Professional Documents

Culture Documents

Set-Up Approval Report-Bar Pillion

Uploaded by

swaran autoqaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Set-Up Approval Report-Bar Pillion

Uploaded by

swaran autoqaCopyright:

Available Formats

SHEET:-

SWARAN AUTO SYSTEM

( A UNIT OF SWARAN ENTERPRISES)

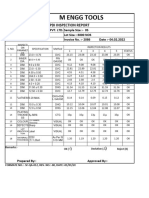

FIRST PCS INSPECTION REPORT(SET-UP APPROVAL REPORT) Doc No. SAS/QA/F-10

Part Name Bar Pillion R/L Step M/c Name Rev.No/Date 0.00/1.4.2018

Part Drg .No. 50715/50716-KCC-9000 M/c No. Insp.Date

Drg.Rev.No Tool/Die Re-Insp.Date

ACTUAL ∆-Temp.Dev.

MFG. MODE OF

S.NO DESCRIPTION SPECIFIED DIMENSION *-Need Rect.

PROCESS INSPECTION 1 2 3 4 5 o-OK

1 Length DVC 112.50~113.50

Tapper

Cutting Excess burr, deformation in

2 Appearance Visually

tube not allowed.

3 Dimension DVC 116.20~117.70

4 Tapper HG *0.20(max)

Angle

5 Angle AP *8°±1°30'

Milling

6 Angle AP *29°±1°30'

no burntmark,tool mark etc

7 Appearance Visually

allowed

8 Dimension DVC/HG 3.50±0.50

Slot Cutting

9 Dimension DVC 12.60+0.10

10 De-burring Appearance Visually Burr should be remove properly

11 Hole Dia DVC/STD PIN *Ø6.10+0.20≡(6.10~6.30)

12 Tapper Visually 0.20(max)

13 Drilling Dimension HG *12.20±0.20

14 Dimension HG *13.00~13.60

15 Dimension HG *7.00±0.50

Chamfering no burr,deepcut,part should be

16 & Gauging Appearance Visually

OK by gauge

Washer fixing no gap between tube &

17 Appearance Visually

washer ,no washer bend etc.

no gap between tube &

18 Riveting Appearance Visually washer,no washer bend/

loose/improper riveting etc.

19 FI As per WI As per WI Should be OK as per WI

DIMENSIONAL APPEARANCE MATERIAL FITMENT

Remarks:-

DECISION

OK

NG

INSPECTED BY VERIFIED BY APPROVED BY

You might also like

- Set-Up Approval Report-Bar Comp PillionDocument1 pageSet-Up Approval Report-Bar Comp Pillionswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator LowerDocument2 pagesSet-Up Approval Report-Separator Lowerswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator MiddleDocument2 pagesSet-Up Approval Report-Separator Middleswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator Fuel TankDocument2 pagesSet-Up Approval Report-Separator Fuel Tankswaran autoqaNo ratings yet

- Inprocess Check Sheet - Bar Comp.Document1 pageInprocess Check Sheet - Bar Comp.swaran autoqaNo ratings yet

- Set-Up Approval Report-ABZA-XDocument1 pageSet-Up Approval Report-ABZA-Xswaran autoqaNo ratings yet

- Set-Up Approval Report-XYZDocument1 pageSet-Up Approval Report-XYZswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator UpperDocument1 pageSet-Up Approval Report-Separator Upperswaran autoqaNo ratings yet

- Set-Up Approval Report-Brkt - HC CollectorDocument2 pagesSet-Up Approval Report-Brkt - HC Collectorswaran autoqaNo ratings yet

- 2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXDocument1 page2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXSonali AhirwarNo ratings yet

- Yhb Rear Piston Rod (M7a100280) Omega BrightDocument3 pagesYhb Rear Piston Rod (M7a100280) Omega BrightOBSC PerfectionNo ratings yet

- BanK Statement ConfideDocument8 pagesBanK Statement ConfideSanjeev PurriNo ratings yet

- CB0C050F0Document12 pagesCB0C050F0roshni mehraNo ratings yet

- CB1C006F0Document6 pagesCB1C006F0roshni mehraNo ratings yet

- Layout FormatDocument13 pagesLayout FormatBharatNo ratings yet

- YV4 FRONT Pioston Rod (M7A120026 OmegaDocument2 pagesYV4 FRONT Pioston Rod (M7A120026 OmegaOBSC PerfectionNo ratings yet

