Professional Documents

Culture Documents

A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0

Uploaded by

m.shehreyar.khanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0

Uploaded by

m.shehreyar.khanCopyright:

Available Formats

KPD-TAY Integrated Development Project Phase-II

PROC-FC/CB/PROJ-667/767321/2013

Xinjiang Petroleum Project No. FPA13013D

Investigation Design and

Research Institute(Co.,Ltd.) Document No. A44-01-PRO-DAS-08

Datasheet for Inlet Gas Trim Cooler

E-4401 / E-5401

F0 11-08-2015 AS-BUILT WJH ZY SQ GJF

Revise For

1 12-04-2014 WJH ZY SQ GJF

Approved

0 27-12-2013 Approved WJH ZY SQ GJF

Rev. Date Description Prepared by Checked by Reviewed by Approved by

Project No. FPA13013D

KPD-TAY Integrated Development Project Phase-Ⅱ

PROC-FC/CB/PROJ-667/767321/2013 Document No. A44-01-PRO-DAS-08

Xinjiang Petroleum

Investigation Design and

Research Institute(Co.,Ltd.) Doc. Name Datasheet for Inlet Gas Trim Cooler Unit 44/54 Sheet 1 of 1

Client: OIL & GAS DEVELOPMENT COMPANY LTD. Unit.: 44 (Tarin-1)/54 (Train-2)

Plant: AMINE SWEETENING UNIT No. of Unit.: 2

Req. No.: Order No.:

Bid Job No. : 165-4

Bid Dwg. No.: Model No.:

Equipment Tag No. E-4401 / E-5401 Manufacturer: KR

Type: BEU-HORIZONTAL Size: 40 x 196.85 in Connected in 1 Parallel 1 Series

Surface/Unit (Gross) (Eff.) ft2 4361.62 / 4228.34 Shell/Unit 1 Surface/Shell(Gross)(Eff.) ft2 4361.62 / 4228.34

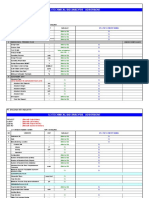

1 PERFORMANCE OF ONE UNIT

2 Fluid Allocation TUBE SIDE SHELL SIDE

3 Fluid Circulated GAS WATER

4 Fluid Quantity Tota lb./h 290832 x 1.1 190096 x 1.1

5 Vapor (In/Out) lb./h 290832 x 1.1 290832 x 1.1

6 Liquid (In/Out) lb./h 190096 x 1.1 190096 x 1.1

7 - Steam lb./h

8 -water lb./h

9 -Non-Condensable lb./h

10 Temperature (In/Out) ºF 140.0 110.0 93.0 115.0

3

11 Density(Vap/Liq) lb/ft 3.9 4.2 62.5 61.9

12 Viscosity (Vapor/Liquid) cP 0.01 0.01 0.74 0.58

13 Molecular Weight (Vapor/Liquid) 20.96 20.96 18 18

14 Mol. Wt., Noncondensable

15 Specific Heat (Vap/Liq) Btu/lb.ºF 0.48 0.47 1.00 1.00

16 Thermal Conductivity Btu-ft/h-ft2-°F 0.02 0.02 0.36 0.37

17 Latent Heat (Vap/Liq) Btu/lb

18 Inlet Pressure psig 1045.00 50.00

19 Velocity ft/sec 16.09 0.53

20 Pressure Drop Allow./Calc. psi 10 / 3.244 5 / 0.683

21 Fouling Resistance (Min) hr-ft2-°F/Btu 0.001 0.002

22 Heat Exchanged Btu/h 4176060 x 1.1 MTD Corrected, ºF 14.5

23 Transfer Rate Btu/h-ft2 -ºF Service 75.18 Dirty 83.29 Clean 113.69

24 CONSTRUCTION OF ONE SHELL SKETCH (BUNDLE/NOZZLE ORIENTATION)

25 TUBE SIDE SHELL SIDE

26 Design/Test Pressure, psig 1200 150

27 Design Temperature, ºF 200 150

28 No. Passes per Shell 2 1

40

29 Corrosion Allowance, mm 0 3 inch

30 In 10"/600#RF In 6"/150#RF

31

32 Connections (Size/Rating) Out 10"/600#RF Out 6"/150#RF 16.404

ft

33

34 Intermediate

35 Tube No. 635U OD 0.75 in

Thk.(Min./Avg.) 0.065 in Length 196.85 in Pitch 0.9843 in 30 deg.

