Professional Documents

Culture Documents

K-27478 Corian Solid Surface Product Overview

Uploaded by

Shraddha DateyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K-27478 Corian Solid Surface Product Overview

Uploaded by

Shraddha DateyCopyright:

Available Formats

CORIAN® SOLID SURFACE

PRODUCT BULLETIN

NA/ENGLISH

CORIAN ® SOLID SURFACE

PRODUCT OVERVIEW

PRODUCT NAME Corian® Sinks and Lavatories

Corian® Solid Surface A wide range of Corian® sinks and lavatories is available in solid colors for

custom integration with Corian® sheets to create a continuous surface.

MANUFACTURER This includes vanity basins in solid colors for bathrooms, and single and

Corian® Design double sinks for kitchens, bars and small wash-up areas, hospitals and

Chestnut Run Plaza 735 laboratories. Seamed undermounting eliminates rims that trap dirt and

974 Centre Road water, minimizing cleaning and maintenance and providing improved

Wilmington, DE 19805 hygiene. Care, maintenance and installation instructions are included in

Toll free 1-800-4-CORIAN (1-800-426-7426) the packaging. Appropriate accessory products, including installation

www.corian.com hardware, are available and recommended for residential kitchens only.

PRODUCT DESCRIPTION The Colors of Corian® Solid Surface

Basic use A broad palette of colors allows for an almost unlimited working palette.

Corian® Solid Surface is an advanced composite product used as an You can choose a single color; a neutral basis for design; or experiment

architectural and design material in a variety of residential and commercial with eye-catching harmonies. Corian® Solid Surface can also be used as

applications. Corian® Solid Surface offers design versatility, functionality inlays, accents, or as a versatile complement to other materials like metal,

and durability. Supplied in sheets and shapes, it can be fabricated with wood, stone, etc.

conventional woodworking tools into virtually any design. It is the

For complete information on colors, refer to corian.com. Hues, patterns

original Solid Surface material made only by DuPont. It is widely

and textures are related by style and character. Dark, heavily pigmented

accepted as a material for countertops, vanity tops, tub/shower walls,

Corian® colors will show scratches, dust and ordinary wear and tear more

kitchen sinks, vanity basins and laboratory bench tops in numerous

readily than lighter, textured colors. As a result, these colors are

markets including lodging, healthcare, banks, boutiques, restaurants.

recommended for applications where surface contact is light or for use as

Composition inlays and accent colors. However, the DeepColor™ series incorporates an

Corian® Solid Surface is a solid, nonporous, homogeneous surfacing innovative, proprietary technology that delivers greater depth of color

material, composed of ≈1/3 acrylic resin (also known as polymethyl and increased durability compared to other dark Corian® colors. Corian®

methacrylate or PMMA), and ≈2/3 natural minerals. These minerals are Solid Surface with Resilience Technology™ features superior damage

composed of aluminum trihydrate (ATH) derived from bauxite, an ore forgiveness, easier and quicker stain removal, and less need for

from which aluminum is extracted. For more information on the maintenance. This best-in-class premium technology reduces physical

composition of the material, please consult the Corian® Solid Surface and visible damage from scratching, heat, and impact, typical of daily

Safety Data Sheets (SDS) available via the msds.dupont.com website or usage in commercial environments.

via your local supplier.

Corian® Solid Surface with Resilience Technology™ is also quicker and

STANDARD PRODUCTS easier to renew. Its surface looks new for a longer time and is easily

Corian® Sheets maintained by occasional washing with water and a slightly abrasive pad

Available in various standard thicknesses, easily cut to size by professional by end-users. This gentle washing visibly removes low-level scratches.

fabricators. These superior properties are built into the material and the performance

is permanent, lasting for the entire life of the material.

All colors in the standard color palette are available in 12 mm (1/2") sheets

that are 30" x 144" (760 mm x 3658 mm). Select colors may be available Custom Sheets

in 19 mm (3/4") sheet with the same length and width or 6 mm (1/4") sheets DuPont can manufacture Corian® sheets in custom colors, patterns and

that are 30" x 98" (2490 mm x 760 mm). 36.6" (930) wide sheets are dimensions, within manufacturing capability limits and based on a

available in select 6 and 12 mm colors. Please consult the Corian® Design minimum order quantity.

website, corian.com or Corian® Solid Surface Sheet Products (K-24016) and

See Corian® Shapes (K-29965) for an overview of dimensions available.

