Professional Documents

Culture Documents

Guide For Maritime Transportation of Direct Reduced Iron (A) (Briquettes, Hot-Moulded)

Uploaded by

EnriqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide For Maritime Transportation of Direct Reduced Iron (A) (Briquettes, Hot-Moulded)

Uploaded by

EnriqueCopyright:

Available Formats

Maritime Guide for Direct Reduced Iron (A).

Briquettes, hot - moulded Pag:1 of 17

GUIDE FOR MARITIME TRANSPORTATION

OF DIRECT REDUCED IRON (A)

(Briquettes, hot-moulded)

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:2 of 17

CONTENTS

1.- MATERIAL DESCRIPTION 3

2.- MATERIAL CLASSIFICATION 4

3.- BULK CARGO SHIPPING NAME 4

4.- HAZARDS 4

4.1.- Oxygen depletion 4

4.2.- Hydrogen generation 4

4.3.- Self-heating 4

4.4.- Dust generation 4

5.- STOWAGE & SEGREGATION 4

6.- GENERAL NORMS, GUIDELINES AND PRECAUTIONS 5

7.- LOADING PROCEDURES 7

7.1.- Logistics and loading particulars of Port 7

7.2.- Requirements prior to loading 7

7.3.- Requirements during loading 8

7.4.- Top-off operations 9

8.- VOYAGE PRECAUTIONS 10

8.1.- Ventilation 10

8.2.- Routine checks 11

8.3.- Monitoring 11

8.3.1.- Procedures for measuring hydrogen or explosivity in cargo spaces 12

8.3.2.- Procedures for measuring temperature of the stow 12

8.3.3.- Procedures for measuring oxygen in cargo spaces 13

9.- UNLOADING 13

9.1.- Lightering operations at discharge port 14

10.- EMERGENCY PROCEDURES 14

10.1.- Additional Precautions If Concentration Of Hydrogen Over 1% (25% LEL) 15

10.2.- Procedures If Briquettes Temperatures Rise Above 65°C (Overheating) 15

10.3.- Procedures if seawater enters the cargo holds 17

WARNING 17

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:3 of 17

GUIDE FOR MARITIME TRANSPORTATION OF DIRECT REDUCED IRON (A)

The scope of these guidelines is to act as a core document from which charterers, carriers

and terminal operators can develop specific and detailed instructions for the areas of their

responsibility describing how the standards of these guidelines are to be applied and

maintained.

1.- MATERIAL DESCRIPTION

Direct Reduced Iron (A). Briquettes, hot-moulded - DRI (A) is produced by removing oxygen

from iron ore by reaction with hydrogen and carbon monoxide at high temperature. This

reduced product is then compacted to form briquettes at 650 °C, and the briquettes are then

passivated.

DRI(A), is defined by the International Maritime Solid Bulk Cargoes Code (IMSBC Code)

published by the International Maritime Organization as “… a metallic grey material, moulded

in a briquette form, emanating from a densification process whereby the direct reduced iron

(DRI) feed material is at a temperature greater than 650°C at time of molding (Hot Briquetting)

and has a density greater than 5,000 Kg/m 3. Fines and small particles (under 6.35 mm) shall

not exceed 5% by weight.”

The material typically has the following Chemical and Physical Specifications in percentage:

Chemical Specifications (%) Physical

Specifications

Total Iron (FeT) 89.60 mín Size: 108 mm x 48 mm x 32

mm

Metallic Iron (Fe°) 84.70 mín Weight: 0.5 – 0.7 kg

Carbon (C) 0.80 mín Apparent Density: > 5.00 g/cm3

Phosphorous (P) 0.130 máx Bulk Density: 2.40 – 2.80 t/m3

Sulfur (S) 0.010 máx Granulometric > 6.35 mm: 95.0 % min

Distribution:

< 6.35 mm: 5.0 % max

Total Gangue 6.50 máx Moisture: 0.5 % max

A preliminary certificate of analysis of the product loaded will be supplied to the Master before

sailing.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:4 of 17

2.- MATERIAL CLASSIFICATION

This material is classified as DIRECT REDUCED IRON (A) Briquettes, Hot Moulded, Class

MHB (Material Hazardous only in Bulk), Group B, Appendix 1, of the International Maritime

Solid Bulk Cargoes Code (IMSBC Code), and as such is suitable for sea carriage without the

use of inert gas or other special precautions. DRI (A) conforms to the requirement of the

above-mentioned IMO CODE in its latest edition. A copy of the relevant pages of the IMSBC

Code is included with this package as a courtesy only. Carriers are responsible for the latest

IMO documents on bulk cargoes.

3.- BULK CARGO SHIPPING NAME

The Bulk Cargo Shipping Name for this material as per the IMSBC Code is Direct Reduced

Iron (A) Briquettes, hot-moulded and shall be identified with such name in all shipping

documents.

4.- HAZARDS

4.1.- Oxygen depletion

DRI (A) is liable to cause oxygen depletion in cargo spaces.

4.2.- Hydrogen generation

The material may slowly evolve hydrogen after contact with water (notably saline water).

Hydrogen is a flammable gas that can form an explosive mixture when mixed with air in

concentration above 4% in volume (100% LEL) and can cause explosions in the

presence of an ignition source.

4.3.- Self-heating

Temporary increase in temperature of about 30°C due to self-heating may be

expected after material handling in bulk.

This cargo is non-combustible or has a low fire-risk.

4.4.- Dust generation

Dust is generated during material handling in bulk at loading and unloading.

5.- STOWAGE & SEGREGATION

Separated from good of class 1 (division 1.4S), 2, 3, 4 and 5 and class 8 acids in packaged

form (see IMDG Code).

Separated from solid bulk materials of classes 4 and 5.

Separated longitudinally by an intervening complete compartment or hold from goods of class

1 others than division 1.4S.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:5 of 17

Boundaries of compartments where this cargo is carried shall be resistant to fire and passage

of liquid.

6.- GENERAL NORMS, GUIDELINES AND PRECAUTIONS

Any ship intended for the carriage of DRI (A) should hold the appropriate valid statutory

certification. The certificates should be valid during the period of loading, carriage and

unloading.

