0% found this document useful (0 votes)

601 views2 pages8D - Format

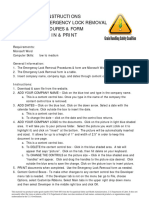

This 8D report summarizes a quality issue involving a part delivered to a customer. The team identified the root causes as a design issue and a process control issue. The permanent corrective actions chosen were to update the design drawings and control plan to prevent future issues. These actions were implemented by target dates to address the problem at its occurrence and escape points.

Uploaded by

Machining Gokul FerrocastCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

601 views2 pages8D - Format

This 8D report summarizes a quality issue involving a part delivered to a customer. The team identified the root causes as a design issue and a process control issue. The permanent corrective actions chosen were to update the design drawings and control plan to prevent future issues. These actions were implemented by target dates to address the problem at its occurrence and escape points.

Uploaded by

Machining Gokul FerrocastCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd