Professional Documents

Culture Documents

Set-Up Approval Report-Bar Comp Pillion

Uploaded by

swaran autoqaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Set-Up Approval Report-Bar Comp Pillion

Uploaded by

swaran autoqaCopyright:

Available Formats

SHEET:-

SWARAN AUTO SYSTEM

( A UNIT OF SWARAN ENTERPRISES)

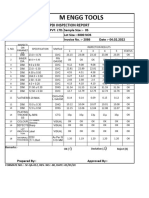

FIRST PCS INSPECTION REPORT(SET-UP APPROVAL REPORT) Doc No. SAS/QA/F-10

Part Name Bar Comp.Pillion Step M/c Name Rev.No/Date 0.00/1.4.2018

Part Drg .No. 50715-405-0000 M/c No. Insp.Date

Drg.Rev.No Tool/Die Re-Insp.Date

ACTUAL ∆-Temp.Dev.

MFG. MODE OF

S.NO DESCRIPTION SPECIFIED DIMENSION *-Need Rect.

PROCESS INSPECTION 1 2 3 4 5 o-OK

1 Length DVC *117.90~118.60

2 Angle DVC *8◦+1°≡(8°~9°)

Angle

3 Angle DVC *29°±1°30'≡(27.5°~30.5°)

Cutting

4 Tapper DVC *0.20(max)

Burr/ovality/angle profile out

5 Appearance Visually

not allowed

6 Hole Dia DVC/STD PIN *Ø6.10+0.20≡(6.10~6.30)

7 Drilling Tapper HG 0.20(max)

8 Dimension HG *12.07~12.47

Drilling

9 Dimension HG *13.40~13.80

10 Dimension HG *1.00±0.20

Hole positionout,shift/ ovality

11 Appearance Visually in hole etc not allowed.

excess cut,burr not

Chamfering

12 Appearance Visually allowed.Part should be

& Gauging

OK by gauge

Dimension DVC/HG 3.10+0.20≡(3.10~3.30)

13 Slot Cutting

Dimension DVC 12.50-0.10≡(12.40~12.50)

In-side no burr in tube ID/excess cut at

14 Appearance Visually

Deburring wall thickness etc.

Appearance Visually Burr not allowed

OD

15

Deburring Part should be OK by ring

Ring Gauging Gauge

gauge

Nogap between tube &

Washer washer,no washer bend,damage

16 Appearance Visually

Fixing etc.

17 Riveting Dimension HG *1.00±0.20≡(0.80~1.20)

18 FI As per WI As per WI Should be OK as per WI

DIMENSIONAL APPEARANCE MATERIAL FITMENT

Remarks:- DECISION

OK

NG

INSPECTED BY VERIFIED BY APPROVED BY

You might also like

- 5.1 Design Calculation of Vertical Pressure Vessel (MGF - ACF)Document2 pages5.1 Design Calculation of Vertical Pressure Vessel (MGF - ACF)shakib nazmus100% (2)

- Why Compressors Fail Part 4 - OverheatingDocument4 pagesWhy Compressors Fail Part 4 - OverheatingAlchemist7No ratings yet

- Upset Forging Die DesignDocument4 pagesUpset Forging Die DesignChinmay Das50% (2)

- Report On Helical Gear DesignDocument3 pagesReport On Helical Gear Designdanish100% (1)

- Boiler Survey ProcedureDocument5 pagesBoiler Survey ProcedureMeghali Borle100% (1)

- Set-Up Approval Report-Bar PillionDocument1 pageSet-Up Approval Report-Bar Pillionswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator LowerDocument2 pagesSet-Up Approval Report-Separator Lowerswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator MiddleDocument2 pagesSet-Up Approval Report-Separator Middleswaran autoqaNo ratings yet

- Inprocess Check Sheet - Bar Comp.Document1 pageInprocess Check Sheet - Bar Comp.swaran autoqaNo ratings yet

- Set-Up Approval Report-ABZA-XDocument1 pageSet-Up Approval Report-ABZA-Xswaran autoqaNo ratings yet