In general, the ship should be suitable in all respects for the carriage of bulk cargoes and in

particular suitable for the loading, carriage and unloading of HBI. The specific requirements

are as follows:

Single deck Bulk Carrier

Classed by a world recognized Classification Society

A tank top strength between 12 and 15 mt/m²

Fitted with a natural ventilation system and/or a mechanical ventilation system as per

the DRI (A) schedule listed in the International Maritime Solid Bulk Cargoes Code

(IMSBC Code).

The vessel shall load, stow and unload cargo in accordance with the latest IMSBC Code, the

BLU Code (Code of Practice for the Safe Loading and Unloading of Bulk Carriers) as

supplemented by this Maritime Guide.

The relevant IMO Codes and recommendations on ship/port co-operation, loading, sea

carriage and unloading of bulk cargoes should be complied with (i.e., SOLAS, BLU Code,

IMSBC Code).

DRI (A) is suitable for shipment if it conforms to the following requirements:

the quantity of fines and small particles (up to 6.35 mm in size) is no more than

5% by weight;

the moisture content is less than 1%; and

the temperature does not exceed 65°C

This cargo shall be kept as dry as practicable during loading and the voyage. Open storage is

acceptable prior to loading. This cargo shall not be loaded or transfer from barge to ship, ship

to barge or ship to ship during precipitation.

No water shall be allowed to enter cargo spaces containing this cargo.

All shipboard work necessary for docking, undocking and loading, including but not limited to

line handling and tending, opening & closing hatches and normal deck clean up should be

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:6 of 17

done by the vessel’s crew, after they are made aware by the vessel management of the

possibility of the presence of flammable hydrogen gas.

Cargo spaces containing this cargo and adjacent spaces may become oxygen- depleted.

Flammable gas may also build-up in these spaces. All precautions shall be taken upon

entering the cargo and adjacent spaces.

Personnel should not be permitted to enter a cargo space or enclosed adjacent space unless

the space has been ventilated, the atmosphere tested and found to be gas-free with at least

21% of oxygen. The ship should carry on board the self-contained breathing apparatus

required by SOLAS regulation II-2/19.3.6.2 and should follow the recommendations of IMO

Resolution A.864(20), 05 December 1997 for entering enclosed spaces aboard ships.

Appropriate precautions shall be taken to protect machinery and accommodation from the

dust of the cargo. Bilge wells of the cargo spaces shall be protected from ingress of the cargo.

Radars and exposed radio communication equipment of the ship, which carry this cargo, shall

be protected from the dust of this cargo.

Persons, who may be exposed to the dust of the cargo, shall wear protective clothing,

goggles, or other dust eye-protection and dust filter masks, as necessary.

Boundaries of cargo spaces should be resistant to fire and passage of water. So far as

possible, the cargo should not be stowed adjacent to hot areas.

Electrical fittings, cables, components and equipment located in cargo spaces, adjacent

spaces and on deck should be free from defects, properly safeguard against short circuits and

sparking, safe for use in an explosive atmosphere or positively isolated. Proper grounding of

deck components should be in place to avoid static. For example, incandescent lighting in a

hold (a broken bulb will briefly expose the light element, which is at high heat), unprotected

cables that may cause spark, etc., should be avoided. In addition, special precautions shall be

taken to ensure that no source of ignition gets into the cargo spaces. Where a bulkhead is

required to be suitable for segregation purposes, cable and conduit penetrations of the decks

and bulkheads should be adequately sealed.

Smoking, the use of naked flames, burning, cutting, chipping, welding or other sources of

ignition shall not be permitted near cargo spaces, adjacent spaces or on deck at any time

during handling, loading, carriage and unloading. “NO SMOKING” signs shall be posted on

decks and in areas adjacent to cargo spaces and no naked lights shall be permitted in these

areas. Prohibition of smoking, hot-work or any possible ignition source in cargo or adjacent

spaces shall be strictly enforced.

It is advisable that vessels have hydraulic fast opening / closing system of hatch covers in

order to avoid rain falling into the holds during loading.

Where practicable, ballast tanks adjacent to the cargo spaces containing this cargo, other

than double-bottom tanks, shall be kept empty.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:7 of 17

Weather deck closures shall be inspected and tested to ensure integrity.

7.- LOADING PROCEDURES

7.1.- Logistics and loading particulars of Port

- The Vessel will be berthed with the port side to the pier.

- Ship loader moves running along the pier (forward to aft) and the loader arm moves from

port to starboard. In this way, cargo can be loaded and evenly spread into the hold, which is

SHIPPER’s loading recommendation.

- During loading, our personnel will be on the pier and/or the Vessel assisting the operation

and acting as a link between the Vessel’s Staff and the operator’s loading system at the Port

terminal. Shipper’s personnel will use best efforts to cooperate and/or assist vessel’s staff

during loading operations.

- Pre-stowage plan and loading sequence program is the responsibility of the Vessel.

- Loading will be under the Vessel’s control and supervision. Therefore, SHIPPER will not be

responsible of the way the cargo is distributed inside the hold upon completion of loading.

- It is Crew’s responsibility that the Vessel remains against the pier for an adequate stowage.

Please keep a constant watch on mooring lines.

NOTE: IF THE PORT OPERATOR DECIDES TO STOP THE LOADING OPERATIONS DUE

TO VESSEL SEPARATION FROM THE PIER, THIS TIME PERIOD WILL BE FOR VESSEL’S

ACCOUNT.

“We would like to point out that any time lost due to: (1) - Deballasting the Vessel, (2) -

Problems with hatch covers, (3) - by any other problem of Vessel’s concern that may stop

loading and (4) - checking draft and calculating trimming operations, WILL BE FOR

VESSEL’S ACCOUNT in excess of normal draft checking (Initial-intermediate and

final)”.

7.2.- Requirements prior to loading

Open storage of DRI (A) is acceptable prior to loading as per the IMSBC Code entry for this

cargo.

The cargo spaces shall be clean, dry and free from salt and residues of previous cargoes.

Wooden fixtures such as battens, loose dunnage, debris and combustible materials shall be

removed.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:8 of 17

Bilge wells shall be clean, dry and covered as appropriate, to prevent ingress of the cargo.

