Professional Documents

Culture Documents

Concrete Mix Design

Uploaded by

shafeekOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Mix Design

Uploaded by

shafeekCopyright:

Available Formats

14-Jul

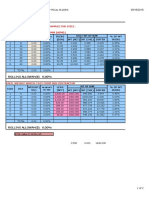

CONCRETE MIX DESIGNS - 20/20 OPC

MIX DESIGN PARAMETERS [Revision Number : 1]

Project DOHA METRO RED LINE PROJECT Mix Code 005 Product Code

Client QATAR RAIL Issue Date 3-JAN-2015 Max.Agg. Size 20

2) 20 Free

Consultant Target strength(N/m Specified

water/cem-

Contractor RLS - JV Specified Slump,mm 130 - 180 mm ent ratio Used 0.57

DETAILS OF CONCRETE MIX INGREDIENTS

10/20 mm 10mm

Type 0/4 washed OPC SODAMCO Water

crushed crushed

Material description

Source Fujairah Fujairah QNCC QNCC CF 208 KAHRAMA

Quantity, Kg / m 3

705 425 854 300 6.00 171

Specific Gravity 2.84 2.82 2.67 3.15 1.2 1.0

Absolute Volume,litre 248.24 150.71 319.85 95.24 5.0 171.00

Water Absorption,% 0.5 0.6 1.4 - - -

Moisture content,% - -

Moisture correction, Kg / m3

Corrected Quantity, Kg / m3 702 423 844 300 6.00 186

Actual Plastic Density of Concrete, Mix Description

REMARKS

Kg / m3

Estimated Density of Concrete,

2461.00

1. The tolerence for Slump, may vary according to QCS 2010 LIMIT Kg / m3 20/20 OPC

Agg/cement

Total SO3 as % of cement 2.76

2.Moisture content of the aggregates is monitored on a daily basis and necessary ratio

corrections applied to mix whenever required.

Total Cl as % of cement 0.03 Total Absolute

Volume of

Air Content (%) 2.00 Concrete , litr

3. Admixture dosage as per manufacturer's specification and may vary according to Dosage of Admixture may vary from 5 to 6.5 Ltrs.This mix will Achieve all the High

workability requirement and climatic conditions. Durable Parameters.

COMBINED GRADING

100.00

90.00

20.000

25.000

80.00

14.000

CUMULATIVE % PASSING

70.00

31.500

60.00

50.00

40.00

30.00

20.00

1.000

10.00

0.500

0.250

40.000

0.00

0.125

63.000

0.063

Calculated combined grading 100 100 100 100 97.4 83.4

75.1 63.2 53.4 49 45 39.7 29.6 8.5 1.3 0.8

lower 100 98 90 50 20 SIEVE SIZE (MM)

PARTICLE SIZE DISTRIBUTION AND COMBINED GRADING PERCENTAGE OF AGGREGATES IN THE MIX (INDIVIDUAL)

Sieve sizes, mm 31.5 20.0 10.0 2.000 1.000 0.063 20 MM 10 MM W. SAND Total (%)

20mm agg.%passing 100 89 1 0.20 0.20 0.10 35 21.2 45.1 101.3

10mm agg.% passing 100 100 96 1.00 1.00 0.90

Washed Sand%passing Quality Control

100 100 100 93 82 1

Dune Sand,%passing 100 100 100 100 100 100

Combined, % passing 100.0 97.4 75.1 45.0 39.70 0.8

Target, % passing 99.0 94.5 70.0 40.0 10.0 2.5

Upper Limit 100 99 90 60 20 3

Lower Limit 98 90 50 20 0 0

proposed mix design page 1

14-Jul

CONCRETE MIX DESIGNS - 25/20 OPC

MIX DESIGN PARAMETERS [Revision Number : 1]