36 Tube Type Plain Material SS316L

37 Shell SA-516Gr.70 ID 40 in Thk. 0.472 in Shell Cover SA-516Gr.70 (Integ.)(Remov.) Thk. 0.472 in

38 Channel or Bonnet SA-516Gr.70+ SS316L clad Thk. 1.496”+0.118” Channel Cover SA-516Gr.70+ SS316L clad Thk. 1.496”+0.118”

39 Tubesheet Stationary SA-516Gr.70+ SS316L clad Tubesheet Floating ╱

40 Floating Head Cover ╱ Impingement Protection None

41 Baffles (Cross) 17 Type Double Segmental %Cut 26.83 Spacing c/c 11.0236 Inlet 25.0826 in.

42 Baffles (Long) ╱ Seal Type ╱

43 Supports Tube SA-106 Gr.B U-Bend SA-213 TP316L Type Semicircle

44 Bypass Seal Arrangement None Tube/Tubesheet Joint Strength welding plus expanding Gaskets ╱

45 Expansion Joint None Type ╱

46 rv-2 inlet nozzle 1350.01 Bundle entrance 124.45 Bundle Exit 178.35 lb/ ft-sec2

47 Gaskets Shell Side S.S.316L/F.G Tube Side S.S.316L/F.G

48 Floating Head ╱

49 Code Requirements ASME SectionⅧ Division Ⅰ& Ⅱ Code Stamp Yes/No YES TEMA Class R

50 Weights/Shell Shipping 26120 Filled with Water 36327 Bundle 15138 lb

51 Full Radiographed Yes Joint Efficiency 100%

52

53

54

You might also like

- Dokumen - Tips - Gpsa 13 Ed Separation PDFDocument48 pagesDokumen - Tips - Gpsa 13 Ed Separation PDFNovi WulansariNo ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- Vent To Flare 1683883352Document31 pagesVent To Flare 1683883352saheem_783617392No ratings yet

- P RefStd - 4043 - v091130 - EN - LOPADocument18 pagesP RefStd - 4043 - v091130 - EN - LOPAlucianduNo ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Control Valve Data Sheet Form S20 50 PDFDocument4 pagesControl Valve Data Sheet Form S20 50 PDFPanner2009No ratings yet

- Bulletin 71.4MR108 PDFDocument20 pagesBulletin 71.4MR108 PDFBledarNo ratings yet

- 31-MBD-127 Inlet Separator-Rev.0 (On Pile)Document53 pages31-MBD-127 Inlet Separator-Rev.0 (On Pile)Didi Hadi RiantoNo ratings yet

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaNo ratings yet

- 1.0 J1415 QF200-2 PSA DatasheetDocument2 pages1.0 J1415 QF200-2 PSA DatasheetCarlos MagNo ratings yet

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocument4 pagesR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRANo ratings yet

- HAZOP Study Checklist (26092011) - 2Document2 pagesHAZOP Study Checklist (26092011) - 2Hina ImranNo ratings yet

- Line ListDocument1 pageLine Listهيمنت بيلودياNo ratings yet

- Kvaerner John Brown: Leff (Hor.) /H (Vert.)Document1 pageKvaerner John Brown: Leff (Hor.) /H (Vert.)bharathscdsNo ratings yet

- Guide Document GE P312 4.1.2 I General ConsiderationsDocument31 pagesGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraNo ratings yet

- Qatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1Document23 pagesQatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1varatharajan g rNo ratings yet

- 3443-SZ-RT-101 - 04 Attachment 15Document8 pages3443-SZ-RT-101 - 04 Attachment 15tak-1963No ratings yet