Burlap or any combustible material shall not be used. All bilge lines, sounding pipes and other

service lines within the cargo spaces should be checked and be in good order. Bilge wells

should be sift-proof and kept dry during the voyage.

Weather deck closures and hatch covers shall be inspected and tested to ensure integrity and

weather tightness which shall be maintained throughout the voyage. Water tightness testing

will be carried out prior to loading. Hatches and other hold openings shall be watertight.

The master of the ship is responsible for the integrity of the cargo holds in order to ensure that

no water gets inside. Seawater wetting the cargo can give rise to severely adverse

consequences.

Radar, RDF scanners, deck motors, hatch pistons and similar delicate equipment should be

protected against dust and fines during loading and unloading.

Prior to loading this cargo, the shipper shall provide the master with a certificate issued by a

competent person recognized by the National Administration of the port of loading stating that

the cargo, at the time of loading , is suitable for shipment and that it conforms with the

requirements of the IMSBC Code; that the quantity of fines and small particles (up to 6.35 mm

in size) is no more than 5% by weight; the moisture content is less than 1.0%; and the

temperature does not exceed 65°C.

Pre-stowage plan and loading sequence program is the responsibility of the Captain of the

vessel. A loading sequence form and individual hold loading sequence form should be

prepared prior to arrival for presentation to the shipper upon docking. The sequence should

allow for each pour not to be more than 2,000 tonnes for small holds and 3,000 tonnes for

large holds. Furthermore, the loading sequence should allow for the maximum amount of

cooling time before coming back to the same hold. Thus, if the initial sequence is, for

example, cargo holds 3/5/1/7; then the second run should be in the same order.

7.3.- Requirements during loading

The loading of DRI (A) should not be conducted if the quantity of fines and small particles (up

to 6.35 mm in size) is more than 5% by weight; its moisture content is over 1% and its

temperature exceeds 65°C.

The loading of DRI (A) shall only be done in dry weather conditions. If it begins to rain during

the loading process, the loading operation shall be halted and the hatches closed until the

rain stops. During rainy seasons, only one hold at a time should be opened.

The deck officer on watch shall ensure the spreading of the cargo throughout the cargo hold

to obtain an even surface trim of the cargo. Vessel personnel shall check that trimming is

done correctly and to the master’s requirements and entire satisfaction. The master is

responsible at all times for the safe loading and unloading of the ship as per the IMO BLU

Code.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:9 of 17

If damp DRI (A) (below 1% moisture content) were loaded, it may warm up to about 65° C,

and may produce water vapor (steam) and a small amount of hydrogen gas as it dries. This is

a normal condition and may last from one to two days until the DRI (A) is completely dry.

Steam and hydrogen gas evolution will cease. Natural ventilation is necessary.

Whenever weather permits, the hatch covers should be kept open to allow cooling after cargo

handling in bulk.

Immediately after completion of loading and sealing of cargo spaces for water tightness,

accumulations of dust from this cargo on deck or in proximity to cargo spaces shall be

removed as quickly as possible. Cleaning exposed radio communications equipment to which

dust from cargo might adhere is highly advisable.

Upon completion of loading, DRI (A) may be expected to warm up to about 45°C (in tropical

areas, this temperature may vary depending on the atmosphere), and may produce water

vapor (steaming), which is a normal condition. Hydrogen gas from water condensation may

be generated and due attention shall be paid as to open the natural ventilation as necessary.

7.4.- Top-off operations

In the case of top-off operations with barges, the same precautions taken for loading as

described in above section should be strictly followed where applicable. Additionally, the

following precautions and steps should be undertaken:

Barges’ cargo hopper shall be clean, dry and free from salt and residues of previous cargoes.

The cargo hold should have no residual chlorides or past cargoes, particularly those which

may increase oxidization, such as cement, lye, and borax.

Top-off operations shall not be performed during precipitation.

Barges for top-off operations should be provided with covers or the DRI (A) loaded should be

covered with appropriate material such as canvass or tarpaulin in order to limit water

absorption during the voyage from the loading dock to the toping-off area.

Additionally, great care shall be taken to minimize the entrance and accumulation of water in

the hoppers. Barge operators should have portable bilge pumps to pump out any water

accumulated in barge hoppers’ bilges and avoid excessive wetting of DRI (A).

Barges should be loaded in such a way as to have them with an adequate trim by the stern

(0.3 m or so) so that water accumulates in the aft part of the barge hopper for its easy

pumping out.

The DRI (A) should be loaded in the central part of the barge, leaving free space on port and

starboard sides for easy drainage of water to the stern and towards the bilge well. Free space

of about 2 meters should also be left from the aft part to avoid wetting of cargo with bilge

water accumulated.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:10 of 17

The DRI (A) should be evenly distributed in the barge, making the pile as flat as possible, in

small heaps. The drop of the briquette should be minimized, to reduce breakage and fine

generation.

The DRI (A) shall not be loaded if temperature is in excess of 65 °C.

The loading operations should be started in one end of the barge and thereafter continue

along the length of the barge hopper until reaching the other end of the barge.

Once the cargo is evenly distributed in the hoppers, loading personnel shall have available

space for inspection purposes.

The loading operations shall be supervised by personnel familiar with the safety precautions

and emergency procedures associated with handling of DRI (A). The loading operators shall

be trained in the appropriate safety precautions and emergency procedures for handling this

material

.

Unmanned covered barges used to transport DRI (A) shall be fitted with adequate vents to

provide natural ventilation.

If at any time the cargo compartment of a covered barge shall be entered, the compartment

shall be checked for adequate oxygen concentration. Before any person enter a covered

cargo compartment containing DRI (A), the hatches shall be opened for a sufficient length of

time to dissipate any accumulated gas.

8.- VOYAGE PRECAUTIONS

Provisions stated in the IMSBC Code for the carriage of this material shall be complied with.

Hatches shall remain closed while at sea to prevent the entry of seawater into the holds.

Under no circumstances should seawater be allowed to enter the holds.