Corian® Solid Surface Sheet Color Options (K-26836) for more details.

Corian® Solid Surface Product Bulletin 1 /3

CORIAN® SOLID SURFACE

PRODUCT BULLETIN

NA/ENGLISH

Limitations Corian® Solid Surface is nontoxic and nonallergenic to humans. Corian®

Although Corian® Solid Surface can withstand high temperatures, it Solid Surface meets or exceeds emissions guidelines for volatile organic

should be protected against direct heat with hot pads or heat shields. compounds (VOCs), hazardous air pollutants (HAPs) and has achieved

GREENGUARD GOLD Certification.

Use of 6 mm (1/4") sheets should be restricted to vertical applications or

certain furniture applications only. The choice between 12 mm and 19 mm When burned, it releases mainly carbon oxides and the smoke generated

(1/2" and 3/4") is generally based on performance and cost considerations. is optically light and does not contain toxic halogenated gases. Because of

these properties, Corian® Solid Surface is used in public spaces and

Due to the complex blending of natural minerals and man-made acrylics, delicate applications such as airport check-in counters, wall and work

slight color variations may be found within a sheet or from sheet to sheet surfaces in hospitals and hotels.

of same color. Therefore, checking for color matching is an essential

element of sheet inspection before starting fabrication. Corian® Solid Surface sheets can be thermoformed in wooden or metal

molds at controlled temperatures in order to create various 2D and 3D

Corian® Solid Surface is nonporous so spills and stains remain on the design objects. Embossing effects can also be created.

surface. However, some chemicals can stain, discolor or damage the

surface of Corian® Solid Surface. These chemicals include strong acids The translucency of Corian® sheet is especially striking in the lighter

(like concentrated sulfuric acid), ketones (like acetone), chlorinated colors as well as in thinner sheets. As a result, many designers are using it

solvents (like chloroform) or strong solvent combinations (like paint to create lamps or lighting effects in various applications.

remover). The extent of the damage will depend on the length of contact.

Except for strong solvents such as paint remover, short periods of contact Inlaying Corian® Solid Surface with different materials or with different

will not usually cause severe damage to Corian® Solid Surface. Acid drain colors of Corian® is possible and can enhance the inherent beauty of the

cleaners should not be used as they can damage both Corian® Solid material. Inlays and logos can also be created on Corian® Solid Surface

Surface and any plastic plumbing beneath. Corian® Solid Surface is not using dye sublimation or direct printing techniques.

recommended for use in photographic processing laboratories. More

FABRICATION AND INSTALLATION

information can be found in Corian® Chemical Resistance (K-27406). In

Corian® Design trains and certifies fabricators and installers who are

some hospitals and laboratories where strong disinfectants come in

provided detailed information regarding proper procedures; the following

contact with Corian® applications, the recommendation is to use solid

is a general overview, not a comprehensive guide to proper use.

colors and avoid extended contact.

Seams

PERFORMANCE PROPERTIES AND CHARACTERISTICS

To minimize material usage and facilitate installation, a corner block of

Since its introduction in 1967, Corian® Solid Surface has proven itself to

Corian® Solid Surface should be made square (butt) rather than mitered.

be remarkably durable, versatile and easy to live with in both the home

The edges to be joined should be straight, smooth and clean. Some seams

and commercial environments.

need to be reinforced (see fabrication manual for details). Joints should

Typical performance properties of Corian® products are shown in Corian® only be made with Corian® Joint Adhesive. Cutouts should be made with

Performance Properties (K-26829). The performance of Corian® sheets a router equipped with a sharp carbide bit, with a minimum diameter of

3/8" (10 mm). All corners of a cutout must be rounded to 5 mm radius

may vary according to the thickness of the material, its aesthetics and

surface finish. and the edges smoothed, both on top and bottom, all around a cutout.

“L” and “U” shaped corners need smooth, 3/16" (5 mm) radius inside

Colors and patterns run through the entire thickness of the material and corners. For hob cutouts, corners should be reinforced with a Corian®

cannot wear away or delaminate. Joints can be glued inconspicuously, corner block. See fabrication manual for more details.

making virtually unlimited surfaces possible.

