Professional Documents

Culture Documents

Mab 206 PDF

Uploaded by

S GULAM MUSTAFAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mab 206 PDF

Uploaded by

S GULAM MUSTAFACopyright:

Available Formats

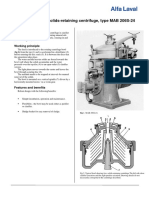

MAB 206

Solids-retaining Centrifugal Separator

Efficiant oil cleaning

Clean oil is crucial for the safe, reliable and economical

running of virtually all kinds of equipment that uses oils

for either fuel, lubrication or in hydraulic systems. Clean

oil reduces wear and corrosion on all equipment installed

downstream, thus helping avoid breakdowns and cutting back

on downtime throughout a plant or installation.

The impact of contaminants in oil

Contaminants in lubricating and hydraulic oils have serious

effects on system performance, operating costs and

durability.

For example, the presence of solid particles:

• abrades metal surfaces

• increases friction

• clogs filters

Similarly, if water is present in the oil, this:

• causes corrosion MAB 206 complete with motor

• reacts with additives

• forms oil/water emulsions

• causes significant deterioration in the performance of Features and benifits

the oil. Compact and robust design with the following benefits:

• eliminates or reduces corrosion by removing any • Simple installation, operation and maintenance

waterpresent in the oil • Internal paring disc for discharge of clean oil

• Large sludge space

• Sludge basket for easy removal of sludge

Standard equipment • Flexibility: the bowl may be used either as purifier or

The separator is working either with two or three phases and clarifier

could easaly be changed between the two diffrent versions • Extremely reliable, ensuring long service life eliminates

clarifier and purifier. or reduces corrosion by removing any

waterpresent in the oil

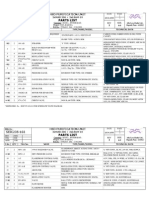

Dimensions Clarifier

1. Oil inlet

2. Clean oil outlet

3. Sludge

Fig 2 MAB bowl arranged as a clarifier for

separating oils containing sludge and a very

small quantity of water.

Purifier

1. Oil inlet

1055 mm (3 ft 5 17/32 inch) 2. Clean oil outlet

3. Sludge

4. Oil/water

interface

1430 mm (4 ft 8 19/64 inch) 5. Water outlet

Fig 3 MAB bowl arranged as a purifier for

separating oils containing sludge and an

appreciable quantity of water.

Technical specifications

Max. throughput capacity 10.6 m3/h1)

Sludge and water space 3.4 l

Feed temperature range 0 - 100 °C

Installed motor power 5.5 / 12 kW 2)

Sound pressure 75 dB(A)3)

1)

Actual capacity depends on composition of feed and separation demands.

2)

Without built-on pump 5.5 kW

With built-on pump 12 kW

1810 mm (5 ft 11 17/64 inch) 3)

According to ISO 3744 or 3746

Shipping data (approximate) Utilities consumption

Net weight 420 kg (926 lbs) Electric power 3.3 – 8 kW4)

Gross weight 525 kg (1 157 lbs)

4)

Actual consumption depends on throughput capacity, feed characteristics.

Volume 2.1 m 3

PCHS00112EN 1309 Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval

Up-to-date Alfa Laval contact

details for all countries are

always available on our website

at www.alfalaval.com.

You might also like

- Concrete WorksDocument82 pagesConcrete WorksarnoldalejadoNo ratings yet

- Mab 206Document82 pagesMab 206david100% (1)

- MARPOL Annex V RegulationsDocument18 pagesMARPOL Annex V Regulationsvidriyirku100% (2)

- FWG Explained (Autosaved)Document21 pagesFWG Explained (Autosaved)Junehenry YalduaNo ratings yet

- 9.5 Oil Purifier - Maintenance ManualDocument104 pages9.5 Oil Purifier - Maintenance Manualsumitchandwaniseros equiptransNo ratings yet

- Alfa Laval PHE For REFDocument4 pagesAlfa Laval PHE For REFNiraj ReginaldNo ratings yet

- Alfa-Laval Modelo MAB-206 - Dados TecnicosDocument2 pagesAlfa-Laval Modelo MAB-206 - Dados Tecnicoszzapieche100% (1)

