Professional Documents

Culture Documents

Test Specifications for Mazda R2 Injection Pump

Uploaded by

Miguel RojasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Specifications for Mazda R2 Injection Pump

Uploaded by

Miguel RojasCopyright:

Available Formats

FOR EPS - 815

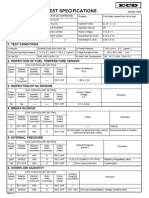

INJECTION PUMP TEST SPECIFICATIONS 096500-3060

INJECTION PUMP 096500-3060 (VE4/10E2300RND306) Rotation Clockwise viewed from drive side

MANUFACTURER MAZDA

ENGINE TYPE R2 Injection Order A-B-C-D

VEHICLE MODEL E SERIES Injection Interval 90°

GOVERNOR TYPE Electronic control Rated Voltage 14 ± 0.1 V

TIMER Electronic control Dimension KF (mm) 5.30 ± 0.10

Pump Select Switch No. (ECD Controller) 4 Dimension K (mm) 3.30 ± 0.10

1. TEST CONDITIONS

1) Nozzle 093400-3230 (DN12SD12A) 4) Feed Pressure 19.6 kPa ( 0.2 kg/cm2)

2) Nozzle Opening Pressure 14.7 ± 0.2 MPa ( 150 ± 2 kg/cm2) 5) High Pressure Pipe Ø2 × Ø6 × 840 mm

3) Test Oil SAE J967 (ISO4113) 6) Inlet Fuel Temperature 40 - 43 °C (104 - 109.4 °F)

2. INSPECTION OF FUEL TEMPERATURE SENSOR

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty Pump Sensor Resistance

Remarks

(rpm) Selector Quantity Ratio Select (k )

Command Command Switch

Fuel

— Temperat — — REC OFF 1.85 ± 1.50

3. INSPECTION OF Ne SENSOR

ECD CONTROLLER SETTING

Pump Sensor Output

Speed Display Injection Duty Pump Voltage Remarks

(rpm) Selector Quantity Ratio Select (V)

Command Command Switch

50 Np — — REC OFF 0.1 or more

4. BREAK-IN DRIVE

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty Pump Check Remarks

(rpm) Selector Quantity Ratio Select

Command Command Switch

0 SPV OFF 446 0 REC OFF — Setting

No fuel leaks, no abnormal noise, and no Drive more than 5 minutes.

1275 SPEED 446 0 REC OFF abnormal temperature rising.

5. INTERNAL PRESSURE

ECD CONTROLLER SETTING

Pump

Speed Display Injection Duty Pump Internal Pressure

Remarks

(rpm) Selector Quantity Ratio Select (kg/cm2)

Command Command Switch

0 SPV OFF 3D0 0 REC OFF —

2125 SPEED 3D0 0 REC OFF 8.75 ± 0.15 (857.9 ± 14.7 kPa) Adjust by Regulating Valve

100 SPV OFF 539 0 REC OFF 2.00 or more (196 kPa) Confirmation

6. OVERFLOW QUANTITY

ECD CONTROLLER SETTING

Pump Overflow

Speed Display Injection Duty Pump Quantity Remarks

(rpm) Selector Quantity Ratio Select (cc/1000st)

Command Command Switch

0 SPV OFF 3D0 0 REC OFF —

2125 SPEED 3D0 0 REC OFF 157 - 251 If it’s out of specification, change overflow valve.

2005.03.21

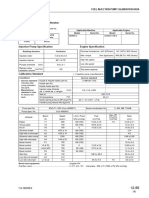

FOR EPS - 815 096500-3060

7. ADJUSTMENT OF TIMER (Always stop pump when changing the first digit of injection quantity command.)

ECD CONTROLLER SETTING

Pump

Display Injection Duty Pump Timer Stroke

Speed Remarks

Selector Quantity Ratio Select (mm)

(rpm)

Command Command Switch

2125 Timer Adjust 000 0 REC OFF 10.30 ± 0.24

1275 Timer Adjust 100 0 REC OFF 10.30 ± 0.24

1275 Timer Adjust 200 50 REC OFF 5.00 ± 2.50

1275 Timer Adjust 300 100 REC OFF 0

200 Timer Adjust 400 0 REC OFF 3.60 or more

100 Timer Adjust 500 0 REC OFF 0.40 or more Internal Pressure : 2.0 kgf/cm2 or more (196.0 kPa)

NOTE : Adjustment should be done by Timer Adjust Shim.