- Bearing LSS CoverDocument2 pagesBearing LSS CoverRagul0042No ratings yet

- Repport UT CS - 1Document22 pagesRepport UT CS - 1daemsalNo ratings yet

- Axle Push Lever - B - 97Document1 pageAxle Push Lever - B - 97Preetam KumarNo ratings yet

- Yv4 - Rear Piston Rod (M7a010204) OmegaDocument2 pagesYv4 - Rear Piston Rod (M7a010204) OmegaOBSC PerfectionNo ratings yet

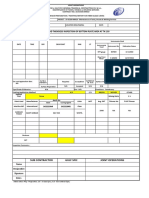

- Sample Inspection Report: SR - NO. DateDocument1 pageSample Inspection Report: SR - NO. DateBhuvanesh KumarNo ratings yet

- Ut-Pcp Sanha-P23-1072956-002-0623Document4 pagesUt-Pcp Sanha-P23-1072956-002-0623Anoop KavirajanNo ratings yet

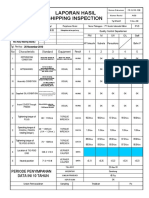

- Laporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukDocument4 pagesLaporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukBrata IvanNo ratings yet

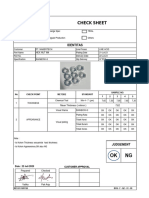

- Check Sheet Inspection: Pt. DffiDocument1 pageCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Operaction STD - ForgingDocument12 pagesOperaction STD - Forgingakaman614No ratings yet

- QAR-QD405-800 Rod As-Hoist CylinderDocument6 pagesQAR-QD405-800 Rod As-Hoist CylinderIrwanto ManafNo ratings yet

- Repport UT CS - 7Document1 pageRepport UT CS - 7daemsalNo ratings yet

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- Customer: AP-0020-105 Segment: Work Location:: Nesr G-Energy Work Order. No: Rig NoDocument2 pagesCustomer: AP-0020-105 Segment: Work Location:: Nesr G-Energy Work Order. No: Rig NooussamaNo ratings yet

- Elbow 3 s80 90d LR - OkDocument1 pageElbow 3 s80 90d LR - OkJovianto PrisilaNo ratings yet

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- 2316C79301 FirDocument1 page2316C79301 FirInder SabhrawalNo ratings yet

- QAR-QD#407-7 Hollow Printing RollsDocument2 pagesQAR-QD#407-7 Hollow Printing RollsIrwanto ManafNo ratings yet

- Measurement Data of 3210D704201300Document3 pagesMeasurement Data of 3210D704201300wawan darmawanNo ratings yet

- Elbow 2 S80 90D LR - OkDocument1 pageElbow 2 S80 90D LR - OkJovianto PrisilaNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Pdi Report: JN Engg Works DATE: 22/12/18Document56 pagesPdi Report: JN Engg Works DATE: 22/12/18Anil kumarNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 pageKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravNo ratings yet

- Dimensional Inspection Report - Rev.01.Document2 pagesDimensional Inspection Report - Rev.01.GARIMA CASTINGS, JAIPURNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- 22.07.23 Hex Nut M4Document1 page22.07.23 Hex Nut M4Heri IrawanNo ratings yet

- Certificado TACO ANCLAJE ZN 3.8Document1 pageCertificado TACO ANCLAJE ZN 3.8Juan Carlos Laurie FigueroaNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- SSC SA-156 HD 785-7 Retainer BrakeDocument4 pagesSSC SA-156 HD 785-7 Retainer BrakeEngineering ProductionNo ratings yet

- CB2C010F0Document7 pagesCB2C010F0roshni mehraNo ratings yet

- Elbow 8 STD s40 90d LR - OkDocument1 pageElbow 8 STD s40 90d LR - OkJovianto PrisilaNo ratings yet

- SACEP - RTCC - Delivery #0971558-12Document16 pagesSACEP - RTCC - Delivery #0971558-12Ryan condeNo ratings yet