Some Corian® Solid Surface colors that feature random veins and

Corian® Solid Surfaces are restorable, meaning they can be fully restored irregular patterns require special considerations regarding the seams.

with ordinary mild abrasive cleansers and a scouring pad. Cigarette Please refer to the related technical bulletin for best practices in

burns, for example, can be easily removed in this way. Damage caused by fabrication of these colors.

abuse can usually be repaired on site without having to completely

replace the material. Sealants and Adhesives

Corian® Solid Surface is compatible with many commercially available

Corian® Solid Surface is nonporous with a smooth, seamless appearance. caulks and sealants. 100% silicone products are recommended. Vertical

With proper cleaning, the material does not promote the growth of panels of Corian® may be installed over suitable substrates, including

mold, mildew and bacteria. water-resistant gypsum board, marine-grade plywood and ceramic tiles.

In case a support is needed, apply perimeter frame or full support direct

to Corian® using large beads of flexible adhesive leaving a space with a

minimum thickness of 1/16" (1.5 mm).

Corian® Solid Surface Product Bulletin 2 /3

CORIAN® SOLID SURFACE

PRODUCT BULLETIN

NA/ENGLISH

CORIAN ® SOLID SURFACE

PRODUCT OVERVIEW

For making seams in countertops, repairs and custom edges, color- MAINTENANCE

coordinated Corian® Joint Adhesive should be used. When used in Preventing Damage to Corian® Solid Surface

accordance with manufacturer’s instructions, it provides a smooth and Avoid prolonged exposure to strong chemicals such as acids, bases, and

inconspicuous joint. Corian® Joint Adhesive is available from Corian® organic solvents. Spills should be cleaned up promptly. Refer to Corian®

Design or its distributors. Chemical Resistance (K-27406) for additional details regarding chemical

exposures, and Corian® Solid Surface Care and Maintenance for Facility

Clearances Managers (K-29810) for clean up, and general maintenance. In case of

The minimum expansion clearance in inches for Corian® Solid Surface is exposure outside the specifications listed in the Class I Reagents section,

2.2 x 10-5 in./in.°F x (length of the piece of Corian® Solid Surface in the 10-year limited product warranty will be void and handled as a case

inches) x (biggest temperature range expected in °F) In mm the minimum of abuse. While unaffected by minor impacts, Corian® Solid Surface can

expansion clearance is 3.9 x 10-5 mm/mm °C x (length of the piece of be damaged by heavy impacts, especially from pointed objects. It can

Corian® Solid Surface in mm) x (biggest temperature range expected in also be damaged by excessive heat. A local Corian® Design specialist can

°C). Joints to be caulked should be a minimum of 1/16" (1.5 mm) wide help you include appropriate heat management into your designs.

to allow satisfactory sealant penetration and expansion.

Repairing Corian® Solid Surface

Precautions Corian® Solid Surface provides superior value by being inconspicuously

Product dimensions are nominal. If tolerances are critical, review your repairable in most cases. Minor cuts, scratches, and stains can be removed

needs with a Corian® specialist. by owners using fine sandpaper and Scotch-Brite™ pads. Deeper cuts or

impact damage such as cracks may require an authorized Corian®

AVAILABILITY AND COST

fabricator/installer to make inconspicuous repairs.

Availability

Corian® Design sheet, shape, and accessory products are readily ADDITIONAL INFORMATION

available through a worldwide network of Distributors and certified For additional information or support please contact your local

Fabricators/Installers. distributor, visit corian.com or call 1-800-4-CORIAN (800-426-7426).

Cost REFERENCED DOCUMENTS

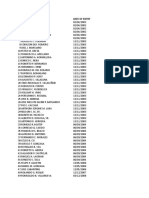

Cost varies with color, thickness, and width as well as custom fabrication Corian® Performance Properties (K-26829)

and installation details.