Project DOHA METRO RED LINE PROJECT Mix Code 106 Product Code

Client QATAR RAIL Issue Date 2-FEB-2015 Max.Agg. Size 20

2) 20 Free

Consultant Target strength(N/m Specified

water/cem-

Contractor RLS - JV Specified Slump,mm 150 +/- 25 mm ent ratio Used 0.53

DETAILS OF CONCRETE MIX INGREDIENTS

10/20 mm 10mm

Type 0/4 washed OPC SODAMCO Water

crushed crushed

Material description

Source Fujairah Fujairah QNCC QNCC CF 208 KAHRAMA

Quantity, Kg / m 3

700 440 843 310 5.50 164

Specific Gravity 2.84 2.82 2.67 3.15 1.2 1.0

Absolute Volume,litre 246.48 156.03 315.73 98.41 4.6 164.00

Water Absorption,% 0.5 0.6 1.4 - - -

Moisture content,% - -

Moisture correction, Kg / m3

Corrected Quantity, Kg / m3 697 438 833 310 5.50 179

Actual Plastic Density of Concrete, Mix Description

REMARKS

Kg / m3

Estimated Density of Concrete,

2462.50

1. The tolerence for Slump, may vary according to QCS 2010 LIMIT Kg / m3 25/20 OPC

Agg/cement

Total SO3 as % of cement 2.76

2.Moisture content of the aggregates is monitored on a daily basis and necessary ratio

corrections applied to mix whenever required.

Total Cl as % of cement 0.03 Total Absolute

Volume of

Air Content (%) 2.00 Concrete , litr

3. Admixture dosage as per manufacturer's specification and may vary according to Dosage of Admixture may vary from 5 to 6.5 Ltrs.This mix will Achieve all the High

workability requirement and climatic conditions. Durable Parameters.

COMBINED GRADING

100.00

90.00

20.000

25.000

80.00

14.000

CUMULATIVE % PASSING

70.00

31.500

60.00

50.00

40.00

30.00

20.00

1.000

10.00

0.500

0.250

40.000

0.00

0.125

63.000

0.063

Calculated combined grading 100 100 100 100 97.4 83.4

75.1 63.2 53.4 49 45 39.7 29.6 8.5 1.3 0.8

lower 100 98 90 50 20 SIEVE SIZE (MM)

PARTICLE SIZE DISTRIBUTION AND COMBINED GRADING PERCENTAGE OF AGGREGATES IN THE MIX (INDIVIDUAL)

Sieve sizes, mm 31.5 20.0 10.0 2.000 1.000 0.063 20 MM 10 MM W. SAND Total (%)

20mm agg.%passing 100 89 1 0.20 0.20 0.10 34.5 21.9 44.3 100.7

10mm agg.% passing 100 100 96 1.00 1.00 0.90

Washed Sand%passing Quality Control

100 100 100 93 82 1

Dune Sand,%passing 100 100 100 100 100 100

Combined, % passing 100.0 97.4 75.1 45.0 39.70 0.8

Target, % passing 99.0 94.5 70.0 40.0 10.0 2.5

Upper Limit 100 99 90 60 20 3

Lower Limit 98 90 50 20 0 0

proposed mix design page 1

14-Jul

CONCRETE MIX DESIGNS - 30/20 OPC

MIX DESIGN PARAMETERS [Revision Number : 1]