- Steam CoilDocument6 pagesSteam CoilMyung Ho SynNo ratings yet

- SP 1125Document12 pagesSP 1125Venkat RanganNo ratings yet

- SNBP-EPC-20-PRO-PID-008 PID Open Drain Header - RRDocument2 pagesSNBP-EPC-20-PRO-PID-008 PID Open Drain Header - RRsugeng wahyudiNo ratings yet

- Relief and Blowdown Report: Page 1 of 21Document21 pagesRelief and Blowdown Report: Page 1 of 21TarekNo ratings yet

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxNo ratings yet

- Process Design Basis: Doc. No.: DB-SP2021ON-PR-103-P312-0201Document19 pagesProcess Design Basis: Doc. No.: DB-SP2021ON-PR-103-P312-0201mohsen ranjbarNo ratings yet

- WHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsDocument17 pagesWHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsYasin ElaswadNo ratings yet

- Centrifugal PumpsDocument14 pagesCentrifugal PumpsAshishAgarwalNo ratings yet

- HMB Latest Stream ReporterDocument20 pagesHMB Latest Stream ReporterConnor SailorNo ratings yet

- Overview of PV EliteDocument35 pagesOverview of PV EliteVishaka ThekkedathNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- MetoxidoDocument8 pagesMetoxidocessavelinoNo ratings yet

- Page 1 of 5 Compressor Blocked Discharge - Chemical EngineersDocument5 pagesPage 1 of 5 Compressor Blocked Discharge - Chemical EngineersKarthikeyan SivaNo ratings yet

- K PR 00 DSC 001 1 Process DescriptionDocument14 pagesK PR 00 DSC 001 1 Process DescriptionvahidforoughiNo ratings yet

- B31.8 Schedule Calculator v1.0Document5 pagesB31.8 Schedule Calculator v1.0Saqib LaeeqNo ratings yet

- Training CaseDocument15 pagesTraining CaseThái Xuân QuangNo ratings yet

- NKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)Document15 pagesNKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)ahmad santoso100% (1)

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADocument4 pagesMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanNo ratings yet

- 1231 de 00 DC PCJ 001 01Document33 pages1231 de 00 DC PCJ 001 01Hamid MansouriNo ratings yet

- Gas Liquid Seperation by VesselsDocument2 pagesGas Liquid Seperation by VesselszapspazNo ratings yet

- Reviewed: by Nadiera at 11:45 Am, 5/17/22Document16 pagesReviewed: by Nadiera at 11:45 Am, 5/17/22carlos farinaNo ratings yet

- Specification For Tank To Tank Transfer Pump (Rev.0) - (P-1501)Document9 pagesSpecification For Tank To Tank Transfer Pump (Rev.0) - (P-1501)Panisa BanimaNo ratings yet

- AR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFDocument6 pagesAR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFYaakoubi FethiNo ratings yet

- 4 - 02. Section II - 4420003405Document137 pages4 - 02. Section II - 4420003405JonesNo ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- PVT Report - 140319 - Zone - 8 - May'17 Separator SampleDocument28 pagesPVT Report - 140319 - Zone - 8 - May'17 Separator SampleIBIKUNLENo ratings yet

- 720-C-001 (Vent Wash Column)Document4 pages720-C-001 (Vent Wash Column)idilfitriNo ratings yet

-  Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)Document16 pages Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)KalpeshJadhavNo ratings yet

- Process Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Document15 pagesProcess Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Silas OnyekweNo ratings yet

- Volume 3-The Origins of ProtreatDocument2 pagesVolume 3-The Origins of ProtreatIbhar Santos MumentheyNo ratings yet

- Pipe Distributor Sizing Calculations - 07-08-2013Document26 pagesPipe Distributor Sizing Calculations - 07-08-2013pelotoNo ratings yet

- Hook Ups PDFDocument8 pagesHook Ups PDFAnonymous d7Jde8No ratings yet

- RTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVDocument15 pagesRTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVroronoa_zorro11No ratings yet

