Professional Documents

Culture Documents

Katalog ACC DX

Uploaded by

Victor GodoyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Katalog ACC DX

Uploaded by

Victor GodoyCopyright:

Available Formats

PRECISION SURFACE GRINDING MACHINES

OKAMOTO MACHINE TOOL EUROPE GMBH

Raiffeisenstraße 7b, D-63225 Langen, Germany

TEL: +49-6103-201100 FAX: +49-6103-2011020

ACC-DX SERIES

www.okamoto-europe.de

OKAMOTO MACHINE TOOL WORKS, LTD.

3-5-7 Nakamachidai, Tsuzuki-ku, Yokohama, Kanagawa, 224-0041 Japan

TEL: +81-45-949-3881 FAX: +81-45-949-3787

www.okamoto.co.jp

k Warning

!

Before using these products please read the warning and safety notices

mentioned in the operators instruction manual and shown on the machine

warning plates.

We reserve the right to make changes without warning.

Products regulated by Foreign Laws and Export Regulations require an

Export License from the Japanese Authorities before they are exported

outside of the European Union.

Printed in Germany in February 2016

ACC-DX Series

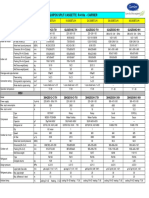

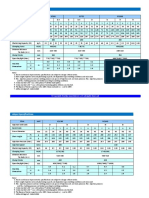

Description Unit 52DX 63DX 64DX 65DX 84DX 105DX

Working Capacity (Length x Width) mm 550x230 650x340 650x440 650x540 850x440 1016x550

50/60Hz, 205mm Wheel mm 47.5 ~ 397.5 – – – – –

Max. Distance

New Wheel to 50Hz, 355mm Wheel mm – 22.5 ~ 322.5 22.5 ~ 322.5 22.5 ~ 522.5 22.5 ~ 522.5 22.5 ~ 522.5

Table

60Hz, 305mm Wheel mm – 22.5 ~ 347.5 47.5 ~ 347.5 47.5 ~ 547.5 47.5 ~ 547.5 47.5 ~ 547.5

Table

Standard Magnetic Chuck

mm 500x200x80 600x300x80 600x400x80 600x500x110 800x400x105 100x500x110

Size (LxWxH)

Table Load Capacity (incl. Chuck) kg 200 420 420 700 700 700

T-Slots (Width x No) mm 17x1 17x3

Max. Travel mm 650 750 750 750 950 1150

Length

ACC 105 DX Hydraulic Table Speed m/min 0.3 ~ 25 0.3 ~ 25 0.3 ~ 25 0.3 ~ 25 3 ~ 25 3 ~ 25

Feed

Table Feed per Handwheel Turn mm 47

Max. Travel mm 230 340 440 540 440 540

Hand per Handwheel Turn mm 5.0

Cross Movement per Handwheel Division mm 0.02

Feed

Automatic

Intermittend Feed mm 0.5 ~ 12 0.5 ~ 20 0.5 ~ 20 0.5 ~ 20 0.5 ~ 20 0.5 ~ 2

Movement

Continuous Feed m/min 0.1 ~ 1.0 0.1 ~1.0 0.1 ~ 1.0 01 ~ 1.0 0.2 ~ 1.0 0.2 ~ 1.0

Machine Construction Automatic Downfeed

0,1x/1x/10x

mm 0.0001 ~ 0.03 <15 Steps>

Hand per Handwheel Division

mm 0.0001 / 0.001 / 0.01

Hydraulic Crossfeed Wheelhead Down Movement

Cast iron construction for optimum stiffness The wheel spindle is built into a cartridge assembly with Feed per Handwheel Turn mm 0.01 / 0.1 / 1.0

and precision. pre-loaded precision angular contact bearings.

Sparkouts No. 0~5

Robust double V crossfeed slideways. Wheel spindle with direct drive via elastic coupling

Precision ball screw. between motor and shaft. Rapid Positioning mm/min 600

Crossfeed handwheel travel, 5 mm per revolution and The wheelhead is adjusted within the column with

0.02 mm per division. 3 adjustable wedges to withstand the highest forces. Grinding Diameter (50/60Hz) x W x Bore mm ø205x19x ø50.8 ø355 / 305 x 38 x ø 127

Continuous or stepped crossfeed. Automatic lubrication for all slideways. Wheel Wheel Speed (50/60Hz) R.P.M. 3000 1500 / 1800

Mechanical crossfeed lock. Wheel Spindle kW/P 1.5 / 2 3.7 / 4

Non contact switches for table reversal. Hydraulic Controls

All hydraulic control adjustments are set from the front Motors Hydraulic Pump kW/P 0.75/4 3.7 1.5 / 4 2.2 / 4

Machine Table of the machine. Downfeed kW 0.4 (AC Servomotor)

Hydraulically driven table movement.

