Professional Documents

Culture Documents

CA0C10000

Uploaded by

roshni mehra0 ratings0% found this document useful (0 votes)

1 views8 pagesCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views8 pagesCA0C10000

Uploaded by

roshni mehraCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 8

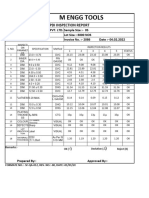

MET M ENGG TOOLS

PDI INSPECTION REPORT

Customer Name : HI-LEX INDIA PVT. LTD. Sample Size : 05 T.C No.

Part Name : UPPER BRACKET ASSY L Lot Size :- 1000 NOS

Part No: CA0C10000 Invoice No. : 2085 Date :04.02.2022

S. INSPECTION INSPECTION RESULTS

SPECIFICATION Method

NO. PARAMETER 1 2 3 4 5 STATUS

Height Gauge /

1 DIM 6.0(±0.10)

Receiving Gauge OK OK OK OK OK OK

Height Gauge /

2 DIM 8.0(±0.10)

Receiving Gauge OK OK OK OK OK OK

vernier / Receiving

3 DIM 55.0(±0.30)

Gauge OK OK OK OK OK OK

4 Inner Dia Ø6.20(+0.05/-0.15) Pin GAUGE OK OK OK OK OK OK

5 True Position 1.40 A B C Receiving Gauge OK OK OK OK OK OK

6 Thread 2XM6X1.0 Thead Plug Gauge OK OK OK OK OK OK

7 Perpendicularty 0.25 A Receiving Gauge OK OK OK OK OK OK

8 True Position 1.0 A B Receiving Gauge OK OK OK OK OK OK

9 Perpendicularty 0.25 A Receiving Gauge OK OK OK OK OK OK

10 DIM 5.0(±0.50) vernier 5.25 5.13 5.19 5.17 5.21 OK

11 DIM 0.40(+0.10/-0) Height Gauge 0.47 0.49 0.46 0.47 0.46 OK

12 Identification Mark L Visual OK OK OK OK OK OK

13 Dim 9.20(±0.50) Height Gauge 9.37 9.28 9.24 9.35 9.28 OK

14 Dimple Height 4X0.60(±0.10) Height Gauge 0.66 0.68 0.64 0.65 0.69 OK

15 Dimple Outer Dia 4XØ3.0(+0.30/-0) vernier 3.15 3.17 3.19 3.17 3.15 OK

16 DIM 6.0(±0.30) Height Gauge 5.92 6.02 5.98 5.97 6.05 OK

Height Gauge +

17 DIM 3.0(+0.20/-0) Vernier 3.14 3.14 3.15 3.12 3.16 OK

18 DIM 10.0(±0.50) vernier 10.12 10.15 10.14 10.1 10.15 OK

Height Gauge + Puppy

19 Flatness 0.20 Max

DialGauge 0.16 0.18 0.15 0.16 0.14 OK

20 DIM 8.0(+0.20/-0) vernier 8.15 8.15 8.14 8.16 8.16 OK

Height Gauge /

21 DIM 12.50(±0.20)

Receiving Gauge OK OK OK OK OK OK

3.0(+0.10/-0) X 3.09 3.08 3.06 3.08 3.07

22 DIM (Slot) 4.0(±0.30) vernier 4.14 4.11 4.16 4.08 4.11 OK

23 INNER DIA Ø3.0 (+0.10) PIN GAUGE OK OK OK OK OK OK

SHEAR STRENGTH OF

24 WELD NUT

1.96 KN MINI. T.T.M. 2.06 2.14 2.10 2.15 2.10 OK

NO BUMP ON

25 AFTER WELDING

SURFACE A

VISUAL OK OK OK OK OK OK

TIGHTENING 12.70 NM MINI. IN 3 M6 FLANGE BOLT +

26 TORQUE TIMES TORQUE WRENCH 13.1 13.05 13.18 13.08 13.04 OK

PLATING THICKNESS

27 PLATING THICKNESS 8μ MINI

TESTER 14μ 10μ 11μ 12μ 14μ OK

28 COLOUR TRI-VALENT CHROME VISUAL OK OK OK OK OK OK

29 DEFECTS NO BURR, RUST ETC. VISUAL OK OK OO OK OK OK

30 LOT IDENTIFICATION LABEL VISUAL OK OK OK OK OK OK

MATERIAL/ AS PER IS:513 2008

31 THICKNESS

CRC -D/ t-1.60 (± 0.11) STANDERD/VERNIER 1.59 1.59 1.59 1.58 1.59 OK

32 RM Width 97.0 ± 0.50 vernier 97.29 97.19 97.31 97.11 97.15 OK

Remarks:- OK (√) Deviation (∆) Reject (X)