- Set-Up Approval Report-XYZDocument1 pageSet-Up Approval Report-XYZswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator UpperDocument1 pageSet-Up Approval Report-Separator Upperswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator Fuel TankDocument2 pagesSet-Up Approval Report-Separator Fuel Tankswaran autoqaNo ratings yet

- 2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXDocument1 page2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXSonali AhirwarNo ratings yet

- CB1C006F0Document6 pagesCB1C006F0roshni mehraNo ratings yet

- CB0C050F0Document12 pagesCB0C050F0roshni mehraNo ratings yet

- Set-Up Approval Report-Brkt - HC CollectorDocument2 pagesSet-Up Approval Report-Brkt - HC Collectorswaran autoqaNo ratings yet

- Layout FormatDocument13 pagesLayout FormatBharatNo ratings yet

- BanK Statement ConfideDocument8 pagesBanK Statement ConfideSanjeev PurriNo ratings yet

- CB2C010F0Document7 pagesCB2C010F0roshni mehraNo ratings yet

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- Layout K1SG-RHDocument11 pagesLayout K1SG-RHNPD TEAM HosurNo ratings yet

- Sample Inspection Report: SR - NO. DateDocument1 pageSample Inspection Report: SR - NO. DateBhuvanesh KumarNo ratings yet

- Axle Push Lever - B - 97Document1 pageAxle Push Lever - B - 97Preetam KumarNo ratings yet

- 2316C79301 FirDocument1 page2316C79301 FirInder SabhrawalNo ratings yet

- Yhb Rear Piston Rod (M7a100280) Omega BrightDocument3 pagesYhb Rear Piston Rod (M7a100280) Omega BrightOBSC PerfectionNo ratings yet

- Pdi Report: JN Engg Works DATE: 22/12/18Document56 pagesPdi Report: JN Engg Works DATE: 22/12/18Anil kumarNo ratings yet

- QAR-QD#407-7 Hollow Printing RollsDocument2 pagesQAR-QD#407-7 Hollow Printing RollsIrwanto ManafNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Machining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingDocument3 pagesMachining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingEngineering ProductionNo ratings yet

- Bearing LSS CoverDocument2 pagesBearing LSS CoverRagul0042No ratings yet

- 2KVADocument20 pages2KVASandeep MauryaNo ratings yet

- Yv4 - Rear Piston Rod (M7a010204) OmegaDocument2 pagesYv4 - Rear Piston Rod (M7a010204) OmegaOBSC PerfectionNo ratings yet

- QAR-QD405-800 Rod As-Hoist CylinderDocument6 pagesQAR-QD405-800 Rod As-Hoist CylinderIrwanto ManafNo ratings yet

- FJP14213Document5 pagesFJP14213Arun .vNo ratings yet

- Part Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDDocument5 pagesPart Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDArun .vNo ratings yet

- Pioneer Nuts and Bolts (P) Ltd. Final Inspection Report: 13-B, Friends Industrial Estate, Focal Point, LudhianaDocument2 pagesPioneer Nuts and Bolts (P) Ltd. Final Inspection Report: 13-B, Friends Industrial Estate, Focal Point, LudhianaTUff LabNo ratings yet

- YV4 FRONT Pioston Rod (M7A120026 OmegaDocument2 pagesYV4 FRONT Pioston Rod (M7A120026 OmegaOBSC PerfectionNo ratings yet

- Measurement Data of 3210D704201300Document3 pagesMeasurement Data of 3210D704201300wawan darmawanNo ratings yet

- Sidhi Alcast: Product AuditDocument4 pagesSidhi Alcast: Product AuditRohit BiriwalNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- Operaction STD - ForgingDocument12 pagesOperaction STD - Forgingakaman614No ratings yet

- 441-9750 DoowonDocument2 pages441-9750 DoowonKetlin FraitagNo ratings yet

- Layout Inspection Report: M/s Pricol LTDDocument35 pagesLayout Inspection Report: M/s Pricol LTDPrakash kumarTripathiNo ratings yet