Corian® Chemical Resistance (K-27406)

WARRANTY Corian® Commercial (Product Only) 10-Year Limited Warranty For North America

DuPont offers limited commercial and residential warranties. Corian® 10-Year Limited Residential Warranty For North America

Corian® Solid Surface Sheet Products (K-24016)

Corian® Solid Surface Sheet Color Options (K-26836)

Corian® Solid Surface Care and Maintenance for Facility Managers (K-29810)

PLEASE VISIT OUR WEB SITE: WWW.CORIAN.COM OR CONTACT YOUR CORIAN® REPRESENTATIVE

FOR MORE INFORMATION ABOUT CORIAN® SOLID SURFACE

This information is based on technical data that E. I. du Pont de Nemours and Company and its affiliates (“DuPont”) believe to be reliable, and is intended for use by persons having technical skill and at their own discretion and

risk. DuPont cannot and does not warrant that this information is absolutely current or accurate, although every effort is made to ensure that it is kept as current and accurate as possible. Because conditions of use are outside

DuPont’s control, DuPont makes no representations or warranties, express or implied, with respect to the information, or any part thereof, including any warranties of title, non-infringement of copyright or patent rights of others,

merchantability, or fitness or suitability for any purpose and assumes no liability or responsibility for the accuracy, completeness, or usefulness of any information. This information should not be relied upon to create specifications,

designs, or installation guidelines. The persons responsible for the use and handling of the product are responsible for ensuring the design, fabrication, or installation methods and process present no health or safety hazards. Do not

attempt to perform specification, design, fabrication, or installation work without proper training or without the proper personal protection equipment. Nothing herein is to be taken as a license to operate under or a recommendation

to infringe any patents. DuPont shall have no liability for the use of or results obtained from such information, whether or not based on DuPont’s negligence. DuPont shall not be liable for (i) any damages, including claims relating

to the specification, design, fabrication, installation, or combination of this product with any other product(s), and (ii) special, direct, indirect or consequential damages. DuPont reserves the right to make changes to this information

and to this disclaimer. DuPont encourages you to review this information and this disclaimer periodically for any updates or changes. Your continued access or use of this information shall be deemed your acceptance of this disclaimer

and any changes and the reasonableness of these standards for notice of changes..

Copyright© 2018 E. I. du Pont de Nemours and Company. The Corian® Solid Surface Logo and Corian® are trademarks of E. I. du Pont de Nemours and Company or its affiliates. All rights reserved.

K-27478-NA 10/18 Corian® Solid Surface Product Bulletin 3 /3

You might also like

- Corian Product OverviewDocument4 pagesCorian Product Overviewayman ammarNo ratings yet

- K 26840 Corian Solid Surface Care and MaintenanceDocument4 pagesK 26840 Corian Solid Surface Care and MaintenanceNac MickNo ratings yet

- External CladdingDocument32 pagesExternal CladdingMarcos PansaniNo ratings yet

- corian_solid_surface_routine_careDocument13 pagescorian_solid_surface_routine_careablancoNo ratings yet

- Brochure - Exterior Decorative CoatingsDocument8 pagesBrochure - Exterior Decorative CoatingsseydolackNo ratings yet

- Duluxdiamond Productbrochure Ext r2 SinglepagesDocument4 pagesDuluxdiamond Productbrochure Ext r2 Singlepagesnbarratt2No ratings yet

- Ici Friendly EnvironmentDocument9 pagesIci Friendly EnvironmentAta Ur Rahman KhalidNo ratings yet

- Food & Beverage Market Brochure - 0519-LoDocument8 pagesFood & Beverage Market Brochure - 0519-LoBERSE MAJU INDONESIANo ratings yet

- Laminate FlooringDocument68 pagesLaminate FlooringGuru Vignesh SelvarajanNo ratings yet

- 3A Imagebroschuere GB WebDocument16 pages3A Imagebroschuere GB WebLatranikaNo ratings yet

- BASF Architectural Coatings PSG ArchCoat022017PSGDocument40 pagesBASF Architectural Coatings PSG ArchCoat022017PSGJose Luis Soto PetralandaNo ratings yet

- BergerDocument6 pagesBergerAmit KrNo ratings yet

- Coatings Paints BrochureDocument2 pagesCoatings Paints BrochureroladinNo ratings yet

- Finishing Chemicals EN FinalDocument4 pagesFinishing Chemicals EN FinalBalaraman SNo ratings yet

- A.M.O.S. Design Corian ManualDocument12 pagesA.M.O.S. Design Corian ManualamosdesignNo ratings yet