- Report Hydraulic JumpsDocument11 pagesReport Hydraulic JumpsMayLeongNo ratings yet

- HCL Corrosion Under ControlDocument4 pagesHCL Corrosion Under ControlNXVNNo ratings yet

- JWP -16-C40 and 50 Dimensions ЧертежDocument1 pageJWP -16-C40 and 50 Dimensions ЧертежAlexanderNo ratings yet

- MH - 8 Test Report of Oil PurifierDocument12 pagesMH - 8 Test Report of Oil Purifieralin_popovici_12No ratings yet

- Everything You Need to Know About Performance Curves for Oil SeparatorsDocument8 pagesEverything You Need to Know About Performance Curves for Oil SeparatorsRanjit PaulNo ratings yet

- Compressor 143Document30 pagesCompressor 143James Wayne BarkerNo ratings yet

- WSST Oi Ose 5 10 20 40 80 enDocument2 pagesWSST Oi Ose 5 10 20 40 80 enjing qiangNo ratings yet

- Separator Manual High Speed Separator: MMB 305S-11Document164 pagesSeparator Manual High Speed Separator: MMB 305S-11Bima Surya UtamaNo ratings yet

- Oil SeparatorDocument102 pagesOil SeparatorĐTĐCNHT PXĐTĐNo ratings yet

- Alfa Laval Installation System Reference 01810818Document104 pagesAlfa Laval Installation System Reference 01810818André HeunisNo ratings yet

- MBR Process Design Calculations - US UnitsDocument26 pagesMBR Process Design Calculations - US Unitsmuhammad naseemNo ratings yet

- Mab104 MANUALDocument167 pagesMab104 MANUALMiguel PerezNo ratings yet

- 3 Operation InstructionDocument22 pages3 Operation Instructioncengiz kutukcuNo ratings yet

- Alfa Laval Manaul 26 C 100 PDFDocument131 pagesAlfa Laval Manaul 26 C 100 PDFMARCO VERAMENDINo ratings yet

- SJ30FDocument2 pagesSJ30FRizky Dwi100% (1)

- Alfa Laval MAB206 PDFDocument196 pagesAlfa Laval MAB206 PDFThái Mai ĐìnhNo ratings yet

- SEJC235-102 Parts List: HSD Purification UnitDocument3 pagesSEJC235-102 Parts List: HSD Purification UnitidigitiNo ratings yet

- InsurgentDocument346 pagesInsurgentMubarock84% (19)

- MSPXDocument2 pagesMSPXMarc van der LindeNo ratings yet

- SJ 08 - BrochureDocument2 pagesSJ 08 - BrochureCentrifugal SeparatorNo ratings yet

- Afpx 517Document2 pagesAfpx 517banerjeeamlanNo ratings yet

- 210 прямого действияDocument2 pages210 прямого действияAlexanderNo ratings yet

- Project Guide G50ME C9 - 6 GIDocument674 pagesProject Guide G50ME C9 - 6 GIΚώστας ΧατζηδάκηςNo ratings yet

- Compatible Spare Parts FOR Centrifugal Separators: Alfa LavalDocument4 pagesCompatible Spare Parts FOR Centrifugal Separators: Alfa LavalJerom RonquilloNo ratings yet

- 57,700 DWT Bulk Carrier Whistle System DrawingsDocument31 pages57,700 DWT Bulk Carrier Whistle System DrawingsHemananth VeerasekaranNo ratings yet

- Pump Manual and Parts ListDocument156 pagesPump Manual and Parts ListtechbhazNo ratings yet

- Product Range Alfa LavalDocument13 pagesProduct Range Alfa LavalSoficu DanielNo ratings yet

- MAB Separator PDFDocument2 pagesMAB Separator PDFSundarNo ratings yet

- Instruction - Cleaning Dolphin-JWP-DPUDocument5 pagesInstruction - Cleaning Dolphin-JWP-DPUGiovanni ColonnaNo ratings yet

- FWGDocument141 pagesFWGWajihNo ratings yet

- Separator Spares InternationalDocument8 pagesSeparator Spares InternationalAlexanderNo ratings yet

- 5510 0172 00ppr - Using Methanol Fuel in The - Low PDFDocument16 pages5510 0172 00ppr - Using Methanol Fuel in The - Low PDFarunNo ratings yet