Project DOHA METRO RED LINE PROJECT Mix Code 108 Product Code

Client QATAR RAIL Issue Date 3-JAN-2015 Max.Agg. Size 20

2) 30 Free

Consultant Target strength(N/m Specified

water/cem-

Contractor RLS - JV Specified Slump,mm 150 +/- 40 mm ent ratio Used 0.54

DETAILS OF CONCRETE MIX INGREDIENTS

10/20 mm 10mm

Type 0/4 washed OPC SODAMCO Water

crushed crushed

Material description

Source Fujairah Fujairah QNCC QNCC CF 208 KAHRAMA

Quantity, Kg / m 3

701 430 850 320 5.50 173

Specific Gravity 2.84 2.82 2.67 3.15 1.2 1.0

Absolute Volume,litre 246.83 152.48 318.35 101.59 4.6 173.00

Water Absorption,% 0.5 0.6 1.4 - - -

Moisture content,% - -

Moisture correction, Kg / m3

Corrected Quantity, Kg / m3 698 428 840 320 5.50 188

Actual Plastic Density of Concrete, Mix Description

REMARKS

Kg / m3

Estimated Density of Concrete,

2479.50

1. The tolerence for Slump, may vary according to QCS 2010 LIMIT Kg / m3 30/20 OPC

Agg/cement

Total SO3 as % of cement 2.76

2.Moisture content of the aggregates is monitored on a daily basis and necessary ratio

corrections applied to mix whenever required.

Total Cl as % of cement 0.03 Total Absolute

Volume of

Air Content (%) 2.00 Concrete , litr

3. Admixture dosage as per manufacturer's specification and may vary according to Dosage of Admixture may vary from 5 to 6.5 Ltrs.This mix will Achieve all the High

workability requirement and climatic conditions. Durable Parameters.

COMBINED GRADING

100.00

90.00

20.000

25.000

80.00

14.000

CUMULATIVE % PASSING

70.00

31.500

60.00

50.00

40.00

30.00

20.00

1.000

10.00

0.500

0.250

40.000

0.00

0.125

63.000

0.063

Calculated combined grading 100 100 100 100 97.4 83.4

75.1 63.2 53.4 49 45 39.7 29.6 8.5 1.3 0.8

lower 100 98 90 50 20 SIEVE SIZE (MM)

PARTICLE SIZE DISTRIBUTION AND COMBINED GRADING PERCENTAGE OF AGGREGATES IN THE MIX (INDIVIDUAL)

Sieve sizes, mm 31.5 20.0 10.0 2.000 1.000 0.063 20 MM 10 MM W. SAND Total (%)

20mm agg.%passing 100 89 1 0.20 0.20 0.10 33.7 21.8 45.5 101

10mm agg.% passing 100 100 96 1.00 1.00 0.90

Washed Sand%passing Quality Control

100 100 100 93 82 1

Dune Sand,%passing 100 100 100 100 100 100

Combined, % passing 100.0 97.4 75.1 45.0 39.70 0.8

Target, % passing 99.0 94.5 70.0 40.0 10.0 2.5

Upper Limit 100 99 90 60 20 3

Lower Limit 98 90 50 20 0 0

proposed mix design page 1

21-Feb

CONCRETE MIX DESIGN 35/20 SRC

CONTRACT DETAILS MIX DESIGN PARAMETERS

Project STANDARD Mix Code AMR/MD/117/13 Product Code 109

Client Date 11.03.2013 Max.Agg. Size 20 mm

Consultant Specified Strength,Mpa 35 Free Specified

water/cem-

Contractor Specified Slump,mm 150+/-25 ent ratio Used 0.42

DETAILS OF CONCRETE MIX INGREDIENTS

10/20 mm 4/10mm Super

Type 0/4 washed Dune sand Microsilica GGBS SRC Water profer Water

Material crushed crushed plasticizer

description

SODAMCO

Source Fujairah Fujairah QPMC Al Ain ….. ……. QNCC kim-hs KAHRAMA

CF-80

Quantity, Kg / m3 727 444 848 0 0 0 350 5.9 147

Specific Gravity 2.92 2.98 2.66 2.62 2.24 2.7 3.15 1 1.2 1.0

Absolute Volume,litre 248.99 149.10 318.88 0.00 0.00 0.00 111.11 0.00 4.9 147.00

Water Absorption,% 0.5 0.7 0.9 0.9 - - - - - -

Moisture content,% 0 0 0 0 - - - - - -

Moisture correction, Kg / m3 3.64 3.11 7.63 0.00 - - - - 14.4

Corrected Quantity, Kg / m3 723 441 841 0 0 0 350 0 5.9 161

Actual Plastic Density of Concrete, Mix Description

REMARKS 2520

Kg / m3

Estimated Density of Concrete,

2522

1. The tolerence for Slump, may vary according to QCS 2010 LIMIT Kg / m3 35.20 SRC

Yield, m3 1.001

Agg/cement

Total SO3 as % of cement 2.76 5.77

2.Moisture content of the aggregates is monitored on a daily basis and necessary ratio