Minimal overhang with all models. Table Speed Power Power Requirement kVA 4.5 7.5 8.0

Double V slideways. Stepplessly variable up to 25m/min. Dimensions Length x Width x Height mm 3030x1593x1800 3350x1929x1800 3350x2180x1800 3350x2450x2060 4220x2205x2060 4870x2264x2060

T-Slot for fixing work holding equipment.

Weight Net Weight kg 2100 2800 3000 3500 3900 4800

Non contact switches for table reversal.

Control Panel Rapid Movement of the Wheelhead

The rapid feed upwards and downwards

Function can be set on the panel.

Cycle start and stop set with switches

and push buttons. Manual Movement of the Wheelhead

Via an electronic handwheel with

Feed Rates 3 increments –

2 separate downfeed rates: coarse feed 0,0001 · 0,001 · 0,01 mm

between 0 and 30 μm, fine feed Detail: Wheel Spindle Head in Column

looking down

betwewen 0 and 10 μm selectable. Automatische Zustellung wie folgt:

Coarse Feed

Feed Change

Independently adjustable change points

Feed Change Optional Equipment

Fine Feed

between coarse and fine downfeed Sparkout at Zero Digital Display for Crossfeed

(between 0 and 30 μm). Cycle Stop Micro Crossfeed Knob

Coolant System

Sparkout at Zero

Wheelflange

Adjustable between 0 and 5

Wheel Head Mounted

reciprocations at zero.

Straight Line Dresser

LoVo Work Light

Hand scraped slideways Okamoto control panel

You might also like

- Split Cassette Carrier R410a Ficha TecnicaDocument1 pageSplit Cassette Carrier R410a Ficha TecnicaCarlos ManriquezNo ratings yet

- Documentatie VRV Compact Multi Flow CassetteDocument1 pageDocumentatie VRV Compact Multi Flow CassetteSergio RoyerNo ratings yet

- WeillerDocument10 pagesWeillerSantia Fitri SNo ratings yet

- Okamoto Brochure 2Document38 pagesOkamoto Brochure 2Legi YangNo ratings yet

- AFC492 eDocument3 pagesAFC492 eAlvaro SanchezNo ratings yet

- Dyna DrillDocument156 pagesDyna DrillLeonardo BarriosNo ratings yet

- Split Duct DaikinDocument2 pagesSplit Duct DaikinRochmad Fauzi100% (2)

- FTKC50TVM4Document1 pageFTKC50TVM4Ulya HasnaNo ratings yet

- AC Split Premium Inverter DAIKIN - STKM25SVDocument1 pageAC Split Premium Inverter DAIKIN - STKM25SVDanny AndriandaruNo ratings yet

- 2015 Hino 195 Class 5 SpecificationsDocument2 pages2015 Hino 195 Class 5 SpecificationsVictor MolinaNo ratings yet

- Especificaciones MubDocument1 pageEspecificaciones MubArquimedes RigualNo ratings yet

- Power Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsDocument2 pagesPower Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsRadiadores PlanosNo ratings yet

- Plastic Injection Moulding Machines: Mega NH SeriesDocument12 pagesPlastic Injection Moulding Machines: Mega NH SeriesMarcelo BoneNo ratings yet

- Line Proven Solution: Press BrakesDocument2 pagesLine Proven Solution: Press BrakesAndresEliseoCastellarRosadoNo ratings yet

- 04 MRHT SpecsDocument8 pages04 MRHT SpecsjorgeNo ratings yet

- Doosan D35S-5 Forklift Kubota V3800 in US PDFDocument2 pagesDoosan D35S-5 Forklift Kubota V3800 in US PDFAditi DasNo ratings yet

- 1sp V 2sp V Series Full Specs 2015 04 30 PDFDocument1 page1sp V 2sp V Series Full Specs 2015 04 30 PDFAlexandru ZdbNo ratings yet

- S002EN08-2203 - SE-EV-Dimensões e FundamentosDocument8 pagesS002EN08-2203 - SE-EV-Dimensões e FundamentosJean AlexNo ratings yet

- ACE Manual Feed: New Generation Magnetic Base Drilling Machines Help Meet Productivity and Safety GoalsDocument2 pagesACE Manual Feed: New Generation Magnetic Base Drilling Machines Help Meet Productivity and Safety GoalsAyien MuhammadNo ratings yet