Prepared By:- Approved By:-

FORMATE NO.:-SF-QA-012, REV. NO.:-00, DATE:-01/01/2021

M. ENGINEERING TOOLS

PDI INSPECTION REPORT

Customer:- HI-LEX INDIA PVT. LTD. Sample Size:- 05 Nos

Part Name:- UPPER BRACKET ASSY. 6 Lot Size:- 1000 Nos

Part No.:- CA0C010000 Invoice No.:- 2233 Date:- 16.02.2022

INPSCTION INSPECTION RESULTS

S. NO. SPECIFICATION Method

PARAMETER 1 2 3 4 5 STATUS

1 DIM 6.0(±0.10) DHG/RCG OK OK OK OK OK √

2 DIM 8.0(±0.10) DHG/RCG OK OK OK OK OK √

3 DIM 55.0(±0.30) DVC/RCG OK OK OK OK OK √

4 Inner Dia Ø6.20(+0.05/-0.15) PG OK OK OK OK OK √

5 True Position 1.40 A B C RCG OK OK OK OK OK √

6 Thread 2XM6X1.0 T.PG OK OK OK OK OK √

Perpendiculart

7 0.25 A RCG OK OK OK OK OK √

y

8 True Position 1.0 A B RCG OK OK OK OK OK √

Perpendiculart

9 0.25 A RCG OK OK OK OK OK √

y

10 DIM 5.0(±0.50) DVC 5.25 5.13 5.19 5.17 5.21 √

11 DIM 0.40(+0.10/-0) DHG 0.47 0.49 0.46 0.47 0.46 √

Identification

12 L Visual OK OK OK OK OK √

Mark

13 Dim 9.20(±0.50) DHG 9.37 9.28 9.24 9.35 9.28 √

14 Dimple Height 4X0.60(±0.10) DHG 0.66 0.68 0.64 0.65 0.69 √

Dimple Outer

15 4XØ3.0(+0.30/-0) vernier 3.15 3.17 3.19 3.17 3.15 √

Dia

16 DIM 6.0(±0.30) DHG 5.92 6.02 5.98 5.97 6.05 √

17 DIM 3.0(+0.20/-0) DHG/DVC 3.14 3.14 3.15 3.12 3.16 √

18 DIM 10.0(±0.50) DVC 10.12 10.15 10.14 10.1 10.15 √

19 Flatness 0.20 Max DHG/DVC 0.16 0.18 0.15 0.16 0.14 √

20 DIM 8.0(+0.20/-0) DVC 8.15 8.15 8.14 8.16 8.16 √

21 DIM 12.50(±0.20) DHG/DVC OK OK OK OK OK √

3.0(+0.10/-0) X 3.09 3.08 3.06 3.08 3.07

22 DIM (Slot) DVC 4.14 4.11 4.16 4.08 4.11 √

4.0(±0.30)

23 INNER DIA Ø3.0 (+0.10) PG OK OK OK OK OK √

SHEAR

24 STRENGTH OF 1.96 KN MINI. T.T.M. 2.06 2.14 2.10 2.15 2.10 √

WELD NUT

AFTER NO BUMP ON

25 VISUAL OK OK OK OK OK √

WELDING SURFACE A

M6 FLANGE

TIGHTENING 12.70 NM MINI. IN 3 BOLT +

26 13.1 13.05 13.18 13.08 13.04 √

TORQUE TIMES TORQUE

WRENCH

PLATING

PLATING

27 8μ MINI THICKNESS 14μ 10μ 11μ 12μ 14μ √

THICKNESS TESTER

28 COLOUR TRI-VALENT CHROME VISUAL OK OK OK OK OK √

29 DEFECTS NO BURR, RUST ETC. VISUAL OK OK OO OK OK √

LOT

30 IDENTIFICATIO LABEL VISUAL OK OK OK OK OK √

N AS PER

MATERIAL/ IS:513 2008

31

THICKNESS CRC -D/ t-1.60 (± 0.11) STANDERD

1.59 1.59 1.59 1.58 1.59 √

/VERNIER

32 RM Width 97.0 ± 0.50 vernier 97.29 97.19 97.31 97.11 97.15 √

Remarks:- OK (√) Deviation (∆) Reject (X)