corrections applied to mix whenever required.

Total Cl as % of cement 0.03 Total Absolute

Volume of 1000.00

Volume of air per m3 of Concrete, 20.00 Concrete , litr

litre

3. Admixture dosage as per manufacturer's specification and may vary according

Dosage of CF 80 may vary from 2.0 Ltr to 6Ltr / M³.

to workability requirement and climatic conditions.

COMBINED GRADING

100.00

90.00

80.00

CUMULATIVE % PASSING

70.00

60.00

50.00

40.00

30.00

20.00

10.000

10.00

2.000

0.00

1.000

0.063

31.500

Combined, % passing Upper Limit Lower Limit

20.000

SIEVE SIZE (MM)

PARTICLE SIZE DISTRIBUTION AND COMBINED GRADING PERCENTAGE OF AGGREGATES IN THE MIX (INDIVIDUAL)

Sieve sizes, mm 31.5 20.0 10.0 2.000 1.000 0.063 20 MM 10 MM 5 MM

20mm agg.%passing 100 97 58 55 2 0 36 22 42

10mm agg.% passing 100 96 75 0 0 0

Quality Controller -

4mm agg.%passing 100 100 99 65 30 5 Jasfer M Abdulrahman

Dune Sand,%passing 100 100 100 100 100 100

Combined, % passing 100.0 98.0 79.0 47.1 13 2.1 e - mail jasfer@almajalqatar.com

Target, % passing 99.0 94.5 70.0 40.0 10.0 2.5 Mobile- 70336545

Upper Limit 100 99 90 60 20 3

Lower Limit 98 90 50 20 0 0

proposed mix design page 1

14-Jul

CONCRETE MIX DESIGNS - 40/20 OPC

MIX DESIGN PARAMETERS [Revision Number : 1]

Project DOHA METRO RED LINE PROJECT Mix Code 112 Product Code

Client QATAR RAIL Issue Date 3-JAN-2015 Max.Agg. Size 20

2) 40 Free

Consultant Target strength(N/m Specified

water/cem-

Contractor RLS - JV Specified Slump,mm 150 +/- 40 mm ent ratio Used 0.43

DETAILS OF CONCRETE MIX INGREDIENTS

10/20 mm 10mm

Type 0/4 washed OPC BASF Water

crushed crushed

Material description

Glenium

Source Fujairah Fujairah QNCC QNCC KAHRAMA

110

Quantity, Kg / m 3

712 488 834 350 3.00 150

Specific Gravity 2.84 2.82 2.67 3.15 1.2 1.0

Absolute Volume,litre 250.70 173.05 312.36 111.11 2.5 150.00

Water Absorption,% 0.5 0.6 1.4 - - -

Moisture content,% - -

Moisture correction, Kg / m3

Corrected Quantity, Kg / m3 709 486 824 350 3.00 165

Actual Plastic Density of Concrete, Mix Description

REMARKS

Kg / m3

Estimated Density of Concrete,

2537.00

1. The tolerence for Slump, may vary according to QCS 2010 LIMIT Kg / m3 40/20 OPC

Agg/cement

Total SO3 as % of cement 2.76

2.Moisture content of the aggregates is monitored on a daily basis and necessary ratio

corrections applied to mix whenever required.

