Professional Documents

Culture Documents

ASNA2180

Uploaded by

Felix FloresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASNA2180

Uploaded by

Felix FloresCopyright:

Available Formats

ASNA2180

Issue : V

REPAIR SIZE, OVERSIZING Date : Nov 2021

Page : 1/29

This document is

applicable for legacy

programs: SA, LR, A380

SUMMARY and A400M.

1 - GENERAL For further A/C programs,

2 - REFERENCES refer to ABS1771.

3- SOLID RIVET

4 - BOLTS AND COLLARS OVERSIZING

5 - REPAIR BUSHINGS

AMENDMENT RECORD SHEET

1 - GENERAL

This document defines the over-sizing possibilities for different assemblies.

These design offices instructions shall be used as support for maintenance and repair of aircrafts.

- Solid rivets.

- Parallel shank, taper shank bolts, nuts and collars.

- Protection bushings installed using liquid nitrogen or a press.

- Mechanical bushings installed by sliding into place gently or using force.

- Crimping bushes for roller bearings and ball joints.

2 - REFERENCES

ADET0029 : Installation of cylindrical shear bolts.

ADET0030 : Structural bolt tightening torques.

ADET0034 : Manufacture of screw and threaded pins in our workshops.

ADET0059 : Inspection of permanent or removable shear bolts after installation.

ADET0077 : Installation of permanent cylindrical bolts with interference.

The content of this document is the property of AIRBUS FRANCE. It is supplied in confidence and commercial security on its contents must be

maintained. It must not be used for any purpose other than that for which it is supplied nor may information contained in it be disclosed to

unauthorized persons. It must not be reproduced in whole or in part without permission in writing from AIRBUS FRANCE.

AIRBUS FRANCE Trade Secrets or Commercial or Financial information, 5 U.S.C. (b) (4).

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 2

ADET0078 : Structural riveting.

ADET0085 : Installation of tension bolts.

ADET0134 : Installation of blind fasteners

ADET0188 : Installation of taper-lock bolts.

ABS0094 : Pin – Titanium alloy, 100° countersunk head, break stem, tension head

ABS0095 : Pin – Titanium alloy, 100° countersunk head, break stem, medium head

height

ABS0114 : Bolt, hexagonal head, close tolerance, 6AL-4V titanium alloy.

ABS0269 : Pin – Protruding tension head, swaged

ABS0548 : Pin, swage locking, pull type, 100° countersunk intermediate head.

ABS0549 : Pin, swage locking, pull type, protruding intermediate head.

ABS0550 : Pin, swage locking, stump type 100° countersunk intermediate head.

ABS0876 : Bolt – Protruding tension head pull type – For fatigue applications.

ABS0889 : Tapered shank bolt, protruding head, short thread.

ABS0907 : Bolt – Protruding tension head, short thread, break stem, for interference

fit.

ABS0925 : Bolt – Protruding tension head, pull type – For fatigue applications.

ABS0927 : Bolt – Tensile, Nimonic.

ABS0950 : Screw – 100° head, cruciform recess, 6AI-4V titanium alloy.

ABS0995 : Pin – 100 ° intermediate CSK head for shear/tension metallic applications,

swage locking, 6Al-4V titanium (95 KSI shear).

ABS0997 : Bolt – Self aligning head (slope 5° max.), pull type – For fatigue

applications.

ABS0998 : Pin – Tension protruding head for shear/tension composite applications,

swage locking, 6Al-4V titanium (95 KSI shear).

ABS1418 : Tapered shank bolt, 100° countersunk head, short thread.

ABS1504 : Pin – 100 ° tension CSK head for shear/tension metallic applications,

swage locking, 6Al-4V titanium (95 KSI shear).

ABS1506 : Pin – Tension protruding head for tension metallic applications, swage

locking, 6Al-4V titanium (95 KSI shear).