- Reduce Your Casting Costs, and Improve Your Environment, Casting Productivity, and QualityDocument8 pagesReduce Your Casting Costs, and Improve Your Environment, Casting Productivity, and QualityAjay WanveNo ratings yet

- Fixtures & Fittings Section (Product Catalogue)Document48 pagesFixtures & Fittings Section (Product Catalogue)mikedigitaleggNo ratings yet

- Expand Your Horizons With Designer Colours and Unrivalled PerformanceDocument6 pagesExpand Your Horizons With Designer Colours and Unrivalled PerformanceJoão TarelhoNo ratings yet

- Endura Series: Interior/Exterior High Performance CoatingsDocument6 pagesEndura Series: Interior/Exterior High Performance CoatingsJami AhmedNo ratings yet

- Printing InksDocument28 pagesPrinting InksBoonyarit Lurdgrienggraiying100% (3)

- Powder Vs PVDFDocument2 pagesPowder Vs PVDFYan LimNo ratings yet

- 2015 BASF Flexible-Packaging-Inks Landscape ELDocument12 pages2015 BASF Flexible-Packaging-Inks Landscape ELPongthip PesachpinankulNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data Sheetapply19842371No ratings yet

- Alucobond - enDocument16 pagesAlucobond - enOscarNo ratings yet

- Flat Glass System Gi Ard in ADocument32 pagesFlat Glass System Gi Ard in AvirkedNo ratings yet

- Drip Irrigation Borealis PDFDocument2 pagesDrip Irrigation Borealis PDFchinmoyd1100% (1)

- Ec Am-StargazingviewbookpdfDocument16 pagesEc Am-StargazingviewbookpdfWissam NumanNo ratings yet

- Fuchs Brochure Sok Concrete-Release-AgentsDocument16 pagesFuchs Brochure Sok Concrete-Release-Agentsx5gh2dm6hwNo ratings yet

- 17b1b807-fe18-4cea-ac2e-a5099f7b1d60Document15 pages17b1b807-fe18-4cea-ac2e-a5099f7b1d60eromax1No ratings yet

- 3 Laboratorycounter Top Worktop 2Document4 pages3 Laboratorycounter Top Worktop 2Serhat YıldırımNo ratings yet

- PROTECT STEEL WITH MOST USED PAINTSDocument12 pagesPROTECT STEEL WITH MOST USED PAINTSsmartcharlinNo ratings yet

- Arborite High Wear Laminates - December 2013Document5 pagesArborite High Wear Laminates - December 2013rahmadNo ratings yet

- Retail colorchart-REYNOBONDDocument8 pagesRetail colorchart-REYNOBONDJonathanNo ratings yet

- Concure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust ProoferDocument4 pagesConcure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust Prooferhemantrulz100% (1)

- TDS - 0121 - CapaCare Classic - 201912Document5 pagesTDS - 0121 - CapaCare Classic - 201912ayviwurbayviwurbNo ratings yet

- Dow SurfactantsDocument12 pagesDow Surfactantsv100% (1)

- Topcoats Brochure 2015 - tcm189 1442 PDFDocument16 pagesTopcoats Brochure 2015 - tcm189 1442 PDFfranky leo fernandezNo ratings yet

- Applications of PaintsDocument30 pagesApplications of Paintsneha bishtNo ratings yet

- Colorbond Brochure 140220Document40 pagesColorbond Brochure 140220jeslynlimNo ratings yet

- Acrylic Undercoat for Exterior and Interior SurfacesDocument2 pagesAcrylic Undercoat for Exterior and Interior SurfacesAlexNo ratings yet

- Acrylic Binders For Low Voc PaintsDocument31 pagesAcrylic Binders For Low Voc PaintsMaina1206550% (2)

- Benjamin Moore Product Guide US 3-10-10Document62 pagesBenjamin Moore Product Guide US 3-10-10Norbert HodiNo ratings yet

- Overcoming Performance Challenges - JPCL - 2016rev091416Document46 pagesOvercoming Performance Challenges - JPCL - 2016rev091416Ana Mae Estaniel-QuezonNo ratings yet

- Technology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishDocument8 pagesTechnology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishUsama AwadNo ratings yet

- Akzo Nobel's Duomeen TDO: PointDocument1 pageAkzo Nobel's Duomeen TDO: PointさいとはちこNo ratings yet