Total Cl as % of cement 0.03 Total Absolute

Volume of

Air Content (%) 2.00 Concrete , litr

3. Admixture dosage as per manufacturer's specification and may vary according to Dosage of Admixture may vary from 3 to 5 Ltrs.This mix will Achieve all the High Durable

workability requirement and climatic conditions. Parameters.

COMBINED GRADING

100.00

90.00

20.000

25.000

80.00

14.000

CUMULATIVE % PASSING

70.00

31.500

60.00

50.00

40.00

30.00

20.00

1.000

10.00

0.500

0.250

40.000

0.00

0.125

63.000

0.063

Calculated combined grading 100 100 100 100 97.4 83.4

75.1 63.2 53.4 49 45 39.7 29.6 8.5 1.3 0.8

lower 100 98 90 50 20 SIEVE SIZE (MM)

PARTICLE SIZE DISTRIBUTION AND COMBINED GRADING PERCENTAGE OF AGGREGATES IN THE MIX (INDIVIDUAL)

Sieve sizes, mm 31.5 20.0 10.0 2.000 1.000 0.063 20 MM 10 MM W. SAND Total (%)

20mm agg.%passing 100 89 1 0.20 0.20 0.10 35 24.2 43.6 102.8

10mm agg.% passing 100 100 96 1.00 1.00 0.90

Washed Sand%passing Quality Control

100 100 100 93 82 1

Dune Sand,%passing 100 100 100 100 100 100

Combined, % passing 100.0 97.4 75.1 45.0 39.70 0.8

Target, % passing 99.0 94.5 70.0 40.0 10.0 2.5

Upper Limit 100 99 90 60 20 3

Lower Limit 98 90 50 20 0 0

proposed mix design page 1

You might also like

- Design Mix ExampleDocument4 pagesDesign Mix ExampleLeanna Abdul WahabNo ratings yet

- Concrete Lab ManualDocument42 pagesConcrete Lab ManualVENKATA RANGANADHNo ratings yet

- GRANITE & MARBLE STONE VENEERING WORKDocument14 pagesGRANITE & MARBLE STONE VENEERING WORKDebraj RoyNo ratings yet

- Building ConstructionDocument29 pagesBuilding ConstructionArpit100% (1)

- Mr. Pintu Agrawal Boundary Wall BOQDocument1 pageMr. Pintu Agrawal Boundary Wall BOQAkash PatelNo ratings yet

- Summary of Balance Quantity R17 27-10-18Document75 pagesSummary of Balance Quantity R17 27-10-18Priyank DUbeyNo ratings yet

- Bridge DPR BOQ (Pkg. No. UP67163)Document77 pagesBridge DPR BOQ (Pkg. No. UP67163)amit singhNo ratings yet

- Analysis Book-2012Document4,514 pagesAnalysis Book-2012Muhammad Danish KhanNo ratings yet

- DLC Methodology - Nagpur MumbaiDocument13 pagesDLC Methodology - Nagpur MumbaiGanesh Kumar TulabandulaNo ratings yet

- Concrete Mix Design m75Document2 pagesConcrete Mix Design m75nil sutar100% (1)

- SWD NotesDocument44 pagesSWD Notesillya amyraNo ratings yet

- Paver Block Rate AnalysisDocument1 pagePaver Block Rate AnalysisTech Guide- HindiNo ratings yet

- GSB Test FormatsDocument4 pagesGSB Test FormatsGaurav TripathiNo ratings yet

- Concrete Mix Design ReportDocument5 pagesConcrete Mix Design ReportAniruddha ChakrabortyNo ratings yet

- Mix Design (Aci - Method)Document14 pagesMix Design (Aci - Method)Bengkulu BetonNo ratings yet

- LAB EQUIPMENT INVENTORYDocument17 pagesLAB EQUIPMENT INVENTORYPalla Bhaskara RaoNo ratings yet