During voyage, ventilation, routine checks and monitoring of the cargo should be given due

consideration and exercised as per below procedures:

8.1.- Ventilation

Surface ventilation only, either natural or mechanical, shall be conducted, as necessary,

during the voyage for this cargo. On no account shall air be directed into the body of the

cargo. When mechanical ventilation is used, the fans shall be certified as explosion-proof and

shall prevent any spark generation thereby avoiding the possibility of ignition of hydrogen air

mixture. Suitable wire mesh guards shall be fitted over inlet and outlet ventilation openings.

Ventilation shall be such that escaping gases cannot enter living quarters in hazardous

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:11 of 17

concentrations. During non-favorable weather and sea conditions, surface ventilation should

be conducted as practical and safe as possible.

Ventilation should be closed during heavy seas to keep seawater and moisture out.

8.2.- Routine checks

Personnel shall not be permitted to enter cargo spaces at any time. Suitable signs should be

displayed at all access points and where possible access points to cargo spaces should be

locked.

Bilges shall be sounded twice a day and any excess water pumped out.

Enclosed spaces adjacent to cargo spaces, e.g. storerooms, carpenter’s shops,

passageways, tunnels, etc., should also be regularly monitored for the presence of hydrogen.

Such spaces should be adequately ventilated and, in the case of mechanical ventilation, only

equipment safe for use in an explosive atmosphere should be used. Testing is especially

important prior to permitting personnel to enter such spaces or activating any equipment

located in such spaces.

Before entry by any personnel, enclosed adjacent spaces should be thoroughly ventilated and

the atmosphere tested and found to be gas-free and to have 21% oxygen. If this is not

possible, only trained personnel wearing self-contained breathing apparatus under the

supervision of a responsible officer should undertake emergency entry into such spaces. In

addition, special precautions to ensure that no source of ignition is carried into the space

should be observed

8.3.- Monitoring

Temperature of the cargo shall be taken regularly during the voyage and a record kept on

board for a minimum of two years. For better control, it is advisable that the ship is fitted

and/or carries on board adequate equipment for remotely taking temperature measurements

of the cargo being carried in each hold. The ship should also have means of determining

qualitatively and quantitatively oxygen and hydrogen content of the cargo spaces, without

requiring entry into the cargo spaces. All this equipment should be operational and properly

calibrated at the commencement of loading. The vessel’s crew should be properly trained in

the use of this equipment.

The vessel’s crew should actively use this equipment at least once every shift throughout the

voyage. The information collected should be recorded, kept on board for a minimum of two

years and made available upon request. Results of monitoring during the voyage shall be

sent to the shipper during the voyage or at the end of it.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:12 of 17

8.3.1.- Procedures for measuring hydrogen or explosivity in cargo spaces

For quantitative measurements of hydrogen, a suitable detector shall be on board while this

cargo is carried. The detector shall be suitable for use in an atmosphere without oxygen and

of certified safe type for use in explosive atmosphere. The concentrations of hydrogen in the

cargo spaces carrying this cargo shall be measured regularly, during voyage, and the results

of the measurements shall be recorded and kept on board.

The ingress of moisture into the instrument should be restricted in order to get accurate

results. Proper calibration as per instrument’s manufacturer should be ensured.

The ship’s hatch covers should be fitted with appropriate sampling points (minimum one;

preferable two) for the measurement of hydrogen gas in each cargo hold throughout the

voyage.

The concentration of Hydrogen in the cargo spaces should be kept below 1% or 25% LEL

(Lower Explosivity Limit). If this value is exceeded, immediate measures for dissipating

hydrogen shall be taken as per the Emergency Procedures section of this Guide.

Throughout the voyage, hydrogen gas analyses shall be conducted as frequently as

necessary. In the case, the Hydrogen surpasses 1% or LEL surpasses 25%,, additional

ventilation procedures should be undertaken. Refer to the Emergency Procedures section of

this Guide.

8.3.2.- Procedures for measuring temperature of the stow

Temperature of the cargo shall be taken regularly during the voyage and a record kept on

board for a minimum of two years.

It is advisable that adequate equipment for remote monitoring of temperatures within different

parts of the stowage is incorporated at approximately half depth. It is advisable that at least

four spots in the cargo be monitored per hold.

In warm latitudes the ambient temperature of the cargo spaces above the stowage may rise

to a high during the day due to solar warming, combined with the accompanying

condensation This should not significantly affect the temperature within the cargo. There may

be a steady rise in the cargo temperature for the first 24-36 hours after loading due to

disturbances caused by material handling. A gradual temperature decline towards the ambient

temperature should then follow.

If the temperature rises above 65°C (150F), refer to the Emergency Procedures section of

this Guide.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:13 of 17

8.3.3.- Procedures for measuring oxygen in cargo spaces

An adequate instrument for measuring oxygen concentration in the cargo holds is required.

The ingress of moisture into the instrument should be restricted in order to get accurate

results. Proper calibration as per instrument’s manufacturer should be ensured.

The ship’s hatch covers should be fitted with appropriate sampling points (minimum one;

preferable two) for the measurement of oxygen gas in each cargo hold throughout the

voyage.

Caution: Emergency entry into a cargo space should be undertaken only by personnel

trained in confined space operations and wearing self-contained breathing apparatus, and

protective clothing if necessary, and always under the supervision of a responsible qualified

officer.

9.- UNLOADING

Prior to arrival at the dock or before opening cargo holds, hydrogen gas concentration in

cargo or adjacent spaces should be checked. Care should be taken to vent any accumulated

gases prior to opening of hatch covers. Cargo hatches and other openings should be opened

carefully to avoid creating sparks. If hydrogen concentration is found to be over 1%, the

Captain should notify the harbormaster of the potential dangerous conditions and follow the

procedures outlined in the Emergency Procedures section of this Guide.

Oxygen concentration before entering any cargo spaces shall be also measured. At the

discharging port, no one is to enter any holds until the oxygen content has been verified and

ensured to be over 21%. No one is to go into the holds until after several hours of opening

holds and verifying that the oxygen concentration has been restored.

Check cargo temperature inside cargo holds before unloading. If temperatures of cargo are

over 65°C, follow the procedures outlined in the Emergency Procedures section of this Guide.

