglad BasinIOSRjournalNo ratings yet

- MetalDocument57 pagesMetalPrashant PuriNo ratings yet

- Nonlinear Analysis of Reinforced Concrete Columns With HolesDocument14 pagesNonlinear Analysis of Reinforced Concrete Columns With HolesDan GheorghiuNo ratings yet

- Simplified Melc-Based Budget of Lessons in General Biology 2Document3 pagesSimplified Melc-Based Budget of Lessons in General Biology 2irene belle dableolesiguesNo ratings yet

- Man Ci 056enDocument4 pagesMan Ci 056enRicardo AzevedoNo ratings yet

- What happens when air is heatedDocument19 pagesWhat happens when air is heatedMicoy LekawskiNo ratings yet

- Empirical Formula of Magnesium Oxide (MgODocument10 pagesEmpirical Formula of Magnesium Oxide (MgOsamNo ratings yet

- CUFSM Advanced Functions: Boundary Conditions Constraints Springs Multiple Materials Orthotropic MaterialDocument34 pagesCUFSM Advanced Functions: Boundary Conditions Constraints Springs Multiple Materials Orthotropic MaterialkhayatNo ratings yet

- Scapa NA Pipeline Brochure PDFDocument6 pagesScapa NA Pipeline Brochure PDFVernon SantosNo ratings yet

- Iso 7393 2 2017Document11 pagesIso 7393 2 2017Josias EmanuelNo ratings yet

- Manual de Usuario BioClaveDocument15 pagesManual de Usuario BioClaveMJ DentalNo ratings yet

- 2-74-1343890128-Gen Engg - Ijget - Development - T Karthik - UnpaidDocument18 pages2-74-1343890128-Gen Engg - Ijget - Development - T Karthik - UnpaidAnonymous Pt7NHkat9No ratings yet

- Jurassic Au-Skarn and Porphyry Cu Deposits in Ecuador Imply Extensive Metallogenic BeltDocument17 pagesJurassic Au-Skarn and Porphyry Cu Deposits in Ecuador Imply Extensive Metallogenic BeltMichael AltamiranoNo ratings yet

- API ISO definitions of gross net total volumesDocument2 pagesAPI ISO definitions of gross net total volumesVu TuanNo ratings yet

- Experimental Research On The Behaviour of High Frequency Fatigue in ConcreteDocument10 pagesExperimental Research On The Behaviour of High Frequency Fatigue in Concreteming_zhu10No ratings yet

- SSRN Id4382848Document27 pagesSSRN Id4382848MUHAMMAD SAFWAN AHMAD MUSLIMNo ratings yet

- DNA Sequencing TechniquesDocument16 pagesDNA Sequencing TechniquesAaron CzikNo ratings yet

- REACTION PATHWAYSDocument28 pagesREACTION PATHWAYSkonstantas100% (2)

- Profil PhenobarbitalDocument2 pagesProfil PhenobarbitalOana Maria AndreiNo ratings yet

- Códigos y normas de referenciaDocument26 pagesCódigos y normas de referenciaDarwin_SidneyNo ratings yet

- Shoe WO9001276A1Document40 pagesShoe WO9001276A1Gek CagatanNo ratings yet

- Nisshin Steel Quality Products GuideDocument26 pagesNisshin Steel Quality Products GuidejonnhlNo ratings yet

- Sand Filter BrochureDocument2 pagesSand Filter BrochureadrianioantomaNo ratings yet

- Bed Material Dan Heat TransferDocument44 pagesBed Material Dan Heat Transfer07putra07No ratings yet