8. PRESETTING FOR CAM ANGLE ADJUSTMENT

ECD CONTROLLER SETTING

DENSO

Pump Display Injection Quantity Duty Pump Standard Bench Standard

Speed Selector Command Ratio Select [ND - CPS] Remarks

(mm3/st·cyl.)

(rpm) Command Switch (cc/200st·cyl.)

First Second Third

digit digit digit

0 SPV OFF 4 5 3 100 REC OFF — —

360 SPL 4 5 3 100 REC OFF 3.4 ± 0.1 17.0 ± 0.1

If Q is out of Target

360 SPV OFF 4 100 REC OFF — — Quantity with 4, 5, 3, adjust

2nd. and 3rd. digits to get

"Target Quantity".

360 SPL 4 100 REC OFF 3.4 ± 0.1 17.0 ± 0.1 Re-measurement

※ When the correction value is raised by 1 level,

the injection quantity is increased approx. 0.2 - 0.3 mm3/st (0.04 - 0.06 cc/200st).

9. ADJUSTMENT OF CAM ANGLE

ECD CONTROLLER SETTING

Pump Display Injection Quantity Duty Pump Target Angle

Speed Selector Command Ratio Select (°CA) Remarks

(rpm) Command Switch [Data on Display]

First Second Third

digit digit digit

0 Cam

to Angle 0 0 0 100 REC OFF 14.05 ± 0.50

360

Cam Adjust 2nd. and 3rd. digits to get "Target

360 Angle 0 100 REC OFF 14.05 ± 0.50 Angle".

NOTE : Select "REC ON" position after "Target Angle" is gotten.

: Never forget removing pressure sensor from piping.

FOR EPS - 815 096500-3060

10. ADJUSTMENT OF FUEL DELIVERY ( When the correction value is raised by 1 level, the injection quantity

is increased approx. 0.2 - 0.3 mm /st•cyl (0.04 - 0.06 cc/200st•cyl).

3 )

ECD CONTROLLER SETTING Max.

Pump Target Quantity Spread In Outlet Fuel

Display Injection Duty Pump Bench Standard

Speed [DENSO Standard] Delivery Temperature

Selector Quantity Ratio Select (mm3/st·cyl.)

(rpm) (cc/200st·cyl.) (mm3/st) (°C)

Command Command Switch

100 Q Adjust 000 0 REC OFF 3.8 ± 0.3 17.6 ± 1.7 — 41.0 ± 1.5

100 Q Adjust 100 0 REC OFF 10.2 ± 0.5 49.1 ± 2.5 6.0 41.0 ± 1.5

340 Q Adjust 200 0 REC OFF 1.6 ± 0.2 6.9 ± 1.0 2.0 41.0 ± 1.5

340 Q Adjust 300 0 REC OFF 6.8 ± 0.3 31.7 ± 1.5 — 41.0 ± 1.5

850 Q Adjust 400 0 REC OFF 2.8 ± 0.3 13.2 ± 1.5 2.5 42.0 ± 1.5

850 Q Adjust 500 0 REC OFF 8.3 ± 0.3 40.7 ± 1.5 — 42.0 ± 1.5

1275 Q Adjust 600 0 REC OFF 2.8 ± 0.3 13.3 ± 1.5 2.5 44.0 ± 1.5

1275 Q Adjust 700 0 REC OFF 9.1 ± 0.3 44.3 ± 1.5 — 44.0 ± 1.5

2125 Q Adjust 800 0 REC OFF 3.4 ± 0.4 16.9 ± 1.8 2.5 50.0 ± 1.5

2125 Q Adjust 900 0 REC OFF 8.8 ± 0.3 40.4 ± 1.5 — 50.0 ± 1.5

NOTE : Adjust 2nd. and 3rd. degits of "Injection Volume Command Value" switch to get target quantity.

11. RECONFIRMATION OF FUEL DELIVERY

ECD CONTROLLER SETTING Max.