Radar, RDF scanner and other delicate equipment should be protected against dust.

Any bulk material handling system such as cranes and grabs can do unloading. Conveyor

belt system is most appropriate for handling from dock to yard. In the yards, front-end loaders

are used to handle the cargo in bulk.

Unloading can be conducted under all weather conditions, as long as the DRI (A) remains

outdoors, is not going to be transshipped, will not be stored in a confined space, and will not

have a confined space directly above.

During unloading, a fine spray (not excessive) of fresh water is permitted for dust control. It is

not recommended to apply a fine spray of fresh water to this cargo when it will be stored in an

enclosed space or is to be transshipped.

The cargo temperature should be monitored during unloading.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:14 of 17

If hot product needs to be discharged, it should be done in an open and clean space free and

away from combustible materials such as coke, wood, lye, chlorines, etc. No hot material

shall be discharged on wooden docks. Refer to the Emergency Procedures section of this

Guide.

Immediately after unloading, accumulations of dust or small particles from this cargo on deck

or in proximity of cargo spaces shall be removed as quickly as possible.

After the holds are clean, the hatches should be shut, and the deck and ships’ structure

should be thoroughly cleaned using an environmental friendly method and media in order to

remove any fines or dust that may have accumulated. Local and international environmental

regulations should be strictly followed for this procedure.

9.1.- Lightering operations at discharge port

Ships carrying DRI (A) and discharging on barges should follow the same procedures as

described in the Top-off Operations section of this Guide. The same precautions should be

strictly followed concerning limiting the water absorption of the product during its

transportation by barge to the discharging site.

Unloading can be conducted under all weather conditions, as long as the DRI (A) remain

outdoors and is not in a confined space, and does not have a confined space directly above.

10.- EMERGENCY PROCEDURES

In case of any emergency in which the cargo of DRI (A) is involved, do the following:

a. Follow the procedures below for each particular case,

b. CONTACT THE SHIPPER IMMEDIATELY for detailed instructions at any of the

following telephone or fax numbers:

Shipper: Contact Telephone Fax e-mail

Antonieta Paciello (58-286) 7006027 (58-286) 9941091 apaciello@venprecar.com

Félix Rodríguez (58-286) 7006024 (58-286) 9940607 rfelix@venprecar.com

José Arcadio Castillo (58-286) 7006141 (58-286) 9940607 josecastillo@venprecar.co

m

(58-286) 7006142

Port:

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:15 of 17

c. Inform your P & I Club immediately and seek expert advice. Have the P&I Club contact

the shipper.

10.1.- Additional Precautions If Concentration Of Hydrogen Over 1% (25% Lel):

INFORM THE SHIPPER IMMEDIATELY AND SEEK EXPERT ADVICE.

KEEP THE NATURAL SURFACE VENTILATION OPEN AT ALL TIMES.

Monitor LEL in the holds continuously until level drops to less than 25 %.

Avoid any possible ignition source on the vicinity.

Care shall be taken as to prevent any spark generation.

Monitor the hydrogen concentration in the holds and keep the surface ventilation (either

natural or mechanical) until values fall below 1%.

When hydrogen levels are within safe values, proceed as normal.

On the contrary, additional ventilation should be applied to the space if available and re-

testing should be conducted after a suitable interval.

Contact the P & I Club and Shipper and follow the instructions of the appointed expert or

surveyor.

At sea, do not open the troubled hold without explicit instructions from the shipper or

appointed expert or surveyor.

Ensure there are no possible sources of ignition near the cargo spaces, adjacent spaces or

open decks.

10.2.- Procedures If HBI Temperatures Rise Above 65°C (Overheating).

a. INFORM THE SHIPPER IMMEDIATELY AND SEEK EXPERT ADVICE.

b. Monitor the temperature of the cargo in the holds and adjacent bulkheads

more frequently and evaluate its tendency.

c. Check if the temperature rise is temporary. Temperature increase of about

30 °C due to self-heating may be expectated after material handling.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:16 of 17

d. Batten down until assessing the situation.

e. Check whether there was any ingress of water in cargo holds.

o If there was ingress of seawater, the effect will only be noticed after

16-24 hour.

o The temperature would increase and then should stabilize

f. Check bilge wells and remove any water

g. Check for steaming of cargo

o If so the natural ventilation should be kept open at all times

h. DO NOT USE WATER TO COOL DOWN THE CARGO

i. If the temperature of the cargo continues rising, if weather permits and

unloading gear is available, open the hatch covers to spread out the hot

spots of cargo inside the hold as much as possible. Evaluate the cargo

temperature tendency. If the cargo temperature shows sign of decreasing,

continue with this operation until temperatures drops to below 65°C. Then,

close the hatch covers and keep the natural ventilation open.

j. If temperatures of the cargo reaches and surpasses 120 °C, preparation to

jettison or discharge the cargo at the nearest safe and suitable port should

be conducted.

k. Bulkheads of empty cargo holds adjacent to loaded holds with hot cargo can

be sprayed with water to help indirectly cool down the cargo in the adjacent

space. DO NOT USE WATER DIRECTLY ON HOT CARGO.

Consult immediately the P & I Club in order to define what further action should be taken.

At sea, do not open the trouble hold until assessing the situation and tendency of cargo

temperature and without explicit instructions from the shipper, appointed expert or surveyor.

Temperatures of the cargo can also be checked by lowering a thermometer down the

sounding pipes to bilges’ double bottom and wing tanks and record the temperatures.

In holds that do not carry DRI (A), open the hatch covers sufficiently to ventilate to allow safe

entry into these areas to check for bulkhead heating. Record any changes and spray the

bulkheads with water if heating is noted, providing the bulkheads are mechanically sound and

watertight.

Monitor the material temperature every hour. Record all the temperature readings.

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

Maritime Guide for Direct Reduced Iron (A). Briquettes, hot - moulded Pag:17 of 17

DO NOT AT ANY TIME USE WATER DIRECTLY ON DRI (A) TO COOL THEM OR IN ANY

SPACE CONTAINING DRI (A). DRI (A) can only be cooled with water when they are spread

out in fine layers in open yards or as a last resort completely flooded when in an enclosed

compartment; the latter action may give rise to considerable hydrogen generation and should

only be done upon expert advice.