PREPARED BY:- APPROVED BY:-

Format No. : SF-QA-012, Rev. No. 00, Date: 01.01.2021

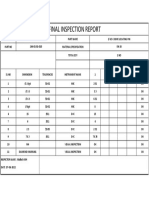

M. ENGINEERING TOOLS

PDI INSPECTION REPORT

Customer:- HI-LEX INDIA PVT. LTD. Sample Size:- 05 Nos

Part Name:- UPPER BRACKET ASSY. 6 Lot Size:- 1000 Nos

Part No.:- CA0C010000 Invoice No.:- 2311 Date:- 22.02.2022

INPSCTION INSPECTION RESULTS

S. NO. SPECIFICATION Method

PARAMETER 1 2 3 4 5 STATUS

1 DIM 6.0(±0.10) DHG/RCG OK OK OK OK OK √

2 DIM 8.0(±0.10) DHG/RCG OK OK OK OK OK √

3 DIM 55.0(±0.30) DVC/RCG OK OK OK OK OK √

4 Inner Dia Ø6.20(+0.05/-0.15) PG OK OK OK OK OK √

5 True Position 1.40 A B C RCG OK OK OK OK OK √

6 Thread 2XM6X1.0 T.PG OK OK OK OK OK √

Perpendiculart

7 0.25 A RCG OK OK OK OK OK √

y

8 True Position 1.0 A B RCG OK OK OK OK OK √

Perpendiculart

9 0.25 A RCG OK OK OK OK OK √

y

10 DIM 5.0(±0.50) DVC 5.25 5.13 5.19 5.17 5.21 √

11 DIM 0.40(+0.10/-0) DHG 0.47 0.49 0.46 0.47 0.46 √

Identification

12 L Visual OK OK OK OK OK √

Mark

13 Dim 9.20(±0.50) DHG 9.37 9.28 9.24 9.35 9.28 √

14 Dimple Height 4X0.60(±0.10) DHG 0.66 0.68 0.64 0.65 0.69 √

Dimple Outer

15 4XØ3.0(+0.30/-0) vernier 3.15 3.17 3.19 3.17 3.15 √

Dia

16 DIM 6.0(±0.30) DHG 5.92 6.02 5.98 5.97 6.05 √

17 DIM 3.0(+0.20/-0) DHG/DVC 3.14 3.14 3.15 3.12 3.16 √

18 DIM 10.0(±0.50) DVC 10.12 10.15 10.14 10.1 10.15 √

19 Flatness 0.20 Max DHG/DVC 0.16 0.18 0.15 0.16 0.14 √

20 DIM 8.0(+0.20/-0) DVC 8.15 8.15 8.14 8.16 8.16 √

21 DIM 12.50(±0.20) DHG/DVC OK OK OK OK OK √

3.0(+0.10/-0) X 3.09 3.08 3.06 3.08 3.07

22 DIM (Slot) DVC 4.14 4.11 4.16 4.08 4.11 √

4.0(±0.30)

23 INNER DIA Ø3.0 (+0.10) PG OK OK OK OK OK √

SHEAR

24 STRENGTH OF 1.96 KN MINI. T.T.M. 2.06 2.14 2.10 2.15 2.10 √

WELD NUT

AFTER NO BUMP ON

25 VISUAL OK OK OK OK OK √

WELDING SURFACE A

M6 FLANGE

TIGHTENING 12.70 NM MINI. IN 3 BOLT +

26 13.1 13.05 13.18 13.08 13.04 √

TORQUE TIMES TORQUE

WRENCH

PLATING

PLATING

27 8μ MINI THICKNESS 14μ 10μ 11μ 12μ 14μ √

THICKNESS TESTER

28 COLOUR TRI-VALENT CHROME VISUAL OK OK OK OK OK √

29 DEFECTS NO BURR, RUST ETC. VISUAL OK OK OO OK OK √

LOT

30 IDENTIFICATIO LABEL VISUAL OK OK OK OK OK √

N AS PER

MATERIAL/ IS:513 2008

31

THICKNESS CRC -D/ t-1.60 (± 0.11) STANDERD

1.59 1.59 1.59 1.58 1.59 √

/VERNIER

32 RM Width 97.0 ± 0.50 vernier 97.29 97.19 97.31 97.11 97.15 √

Remarks:- OK (√) Deviation (∆) Reject (X)