- FJP14313Document5 pagesFJP14313Arun .vNo ratings yet

- RIT-Wheel Front Drum Layout ReportDocument11 pagesRIT-Wheel Front Drum Layout Reportrama.chandranNo ratings yet

- 2324-301123108 Rubber Cowl 77267-KTR-9000Document1 page2324-301123108 Rubber Cowl 77267-KTR-9000Sonali AhirwarNo ratings yet

- Elbow 2 S80 90D LR - OkDocument1 pageElbow 2 S80 90D LR - OkJovianto PrisilaNo ratings yet

- FV549913Document6 pagesFV549913Arun .vNo ratings yet

- CA0C10000Document8 pagesCA0C10000roshni mehraNo ratings yet

- BFNS Cheek Sheets JindalDocument13 pagesBFNS Cheek Sheets JindalShekher NikhilNo ratings yet

- Customer: AP-0020-105 Segment: Work Location:: Nesr G-Energy Work Order. No: Rig NoDocument2 pagesCustomer: AP-0020-105 Segment: Work Location:: Nesr G-Energy Work Order. No: Rig NooussamaNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration DataRene VCNo ratings yet

- Elbow 3 s80 90d LR - OkDocument1 pageElbow 3 s80 90d LR - OkJovianto PrisilaNo ratings yet

- Item No. 10Document1 pageItem No. 10QualityNo ratings yet

- SSC SA-156 HD 785-7 Retainer BrakeDocument4 pagesSSC SA-156 HD 785-7 Retainer BrakeEngineering ProductionNo ratings yet

- MMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateDocument1 pageMMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateshrikantNo ratings yet

- Ind Mwide 002 82 Report PB 04Document4 pagesInd Mwide 002 82 Report PB 04Daryl HernandezNo ratings yet

- Ut-Pcp Sanha-P23-1072956-002-0623Document4 pagesUt-Pcp Sanha-P23-1072956-002-0623Anoop KavirajanNo ratings yet

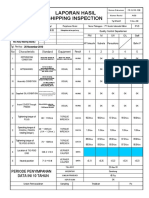

- Laporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukDocument4 pagesLaporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukBrata IvanNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument1 pageCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- SKH Process Report1Document8 pagesSKH Process Report1Mohan KumarNo ratings yet

- FT-SSBR-BLP-QAP-015-QC-003 (QAR-QD407-1 Hydraulic Cylinder Rod-Yoke)Document2 pagesFT-SSBR-BLP-QAP-015-QC-003 (QAR-QD407-1 Hydraulic Cylinder Rod-Yoke)Irwanto ManafNo ratings yet

- A Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelDocument24 pagesA Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelSanjayNo ratings yet

- 5-s Zone MapDocument13 pages5-s Zone Mapswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator UpperDocument1 pageSet-Up Approval Report-Separator Upperswaran autoqaNo ratings yet

- Set-Up Approval Report-XYZDocument1 pageSet-Up Approval Report-XYZswaran autoqaNo ratings yet

- Set-Up Approval Report-Brkt - HC CollectorDocument2 pagesSet-Up Approval Report-Brkt - HC Collectorswaran autoqaNo ratings yet

- Set-Up Approval Report-Separator Fuel TankDocument2 pagesSet-Up Approval Report-Separator Fuel Tankswaran autoqaNo ratings yet

- HM3H Vendors Environmental Compliance Tier-2Document1 pageHM3H Vendors Environmental Compliance Tier-2swaran autoqaNo ratings yet

- Inprocess Check Sheet (AAFF)Document1 pageInprocess Check Sheet (AAFF)swaran autoqaNo ratings yet

- Inprocess Check Sheet (TVS Jupiter)Document1 pageInprocess Check Sheet (TVS Jupiter)swaran autoqaNo ratings yet

- Inprocess Check Sheet (CWH Assy.)Document1 pageInprocess Check Sheet (CWH Assy.)swaran autoqaNo ratings yet