10.3.- Procedures if seawater enters the cargo holds

IF SEAWATER ENTERS THE HOLD CONTAINING DRI (A), THE MASTER SHOULD OPEN

THE VENTS AS SOON AS POSSIBLE AND SHOULD CONTACT THE SHIPPER

IMMEDIATELY.

If the hold is breached due to an accident and becomes flooded with seawater or, there will be

a bubbling action in the flooded cargo due to the production of Hydrogen. Keep the surface

ventilation system (either natural or mechanical) operating continuously and measure

hydrogen concentration. Levels of LEL should be maintained at less than 25%. The

temperature of the water will remain constant. The steaming of DRI (A), if it occurs, may not

be noticed until 16 - 24 hours after the entrance of seawater. DRI (A) contacted by seawater

will oxidize to reddish brown color. Monitor the temperature of the cargo more constantly and

follow the emergency procedures for both high hydrogen levels and overheating included of

this Guide.

Inform the P&I Club and look for advice. Have the P&I Club call the shipper.

If a small amount of seawater enters the holds, due to the hatch cover leaks during heavy

seas, keep the holds closed and sealed. Keep the surface ventilation (either natural or

mechanical) open whenever weather conditions allow (The goal is to allow the hydrogen gas

that may generate to dissipate to the atmosphere). Increase the frequency of monitoring and

follow the emergency procedures for high hydrogen and high temperature of this Guide.

WARNING

DO NOT USE EITHER FRESH WATER OR SEAWATER TO COOL DOWN HOT

MATERIAL in enclosed spaces such a cargo hold on a ship, unless strictly necessary

to keep integrity of vessel and under Master’s expertise. If water shall be used: i) use

large amount of water to completely flood the material and ii) provide adequate

ventilation to let Hydrogen gas generated escape to atmosphere. Be prepared to

jettison cargo if very high temperatures (over 120 °C) are recorded, or make

arrangements to get to the nearest safe and suitable port for discharging the hot

cargo. Hydrogen concentration should be kept below 1% and the ventilation system

should be operating continuously to lower the concentration of hydrogen gas inside

the cargo hold. Consider the solutions with the following priorities as follows:

1.- Unload the troubled cargo at nearest port

2.- Jettison of cargo

3.- Flood the hold with water

_________________ __________________

Captain’s Signature Shipper’s Signature

Document Revision N°: 1. July 2012

You might also like

- Bulk Cargo PresentationDocument55 pagesBulk Cargo PresentationKalai Selvan100% (4)

- P - 8 Procedures and Arrangements ManualDocument306 pagesP - 8 Procedures and Arrangements ManualCristian Stan100% (1)

- My Study Notes for AEE Safety ManagementDocument19 pagesMy Study Notes for AEE Safety ManagementAji Satria Sastrodiardjo80% (5)

- DRI A Hot Briquetted Iron HBI at Terminals Guide For Transporting and HandlingDocument50 pagesDRI A Hot Briquetted Iron HBI at Terminals Guide For Transporting and Handlingفردوس سليمان100% (2)

- Transporting Nitric Acid in Tanks PDFDocument68 pagesTransporting Nitric Acid in Tanks PDFdzungNo ratings yet

- Shell - Cargo Handling Sheet Styrene MonomerDocument5 pagesShell - Cargo Handling Sheet Styrene MonomerJohn StoneNo ratings yet

- Oral Questions MarineDocument15 pagesOral Questions MarineIntuitionNo ratings yet

- Direct Reduced Iron PDFDocument3 pagesDirect Reduced Iron PDFsijanivandiNo ratings yet

- DGS HydrogenGuideDocument18 pagesDGS HydrogenGuideswatimal67% (3)

- Rulefinder Source Document List 9 - 28Document66 pagesRulefinder Source Document List 9 - 28Ruano StumpfNo ratings yet

- Annex 2 RESOLUTION MSC.267 (85) (Adopted On 4 December 2008)Document85 pagesAnnex 2 RESOLUTION MSC.267 (85) (Adopted On 4 December 2008)darrelsilvaNo ratings yet

- Standards in Shipping: Looking ForwardDocument62 pagesStandards in Shipping: Looking ForwardAjithkumar SukumarnNo ratings yet

- Cargo Work: (IMO MODEL COURSE 7.03 REF. NO 2.2.1.)Document10 pagesCargo Work: (IMO MODEL COURSE 7.03 REF. NO 2.2.1.)MayankNo ratings yet

- AAE QUESTIONS ON INTERNATIONAL RULES AND REGULATIONSDocument10 pagesAAE QUESTIONS ON INTERNATIONAL RULES AND REGULATIONSkumarasilanNo ratings yet

- Imdg Code Bp3ip.1Document24 pagesImdg Code Bp3ip.1Ibe 47100% (1)

- 33632DNVGLBulk Cargo LiquefactionDocument20 pages33632DNVGLBulk Cargo LiquefactionSasidharan RajendranNo ratings yet

- IMO - BCH Code - 1994 PDFDocument86 pagesIMO - BCH Code - 1994 PDFAlex KulikNo ratings yet

- Annex B - Polar Code Marine Guidance NoteDocument5 pagesAnnex B - Polar Code Marine Guidance Notesfedu cristianNo ratings yet

- Test I: Identification and Enumeration For The Following QuestionsDocument4 pagesTest I: Identification and Enumeration For The Following QuestionsRuleen Y. BerezoNo ratings yet

- Dredging Management PlanDocument39 pagesDredging Management PlanBambang Permana100% (2)

- Notice To Shipmasters Loading Coal CargoesDocument18 pagesNotice To Shipmasters Loading Coal CargoesDujeKnezevic67% (3)

- MIN 516 SOLID BULK CARGOES 03adoption of AmendmentDocument4 pagesMIN 516 SOLID BULK CARGOES 03adoption of AmendmentSuper YachtNo ratings yet

- Safety of Transport of LGases On TankersDocument197 pagesSafety of Transport of LGases On TankersEmmanouil Sfougg SfouggaristosNo ratings yet