PREPARED BY:- APPROVED BY:-

Format No. : SF-QA-012, Rev. No. 00, Date: 01.01.2021

M. ENGINEERING TOOLS

PDI INSPECTION REPORT

Customer:- HI-LEX INDIA PVT. LTD. Sample Size:- 05 Nos

Part Name:- UPPER BRACKET ASSY. 6 Lot Size:- 600 Nos

Part No.:- CA0C010000 Invoice No.:- 2362 Date:- 26.02.2022

INPSCTION INSPECTION RESULTS

S. NO. SPECIFICATION Method

PARAMETER 1 2 3 4 5 STATUS

1 DIM 6.0(±0.10) DHG/RCG OK OK OK OK OK √

2 DIM 8.0(±0.10) DHG/RCG OK OK OK OK OK √

3 DIM 55.0(±0.30) DVC/RCG OK OK OK OK OK √

4 Inner Dia Ø6.20(+0.05/-0.15) PG OK OK OK OK OK √

5 True Position 1.40 A B C RCG OK OK OK OK OK √

6 Thread 2XM6X1.0 T.PG OK OK OK OK OK √

Perpendiculart

7 0.25 A RCG OK OK OK OK OK √

y

8 True Position 1.0 A B RCG OK OK OK OK OK √

Perpendiculart

9 0.25 A RCG OK OK OK OK OK √

y

10 DIM 5.0(±0.50) DVC 5.25 5.13 5.19 5.17 5.21 √

11 DIM 0.40(+0.10/-0) DHG 0.47 0.49 0.46 0.47 0.46 √

Identification

12 L Visual OK OK OK OK OK √

Mark

13 Dim 9.20(±0.50) DHG 9.37 9.28 9.24 9.35 9.28 √

14 Dimple Height 4X0.60(±0.10) DHG 0.66 0.68 0.64 0.65 0.69 √

Dimple Outer

15 4XØ3.0(+0.30/-0) vernier 3.15 3.17 3.19 3.17 3.15 √

Dia

16 DIM 6.0(±0.30) DHG 5.92 6.02 5.98 5.97 6.05 √

17 DIM 3.0(+0.20/-0) DHG/DVC 3.14 3.14 3.15 3.12 3.16 √

18 DIM 10.0(±0.50) DVC 10.12 10.15 10.14 10.1 10.15 √

19 Flatness 0.20 Max DHG/DVC 0.16 0.18 0.15 0.16 0.14 √

20 DIM 8.0(+0.20/-0) DVC 8.15 8.15 8.14 8.16 8.16 √

21 DIM 12.50(±0.20) DHG/DVC OK OK OK OK OK √

3.0(+0.10/-0) X 3.09 3.08 3.06 3.08 3.07

22 DIM (Slot) DVC 4.14 4.11 4.16 4.08 4.11 √

4.0(±0.30)

23 INNER DIA Ø3.0 (+0.10) PG OK OK OK OK OK √

SHEAR

24 STRENGTH OF 1.96 KN MINI. T.T.M. 2.06 2.14 2.10 2.15 2.10 √

WELD NUT

AFTER NO BUMP ON

25 VISUAL OK OK OK OK OK √

WELDING SURFACE A

M6 FLANGE

TIGHTENING 12.70 NM MINI. IN 3 BOLT +

26 13.1 13.05 13.18 13.08 13.04 √

TORQUE TIMES TORQUE

WRENCH

PLATING

PLATING

27 8μ MINI THICKNESS 14μ 10μ 11μ 12μ 14μ √

THICKNESS TESTER

28 COLOUR TRI-VALENT CHROME VISUAL OK OK OK OK OK √

29 DEFECTS NO BURR, RUST ETC. VISUAL OK OK OO OK OK √

LOT

30 IDENTIFICATIO LABEL VISUAL OK OK OK OK OK √

N AS PER

MATERIAL/ IS:513 2008

31

THICKNESS CRC -D/ t-1.60 (± 0.11) STANDERD

1.59 1.59 1.59 1.58 1.59 √

/VERNIER

32 RM Width 97.0 ± 0.50 vernier 97.29 97.19 97.31 97.11 97.15 √

Remarks:- OK (√) Deviation (∆) Reject (X)

