Professional Documents

Culture Documents

Fluidizing

Uploaded by

SonratOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluidizing

Uploaded by

SonratCopyright:

Available Formats

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 1 of 114

No: 1

STANDARD MAINTENANCE PROCEDURE

FOR

BAG FILTERS OF FLY ASH SILO

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 2 of 114

No: 1

FLOWCHART OF SMP:

APPLY PTW

ISOLATION OF EQUIPMENT

ISSUING PTW

INSPECTION OF WORK

AREA/EQUIPMENT

CARRYING OUT WORK AS PER

CHECKLIST

EQUIPMENT BOX-UP AREA

HOUSEKEEPING

SURRENDER OF PTW AND TRIAL RUN

NORMALIZATION OF EQUIPMENT

CANCELLATION OF PTW

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 3 of 114

No: 1

STANDARD MAINTENANCE PROCEDURE FOR PM

BAG FILTERS OF FLY ASH SILO .

OBJECTIVE:

The purpose of this work instruction is to explain the

procedure for carrying out PM of all the Equipments

involved in BAG FILTERS OF FLY ASH SILO for smooth

operation of Plant.

Areas involved in the bag filters of fly ash silo are as

follows:

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 4 of 114

No: 1

SCOPE: This SMP is applicable for all bag filters of fly ash.

The details of the bag filters of fly ash are as follows

SAFETY PRECAUTIONS:

1. Ensure permit to work is issued on this system.

SAFETY PPE’S: Hand Gloves, Safety Goggles, Ear Plugs Nose Mask, etc.

ACTIVITY TIME REQUIRED: 03 HRS

SPECIAL TOOLS/ EQUIPMENTS: Spanner Set, Allen key Set, Grease,

Gasket & Hole Bari, etc.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 5 of 114

No: 1

STANDARD MAINTANENCE PROCEDURE

FOR

Bag Filters of Fly Ash

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

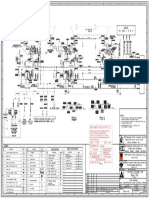

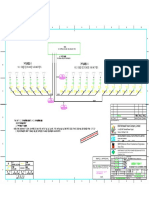

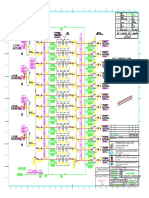

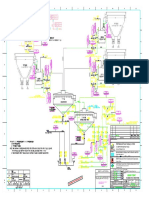

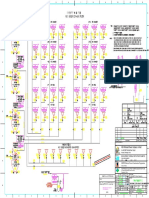

DIAGRAM:

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 7 of 114

No: 1

Installation of the Bags / Cages

- Fold the “U” collar.

- Fit the bag ring on the mirror.

- If a “button” is formed, do not press it, but in the

opposite side.

- The fit needs to be perfect so that there will be no leakage.

- Never use any tools (mallet type).

- Fit the cage inside the bags.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 8 of 114

No: 1

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 9 of 114

No: 1

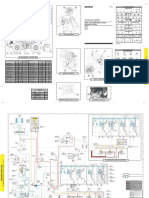

DESCRIPTION:

The bag filter is made of a metallic housing designed for continuous operation and

automatic cleaning.

The fly ash enters through the pipe line in the silo where the heavier particulate is

separated, and the lighter material is carried along with the gas to the filter

intermediate part, being forced to pass through the filtering bags where all the

particulate is collected.

The clean gas is then sent to the higher plenum (filtered air chamber) and then to the

atmosphere or exhausted to the discharge chimney.

The bag cleaning process is automatically performed through compressed air pulses

that are controlled by a programmer. The compressed air is stored in a reservoir

located beside the higher filter chamber. Above each row of bags there is a tube with

holes that are aligned with the central air passage gap, located on top of the bags,

through which compressed air is injected to momentarily invert the gas flow, causing

the particulate material accumulated outside the bags to be removed. Such tube is

connected to the reservoir through a diaphragm valve activated by a

solenoid/temporized sequencer that activates cleaning of a row of bags.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 10 of 114

No: 1

MAINTENANCE:

Housing

Every manhole needs to be completely sealed. Eventual leakages need to

be immediately repaired.

For good functioning Bag Filter, it is important to ensure that dust

extracting parts are operating in perfect conditions.

Cleaning System

On a weekly basis, inspect all cleaning system parts, including: Diaphragm

Valves, Solenoid Valves, gate valve and Bags.

Filtering Bags

Filtering bags need to be treated as carefully as possible.

When bags for damages (holes or tears). They should be immediately

changed any damage is found.

Wet bags immediately replaced by clean/dry bags.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 11 of 114

No: 1

Problem Solving Guide

High load loss:

Check the differential manometer is operating as planned.