- TK-103-FGL-32 Tissue Visual and Thickness InspectionDocument1 pageTK-103-FGL-32 Tissue Visual and Thickness InspectionjoseNo ratings yet

- Ind Mwide 002 82 Report PB 04Document4 pagesInd Mwide 002 82 Report PB 04Daryl HernandezNo ratings yet

- 2KVADocument20 pages2KVASandeep MauryaNo ratings yet

- Ethane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0137Document63 pagesEthane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0137sarangpuneNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Part Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDDocument5 pagesPart Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDArun .vNo ratings yet

- Yha Suv - Front Piston Rod (M7a020130) OmegaDocument3 pagesYha Suv - Front Piston Rod (M7a020130) OmegaOBSC PerfectionNo ratings yet

- REDUCER TEE 3x2 STD X S160 - OKDocument2 pagesREDUCER TEE 3x2 STD X S160 - OKJovianto PrisilaNo ratings yet

- Form Pengukuran GroundingDocument2 pagesForm Pengukuran GroundingghooestiepNo ratings yet

- Item No. 10Document1 pageItem No. 10QualityNo ratings yet

- Set-Up Approval Report-ABZA-XDocument1 pageSet-Up Approval Report-ABZA-Xswaran autoqaNo ratings yet

- Set-Up Approval Report-XYZDocument1 pageSet-Up Approval Report-XYZswaran autoqaNo ratings yet

- 5-s Zone MapDocument13 pages5-s Zone Mapswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator UpperDocument1 pageSet-Up Approval Report-Separator Upperswaran autoqaNo ratings yet

- Set-Up Approval Report-Brkt - HC CollectorDocument2 pagesSet-Up Approval Report-Brkt - HC Collectorswaran autoqaNo ratings yet

- Inprocess Check Sheet (CWH Assy.)Document1 pageInprocess Check Sheet (CWH Assy.)swaran autoqaNo ratings yet

- Inprocess Check Sheet (TVS Jupiter)Document1 pageInprocess Check Sheet (TVS Jupiter)swaran autoqaNo ratings yet

- Consuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs WeightDocument1 pageConsuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs Weightswaran autoqaNo ratings yet

- Change Request Form: Supplier Information Change Tracking Number InformationDocument3 pagesChange Request Form: Supplier Information Change Tracking Number Informationswaran autoqaNo ratings yet

- Inprocess Check Sheet (ACKA)Document1 pageInprocess Check Sheet (ACKA)swaran autoqaNo ratings yet

- Inprocess Check Sheet (AAFF)Document1 pageInprocess Check Sheet (AAFF)swaran autoqaNo ratings yet

- Supplier Change Request (SCR) : Approved PSWDocument3 pagesSupplier Change Request (SCR) : Approved PSWswaran autoqaNo ratings yet

- HM3H Vendors Environmental Compliance Tier-2Document1 pageHM3H Vendors Environmental Compliance Tier-2swaran autoqaNo ratings yet

- Consuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs WeightDocument1 pageConsuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs Weightswaran autoqaNo ratings yet

- HoReCa Re-Start For General and Food Safety CleaningDocument2 pagesHoReCa Re-Start For General and Food Safety CleaningDavidNo ratings yet

- bARC 454 Lecture NotesDocument5 pagesbARC 454 Lecture NotesOkafor VictorNo ratings yet

- Week 1: Lesson 1: Practice Personal Hygiene Protocols at All TimesDocument8 pagesWeek 1: Lesson 1: Practice Personal Hygiene Protocols at All TimesAbner Obniala Venus Jr.No ratings yet

- A1 SITHCCC014 Worksheets Ver October 2019Document9 pagesA1 SITHCCC014 Worksheets Ver October 2019Pitaram PanthiNo ratings yet

- Your Home Interiors Quotation.: WWW - Aantrik.inDocument21 pagesYour Home Interiors Quotation.: WWW - Aantrik.inhiteshNo ratings yet

- J. Santiago Integrated High School: Republic of The Philippines Department of Education Santa Maria DistrictDocument2 pagesJ. Santiago Integrated High School: Republic of The Philippines Department of Education Santa Maria DistrictMariel Lopez - MadrideoNo ratings yet