- Pollution Prevention MARPOL 73 - 78 PDFDocument5 pagesPollution Prevention MARPOL 73 - 78 PDFPopa VasileNo ratings yet

- Nickel Ore BritanniaDocument10 pagesNickel Ore BritanniagusoyongNo ratings yet

- 080 - User Handbook N0000322GB - HDocument69 pages080 - User Handbook N0000322GB - HNam Lê XuânNo ratings yet

- MARPOL QandAnsDocument26 pagesMARPOL QandAnsMMS SNo ratings yet

- The Carriage of Methanol in Bulk Onboard Offshore Vessels: First Edition 2020Document50 pagesThe Carriage of Methanol in Bulk Onboard Offshore Vessels: First Edition 2020Eric FranckNo ratings yet

- Liquefied Hydrogen Carrier Pilot Project in Japan: ClassnkDocument18 pagesLiquefied Hydrogen Carrier Pilot Project in Japan: ClassnkMaximusNo ratings yet

- Bab 4 - LNGDocument64 pagesBab 4 - LNGSatria KenariNo ratings yet

- Real Time Questions For Kolkata MMD Class 2: FN-3 BhoumickDocument19 pagesReal Time Questions For Kolkata MMD Class 2: FN-3 BhoumickHarendra GuptaNo ratings yet

- Arklow Meadow ReportDocument39 pagesArklow Meadow ReportMona TrunajayaNo ratings yet

- Construction Requirements For Chemical TankersDocument35 pagesConstruction Requirements For Chemical TankersRitesh100% (1)

- MarpolDocument9 pagesMarpolTimin Titto AkkaraNo ratings yet

- Safety Procedures and RegulationsDocument35 pagesSafety Procedures and RegulationsAravind100% (1)

- Delivering Quality Bulk Marine GasoilDocument30 pagesDelivering Quality Bulk Marine Gasoilventa kevara100% (1)

- Transport of CO: Coordinating Lead Authors Lead AuthorsDocument16 pagesTransport of CO: Coordinating Lead Authors Lead AuthorsGaurav MishraNo ratings yet

- Cargo Loading and Securing ManualDocument350 pagesCargo Loading and Securing Manualk87100% (4)

- Cargo Securing ManualDocument91 pagesCargo Securing Manualk87100% (1)

- Ship TankerDesignDocument103 pagesShip TankerDesignmariodalNo ratings yet

- Controlled substances and garbage regulationsDocument9 pagesControlled substances and garbage regulationsFaiqah AzmirNo ratings yet

- Imbsc CodeDocument8 pagesImbsc CodeNeeraj SNo ratings yet

- Meo Oral AnsDocument17 pagesMeo Oral AnsKapil Verma100% (4)

- FO-I-04 Report of Safety Inspection Revision 17Document8 pagesFO-I-04 Report of Safety Inspection Revision 17Jack100% (1)

- SR.11.10961 - Sour Well Design GuideDocument52 pagesSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- TSC Fire Guide (Web) PDFDocument52 pagesTSC Fire Guide (Web) PDFJillF.RussellNo ratings yet

- Petronas AAE Q&A - UPDATE PDFDocument20 pagesPetronas AAE Q&A - UPDATE PDFAri Ad100% (2)

- Storage Handling and Boil-Off of LNG On PDFDocument16 pagesStorage Handling and Boil-Off of LNG On PDFĐậu BắpNo ratings yet

- Full Operations Manual v1 CompressedDocument57 pagesFull Operations Manual v1 CompressedSergiy KovernikNo ratings yet

- BibliographyonMaritimeLiterature 28january2010Document74 pagesBibliographyonMaritimeLiterature 28january2010TermiteEnkay0% (1)

- Appendix 2 - MSc-Circ-1149 - Explosion Caused by DRIDocument2 pagesAppendix 2 - MSc-Circ-1149 - Explosion Caused by DRIYevgeniy RNo ratings yet

- Scrubbers On TankersDocument15 pagesScrubbers On TankersJohn RobertsNo ratings yet

- Latest AmmendmentDocument5 pagesLatest AmmendmentAjay MauryaNo ratings yet

- SBO 11 Set QuestionsDocument11 pagesSBO 11 Set QuestionsMamunNo ratings yet

- BCH CodeDocument86 pagesBCH CodeLogovazNo ratings yet

- Entry Into Enclosed Spaces New Regulations MGN 659 M+F MCA 2022Document12 pagesEntry Into Enclosed Spaces New Regulations MGN 659 M+F MCA 2022ARE YOU TECH CRAZYNo ratings yet

- Liquid Chemicals Cargo On Ships - Complete Details Including DiaDocument35 pagesLiquid Chemicals Cargo On Ships - Complete Details Including DiaShoaib100% (1)

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Conwar 2004 - War Risks Clause For Voyage CharteringDocument3 pagesConwar 2004 - War Risks Clause For Voyage CharteringEnriqueNo ratings yet

- Conwar 2004 - War Risks Clause For Voyage CharteringDocument3 pagesConwar 2004 - War Risks Clause For Voyage CharteringEnriqueNo ratings yet

- Your Name: Creative DirectorDocument1 pageYour Name: Creative Directorapi-359244379No ratings yet

- Ogbe Osa - Popoola EnglishDocument80 pagesOgbe Osa - Popoola EnglishEnrique91% (46)

- Ga Plan ShipDocument1 pageGa Plan ShipEnriqueNo ratings yet

- Artist Rules DFGWSSFDocument1 pageArtist Rules DFGWSSFEnriqueNo ratings yet

- Pare La Diabetes en 14 Dias: SearchDocument2 pagesPare La Diabetes en 14 Dias: SearchEnriqueNo ratings yet

- 34,000 DWT Namura Logger SpecsDocument36 pages34,000 DWT Namura Logger SpecsEnriqueNo ratings yet

- Sulphur CargoesDocument6 pagesSulphur CargoesEnriqueNo ratings yet

- Your Name: Creative DirectorDocument1 pageYour Name: Creative Directorapi-359244379No ratings yet

- Appointment ConfirmationDocument2 pagesAppointment ConfirmationEnriqueNo ratings yet