Pump Target Quantity Spread In Outlet Fuel

Display Injection Duty Pump Bench Standard

Speed [DENSO Standard] Delivery Temperature

Selector Quantity Ratio Select (mm3/st·cyl.)

(rpm) (cc/200st·cyl.) (mm3/st) (°C)

Command Command Switch

100 Confirm 000 0 REC OFF 3.8 ± 0.3 17.6 ± 1.7 — 41.0 ± 1.5

100 Confirm 100 0 REC OFF 10.2 ± 0.5 49.1 ± 2.5 6.0 41.0 ± 1.5

340 Confirm 200 0 REC OFF 1.6 ± 0.2 6.9 ± 1.0 2.0 41.0 ± 1.5

340 Confirm 300 0 REC OFF 6.8 ± 0.3 31.7 ± 1.5 — 41.0 ± 1.5

850 Confirm 400 0 REC OFF 2.8 ± 0.3 13.2 ± 1.5 2.5 42.0 ± 1.5

850 Confirm 500 0 REC OFF 8.3 ± 0.3 40.7 ± 1.5 — 42.0 ± 1.5

1275 Confirm 600 0 REC OFF 2.8 ± 0.3 13.3 ± 1.5 2.5 44.0 ± 1.5

1275 Confirm 700 0 REC OFF 9.1 ± 0.3 44.3 ± 1.5 — 44.0 ± 1.5

2125 Confirm 800 0 REC OFF 3.4 ± 0.4 16.9 ± 1.8 2.5 50.0 ± 1.5

2125 Confirm 900 0 REC OFF 8.8 ± 0.3 40.4 ± 1.5 — 50.0 ± 1.5

12. CHECK POINT

ECD CONTROLLER SETTING

Pump Target Quantity Outlet Fuel

Speed Display Injection Duty Pump [DENSO Standard] Bench Standard Temperature

(rpm) Selector Quantity Ratio Select (cc/200st·cyl.) (mm3/st·cyl.) (°C)

Command Command Switch

2550 Confirm A00 0 REC OFF 3.6 ± 0.6 18.3 ± 3.0 52.0 ± 4.0

2600 Confirm B00 0 REC OFF 2.0 or less 9.9 or less 53.0 ± 4.0

13. NOTE

Timing mark re-marking position : Based on cylinder A, cam lift distance (plunger) should be 1.25 mm

You might also like

- Catálogo Caterpillar 924H PDFDocument731 pagesCatálogo Caterpillar 924H PDFSandroCezardeAraujo86% (22)

- So You Want To Get Into Mapping CarsDocument71 pagesSo You Want To Get Into Mapping CarsMajid100% (2)

- Testing Specifications for Isuzu 6HK1-TC Injection PumpDocument2 pagesTesting Specifications for Isuzu 6HK1-TC Injection Pumpคุณชายธวัชชัย เจริญสุข75% (4)

- User Manual Zongshen XP200 (EN) PDFDocument22 pagesUser Manual Zongshen XP200 (EN) PDFFrank AvilaNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsJack RugNo ratings yet

- EI5501Document4 pagesEI5501aaa bbb100% (1)

- 196000-4270 - Toyota Tabela Teste PDFDocument4 pages196000-4270 - Toyota Tabela Teste PDFJaqueline S. S. Maicá100% (1)

- Inj. Pump Calibration Data: 1. Test ConditionsDocument6 pagesInj. Pump Calibration Data: 1. Test ConditionsMiguel RojasNo ratings yet

- Fuel Injection Pump Data SCANIA DC9Document2 pagesFuel Injection Pump Data SCANIA DC9Mateen Younas100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 12V2000 PDFDocument103 pages12V2000 PDFczarate1974100% (1)

- HOW TO USE PARTS CATALOGUEDocument164 pagesHOW TO USE PARTS CATALOGUEdadu tractor76% (17)

- New Holland b115 Loader Backhoe PartsDocument980 pagesNew Holland b115 Loader Backhoe Partsjoe blow100% (3)

- Engines: Symbolisation 062356 B3 Symbolisation 062045 B5Document52 pagesEngines: Symbolisation 062356 B3 Symbolisation 062045 B5Hamid edris100% (2)

- QSK60 G4 PDFDocument2 pagesQSK60 G4 PDFLuki100% (2)