- Project Report On Electronic BikesDocument14 pagesProject Report On Electronic BikesJAMEL CHAKCHAKNo ratings yet

- Kitchen Design 350+ Modular Kitchen Design at Best Price in India (2023 Modular Kitchens Ideas)Document1 pageKitchen Design 350+ Modular Kitchen Design at Best Price in India (2023 Modular Kitchens Ideas)Mayank OhriNo ratings yet

- SITHKOP005 Coordinate Cooking OperationDocument7 pagesSITHKOP005 Coordinate Cooking Operationbijay rai100% (3)

- Test 8Document6 pagesTest 8Kiệt Đỗ TấnNo ratings yet

- Dyson Cyclone V10 Total Clean + (Iron) - User Manual (Original File Name - ''Dyson-stick-V10-Absolute-Vacuum-US-user-guide - PDF'')Document20 pagesDyson Cyclone V10 Total Clean + (Iron) - User Manual (Original File Name - ''Dyson-stick-V10-Absolute-Vacuum-US-user-guide - PDF'')TalNo ratings yet

- Ceiling Fan, Lighting, Pumpset, Transformer, RAC, Chiller & Solar Brand Contact Persons DetailsDocument1 pageCeiling Fan, Lighting, Pumpset, Transformer, RAC, Chiller & Solar Brand Contact Persons DetailsD2O Yash MathurNo ratings yet

- Temperature Control Trainer Flow Control TrainerDocument2 pagesTemperature Control Trainer Flow Control TrainerimmoNo ratings yet

- Comprehension Passage 13 LucyDocument5 pagesComprehension Passage 13 Lucysunny kentNo ratings yet

- Meat 0 Matic BookletDocument11 pagesMeat 0 Matic BookletAntonNo ratings yet

- Manual Programación Lavadora Girbau HS-6057Document87 pagesManual Programación Lavadora Girbau HS-6057rasdasd100% (1)

- T.l.e9 T10 Tools and Equipment in Preparing SandwichesDocument43 pagesT.l.e9 T10 Tools and Equipment in Preparing SandwichesReginald Jr CalderonNo ratings yet

- My House-Logissia Citra-MNJ 2B Malam-241219066Document1 pageMy House-Logissia Citra-MNJ 2B Malam-241219066LogisBilangNo ratings yet

- UNIT TEST 3 Cam 3Document3 pagesUNIT TEST 3 Cam 3Kim LiênNo ratings yet

- Fill inDocument3 pagesFill inSilvinaNo ratings yet

- Frigidaire Dishwasher ManualDocument16 pagesFrigidaire Dishwasher ManualMichael GordanNo ratings yet

- Haier Dishwasher Hdp18pa BKD45 DW-8888-04 Service Manual PDFDocument25 pagesHaier Dishwasher Hdp18pa BKD45 DW-8888-04 Service Manual PDFZeigtNo ratings yet

- For Guidance: Australasian HFG Standard Components Mor-Cs Mortuary - Cool StoreDocument2 pagesFor Guidance: Australasian HFG Standard Components Mor-Cs Mortuary - Cool StoreChristdel VivarNo ratings yet

- PJJ Mechanical FastenerDocument14 pagesPJJ Mechanical FastenerAdib RizqullohNo ratings yet

- Mindset For Ielts 1Document138 pagesMindset For Ielts 1saeed100% (1)

- Chicken Tortilla Casserole Recipe - Trisha Yearwood - Food NetworkDocument1 pageChicken Tortilla Casserole Recipe - Trisha Yearwood - Food NetworkIsabella Rachel Valdivia2No ratings yet

- Structural Steel Inspection ReportDocument2 pagesStructural Steel Inspection Reportsj_scribd84% (38)

- CPI Lucrarea 1 ModelDocument4 pagesCPI Lucrarea 1 ModelGabriel BodeaNo ratings yet

- English TOP CLASS LESSON NOTESDocument14 pagesEnglish TOP CLASS LESSON NOTESbarasa simonNo ratings yet

- Caterpillar Cat 323E LN Excavator (Prefix TDW) Service Repair Manual (TDW00001 and Up)Document27 pagesCaterpillar Cat 323E LN Excavator (Prefix TDW) Service Repair Manual (TDW00001 and Up)kfm8seuudu100% (1)