- Construction of Mppschool Building at Ainapoor Tanda (V) of Doma (M)Document30 pagesConstruction of Mppschool Building at Ainapoor Tanda (V) of Doma (M)vanamgouthamNo ratings yet

- Concrete MIx Design SummaryDocument4 pagesConcrete MIx Design SummaryAmarNo ratings yet

- RATE ANALYSIS FOR CONSTRUCTION MATERIALS AND LABOURDocument81 pagesRATE ANALYSIS FOR CONSTRUCTION MATERIALS AND LABOURAnantPawarNo ratings yet

- Cement Consumption (1) JulyDocument140 pagesCement Consumption (1) JulyRahul SharmaNo ratings yet

- Is Codes ListDocument132 pagesIs Codes ListMuralidhar BalekundriNo ratings yet

- Work Method Statement For Shear Wall FoamworkDocument7 pagesWork Method Statement For Shear Wall FoamworkPrashant MankarNo ratings yet

- Wood Anatomy LabDocument6 pagesWood Anatomy LabmadhujayarajNo ratings yet

- Approval of Concrete Curing CompoundDocument4 pagesApproval of Concrete Curing Compoundsalman tariqNo ratings yet

- Design of Cement Concrete Mix For M30 Grade ConcreteDocument8 pagesDesign of Cement Concrete Mix For M30 Grade ConcreteNarendra BokreNo ratings yet

- AKHPL Concrete Mix Design Summary.Document3 pagesAKHPL Concrete Mix Design Summary.dipl labNo ratings yet

- Bitumen Extraction Test Observation SheetDocument2 pagesBitumen Extraction Test Observation SheetramNo ratings yet

- Lot 1 - Expansion Civil WorksDocument6 pagesLot 1 - Expansion Civil WorksJethro AbanadorNo ratings yet

- Detailed Lesson PlanDocument10 pagesDetailed Lesson Planshaira myrellNo ratings yet

- Item Material Unit Remark SR No Material Coeff. Excl Wastage Wastage Factor Material Co-EffDocument9 pagesItem Material Unit Remark SR No Material Coeff. Excl Wastage Wastage Factor Material Co-EffDeepak KaushikNo ratings yet

- S.No DIA Unit WT of Bar WT (Act) WT (The) Differ Weight (KG) Incrg (DIA) % of WT IncrgDocument2 pagesS.No DIA Unit WT of Bar WT (Act) WT (The) Differ Weight (KG) Incrg (DIA) % of WT IncrgAtulJainNo ratings yet

- AAC BLOCK SUNKEN FILLING CHECKLISTDocument1 pageAAC BLOCK SUNKEN FILLING CHECKLISTASHOKKUMARNo ratings yet

- Mix Design For Concrete Grade M 42Document4 pagesMix Design For Concrete Grade M 42NaveenkumarNo ratings yet

- Material Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Document1 pageMaterial Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Waqas SadiqNo ratings yet

- Quotation FormatDocument4 pagesQuotation FormatNaveen YadavNo ratings yet

- Fosroc Nitocote EM 300 protects concrete from corrosionDocument2 pagesFosroc Nitocote EM 300 protects concrete from corrosionAarish Khan100% (1)

- Wet Mix Macadam CharacteristicsDocument8 pagesWet Mix Macadam CharacteristicsRavishankar HobannaNo ratings yet

- Laying of CC Road From Srinivas Naik (H) To Malyanaik (H) of Utakunta Thanda (V) of Narayanpet (M)Document3 pagesLaying of CC Road From Srinivas Naik (H) To Malyanaik (H) of Utakunta Thanda (V) of Narayanpet (M)K KARTHIKNo ratings yet

- Material Specification & TestDocument3 pagesMaterial Specification & TestmunimiutNo ratings yet

- Mix Design and Pie Chart RepresentationDocument40 pagesMix Design and Pie Chart RepresentationKuldeep ChakerwartiNo ratings yet

- Govt School Certificate PaymentDocument28 pagesGovt School Certificate PaymentSajid SayeedNo ratings yet