- TBA - AdsorbentDocument4 pagesTBA - AdsorbentTifano KhristiyantoNo ratings yet

- Emergency ShutingdownDocument11 pagesEmergency ShutingdownOsama OmayerNo ratings yet

- Water Hammer With Column SeparationDocument88 pagesWater Hammer With Column SeparationVSMS8678No ratings yet

- LNG UNIT-1 2018-19 PDFDocument13 pagesLNG UNIT-1 2018-19 PDFAnil KumarNo ratings yet

- HYSYS PROII Converter - V1.5 PDFDocument28 pagesHYSYS PROII Converter - V1.5 PDFzubair1951No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- BTÑ HTDS - H 10Document1 pageBTÑ HTDS - H 10Juan Pablo Sanchez MelgarejoNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- Low Cost, High Efficiency, Ultra Low Nox Arice Solution Using HCCI Combustion by Flowers Daniel LDocument95 pagesLow Cost, High Efficiency, Ultra Low Nox Arice Solution Using HCCI Combustion by Flowers Daniel Lm.shehreyar.khanNo ratings yet

- Manufacturing Industry PPT Template 0001Document5 pagesManufacturing Industry PPT Template 0001m.shehreyar.khanNo ratings yet

- Training Material For Water Treatment SystemDocument55 pagesTraining Material For Water Treatment Systemm.shehreyar.khanNo ratings yet

- SOP For Setting Up Email SignatureDocument6 pagesSOP For Setting Up Email Signaturem.shehreyar.khanNo ratings yet

- Harmonised Application Form Application For Schengen VisaDocument4 pagesHarmonised Application Form Application For Schengen Visam.shehreyar.khanNo ratings yet

- Science of ExerciseDocument1 pageScience of Exercisem.shehreyar.khan0% (1)

- Production Allocation UtilityDocument6 pagesProduction Allocation Utilitym.shehreyar.khanNo ratings yet

- Calculator of CPD PointsDocument2 pagesCalculator of CPD Pointsm.shehreyar.khanNo ratings yet

- Training of The Refrigeration PackageDocument27 pagesTraining of The Refrigeration Packagem.shehreyar.khanNo ratings yet

- Control System To Self Regulate Adsorption & Desorption Processes For Solid Desiccant Dehydration UnitDocument2 pagesControl System To Self Regulate Adsorption & Desorption Processes For Solid Desiccant Dehydration Unitm.shehreyar.khanNo ratings yet

- Blowdown WorkshopDocument7 pagesBlowdown Workshopm.shehreyar.khan100% (1)

- Gas GatheringDocument17 pagesGas Gatheringm.shehreyar.khanNo ratings yet

- Calculator of CPD PointsDocument2 pagesCalculator of CPD Pointsm.shehreyar.khanNo ratings yet

- NGP 001 PCS 15.03 2001-15-00 Specification For Fired HeaterDocument22 pagesNGP 001 PCS 15.03 2001-15-00 Specification For Fired Heaterm.shehreyar.khanNo ratings yet

- NGP-001-PCS-15.03-0001!00!00 - Specification For Gas Engine Driven Reciprocating CompressorDocument39 pagesNGP-001-PCS-15.03-0001!00!00 - Specification For Gas Engine Driven Reciprocating Compressorm.shehreyar.khanNo ratings yet

- NGP 001 PCS 15.03 0002 04B - 00 - Specification For Turbo Expander RecompressorDocument31 pagesNGP 001 PCS 15.03 0002 04B - 00 - Specification For Turbo Expander Recompressorm.shehreyar.khanNo ratings yet

- Pipesim - 2014 FuandamentalsDocument238 pagesPipesim - 2014 Fuandamentalsm.shehreyar.khanNo ratings yet

- NGP 006 PCS 15.03 0012-10-00 Specification For Loading ArmsDocument9 pagesNGP 006 PCS 15.03 0012-10-00 Specification For Loading Armsm.shehreyar.khanNo ratings yet