- Ọrunmila kmgkfrrDocument3 pagesỌrunmila kmgkfrrEnriqueNo ratings yet

- Form 8832 Entity Classification ElectionDocument1 pageForm 8832 Entity Classification ElectionEnrique50% (2)

- Muelle Punta de PiedraDocument2 pagesMuelle Punta de PiedraAnonymous NsHtoIRc5No ratings yet

- VL4K-C SpecsDocument1 pageVL4K-C SpecsEnriqueNo ratings yet

- Packing List - Amaguaya ExplorationDocument2 pagesPacking List - Amaguaya ExplorationMumy MoraNo ratings yet

- Florida VPK Certificate of EligibilityDocument1 pageFlorida VPK Certificate of EligibilityEnriqueNo ratings yet

- Omar Gallegos: (817) 615-0825 2201 48 St. #2, Galveston, TX 77551Document1 pageOmar Gallegos: (817) 615-0825 2201 48 St. #2, Galveston, TX 77551Mumy MoraNo ratings yet

- Obaragkuhukj 2Document1 pageObaragkuhukj 2EnriqueNo ratings yet

- IsefaagkjDocument1 pageIsefaagkjEnriqueNo ratings yet

- Ojuaaaaann PDFDocument1 pageOjuaaaaann PDFEnriqueNo ratings yet

- OsheshesheDocument1 pageOsheshesheEnriqueNo ratings yet

- Speakkk YoruDocument1 pageSpeakkk YoruEnriqueNo ratings yet

- Esu TraddddcccDocument1 pageEsu TraddddcccEnriqueNo ratings yet

- Efficacious Prayer To OLÓDÚMARË, The Supreme ForceDocument206 pagesEfficacious Prayer To OLÓDÚMARË, The Supreme ForceJose de Tayob92% (12)

- Chartering TermsDocument13 pagesChartering TermsEnriqueNo ratings yet

- Trrrrrat EsuDocument1 pageTrrrrrat EsuEnriqueNo ratings yet

- Ifa History 1111Document1 pageIfa History 1111EnriqueNo ratings yet

- Obi AbaraDocument1 pageObi AbaraEnriqueNo ratings yet

- Nutrition During PregnancyDocument8 pagesNutrition During PregnancyHalliahNo ratings yet

- Impact of Energy Consumption On The EnvironmentDocument9 pagesImpact of Energy Consumption On The Environmentadawiyah sofiNo ratings yet

- Human Capital FormationDocument9 pagesHuman Capital Formationtannu singh67% (6)

- Rudraksha - Scientific FactsDocument20 pagesRudraksha - Scientific FactsAkash Agarwal100% (3)

- Guide Propedevt Stomat 2c EngDocument256 pagesGuide Propedevt Stomat 2c EngJhoel Jhonatan Torres MuñozNo ratings yet

- EEDMATH1 - Teaching Mathematics in The Primary Grades Beed 2E Learning Activity PlanDocument3 pagesEEDMATH1 - Teaching Mathematics in The Primary Grades Beed 2E Learning Activity PlanBELJUNE MARK GALANANNo ratings yet

- Perforamance Based AssessmentDocument2 pagesPerforamance Based AssessmentJocelyn Acog Bisas MestizoNo ratings yet

- Forest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundDocument4 pagesForest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundAnonymous 6iFFjEpzYjNo ratings yet

- Treatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Document5 pagesTreatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Victoria LeahNo ratings yet

- HVDC BasicDocument36 pagesHVDC BasicAshok KumarNo ratings yet

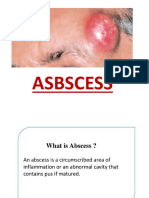

- ABSCESSDocument35 pagesABSCESSlax prajapatiNo ratings yet

- Natural Resources in PakistanDocument5 pagesNatural Resources in PakistanSohaib ENo ratings yet

- Strauss Dental Catalog 2013Document74 pagesStrauss Dental Catalog 2013d3xt3rokNo ratings yet

- BOF, LF & CasterDocument14 pagesBOF, LF & CastermaklesurrahmanNo ratings yet

- Scaffolding Control & MeasuresDocument3 pagesScaffolding Control & Measuresviswamanoj100% (1)

- Notice: Use of Segways® and Similar Devices by Individuals With A Mobility Impairment in GSA-Controlled Federal FacilitiesDocument2 pagesNotice: Use of Segways® and Similar Devices by Individuals With A Mobility Impairment in GSA-Controlled Federal FacilitiesJustia.comNo ratings yet

- Acc101Q7CE 5 3pp187 188 1Document3 pagesAcc101Q7CE 5 3pp187 188 1Haries Vi Traboc MicolobNo ratings yet

- Allium CepaDocument90 pagesAllium CepaYosr Ahmed100% (3)

- InjectorDocument23 pagesInjectorBac Nguyen100% (1)

- Ucg200 12Document3 pagesUcg200 12ArielNo ratings yet

- Mufon Ufo JournalDocument21 pagesMufon Ufo JournalSAB78No ratings yet

- UMR Introduction 2023Document110 pagesUMR Introduction 2023tu reves mon filsNo ratings yet

- RA8485 Animal Welfare Act (Carabao Slaughter)Document2 pagesRA8485 Animal Welfare Act (Carabao Slaughter)Jazreth Gaile100% (1)

- ERS M22 PC4 FerryDocument2 pagesERS M22 PC4 FerryouakgoodNo ratings yet

- OilDocument8 pagesOilwuacbekirNo ratings yet

- VIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhDocument3 pagesVIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhÝ Nguyễn NhưNo ratings yet

- Grab Go Porter S 5 ForcesDocument2 pagesGrab Go Porter S 5 ForcesUtkarsh SharmaNo ratings yet

- Arp0108 2018Document75 pagesArp0108 2018justin.kochNo ratings yet

- Supply Chain Management of VodafoneDocument8 pagesSupply Chain Management of VodafoneAnamika MisraNo ratings yet

- Dimensional Data: For Valves and ActuatorsDocument52 pagesDimensional Data: For Valves and ActuatorsPaulNo ratings yet