- MoRTH Circular Value Engineering 22.02.2023 PDFDocument2 pagesMoRTH Circular Value Engineering 22.02.2023 PDFHimanshu PatelNo ratings yet

- 04-Filling Foundation Concrete Work PlumDocument4 pages04-Filling Foundation Concrete Work PlumBijay Krishna DasNo ratings yet

- BOQ - ConcreteDocument10 pagesBOQ - ConcreteAbhijit HavalNo ratings yet

- Certification of Plywood For Concrete Shuttering WorkDocument10 pagesCertification of Plywood For Concrete Shuttering WorkJGD123No ratings yet

- Underck Insulation MSTDocument8 pagesUnderck Insulation MSTmahesh naikNo ratings yet

- MTC For ThermocolDocument2 pagesMTC For ThermocolhariprasadNo ratings yet

- Rate AnalysisDocument5 pagesRate AnalysisPritom NunisaNo ratings yet

- Fosroc Nitobond EP - Epoxy bonding agent for concreteDocument4 pagesFosroc Nitobond EP - Epoxy bonding agent for concreteganmosesNo ratings yet

- Material Reconciliation - PDF REVISEDDocument32 pagesMaterial Reconciliation - PDF REVISEDlinga2014No ratings yet

- Nitobond AR Std.Document4 pagesNitobond AR Std.Dinesh Kumar PatelNo ratings yet

- Cico Tapecrete P 151 PDFDocument3 pagesCico Tapecrete P 151 PDFBijaya RaulaNo ratings yet

- 6.self Curing ConcreteDocument4 pages6.self Curing ConcreteBhanu Chandar KNo ratings yet

- Method Statement For Sub Grade: Project Procedure Plan - Fipl#2, Phase 1Document4 pagesMethod Statement For Sub Grade: Project Procedure Plan - Fipl#2, Phase 1HARIOM GUPTANo ratings yet

- Rate Analysis - Khulna - Barisal - GopalganjDocument280 pagesRate Analysis - Khulna - Barisal - Gopalganjmd mohiuddinNo ratings yet

- Cebex 100Document2 pagesCebex 100Riyan Aditya NugrohoNo ratings yet

- Concrete Mix Design C30 - ACI METHODDocument4 pagesConcrete Mix Design C30 - ACI METHODMitendra Kumar ChauhanNo ratings yet

- Strip Chart StructureDocument5 pagesStrip Chart StructureBrijesh MishraNo ratings yet

- Fire Proof PlasterDocument1 pageFire Proof PlasterMuhammad Sarmad SonyalNo ratings yet

- Mix Design PosterDocument1 pageMix Design PosterAbhilash KumarNo ratings yet

- BSRDocument92 pagesBSRAfrath_nNo ratings yet

- T6 M30 Pile Fosrco CSandDocument1 pageT6 M30 Pile Fosrco CSandManish NehraNo ratings yet

- Balaji Concrete: A. Mix Stipulation 10Document3 pagesBalaji Concrete: A. Mix Stipulation 10Dhananjay PatelNo ratings yet

- Concrete Mix Design STFA 09 06 2009Document20 pagesConcrete Mix Design STFA 09 06 2009Ahmet ÖzdenNo ratings yet

- Building construction practices standardsDocument5 pagesBuilding construction practices standardsAmanulla KhanNo ratings yet

- Roof Garden Specification PDFDocument41 pagesRoof Garden Specification PDFKhushbooNo ratings yet

- II-6 Agronomy 1-23Document24 pagesII-6 Agronomy 1-23SannyBombeoJomocNo ratings yet

- XCabbage Fertilizer Requirements PDF - Google SearchDocument1 pageXCabbage Fertilizer Requirements PDF - Google SearchLesley ShiriNo ratings yet