- Specs Cat Wheel SawsDocument4 pagesSpecs Cat Wheel SawsEmmanouEl BirikakisNo ratings yet

- NC Specs 3 18 21Document2 pagesNC Specs 3 18 21ai007.rusmanaNo ratings yet

- Millac V Series Full Specs Formatted Rev. 2014 08 12bDocument1 pageMillac V Series Full Specs Formatted Rev. 2014 08 12bGunGunSetiawanNo ratings yet

- Catálogo BOST 2017 - BajaDocument13 pagesCatálogo BOST 2017 - BajaDavid S. Valenzuela PortilloNo ratings yet

- Yadon YC1Document1 pageYadon YC1Baihaki St100% (1)

- SITEC Rivet Blindnietmuttern Mit Kunststoffumspritzung Mit Scheibe enDocument2 pagesSITEC Rivet Blindnietmuttern Mit Kunststoffumspritzung Mit Scheibe enamaliabohusNo ratings yet

- Lifting Your Dreams: 7 Series ForkliftsDocument3 pagesLifting Your Dreams: 7 Series ForkliftsPhương Dung BùiNo ratings yet

- Engine Speed (RPM) : Gross NetDocument5 pagesEngine Speed (RPM) : Gross NetEmily CamilaNo ratings yet

- Screw Conveyor - BrochureDocument4 pagesScrew Conveyor - BrochureAnonymous Cxriyx9HIXNo ratings yet

- GCD15 Product GuideDocument28 pagesGCD15 Product Guideing.juantincoNo ratings yet

- Brosur sw770 - 1419492808Document2 pagesBrosur sw770 - 1419492808ardiansyah arfahNo ratings yet

- All-Round Solutions For Your Industrial Tire Needs: TokaiDocument2 pagesAll-Round Solutions For Your Industrial Tire Needs: TokaiDuong Van HoanNo ratings yet

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- PL 500 Technical LeafletDocument2 pagesPL 500 Technical LeafletAsad AijazNo ratings yet

- EDrive Actuators E-Tac ET BrochureDocument4 pagesEDrive Actuators E-Tac ET BrochureElectromateNo ratings yet

- 90 Degree and Variable Angle Peel FixtureDocument2 pages90 Degree and Variable Angle Peel Fixtureasep rifky subagja (Rifky)No ratings yet

- Hebel Floorpanels DetailsDocument2 pagesHebel Floorpanels Detailsazura nirvasNo ratings yet

- Rotator PipeDocument4 pagesRotator PipetisnaNo ratings yet

- Powerking-Sheet Pile DriverDocument4 pagesPowerking-Sheet Pile DriverwaterkingkorNo ratings yet

- ASDO Marine Structures Tie Bar DesignCapDocument2 pagesASDO Marine Structures Tie Bar DesignCapFelipe Strafite CusterNo ratings yet

- Crosby Hoisting RingDocument1 pageCrosby Hoisting RingI-SignNo ratings yet

- 3a TDA (Smokespill) - KVM - LEA026.ED2Document2 pages3a TDA (Smokespill) - KVM - LEA026.ED2Helda MhptNo ratings yet

- V Belts PDFDocument5 pagesV Belts PDFAsela BandaraNo ratings yet

- V Belt Technical Specification POLYESTER CORD Neoprene Jacketed HIC Manufactured UNIVERSAL BrandDocument5 pagesV Belt Technical Specification POLYESTER CORD Neoprene Jacketed HIC Manufactured UNIVERSAL Brandmonahend100% (1)

- Dyna Drill Spec SheetsDocument105 pagesDyna Drill Spec SheetsDon BraithwaiteNo ratings yet

- TTX-Boom SpecsDocument8 pagesTTX-Boom SpecsIván RodríguezNo ratings yet

- Escogear NDocument5 pagesEscogear Nmarcelo castilloNo ratings yet

- Doosan B20S-5 B25S-5 bc30sc BC32S-5Document2 pagesDoosan B20S-5 B25S-5 bc30sc BC32S-5Saul RosalesNo ratings yet

- 1983-SDEE - Foundation Vibrations STATE of The ARTDocument16 pages1983-SDEE - Foundation Vibrations STATE of The ARTJaime GuamanNo ratings yet

- Member Code: Dyntek Pte. LTDDocument1 pageMember Code: Dyntek Pte. LTDHerbert BishopNo ratings yet

- DX160 HLC DX180 HLC: Construction EquipmentDocument2 pagesDX160 HLC DX180 HLC: Construction EquipmentCopemaq CopemaqNo ratings yet

- Nictoro Brochure Cabinet FanDocument12 pagesNictoro Brochure Cabinet FanFaquruddinNo ratings yet