- Akmal Hussain ShahDocument2 pagesAkmal Hussain Shahm.shehreyar.khanNo ratings yet

- Evolution of The Idea of Human RightsDocument71 pagesEvolution of The Idea of Human Rightsm.shehreyar.khanNo ratings yet

- Distillation ReportDocument5 pagesDistillation Reportweidatan100% (2)

- Transpiration Mechanism of Capillary Transport in The Xylem of PlantsDocument6 pagesTranspiration Mechanism of Capillary Transport in The Xylem of PlantsIrfanNo ratings yet

- Indian Standards IS 12268-4 (1989) - Automatic Steam Traps For Marine Use - Part 4 Performance TestDocument10 pagesIndian Standards IS 12268-4 (1989) - Automatic Steam Traps For Marine Use - Part 4 Performance TestRamesh-NairNo ratings yet

- Singhal Et AlDocument8 pagesSinghal Et AlThePriusNo ratings yet

- P4055 Kavlico Pressure Data Sheets (EU)Document6 pagesP4055 Kavlico Pressure Data Sheets (EU)steve@air-innovations.co.zaNo ratings yet

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- Petrobras SDA Paper PDFDocument5 pagesPetrobras SDA Paper PDFProcess EngineerNo ratings yet

- Anchored Sheet-Pile WallsDocument68 pagesAnchored Sheet-Pile WallsJose MartinezNo ratings yet

- Korba - BAH Online Temp MonitoringDocument7 pagesKorba - BAH Online Temp Monitoringrama jenaNo ratings yet

- NDT Pressure TestingDocument23 pagesNDT Pressure TestingRamu Nallathambi100% (2)

- Geological Society of London Special PublicationsDocument242 pagesGeological Society of London Special PublicationsAhmed HLNo ratings yet

- CE6451-Fluid Mechanics and MachineryDocument13 pagesCE6451-Fluid Mechanics and MachineryGracia StephenNo ratings yet

- Flow Equations & Flow Coefficient (CV and KV) CalculationDocument4 pagesFlow Equations & Flow Coefficient (CV and KV) CalculationMELVIN MAGBANUANo ratings yet

- Design of LPG Refigeration System: 1. Copper TubesDocument20 pagesDesign of LPG Refigeration System: 1. Copper TubesJeevan Landge PatilNo ratings yet

- Elasticity Ee PDFDocument13 pagesElasticity Ee PDFravi0% (1)

- BernoulliDocument2 pagesBernoullilllllNo ratings yet

- 02-FusionCol8000-C210H-MEX 5Document2 pages02-FusionCol8000-C210H-MEX 5samiramixNo ratings yet

- Steady Flow Energy EquationDocument16 pagesSteady Flow Energy Equationcataice100% (1)

- Water Mist CalculationDocument26 pagesWater Mist CalculationManjunath HrmNo ratings yet

- Especificaciones T555 VermeerDocument2 pagesEspecificaciones T555 VermeerRodney VegaNo ratings yet

- G10 - Solids and FluidsDocument46 pagesG10 - Solids and FluidsOliver VillanuevaNo ratings yet

- Hydraulics MCQDocument228 pagesHydraulics MCQShrajit GuptaNo ratings yet

- WISE Pressure Gauge P710, P720, P730Document8 pagesWISE Pressure Gauge P710, P720, P730KayesCjNo ratings yet

- ASME B31.4a PDFDocument69 pagesASME B31.4a PDFhussein100% (1)

- 71. Vehicle barriers for car parks.: δ δ δ mv kN mv kgfDocument3 pages71. Vehicle barriers for car parks.: δ δ δ mv kN mv kgfEiyra NadiaNo ratings yet

- Chem 4922Document2 pagesChem 4922sieausNo ratings yet

- MN2500 Agfo 5716Document8 pagesMN2500 Agfo 5716Wesley MotaNo ratings yet

- Introduction To Cmgs TutorialDocument95 pagesIntroduction To Cmgs TutorialJorge A. Vázquez OlveraNo ratings yet