- Supplier Change Request (SCR) : Approved PSWDocument3 pagesSupplier Change Request (SCR) : Approved PSWswaran autoqaNo ratings yet

- Inprocess Check Sheet (ACKA)Document1 pageInprocess Check Sheet (ACKA)swaran autoqaNo ratings yet

- Change Request Form: Supplier Information Change Tracking Number InformationDocument3 pagesChange Request Form: Supplier Information Change Tracking Number Informationswaran autoqaNo ratings yet

- Consuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs WeightDocument1 pageConsuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs Weightswaran autoqaNo ratings yet

- Consuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs WeightDocument1 pageConsuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs Weightswaran autoqaNo ratings yet

- Exercise 2Document4 pagesExercise 2Ahmed EidNo ratings yet

- Hydraulic Circuitry (Work Cylinders) (Monoblock Main Valve) - MT55Document3 pagesHydraulic Circuitry (Work Cylinders) (Monoblock Main Valve) - MT55Iliyan VasilevNo ratings yet

- Quiz and Answer KeyDocument6 pagesQuiz and Answer KeyEnzoNo ratings yet

- Unit 2 Questions With AnswerDocument3 pagesUnit 2 Questions With Answeranish100% (1)

- EE 01728 1 - 44 R006 Device Summary of STGDocument45 pagesEE 01728 1 - 44 R006 Device Summary of STGVinoth Kumar100% (1)

- Quiz No 1 - Set D PDFDocument2 pagesQuiz No 1 - Set D PDFMayoune Nasinopa GalvezNo ratings yet

- Hardinge HLV H ManualDocument35 pagesHardinge HLV H ManualSergio CarvalhoNo ratings yet

- Duq1 184e PDFDocument5 pagesDuq1 184e PDFRajiv RanjanNo ratings yet

- Unit 3Document26 pagesUnit 3VENKATESHNo ratings yet

- Transmission Hydraulic Control PDFDocument10 pagesTransmission Hydraulic Control PDFSONNo ratings yet

- Upgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLDocument4 pagesUpgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLKushtrim MalaNo ratings yet

- KG 1,100,000 LB 290 M Ton 320 U.S. Ton 2014 KW 2,700 HPDocument4 pagesKG 1,100,000 LB 290 M Ton 320 U.S. Ton 2014 KW 2,700 HPTiago RodriguesNo ratings yet

- Manuals 67c Series Instrument Supply Regulators Instruction Manual Fisher en en 6089024 PDFDocument12 pagesManuals 67c Series Instrument Supply Regulators Instruction Manual Fisher en en 6089024 PDFSebastia Ossa ArteagaNo ratings yet

- CatalogoDocument44 pagesCatalogoMauricio GarcíaNo ratings yet

- Helical3D User's Manual: Advanced Numerical SolutionsDocument192 pagesHelical3D User's Manual: Advanced Numerical Solutionscmm5477No ratings yet

- Final Inspection Release NoteDocument2 pagesFinal Inspection Release NoteMark ThrelfallNo ratings yet

- 2Document9 pages2stathiss11No ratings yet

- AssignmentDocument2 pagesAssignmentUtkarsh ShrivatavaNo ratings yet

- DIN 103 Double ThreadDocument2 pagesDIN 103 Double ThreadDule JovanovicNo ratings yet

- Kurva-S - Ccds - r.2Document1 pageKurva-S - Ccds - r.2yusak adi setiawanNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Document15 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Mohamed Atef100% (1)

- E 303 - 93 R98 - Rtmwmy05m1i5oa - PDFDocument5 pagesE 303 - 93 R98 - Rtmwmy05m1i5oa - PDFNguyễn Văn MinhNo ratings yet

- Field Installation Guide-2014Document34 pagesField Installation Guide-2014vasanthan_sekar_1100% (1)

- Kundendokumentation enDocument309 pagesKundendokumentation enHarri Mündel100% (1)

- Char-Lynn 10000 Series Repair ManualDocument12 pagesChar-Lynn 10000 Series Repair Manualmillers roblesNo ratings yet