- Makita Table SawDocument4 pagesMakita Table SawIka Novianty MANo ratings yet

- CPCD40-45T8,50T8-X 180321Document3 pagesCPCD40-45T8,50T8-X 180321Socma ReachstackersNo ratings yet

- Diepa B50 - High Performance Rotation Resistant Steel Wire RopeDocument1 pageDiepa B50 - High Performance Rotation Resistant Steel Wire RopeKonstantinos SynodinosNo ratings yet

- Toshoba 180S MoldingDocument3 pagesToshoba 180S Moldingadventius S.SNo ratings yet

- Liebherr Measuring Instruments WGT 280 1200Document8 pagesLiebherr Measuring Instruments WGT 280 1200CAT MINING SHOVELNo ratings yet

- 503 HydrilDocument4 pages503 HydrilRagesh Raghavan100% (1)

- Multifan 50 HZ 03-2011Document2 pagesMultifan 50 HZ 03-2011ManiwasakiNo ratings yet

- Elnet LT - User ManualDocument78 pagesElnet LT - User ManualVictor GodoyNo ratings yet

- Marcus: Technical DataDocument2 pagesMarcus: Technical DataVictor GodoyNo ratings yet

- Elnet LT: Power Quality & Energy PowermeterDocument1 pageElnet LT: Power Quality & Energy PowermeterVictor GodoyNo ratings yet

- Installation & Operation Manual: Electrical MeasurementsDocument15 pagesInstallation & Operation Manual: Electrical MeasurementsVictor GodoyNo ratings yet

- LT Option MenuDocument1 pageLT Option MenuVictor GodoyNo ratings yet

- Katalog-SA CA IQDocument16 pagesKatalog-SA CA IQVictor Godoy100% (1)

- Acc DX MetricDocument8 pagesAcc DX MetricVictor GodoyNo ratings yet

- Black1000 3000Document35 pagesBlack1000 3000Mauricio BarreraNo ratings yet

- Dvp02lc-Sl Loadcell o en 20101018Document38 pagesDvp02lc-Sl Loadcell o en 20101018Pst Pst PstNo ratings yet

- Motor MolinoDocument1 pageMotor MolinoVictor GodoyNo ratings yet

- Lista de Refaccion: Modelo Hp2070FDocument3 pagesLista de Refaccion: Modelo Hp2070FVictor GodoyNo ratings yet

- Fundamentals Handbook of Mechanical ScienceDocument252 pagesFundamentals Handbook of Mechanical Sciencehenybam100% (1)

- 2-Speed Hammer Drill 2 Vitesses Perceuse À Percussion 2 Velocidad Taladro de PercusiónDocument28 pages2-Speed Hammer Drill 2 Vitesses Perceuse À Percussion 2 Velocidad Taladro de PercusiónVictor GodoyNo ratings yet

- Siemens Etu45b ManualDocument24 pagesSiemens Etu45b ManualVictor Godoy0% (2)

- Siemens Micromaster 440 Manual PDFDocument312 pagesSiemens Micromaster 440 Manual PDFGustavo Barrera100% (1)

- PV 10 User ManualDocument44 pagesPV 10 User ManualVictor GodoyNo ratings yet

- Es PDFDocument18 pagesEs PDFVictor GodoyNo ratings yet

- S7 300 First Time User enDocument68 pagesS7 300 First Time User enLeonardo AlencastreNo ratings yet

- Manual Blue1000Document2 pagesManual Blue1000Victor GodoyNo ratings yet

- Ficha Tecnica SIEMENS S7300Document124 pagesFicha Tecnica SIEMENS S7300Daniel SuarezNo ratings yet

- PV 10 User ManualDocument44 pagesPV 10 User ManualVictor GodoyNo ratings yet

- PV 10 User ManualDocument44 pagesPV 10 User ManualVictor GodoyNo ratings yet

- Electronic Control Systems: Dust Filter ComponentsDocument18 pagesElectronic Control Systems: Dust Filter ComponentsVictor GodoyNo ratings yet

- Es PDFDocument18 pagesEs PDFVictor GodoyNo ratings yet

- PLC Trainers BrochureDocument12 pagesPLC Trainers BrochureVictor GodoyNo ratings yet

- User'S Manual Siemens S7-224 PLC Reference: RCPU224Document28 pagesUser'S Manual Siemens S7-224 PLC Reference: RCPU224Shesharam ChouhanNo ratings yet