- 1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)Document4 pages1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)bublooo123No ratings yet

- Lime Stuff Product Data Sheet Earthborn Ecopro Silicate Masonry PaintDocument2 pagesLime Stuff Product Data Sheet Earthborn Ecopro Silicate Masonry Paintlynette_cusiter708No ratings yet

- Diaoxy Hi-Build Amine Cured EpoxyDocument4 pagesDiaoxy Hi-Build Amine Cured Epoxybublooo123No ratings yet

- Carbothane 134Document2 pagesCarbothane 134ClarkFedele27No ratings yet

- Jonwax Brouchere PDFDocument24 pagesJonwax Brouchere PDFShyam YadavNo ratings yet

- Green Processes Manufacturer of Paints and CoatingsDocument5 pagesGreen Processes Manufacturer of Paints and CoatingsRai JeanNo ratings yet

- Paints and Pigments ReportDocument7 pagesPaints and Pigments Reportnica roseNo ratings yet

- Paints, Pigments, and Industrial CoatingsDocument59 pagesPaints, Pigments, and Industrial CoatingsRomar Panopio100% (3)

- Surya CorporationDocument9 pagesSurya CorporationGirish HonavarNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Thesis Handbook Part 1 2020Document22 pagesThesis Handbook Part 1 2020Shraddha DateyNo ratings yet

- Thesis Handbook Part 3Document9 pagesThesis Handbook Part 3Shraddha DateyNo ratings yet

- Orphanage & Old Age Home - Thesis by Pooja ViswanathDocument9 pagesOrphanage & Old Age Home - Thesis by Pooja ViswanathUjjwal Kumar Swain25% (4)

- Guide to Thesis Presentation DrawingsDocument21 pagesGuide to Thesis Presentation DrawingsShraddha DateyNo ratings yet

- Name: Shraddha Datey Sub: Interior Design Vii Sem: Vii Sheet No. 2Document1 pageName: Shraddha Datey Sub: Interior Design Vii Sem: Vii Sheet No. 2Shraddha DateyNo ratings yet

- Old Age Home DesignDocument6 pagesOld Age Home DesignRaj Kumar67% (6)

- CONCRETE TECHNOLOGY: GRADES, TESTS AND PROPERTIESDocument14 pagesCONCRETE TECHNOLOGY: GRADES, TESTS AND PROPERTIESShraddha DateyNo ratings yet

- Thesis Undertaking For 2021Document1 pageThesis Undertaking For 2021Shraddha DateyNo ratings yet

- Agen2017 372243Document21 pagesAgen2017 372243Elizabeth LandeoNo ratings yet

- Moment of Inertia FormulaeDocument5 pagesMoment of Inertia FormulaeNilesh GopeeNo ratings yet

- Traditional Approach Towards Contemporary Design: A Case StudyDocument11 pagesTraditional Approach Towards Contemporary Design: A Case StudyShaikh MohsinNo ratings yet

- Estimation and Costing by M Chakraborty PDFDocument4 pagesEstimation and Costing by M Chakraborty PDFAakash Kamthane0% (3)

- Generative Mixology: An Engine For Creating Cocktails: Johnathan Pagnutti and Jim WhiteheadDocument8 pagesGenerative Mixology: An Engine For Creating Cocktails: Johnathan Pagnutti and Jim WhiteheadShraddha DateyNo ratings yet

- Crash Log 1Document1 pageCrash Log 1Shraddha DateyNo ratings yet

- Concrete Tech 1Document27 pagesConcrete Tech 1Shraddha DateyNo ratings yet

- Introduction To Building Services: Second EditionDocument7 pagesIntroduction To Building Services: Second EditionShraddha Datey0% (1)

- The Giffard Spirit of Art BookDocument21 pagesThe Giffard Spirit of Art Bookagdeshpande09100% (2)

- Furniture DesignDocument1 pageFurniture DesignShraddha DateyNo ratings yet

- Rashtrasant Tukadoji Maharaj Nagpur University: (Home Sci.) Iind Sem - Winter 2019 (337 To 344, 344 A)Document3 pagesRashtrasant Tukadoji Maharaj Nagpur University: (Home Sci.) Iind Sem - Winter 2019 (337 To 344, 344 A)Shraddha DateyNo ratings yet