(leakage/clogging)

Check all the solenoid valves are operating in each cycle.

Check if compressed air is dried, clean and free of oil.

Low load loss:

Check if there are holes in the bags and if they are appropriately

connected.

Check there is leakage or clogging in the pipeline of the system. Check if

all system meters are appropriately positioned to allow the air to flow

through the Bag Filter.

Ensure that the mirror plate or the housing does not have any holes,

cracks or loose seals, allowing the air to flow through the Filter without

going through the bags.

Emission of visible dust at the output of the Bag Filter:

Check there are any holes in the bags and if they are appropriately

connected.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Ensure that the mirror plate does not have any holes, cracks or broken

seals that allow the air to pass through the Bag Filter without going

through the filtering bags.

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/DFAES/01

6 X 600 MW Power Plant

Power from knowledge

SMP FOR DRY FLY ASH EVACUATION SYSTEM

Issue Issue Date: Revision: 1 Revision Date: File no: Page 12 of 114

No: 1

STEP WISE PROCEDURE OF WASTE MANAGEMENT:-

WASTE SPECIFICATION: - Jute, Cotton Waste, Cloth, Nuts & Bolts, etc.

Procedure:-

1. After completion of work, floor should be cleaned with broom.

2. All the waste material specified above should properly be accumulated.

3. Then the waste should be disposed in a dumpster & lid should be placed.

4. Proper cleanliness to be maintained near the work place.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK MAHANADI POWER COMPANY LIMITED

6X600 MW ASH HANDLING SYSTEM OF KMPCL

BUFFER HOPPER - Date:

S No. ACTIVITY TO BE DONE DETAIL OF ACTIVITY REMARKS

1 Bags Inspection & Cleaning

Inpection of Moisture content in

2

Purging Air

3 Purging Header Inspection

Fastners/Mounting tightness

4

Checking.

5 Cage Inspection

Inspection of Air Manifold

6

Diapragm & Clamp Tightening.

Inspection of Cage Locking

7

Arrangment

8 Vent Fan Inspection

9 Observation

SIGNATURE OF MMD GLOBUS SIGNATURE OF MMD KSK

ENGINEER ENGINEER

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bah ElevationDocument1 pageBah ElevationSonratNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- SMP For Vacuum PumpDocument9 pagesSMP For Vacuum PumpSonratNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Bah Side ViewDocument1 pageBah Side ViewSonratNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Control Write Up HCSDDocument10 pagesControl Write Up HCSDSonratNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SMP For Sealing Water Pump Multi Stage.Document13 pagesSMP For Sealing Water Pump Multi Stage.SonratNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SMP For Ba Overflow PumpDocument14 pagesSMP For Ba Overflow PumpSonratNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Part List - BEL0800 PDFDocument1 pagePart List - BEL0800 PDFSonratNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- SMP For Dry Ash UnloaderDocument8 pagesSMP For Dry Ash UnloaderSonratNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Sop For Vent FilterDocument6 pagesSop For Vent FilterSonratNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SMP For Supply Water PumpDocument13 pagesSMP For Supply Water PumpSonratNo ratings yet

- SMP For Slurry PumpDocument14 pagesSMP For Slurry PumpSonrat100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- SMP For Fluidizing Air BlowerDocument20 pagesSMP For Fluidizing Air BlowerSonrat100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- FluidizingDocument13 pagesFluidizingSonratNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HCSD PDFDocument1 pageHCSD PDFSonratNo ratings yet

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFDocument1 pageBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFDocument1 pageECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratNo ratings yet

- ASH WATER PUMP HOUSE-Model PDFDocument1 pageASH WATER PUMP HOUSE-Model PDFSonratNo ratings yet

- SMP For Agitator (Slurry Sump)Document9 pagesSMP For Agitator (Slurry Sump)SonratNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- PM For Fly Ash Dry SystemDocument31 pagesPM For Fly Ash Dry SystemSonratNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- StructureDocument1 pageStructureSonratNo ratings yet

- Compressor House ModelDocument1 pageCompressor House ModelSonratNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Over Flow Pump Concentrator Buffer Tank ModelDocument1 pageOver Flow Pump Concentrator Buffer Tank ModelSonratNo ratings yet

- Water & Slurry BalanceDocument1 pageWater & Slurry BalanceSonratNo ratings yet

- ESP-FLD. BLOWER-Model PDFDocument1 pageESP-FLD. BLOWER-Model PDFSonratNo ratings yet

- Silo Blower Compressor ModelDocument1 pageSilo Blower Compressor ModelSonratNo ratings yet