- User1 726Document44 pagesUser1 726Victor GodoyNo ratings yet

- Child Has Does: The Adultery, Child Be and Entitled His Own, The Child's That His DueDocument1 pageChild Has Does: The Adultery, Child Be and Entitled His Own, The Child's That His DuerickmortyNo ratings yet

- Student Counseling Management System Project DocumentationDocument4 pagesStudent Counseling Management System Project DocumentationShylandra BhanuNo ratings yet

- File System ImplementationDocument35 pagesFile System ImplementationSát Thủ Vô TìnhNo ratings yet

- Delivery For OutSystems Specialization Sample Exam - enDocument8 pagesDelivery For OutSystems Specialization Sample Exam - enmahesh manchalaNo ratings yet

- Project - PPT 5 ImplementationDocument39 pagesProject - PPT 5 ImplementationBirhanu AbrhaNo ratings yet

- DWC Ordering InformationDocument15 pagesDWC Ordering InformationbalaNo ratings yet

- CW 3 - Non-Profit Making Organisation Sekolah Harapan Bangsa ACADEMIC YEAR 2020/2021Document3 pagesCW 3 - Non-Profit Making Organisation Sekolah Harapan Bangsa ACADEMIC YEAR 2020/2021Adrian WensenNo ratings yet

- Con Law Koppelman HugeDocument203 pagesCon Law Koppelman HugemrstudynowNo ratings yet

- Stanley Diamond Toward A Marxist AnthropologyDocument504 pagesStanley Diamond Toward A Marxist AnthropologyZachNo ratings yet

- JavaDocument14 pagesJavaGANESH REDDYNo ratings yet

- 18 Kadek Devy Crisna S - Emcee ScriptDocument6 pages18 Kadek Devy Crisna S - Emcee ScriptSugar HoneyTheoryNo ratings yet

- 0x08. C - RecursionDocument13 pages0x08. C - RecursionElyousoufi hakim0% (1)

- Newcastle University Dissertation Cover PageDocument5 pagesNewcastle University Dissertation Cover PageThesisPaperHelpUK100% (1)

- 12 Problem Solving Involving ProportionDocument11 pages12 Problem Solving Involving ProportionKatrina ReyesNo ratings yet

- 6 - Designing Manufacturing Processes - Hill - Product ProfilingDocument20 pages6 - Designing Manufacturing Processes - Hill - Product ProfilingLalit S KathpaliaNo ratings yet

- How The CBO Works: Jonathan Lewis WWW - Jlcomp.demon - Co.ukDocument37 pagesHow The CBO Works: Jonathan Lewis WWW - Jlcomp.demon - Co.ukomeratisNo ratings yet

- 115 Landslide Hazard PDFDocument5 pages115 Landslide Hazard PDFong0625No ratings yet

- Golden Field Farmers Multi-Purpose Cooperative: Palay ProductionDocument3 pagesGolden Field Farmers Multi-Purpose Cooperative: Palay ProductionAps BautistaNo ratings yet

- Liebert Exs 10 20 Kva Brochure EnglishDocument8 pagesLiebert Exs 10 20 Kva Brochure Englishenrique espichan coteraNo ratings yet

- Skott Marsi Art Basel Sponsorship DeckDocument11 pagesSkott Marsi Art Basel Sponsorship DeckANTHONY JACQUETTENo ratings yet

- Coldroom Brochure 2020 (Email Version)Document12 pagesColdroom Brochure 2020 (Email Version)MOHAMED FAHMIE SYAFIQ BIN AHMAD BAKRI (LKIM)No ratings yet

- 090 - IRS Levys and LiensDocument4 pages090 - IRS Levys and LiensDavid E RobinsonNo ratings yet

- LECTURE 11-Microalgal Biotechnology-Biofuels N BioproductsDocument16 pagesLECTURE 11-Microalgal Biotechnology-Biofuels N BioproductsIntan Lestari DewiNo ratings yet

- 4 5827923419810760428Document250 pages4 5827923419810760428T M Santhosh KumarNo ratings yet

- Handling and Working With Analytical StandardsDocument6 pagesHandling and Working With Analytical StandardsPreuz100% (1)

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDocument2 pagesSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNo ratings yet

- Action Research - PPT 1Document24 pagesAction Research - PPT 1Gabriel Pelicano100% (2)

- Oxy150 BrochureDocument2 pagesOxy150 BrochureSEC MachinesNo ratings yet

- Conceptual Framework For Financial Reporting: Student - Feedback@sti - EduDocument4 pagesConceptual Framework For Financial Reporting: Student - Feedback@sti - Eduwaeyo girlNo ratings yet

- Casio fx-82MSDocument49 pagesCasio fx-82MSPéter GedeNo ratings yet