- Apec Engineer ListDocument6 pagesApec Engineer ListhelloNo ratings yet

- Digital Logic Design: "4-Way Traffic Signal"Document11 pagesDigital Logic Design: "4-Way Traffic Signal"Sohaib Arif100% (1)

- Hujjan BerkahDocument12 pagesHujjan BerkahKayla SyaharaniNo ratings yet

- Stationery: CatalogueDocument11 pagesStationery: Cataloguedeepak2628No ratings yet

- Review - Panasonic AG-HPX370Document56 pagesReview - Panasonic AG-HPX370arthur_8No ratings yet

- Serpentine Pavilion Press PackDocument21 pagesSerpentine Pavilion Press PackAlvaro RosaDayerNo ratings yet

- LADDER Program Solution For Multi-Probe Monitoring and Control in Simple Cooling ProcessDocument10 pagesLADDER Program Solution For Multi-Probe Monitoring and Control in Simple Cooling ProcessShivam SinghNo ratings yet

- Château de Versailles paper modelDocument1 pageChâteau de Versailles paper modelguitarist^_^No ratings yet

- MY ResumeDocument3 pagesMY ResumebbcemkeceNo ratings yet

- Ch01 Opr Supply ChainDocument44 pagesCh01 Opr Supply ChainAyudya Rizky Budi UtamiNo ratings yet

- Chef fundamentalsDocument7 pagesChef fundamentalsAbdulrahMan MuhammedNo ratings yet

- Infinity SM 225Document2 pagesInfinity SM 225Bmwmotorsport GabriNo ratings yet

- Carmine Case Analysis of Wolfgang Keller at Königsbräu Hellas A.E.Document6 pagesCarmine Case Analysis of Wolfgang Keller at Königsbräu Hellas A.E.carminemg100% (1)

- Iprocurement Setup GuideDocument418 pagesIprocurement Setup GuidepkaruturiNo ratings yet

- Dedan Kimathi University of Technolog: SemesterDocument17 pagesDedan Kimathi University of Technolog: SemesterGabriel KamauNo ratings yet

- Calculation of Water Current ForcesDocument4 pagesCalculation of Water Current Forcesvasu7900No ratings yet

- Goodman AR Series Air Handler (50 HZ)Document4 pagesGoodman AR Series Air Handler (50 HZ)Ali GurselNo ratings yet

- Weathering Steel Information, A588, A242, Corten Unique PropertiesDocument2 pagesWeathering Steel Information, A588, A242, Corten Unique Propertiesvijayarangam1984No ratings yet

- End Mill Series: Newly Developed "Impact Miracle Coating"Document32 pagesEnd Mill Series: Newly Developed "Impact Miracle Coating"Deepak ShekarNo ratings yet

- DC DC Converter Simulation White PaperDocument12 pagesDC DC Converter Simulation White PaperGiulio Tucobenedictopacifjuamar RamírezbettiNo ratings yet

- Motorola ST v1.5Document85 pagesMotorola ST v1.5László SzabóNo ratings yet

- TOFD - Study Material, Rev.1, 24.05.2019Document125 pagesTOFD - Study Material, Rev.1, 24.05.2019Agung Prastyo Wibowo100% (2)

- Blackmer Parts List Pump Model: Tlglf4BDocument2 pagesBlackmer Parts List Pump Model: Tlglf4BRAUL ARMANDO PALOMO CAMPOSNo ratings yet

- OneSteel Hot Rolled PropertiesDocument22 pagesOneSteel Hot Rolled PropertiesRajeev SharanNo ratings yet

- 4f27e 1Document75 pages4f27e 1Andres Daniel Garcia Farquet89% (9)

- Denis Wick PDFDocument2 pagesDenis Wick PDFvicentikooNo ratings yet

- Post-Secondary Options Classroom Lesson PlanDocument3 pagesPost-Secondary Options Classroom Lesson Planapi-2522299320% (1)

- Abs Dodge Charger 2008Document2 pagesAbs Dodge Charger 2008AUTOMOTRIZ TIPO SPCANo ratings yet

- Coprative BankDocument4 pagesCoprative BankJasmandeep brarNo ratings yet

- Object Cloning Best PracticesDocument15 pagesObject Cloning Best PracticeswaltNo ratings yet