- TileDocument2 pagesTileRICPL - Quality Management Department- HONo ratings yet

- Cucurbit Rootstock Table v6 Jan 14Document5 pagesCucurbit Rootstock Table v6 Jan 14MarianVasilacheNo ratings yet

- Instructors Guides For Teaching Organic GardeningDocument2 pagesInstructors Guides For Teaching Organic GardeningU8x58No ratings yet

- All-in rates for architectural works under 40 charactersDocument1 pageAll-in rates for architectural works under 40 charactersKamal LatifNo ratings yet

- How Water Amount Affects Mung Bean GrowthDocument14 pagesHow Water Amount Affects Mung Bean GrowthClaireSobredilla-JuarezNo ratings yet

- Slab01 Formwork and Reinforcement DrawingsDocument4 pagesSlab01 Formwork and Reinforcement DrawingsEnrike GarciaNo ratings yet

- Evaluation of Growth, Development and Yield of Strawberry under Different Mulching MaterialsDocument12 pagesEvaluation of Growth, Development and Yield of Strawberry under Different Mulching MaterialsJoydeb GomastaNo ratings yet

- Revised Civil QuantitiesDocument10 pagesRevised Civil QuantitiesGabriel TambweNo ratings yet

- TP LOGS - MeterDocument15 pagesTP LOGS - MeterWaqas AhmedNo ratings yet

- Field Crops (Cotton & Sun Flower)Document8 pagesField Crops (Cotton & Sun Flower)Lawrence KasambaNo ratings yet

- 2 - Types of Stone, Brick and Block Masonry-2000Document20 pages2 - Types of Stone, Brick and Block Masonry-2000asadNo ratings yet

- Field Tests for Pollen Viability; a Comparative ApproachDocument8 pagesField Tests for Pollen Viability; a Comparative ApproachnugrahaNo ratings yet

- Dar (Civil) IIDocument888 pagesDar (Civil) IIShyam Kumar100% (1)

- Effect of Nitrogen and Phosphorus on Dry Weight, N and P Content of Tropical LegumesDocument50 pagesEffect of Nitrogen and Phosphorus on Dry Weight, N and P Content of Tropical LegumesYanti Nya IkbalNo ratings yet

- Output LrmdsfsafsadDocument15 pagesOutput LrmdsfsafsadRetro SphinxNo ratings yet

- Yulianto Nugroho, Gatot Mudjiono, Retno Dyah Puspitarini: Jurnal HPT Volume 1 Nomor 3 September 2013 ISSN: 2338 - 4336Document11 pagesYulianto Nugroho, Gatot Mudjiono, Retno Dyah Puspitarini: Jurnal HPT Volume 1 Nomor 3 September 2013 ISSN: 2338 - 4336Septina Maula HusnaNo ratings yet

- Murraya exotica - Orange Jasmine Plant ProfileDocument3 pagesMurraya exotica - Orange Jasmine Plant ProfileViji Thulasiraman100% (1)

- Particular Specifications Masonry Work - Stone Masonry: Indian StandardsDocument14 pagesParticular Specifications Masonry Work - Stone Masonry: Indian StandardsBibek BhattaraiNo ratings yet

- Note On PVC Pipe LayingDocument2 pagesNote On PVC Pipe LayingNitin S JogNo ratings yet

- Sl No Description No L B D CF Quantity Remark: Detailed Estimate 2017/45839: കാലിെڹാഴുڹ് നിർ疂�ാണംDocument3 pagesSl No Description No L B D CF Quantity Remark: Detailed Estimate 2017/45839: കാലിെڹാഴുڹ് നിർ疂�ാണംVishnu DasNo ratings yet

- Radula Complanata Lindenbergiana VolutaDocument1 pageRadula Complanata Lindenbergiana VolutaFlorbela GraçaNo ratings yet

- Characters Distribution and Types of BrassicaseaeDocument11 pagesCharacters Distribution and Types of Brassicaseaesamuel mainaNo ratings yet