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsMartin Miguel Gomez SalviNo ratings yet

- PUMP TEST SPECIFICATIONS FOR MAGASA F113 10HPDocument3 pagesPUMP TEST SPECIFICATIONS FOR MAGASA F113 10HPEdinson Ariel Chavarro QuinteroNo ratings yet

- 01EJ3011Document3 pages01EJ3011Михаил ПетровNo ratings yet

- 01EJ5020Document3 pages01EJ5020Miguel RojasNo ratings yet

- 01EJ3070Document3 pages01EJ3070Miguel RojasNo ratings yet

- Injection Pump Test SpecificationsDocument4 pagesInjection Pump Test SpecificationsJunior IungNo ratings yet

- 01EK1310Document2 pages01EK1310ficoschaNo ratings yet

- Hino FuelPump Calibrate 098000-1150Document2 pagesHino FuelPump Calibrate 098000-1150คุณชายธวัชชัย เจริญสุข100% (2)

- Injection Pump Test Specifications: CPS21 AVM2PC-20hpDocument2 pagesInjection Pump Test Specifications: CPS21 AVM2PC-20hpDilakartikaNo ratings yet

- 02EN0160Document2 pages02EN0160Miguel RojasNo ratings yet

- Tabla de Prueba Bomba Common Rail Denso HP3 (29400-12 (Nissan (1) )Document2 pagesTabla de Prueba Bomba Common Rail Denso HP3 (29400-12 (Nissan (1) )rafaelNo ratings yet

- 01EK2041Document2 pages01EK2041ficoschaNo ratings yet

- Injection pump test specificationsDocument2 pagesInjection pump test specificationsMiguel RojasNo ratings yet

- Tabla 6068TF250 JD PDFDocument3 pagesTabla 6068TF250 JD PDFKevin TtitoNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- 02EN0780 Yd25 PDFDocument2 pages02EN0780 Yd25 PDFKevin TtitoNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsKevin TtitoNo ratings yet

- 02EN0780 Yd25 PDFDocument2 pages02EN0780 Yd25 PDFKevin TtitoNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test Specificationsaddiesel100% (1)

- 01EJ3051Document3 pages01EJ3051ForteLubNo ratings yet

- PUMP TEST SPECSDocument2 pagesPUMP TEST SPECSLaboratorios Diesel MGNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsJunior IungNo ratings yet

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pages096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungNo ratings yet

- Injection Pump Test Specifications 093000-573#: ApproxDocument3 pagesInjection Pump Test Specifications 093000-573#: ApproxBaytolgaNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- 0599 PDFDocument2 pages0599 PDFEdinson Ariel Chavarro QuinteroNo ratings yet

- 0599Document2 pages0599Edinson Ariel Chavarro Quintero100% (1)

- Ei4060 1Document4 pagesEi4060 1Miguel RojasNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsMartin Miguel Gomez SalviNo ratings yet

- 01EJ3060.PDF Prueba en BancoDocument3 pages01EJ3060.PDF Prueba en BancoAlex PakitoNo ratings yet

- 4720Document3 pages4720Junior IungNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test Specificationsadmin tigasaudaraNo ratings yet

- Injection pump test specificationsDocument3 pagesInjection pump test specificationsSuperlativo Igv100% (1)

- INJECTION PUMP TEST SPECIFICATIONSDocument3 pagesINJECTION PUMP TEST SPECIFICATIONSEdinson Ariel Chavarro QuinteroNo ratings yet

- FIP Cal PC130-7Document1 pageFIP Cal PC130-7Agus WijayadiNo ratings yet

- Injection Volume Adjustment Test Conditions: 6c-59-1.tifDocument33 pagesInjection Volume Adjustment Test Conditions: 6c-59-1.tifElvis Eliud HernándezNo ratings yet

- 196000-175# 096000-175#Document4 pages196000-175# 096000-175#Junior Iung100% (1)

- 096000-4860 Toyata Hilux-4 Runner PDFDocument4 pages096000-4860 Toyata Hilux-4 Runner PDFBaytolgaNo ratings yet

- Atos Fuel SDocument133 pagesAtos Fuel Singenieriaelectronic100% (1)