- Mitsubishi Purifier (Separator) SJ10F Spare PartsDocument12 pagesMitsubishi Purifier (Separator) SJ10F Spare PartsSerdar YenerNo ratings yet

- Navy Submarine EM/TEMPEST Falsification FacilityDocument274 pagesNavy Submarine EM/TEMPEST Falsification FacilityMossad News100% (1)

- Alfa Laval Mab 103 24 Spare Parts Manual SPCDocument58 pagesAlfa Laval Mab 103 24 Spare Parts Manual SPCJonathan LisboaNo ratings yet

- Instruction For RBP250-3 and RBP300-3: Anti-Heeling PumpDocument13 pagesInstruction For RBP250-3 and RBP300-3: Anti-Heeling PumpJan MaarschalkerweerdNo ratings yet

- Datasheet TS6Document9 pagesDatasheet TS6HUMBERTO OLIVEIRANo ratings yet

- Scale Inhibitor for Fresh Water GeneratorsDocument2 pagesScale Inhibitor for Fresh Water GeneratorsECO Green and BlueNo ratings yet

- MIB 303 Separation System, Module - Installation Instructions - 1997Document24 pagesMIB 303 Separation System, Module - Installation Instructions - 1997Centrifugal SeparatorNo ratings yet

- Disc Separator SpecificationDocument4 pagesDisc Separator SpecificationyovanNo ratings yet

- SMART WATER – SINGAPORE'S SUCCESSFUL INTEGRATED WATER MANAGEMENTDocument45 pagesSMART WATER – SINGAPORE'S SUCCESSFUL INTEGRATED WATER MANAGEMENTkergabNo ratings yet

- Sondex S7A-S14A-S20A-IDocument2 pagesSondex S7A-S14A-S20A-IEdwin GallegosNo ratings yet

- MAB103Document2 pagesMAB103olhevlaNo ratings yet

- Alfa Laval T5: Gasketed Plate-And-Frame Heat Exchanger For A Wide Range of ApplicationsDocument2 pagesAlfa Laval T5: Gasketed Plate-And-Frame Heat Exchanger For A Wide Range of ApplicationsSergio aldoNo ratings yet

- Feed Pump Long TypeDocument20 pagesFeed Pump Long TypeSyam NairNo ratings yet

- Aldec Decanter CentrifugeDocument4 pagesAldec Decanter CentrifugejailtonpierreNo ratings yet

- Fopx 610TFD-24 SPCDocument74 pagesFopx 610TFD-24 SPCFawllyn Guevara100% (1)

- SA 841 - 846 - Foundation DrawingDocument1 pageSA 841 - 846 - Foundation DrawingCentrifugal SeparatorNo ratings yet

- TPXData SheetDocument4 pagesTPXData Sheetrameshkarthik810No ratings yet

- SA 831 - 836 - Foundation DrawingDocument1 pageSA 831 - 836 - Foundation DrawingCentrifugal SeparatorNo ratings yet

- AFPX 407 Leaflet PDFDocument2 pagesAFPX 407 Leaflet PDFยุทธนา เทียมเมืองNo ratings yet

- Future-Series - Operation Manual 1 - Fie-2000-01-Om1 - Scan3Document71 pagesFuture-Series - Operation Manual 1 - Fie-2000-01-Om1 - Scan3Centrifugal SeparatorNo ratings yet

- Fesx 412B-30Document74 pagesFesx 412B-30Anonymous mGZOP8No ratings yet

- Toyota Cleaner Degraesing Silicon Remover AIM 003 516 0Document5 pagesToyota Cleaner Degraesing Silicon Remover AIM 003 516 0Antonio MartinezNo ratings yet

- Instruction Manual 2301E Speed Controller Simulator KitDocument24 pagesInstruction Manual 2301E Speed Controller Simulator Kityityizhen22No ratings yet

- Purifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsDocument4 pagesPurifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsJohn Lemuel Arquisola0% (1)

- Install and Operate Fixed Tank Cleaning MachineDocument39 pagesInstall and Operate Fixed Tank Cleaning Machinecengiz kutukcuNo ratings yet

- Late Eat Xchanger: HISAKA Web-Simulator (HWS)Document3 pagesLate Eat Xchanger: HISAKA Web-Simulator (HWS)Dika JanuarNo ratings yet