ABS1720 : Pin – 100 ° Intermediate countersunk head for shear/tension composite

applications, swage locking, 6AL-4V titanium (95 KSI shear)

ABS1830 : Bolt, 12 point socket head Tension and shear application

ABS1831 : Nut, 12 point, tension.

AIPS01-01-004 : Installation of solid rivets

AIPS01-02-002 : Installation of Taper Shank Bolts.

ASNA0077 : Rivets blind 100° countersunk head

ASNA0078 : Rivets blind flattened round head

ASNA0081 : Blind bolts with self-locking 100° countersunk head

ASNA0082 : Blind bolts with self-locking hexagonal head

ASNA0092 : Screw – 100 DEG CSK head, in Inconel 718, R = 1 510 Mpa.

ASNA0093 : Bolt – Twelve-point, Inconel 718.

ASNA0094 : Nut, 12-point, self-locking, Inconel 718, R = 1 500 Mpa.

ASNA0095 : Screw – 100 DEG countersunk head torq-set socket, Inconel 718

R = 1 510 Mpa, repair size: Ø + 1/64.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 3

ASNA0096 : Screw – Twelve-point, Inconel 718, oversize Ø + 1/64, R = 1 510 Mpa.

ASNA0097 : Screw – 100 DEG countersunk head torq-set socket, Inconel 718

R = 1 510 Mpa, repair size: Ø + 1/32.

ASNA0098 : Screw – Twelve-point, Inconel 718, oversize Ø +1/32, R = 1 510 Mpa.

ASNA0122 : Screw – Tractive, bi-hex head, R = 1 240 Mpa.

ASNA0123 : Bolt – Twelve-point, Inconel 718, strength class 1 240 Mpa.

ASNA0124 : Fastener – 100 DEG countersunk head torque-set, Inconel 718

R = 1 240 Mpa

ASNA0129 : Fastener-blind, cylindrical round head, mechanically locked shank

ASNA0130 : Fastener-blind, head 100° countersunk, mechanically locked shank

ASNA0139 : Screw – Twelve-point, Inconel 718, oversize Ø + 0,397 mm,

R = 1 240 Mpa.

ASNA0140 : Screw – Twelve-point, Inconel 718, oversize Ø + 0,794 mm,

R = 1 240 Mpa.

ASNA0141 : Bolt – 100 DEG CSK, torque-set, Inconel 718, oversize Ø + 0,397 mm,

R = 1 240 Mpa.

ASNA0142 : Bolt – 100 DEG CSK, torque-set, Inconel 718, oversize Ø + 0,794 mm,

R = 1 240 Mpa.

ASNA2000 : Screw – Hexagonal head.

ASNA2001 : Screw – Countersunk head.

ASNA2003 : Screw – Medium head, 100 DEG CSK, titanium.

ASNA2004 : Bolt – Medium head, flat, steel alloy, titanium.

ASNA2008 : Screw – Medium head “bull-nose”.

ASNA2009 : Bolt – Cylindrical head “bull-nose”.

ASNA2012 : Screw – Medium countersunk head.

ASNA2013 : Screw – Medium cheese-head shearing.

ASNA2016 : Screw – Cylindrical round head, torq-set recess.

ASNA2026 : Bolt – Countersunk head, short thread.

ASNA2027 : Bolt – Protruding head, short thread.

ASNA2040 : Tensile rivets, 100 DEG countersunk head.

ASNA2041 : Rivet, countersunk, Lockbolt

ASNA2042 : Rivet – cylindrical head, Lockbolt

ASNA2043 : Rivet – Countersunk, shear, lock-bolt and repair sizes R1 and R2.

ASNA2048 : Rivet – Cylindrical head, shear, lock-bolt and repair sizes R1 and R2.

ASNA2049 : Solid rivets 100° small countersunk head.

ASNA2050 : Rivet – Aluminium alloy, round flat head, for automatic or not installation.