PREPARED BY:- APPROVED BY:-

Format No. : SF-QA-012, Rev. No. 00, Date: 01.01.2021

You might also like

- Asme B30.20-2006Document3 pagesAsme B30.20-2006Ing. Alejandro Valencia HerreraNo ratings yet

- ME (H4DOTC) MechanicalDocument112 pagesME (H4DOTC) MechanicalMatias RodriguezNo ratings yet

- Gerab Corporate BrochureDocument32 pagesGerab Corporate BrochureGourav SharmaNo ratings yet

- Method Statement Installation of GeneratorDocument5 pagesMethod Statement Installation of GeneratorWilson (Electrical Engineer)100% (3)

- Category (58) - Soil RemediationDocument14 pagesCategory (58) - Soil RemediationAmit Kumar Sikri100% (1)

- ITP For CCTV System Testing & CommissioningDocument1 pageITP For CCTV System Testing & CommissioningTamer EidNo ratings yet

- 092000-5600 Injection Pump Test SpecificationsDocument3 pages092000-5600 Injection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- WSH Approved Codes of Practice Notification 2020Document7 pagesWSH Approved Codes of Practice Notification 2020KamatchiNo ratings yet

- Template Gas Line SizingDocument11 pagesTemplate Gas Line SizingRindie AuroraNo ratings yet

- BSI Standards Publication: Common Rules For Precast Concrete ProductsDocument8 pagesBSI Standards Publication: Common Rules For Precast Concrete ProductsBibhuti Bhusana BisoyiNo ratings yet

- Code of Practice For The Installation and Inspection of Fire Stopping Systems in BuildingsDocument22 pagesCode of Practice For The Installation and Inspection of Fire Stopping Systems in BuildingsNguyen Trung KienNo ratings yet

- Inter Locking Bricks PresentationDocument19 pagesInter Locking Bricks PresentationSiddesh Naik100% (6)

- CB0C050F0Document12 pagesCB0C050F0roshni mehraNo ratings yet

- CB1C006F0Document6 pagesCB1C006F0roshni mehraNo ratings yet

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- CB2C010F0Document7 pagesCB2C010F0roshni mehraNo ratings yet

- Layout K1SG-RHDocument11 pagesLayout K1SG-RHNPD TEAM HosurNo ratings yet

- CYLINDER - ktmHEAD Lay Out (ALICON)Document4 pagesCYLINDER - ktmHEAD Lay Out (ALICON)vikesh1993No ratings yet

- Inspection ReportDocument30 pagesInspection ReportSanjayNo ratings yet

- Part No. Part Name Model 11670-67LBO Bracket Comp, Eng LH MTG S.NO. Item Spec TOL Agro 1 2 Method/ InstrumentDocument4 pagesPart No. Part Name Model 11670-67LBO Bracket Comp, Eng LH MTG S.NO. Item Spec TOL Agro 1 2 Method/ InstrumentAshokNo ratings yet

- 2316C79401 FirDocument1 page2316C79401 FirInder SabhrawalNo ratings yet

- Checking Aids: SBCT Industries LLPDocument1 pageChecking Aids: SBCT Industries LLPSBCT QCNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- HD14512 PDFDocument7 pagesHD14512 PDFjose antonio iglesias infantesNo ratings yet

- Product Audit: Volkswagen AgDocument2 pagesProduct Audit: Volkswagen Agcong daNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- 164-01-01-000 Locating PinsDocument2 pages164-01-01-000 Locating PinscawojNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- 7,-Qad-28sample Inspection Report Mach. 74-100Document1 page7,-Qad-28sample Inspection Report Mach. 74-100azadsingh1No ratings yet

- Wall No.8 (4.2) MDocument5 pagesWall No.8 (4.2) MAli Al-BashaNo ratings yet

- CS Nipple 21K-62-71310Document1 pageCS Nipple 21K-62-71310Inspirasi Kreasi SejahteraNo ratings yet

- Results and CalculationDocument4 pagesResults and CalculationMing Zhao PangNo ratings yet

- Copy of Code Case 2235-9Document2 pagesCopy of Code Case 2235-9Rupam BaruahNo ratings yet