- Pressure Gauge: Component DescriptionDocument6 pagesPressure Gauge: Component DescriptionHAINo ratings yet

- Mab 206Document2 pagesMab 206nathanjimenez1520No ratings yet

- TMP - 28932 Mab 206 55263595 PDFDocument2 pagesTMP - 28932 Mab 206 55263595 PDFGiriDharanNo ratings yet

- Types of Solar CollectorsDocument61 pagesTypes of Solar CollectorsTahaMustahsanNo ratings yet

- Aker Arctic Shuttle Tanker 70000DWTDocument2 pagesAker Arctic Shuttle Tanker 70000DWTscrible2989No ratings yet

- GMAP FertilizerDocument1 pageGMAP FertilizershardulshindeNo ratings yet

- ABS Notations and Symbols - 25 February 2013Document253 pagesABS Notations and Symbols - 25 February 2013Darmono StNo ratings yet

- EVALUASI BIAYA OPERASIONALI WTP (SPH-3Document4 pagesEVALUASI BIAYA OPERASIONALI WTP (SPH-3Martindarma TugasNo ratings yet

- Chandigar H: Submitted To: Submitted By: Ar Pooja Nigam Gagan Kumar Tanwar, 2014PAR5117 Jogeshwar SinghDocument34 pagesChandigar H: Submitted To: Submitted By: Ar Pooja Nigam Gagan Kumar Tanwar, 2014PAR5117 Jogeshwar SinghAchu PeterNo ratings yet

- Honey Karnataka IndiaDocument6 pagesHoney Karnataka IndiaAsh1ScribdNo ratings yet

- Isricu I15889 001Document105 pagesIsricu I15889 001Josif KaevskiNo ratings yet

- Portland Cement: Safety Data SheetDocument11 pagesPortland Cement: Safety Data Sheetanon_381289007No ratings yet

- Final Report The Purse Project PDFDocument115 pagesFinal Report The Purse Project PDFTata RaminathaNo ratings yet

- SCIENCE Paper - 2Document11 pagesSCIENCE Paper - 2Ayush YadavNo ratings yet

- Examining The Stages in Ecological SuccessionDocument3 pagesExamining The Stages in Ecological Successionsharmaegayangos100% (1)

- Hsro-390-Ff & Hsro-4040-FfDocument2 pagesHsro-390-Ff & Hsro-4040-FfYasser Mahmoud ZiadaNo ratings yet

- Multiple Choice Questions (MCQS) : Written/Composed By: - SHAHZAD IFTIKHAR Contact # 0313-5665666 WebsiteDocument8 pagesMultiple Choice Questions (MCQS) : Written/Composed By: - SHAHZAD IFTIKHAR Contact # 0313-5665666 WebsiteFahad NazirNo ratings yet

- Benefits of Waking Up Early and Going to Bed EarlyDocument3 pagesBenefits of Waking Up Early and Going to Bed EarlyAllya NurjanahNo ratings yet

- Conhecimentos Específicos: - IBAMA13 - 003 - 06N925517 - Cespe/Unb - IbamaDocument8 pagesConhecimentos Específicos: - IBAMA13 - 003 - 06N925517 - Cespe/Unb - IbamaMaria ZiglioNo ratings yet

- Step-By-Step Design and Calculations For Water Treatment Plant UnitsDocument16 pagesStep-By-Step Design and Calculations For Water Treatment Plant UnitsGopal SinghNo ratings yet

- Challenges and Coping Mechanisms of Tinago Fisher Folks in Milkfish ProductionDocument8 pagesChallenges and Coping Mechanisms of Tinago Fisher Folks in Milkfish Productionjhon CenaNo ratings yet

- Essco CatalogueDocument76 pagesEssco CataloguePhoneiX Electric ServicesNo ratings yet

- MSDS - Redbac Backing Resin K-001Document6 pagesMSDS - Redbac Backing Resin K-001willian1294No ratings yet

- Doka Formwork SheetsDocument48 pagesDoka Formwork SheetsJasmine Tso100% (1)

- SCPW - What Are Wetland CentresDocument24 pagesSCPW - What Are Wetland CentresAaron Julius M. LeccionesNo ratings yet