- Pdi EspDocument1 pagePdi EspSonratNo ratings yet

- Silo Unloading ModelDocument1 pageSilo Unloading ModelSonratNo ratings yet

- VP To Buffr Hopper-ModelDocument1 pageVP To Buffr Hopper-ModelSonratNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Buffer Hopper & Air Lock Tank-ModelDocument1 pageBuffer Hopper & Air Lock Tank-ModelSonratNo ratings yet

- LAB 1 - Colour Contrast Penetrant TestDocument9 pagesLAB 1 - Colour Contrast Penetrant TestRaiham EffendyNo ratings yet

- Project Beam No. B1 Client Struc STEP-UP Building Title DateDocument1 pageProject Beam No. B1 Client Struc STEP-UP Building Title DateAek JanNo ratings yet

- Module 5 - Design of Isolated Spread FootingDocument21 pagesModule 5 - Design of Isolated Spread FootingRVNo ratings yet

- MCON PriceList2014Document22 pagesMCON PriceList2014tengok69No ratings yet

- Operating Instructions: M M 0 1 B T 2Document13 pagesOperating Instructions: M M 0 1 B T 2adil_farooq_6No ratings yet

- Engineering Report: Braking SystemsDocument7 pagesEngineering Report: Braking SystemsWill GrovesNo ratings yet

- ASNA2180Document29 pagesASNA2180Felix FloresNo ratings yet

- Multicrete Raise Robot - TM - Shotcrete Application UnitDocument2 pagesMulticrete Raise Robot - TM - Shotcrete Application UnitIng del PeleNo ratings yet

- Catalogo de Winch Fa5a PDFDocument60 pagesCatalogo de Winch Fa5a PDFingcalderonNo ratings yet

- Product - Gallery - 2019 05 31 - 14 56 001Document82 pagesProduct - Gallery - 2019 05 31 - 14 56 001chellaliNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Industrial Gas Generator Illustrated Parts CatalogueDocument10 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Specification BookDocument16 pagesSpecification BookaurasNo ratings yet

- KENR7618KENR7618-02 Cargador 924HDocument2 pagesKENR7618KENR7618-02 Cargador 924HEliceo PalominoNo ratings yet

- 3 - Load Distribution Problems SheetDocument22 pages3 - Load Distribution Problems SheetصابرالحجيريNo ratings yet

- MolexDocument3 pagesMolexDeddy WilopoNo ratings yet

- Redneck Golf PlanDocument7 pagesRedneck Golf PlanAndré SilvaNo ratings yet

- Daikin V VZ VD M Series Piston PumpDocument51 pagesDaikin V VZ VD M Series Piston Pumpsunhuynh100% (1)

- RSJ Pole DetailsDocument9 pagesRSJ Pole DetailsPramod B.Wankhade50% (2)

- Condensadora TTB TraneDocument24 pagesCondensadora TTB TraneRoberto Reyes Lara100% (1)

- Tirfor - Tiger LiftingDocument4 pagesTirfor - Tiger LiftingYADAGIRI REDDYNo ratings yet

- Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument2 pagesWorldwide Fastener Standard: Printed Copies Are UncontrolledPrabagarane RamachandranNo ratings yet

- Refrigerant Charging ProcedureDocument3 pagesRefrigerant Charging Procedurenagarajasarma78% (9)

- Klübersynth BEM 44-4600: High-Performance Fluid Grease For Long-Term LubricationDocument2 pagesKlübersynth BEM 44-4600: High-Performance Fluid Grease For Long-Term LubricationHizuafi KhairulNo ratings yet

- Case Study/ Survey:-Department: - Guided By: - Made By:-: Scotch Yoke MechanisumDocument10 pagesCase Study/ Survey:-Department: - Guided By: - Made By:-: Scotch Yoke Mechanisum28048 Pranav KarodpatiNo ratings yet

- Tirehand 3565Document74 pagesTirehand 3565servicio tecnicoNo ratings yet

- Char-Lynn: Hydraulic MotorDocument8 pagesChar-Lynn: Hydraulic MotorRidha AbbassiNo ratings yet

- CGA-PRC001-EN: Air-Cooled Water Chiller 5 30 TonsDocument9 pagesCGA-PRC001-EN: Air-Cooled Water Chiller 5 30 TonsSanto VerasNo ratings yet

- Weak Story Check-ColumnDocument4 pagesWeak Story Check-ColumnConan EdogawaNo ratings yet

- Parts Catalogue For Professional Embroidery Machine PR600 PR600 CDocument43 pagesParts Catalogue For Professional Embroidery Machine PR600 PR600 CcinthiaNo ratings yet

- Duplex Filter PDFDocument4 pagesDuplex Filter PDFmd abNo ratings yet