- 108 - t1, 31.08.2015 Pdi - Qad-28 Sample Inspection Reportslide Chair - Machine (Ber.319-111108)Document1 page108 - t1, 31.08.2015 Pdi - Qad-28 Sample Inspection Reportslide Chair - Machine (Ber.319-111108)azadNo ratings yet

- 164-01-01-007 Locating Pin - Dia 2.8Document1 page164-01-01-007 Locating Pin - Dia 2.8cawojNo ratings yet

- Thickness Calculation (31.3)Document23 pagesThickness Calculation (31.3)sunder ujjainwalNo ratings yet

- t5!18!01 2016 Qad 28 Sample Inspection Reportslide Chair Machine Ber 319 11116Document1 paget5!18!01 2016 Qad 28 Sample Inspection Reportslide Chair Machine Ber 319 11116Sarah FetahNo ratings yet

- Vulcan Core Industries Pvt. LTD.: Sample Inspection ReportDocument1 pageVulcan Core Industries Pvt. LTD.: Sample Inspection ReportazadNo ratings yet

- Layout 5abcdDocument2 pagesLayout 5abcdvikesh1993No ratings yet

- 164-01-01-010 6.5 Cbore PinDocument1 page164-01-01-010 6.5 Cbore PincawojNo ratings yet

- 2316C79301 FirDocument1 page2316C79301 FirInder SabhrawalNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- Manual Wind Load Calculation For Pipe Rack - Rev - 1 - TADocument10 pagesManual Wind Load Calculation For Pipe Rack - Rev - 1 - TAf a chaidirNo ratings yet

- Sample Inspection Report: SR - NO. DateDocument1 pageSample Inspection Report: SR - NO. DateBhuvanesh KumarNo ratings yet

- Ic 7404 (2) HD74LS04PDocument6 pagesIc 7404 (2) HD74LS04PBurhanudin SyamNo ratings yet

- Set-Up Approval Report-Bar Comp PillionDocument1 pageSet-Up Approval Report-Bar Comp Pillionswaran autoqaNo ratings yet

- RIT-Wheel Front Drum Layout ReportDocument11 pagesRIT-Wheel Front Drum Layout Reportrama.chandranNo ratings yet

- Atividade Concreto Armado 3Document4 pagesAtividade Concreto Armado 3felipe willianNo ratings yet

- Wind Design CalculatorDocument9 pagesWind Design CalculatorMuhammad rifaiNo ratings yet

- One Dimensional Consolidation Test Slide Area Reddish With Different ModifiersDocument31 pagesOne Dimensional Consolidation Test Slide Area Reddish With Different ModifiersSyed Zishan AshiqNo ratings yet

- Al TG CaseDocument19 pagesAl TG CaseSurendra SinghNo ratings yet

- SPEC-DMM7510B Oct 2016 0Document25 pagesSPEC-DMM7510B Oct 2016 0SantonioNo ratings yet

- Figure 9. Constant Current Regulator Notes:: KA78XX/KA78XXADocument7 pagesFigure 9. Constant Current Regulator Notes:: KA78XX/KA78XXASec!No ratings yet

- Reel Dimensions Units: MM: T Max G N Min D Min A (13") A (7") C Tape B MinDocument1 pageReel Dimensions Units: MM: T Max G N Min D Min A (13") A (7") C Tape B MinagrajitNo ratings yet

- Pdi 05 01.2015 Qad 28sample Inspection Report Mach. 74 100Document1 pagePdi 05 01.2015 Qad 28sample Inspection Report Mach. 74 100azad100% (1)

- 2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXDocument1 page2324-301123108 Guide Starter Chain (28102-ACK-0100) - XLSXSonali AhirwarNo ratings yet

- Motiongoo Stepper Motor Drawing-17HF13D6031Document1 pageMotiongoo Stepper Motor Drawing-17HF13D6031Make RownNo ratings yet

- SD Stacked Coin Type: Electric Double Layer Capacitors (Gold Capacitor) / SDDocument1 pageSD Stacked Coin Type: Electric Double Layer Capacitors (Gold Capacitor) / SDJORGENo ratings yet

- DRW 0002Document1 pageDRW 0002karpagavalli NNo ratings yet

- 1 1720BL15B0050-1519232 PDFDocument5 pages1 1720BL15B0050-1519232 PDFrakeeNo ratings yet