- 0 402 066 733ab Fuel Injection Pump Calibration DataDocument1 page0 402 066 733ab Fuel Injection Pump Calibration Datahichkiim KukuNo ratings yet

- EH4890Document4 pagesEH4890aaa bbbNo ratings yet

- Injection Pump Test Specifications 196000-517#Document4 pagesInjection Pump Test Specifications 196000-517#Edinson Ariel Chavarro QuinteroNo ratings yet

- T S (SYC00109) F 23, 2011: EST PEC EbruaryDocument4 pagesT S (SYC00109) F 23, 2011: EST PEC EbruaryDennis K ThomasNo ratings yet

- 01EJ2010Document3 pages01EJ2010ForteLubNo ratings yet

- AC Servo Motor and Driver Designation and SpecificationsDocument39 pagesAC Servo Motor and Driver Designation and SpecificationsAnes BelNo ratings yet

- PM Tune-Up Report AnalysisDocument5 pagesPM Tune-Up Report Analysisrohmin ibrahimNo ratings yet

- ALE75-100AV Specification EN 3A40ZS1199P1-04Document27 pagesALE75-100AV Specification EN 3A40ZS1199P1-04Thanh BarcaNo ratings yet

- Komatsu PC400LC-7L A86001 TESTDocument408 pagesKomatsu PC400LC-7L A86001 TESTHai Van100% (2)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Model DBGVCC42!3-8AJ: - Customer Part NoDocument2 pagesModel DBGVCC42!3-8AJ: - Customer Part NoMiguel RojasNo ratings yet

- DBGVC231 7BMDocument3 pagesDBGVC231 7BMMiguel RojasNo ratings yet

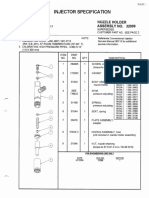

- Injector Specification: Assembly No: 32144Document1 pageInjector Specification: Assembly No: 32144Miguel RojasNo ratings yet

- DBGVC231 6BMDocument3 pagesDBGVC231 6BMMiguel RojasNo ratings yet

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Miguel Rojas100% (1)

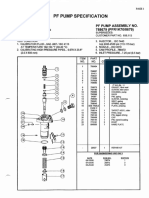

- PF Pump Specification: Stmdyne"Document2 pagesPF Pump Specification: Stmdyne"Miguel RojasNo ratings yet

- Cmi+9/643-H: Descrlptlon AMTDocument2 pagesCmi+9/643-H: Descrlptlon AMTMiguel RojasNo ratings yet

- Injection Pump Specification for Ford 172 Cu. In. Industrial EngineDocument3 pagesInjection Pump Specification for Ford 172 Cu. In. Industrial EngineMiguel RojasNo ratings yet

- DBGV (X429 - 3cli: ModelDocument2 pagesDBGV (X429 - 3cli: ModelMiguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 30163Document2 pagesInjector Specification: Nozzle Holder Assembly No. 30163Miguel RojasNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration DataMiguel RojasNo ratings yet

- Stamping Reference GuideDocument170 pagesStamping Reference GuideMiguel Rojas100% (2)

- Dpico: Inj. Pump Calibration DataDocument3 pagesDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- Stanadyne Corporation: OEM To Fuel Manager Brand Cross Reference P/Ns For Filter Elements 99642 - August 2002Document3 pagesStanadyne Corporation: OEM To Fuel Manager Brand Cross Reference P/Ns For Filter Elements 99642 - August 2002Miguel RojasNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsMiguel RojasNo ratings yet

- 160 300isuzu1Document20 pages160 300isuzu1Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification SheetDocument2 pagesPF Pump Specification SheetMiguel RojasNo ratings yet

- C Program Files Documents and Settings All Users Gerencia Dieselmotor Mis Documentos GERENCIA TESTSPEC TESTSPEC 01EJ0081 PDFDocument3 pagesC Program Files Documents and Settings All Users Gerencia Dieselmotor Mis Documentos GERENCIA TESTSPEC TESTSPEC 01EJ0081 PDFMiguel RojasNo ratings yet

- MODEL DBGFC 637-n AF: Qtilog - Page NO GDocument2 pagesMODEL DBGFC 637-n AF: Qtilog - Page NO GMiguel RojasNo ratings yet