- Glorious Electronics India Private Limited: Sample Inspection ReportDocument2 pagesGlorious Electronics India Private Limited: Sample Inspection ReportYogesh YadavNo ratings yet

- Detail A Scale 7: 1: Corner Should Be C0.2 or R0.2 Except As Note !. DIN ISO 2768Document1 pageDetail A Scale 7: 1: Corner Should Be C0.2 or R0.2 Except As Note !. DIN ISO 2768syaikulNo ratings yet

- Pipe DistribuidoresDocument4 pagesPipe Distribuidoresjunaidmateen2345No ratings yet

- CBR Tak TerendamDocument31 pagesCBR Tak TerendamAnka EkelnikoNo ratings yet

- BK 916 TR DatasheetDocument1 pageBK 916 TR DatasheetMaxim KostyuchenkoNo ratings yet

- ACCProfileDocument8 pagesACCProfilepurshottam hunsigiNo ratings yet

- BS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDFDocument28 pagesBS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDF梁山伯No ratings yet

- University of Sierra Leone Usl Fourah Bay College Civil Engineering Department Module: Pavement DesignDocument4 pagesUniversity of Sierra Leone Usl Fourah Bay College Civil Engineering Department Module: Pavement DesignAlex KamaraNo ratings yet

- The Effect of A Percentage Changes in The Price of Some Selected Construction Materials On The Economic Input of The Nigerian Construction IndustryDocument60 pagesThe Effect of A Percentage Changes in The Price of Some Selected Construction Materials On The Economic Input of The Nigerian Construction Industryrusnom2000No ratings yet

- Plaster Assemblies Chapter 02 Plaster Substrates LathDocument26 pagesPlaster Assemblies Chapter 02 Plaster Substrates LathFare NienteNo ratings yet

- Module I - ANALYSIS of RATE - Architecture - 6th SemDocument32 pagesModule I - ANALYSIS of RATE - Architecture - 6th SemShrayoshree DuttaNo ratings yet

- Takreer - Civil EngineerDocument3 pagesTakreer - Civil EngineerRamilArtatesNo ratings yet

- San Antonio San Pascual, Batangas Palico-Balayan-Batangas RoadDocument2 pagesSan Antonio San Pascual, Batangas Palico-Balayan-Batangas RoadMekaela DiataNo ratings yet

- Site Development Plan Location Plan: Proposed Residential BuildingDocument1 pageSite Development Plan Location Plan: Proposed Residential BuildingCRISS CROSSNo ratings yet

- Summary of Experience: MD Aamir ShahnawazDocument4 pagesSummary of Experience: MD Aamir ShahnawazEr Md AamirNo ratings yet

- Literature and Case Study VI by BenjjuDocument97 pagesLiterature and Case Study VI by BenjjuJeevan BistaNo ratings yet

- Q4 Inter Site Audit Schedule (FY 2021-2022) - WI BU MR SignedDocument2 pagesQ4 Inter Site Audit Schedule (FY 2021-2022) - WI BU MR SignedBalasubramaniamkamarajNo ratings yet

- Exhibit Guidelines For SignaturesDocument3 pagesExhibit Guidelines For Signaturesrhizza basilioNo ratings yet

- Azibrade Corporate Profile v1Document9 pagesAzibrade Corporate Profile v1ZMA BinaNo ratings yet

- Introduction in Construction IndustryDocument16 pagesIntroduction in Construction IndustryGerald KhoNo ratings yet

- T HR Ci 12020 STXXXXDocument99 pagesT HR Ci 12020 STXXXXfastwritenameNo ratings yet

- Pt. Sepuluh Sumber Anugerah: Summary Daily Manpower ReportDocument32 pagesPt. Sepuluh Sumber Anugerah: Summary Daily Manpower ReportbayuNo ratings yet

- Introduction To Korea Building Code (Draft)Document5 pagesIntroduction To Korea Building Code (Draft)rezaNo ratings yet

- Road Work at 4.615%Document91 pagesRoad Work at 4.615%charitha naiduNo ratings yet

- Yrrel Janzedrick Cristobal SalesDocument5 pagesYrrel Janzedrick Cristobal SalesClark InternationalNo ratings yet

- Lecture 4Document30 pagesLecture 4btsNo ratings yet