- Injection pump specification sheetDocument2 pagesInjection pump specification sheetMiguel RojasNo ratings yet

- User's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemDocument5 pagesUser's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemMiguel RojasNo ratings yet

- Diesel Fuel Filter Systems GuideDocument6 pagesDiesel Fuel Filter Systems GuideMiguel RojasNo ratings yet

- DBGVC 433-1DW: ModelDocument2 pagesDBGVC 433-1DW: ModelMiguel RojasNo ratings yet

- OEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Document6 pagesOEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Miguel RojasNo ratings yet

- Porsche Cayenne ManualDocument96 pagesPorsche Cayenne Manualgraig27No ratings yet

- Mathcad - Example 2 - 2 Finite Heat ReleaseDocument7 pagesMathcad - Example 2 - 2 Finite Heat ReleaseQuinn StraubNo ratings yet

- Elantra 2003 2.0LDocument200 pagesElantra 2003 2.0LMaykol Gonzalez0% (1)

- TM 11-900 1942 Pe-75a and Pe-75bDocument63 pagesTM 11-900 1942 Pe-75a and Pe-75bAdvocateNo ratings yet

- Yamaha 20C Service Manual (En)Document284 pagesYamaha 20C Service Manual (En)bernabel pirela50% (2)

- BJ Cicada: Bore: Stroke: Displacement: 0.437" (11.10mm) 0.554" (14.07mm) 0.093 Cuin (1.362cc)Document5 pagesBJ Cicada: Bore: Stroke: Displacement: 0.437" (11.10mm) 0.554" (14.07mm) 0.093 Cuin (1.362cc)Vignesh WaranNo ratings yet

- Códigos de Fallas de Problemas Específicos de PEUGEOTDocument8 pagesCódigos de Fallas de Problemas Específicos de PEUGEOTJesus GarciaNo ratings yet

- Ycf Catalog 2020 PDFDocument136 pagesYcf Catalog 2020 PDFMarco Antonio ZuluagaNo ratings yet

- Controller Firmware Chart R4Document5 pagesController Firmware Chart R4Rafaa AbdelkaderNo ratings yet

- SCIENCE 9 Quarter 4 Assessment TestDocument5 pagesSCIENCE 9 Quarter 4 Assessment TestAngelita MenesesNo ratings yet

- 02 - Engine Operating CharateristicsDocument25 pages02 - Engine Operating CharateristicsFabio BosioNo ratings yet

- Environmental Quality (Control of Petrol and Diesel Properties) Regulations 2007 PDFDocument10 pagesEnvironmental Quality (Control of Petrol and Diesel Properties) Regulations 2007 PDFMyteamFifaNo ratings yet

- Cummins Tabla OverhaulDocument1 pageCummins Tabla Overhaulfdpc1987No ratings yet

- V5 + V3 (172MM-A) Engine Parts CatalogueDocument67 pagesV5 + V3 (172MM-A) Engine Parts Cataloguehenry_lehmannNo ratings yet

- r1040 r1080 k1080 Series Industrial EnginesDocument96 pagesr1040 r1080 k1080 Series Industrial Enginessardhan.rajender84100% (1)

- 2X 1 5Document218 pages2X 1 5Raby AbidiNo ratings yet

- 3512C 1500 KW Performance DataDocument10 pages3512C 1500 KW Performance DatapriyosantosaNo ratings yet

- Mechanical Engineering Questions and AnswersDocument3 pagesMechanical Engineering Questions and AnswerskpNo ratings yet

- ATD - I IA QP FinalDocument1 pageATD - I IA QP FinalSarita UmadiNo ratings yet

- 4.1 Doosan Mitsubishi 2.4L TrainingDocument138 pages4.1 Doosan Mitsubishi 2.4L TrainingAugusto Nuñez50% (2)

- Engine Performance Data at 1800 RPM: Curve Number: Basic Engine ModelDocument3 pagesEngine Performance Data at 1800 RPM: Curve Number: Basic Engine ModelMohamed ElsayedNo ratings yet

- PDE Injector Function Description - 030401eb-1Document16 pagesPDE Injector Function Description - 030401eb-1Risa GirasNo ratings yet