ASNA2051 : Rivet – Aluminium alloy head 100° CSK for automatic or not installation.

ASNA2054 : Tensile rivet – Cylindrical head.

ASNA2060 : Screw – 100 DEG CSK head, 1/64 oversize, torque-set, Rc min. 910 Mpa,

max. +232 °C.

ASNA2061 : Screw – 12-point, 1/64 oversize, Rc min. 910 Mpa, max. +232 °C.

ASNA2062 : Screw – 100 DEG CSK head, 1/32 oversize, torque-set, Rc min. 910 Mpa,

max. +232 °C.

ASNA2063 : Screw – 12-point, 1/32 oversize, Rc min. 910 Mpa, max. + 232 °C.

ASNA2314 : Screw – Countersunk head, torque set, oversize: R1 (Ø + 1/64).

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 4

ASNA2315 : Screw – Countersunk head, torque-set, oversize: R2 (Ø + 1/32).

ASNA2316 : Screw – Fillister head, torque-set, oversize : R1 (Ø + .01562).

ASNA2317 : Screw – Fillister head, torque-set, oversize : R2 (Ø + .03125).

ASNA2318 : Bolt – Hexagonal head, oversize R1 (Ø +1/64).

ASNA2319 : Bolt – Hexagonal head, oversize R2 (Ø +1/32).

ASNA2352 : Bolt – 100 DEG CSK head, short thread.

ASNA2358 : Screw countersunk sealing.

ASNA2391 : Rivet – Medium head, countersunk, lock-bolt.

ASNA2392 : Rivet – Medium head, cylindrical, lock-bolt.

ASNA2394 : Washer – Countersunk, for oversize bolts.

ASNA2528 : Nut – Hexagonal, self-locking, bi-hex, shear type.

ASNA2529 : Nut – Hexagonal, self-locking, aluminium alloy.

ASNA2531 : Nut – Hexagonal, self-locking, steel.

ASNA2532 : Nut – Self-locking, with a spherical joint and a self-alignment washer (slope

5° max.)

ASNA2657 : Bolt – Reduced countersunk head, shear coupling, short thread.

ASNA2701 : Screw – Countersunk, recessed as per NAS4000, repair sizes R2.

ASNA2702 : Screw – Countersunk, recessed as per NAS4000, sealing, repair sizes R2.

ASN-D0001-013 : Specific indications on drawing.

BS 4A 228 : Specification for double hexagon bolts – 1250MPa (180,000 lbf/in²) for

aircraft

DHS781-3 : Miscellaneous plain washers

EN6050 : Aerospace series – Pins, close tolerance, swage locking, 100°

countersunk head reduced, shear type, in aluminium alloy 7050, chemical

film.

EN6069 : Rivets, 100° reduced flush head, closed tolerance – inch series.

EN6080 : Aerospace series – Rivet 100° normal flush head, close tolerance – Inch

series.

EN6081 : Rivets, universal head, closed tolerance, inch based series.

EN6100 : Aerospace series – Rivet, 100° countersunk head, close tolerance, shear

type in aluminium alloy 7050, chemical film – Inch series.

EN6101 : Rivets, 100° medium flush head, closed tolerance – inch series.

EN6114 : Aerospace series – Bolt – Countersunk head, Short thread – Inch series.

EN6115 :Aerospace series – Bolt – Protruding head, Short thread – Inch series.

EN6120 : Aerospace series – Pin, Close tolerance, swage locking protruding head,

shear type in aluminium alloy 7050, chemical film – Inch series.

F00713009 : Fasteners alternatives.

MS20426 : Rivet, solid, countersunk 100°, precision head, aluminium and titanium

columbium alloy

MS20470 : Rivet, solid, universal head, aluminium and titanium columbium alloy

NASM21250 : Bolt, tension, steel, external wrenching, flanged, 12-point, 180 KSI Ftu, 450

degrees F FSC5306.

NAS1131 to NAS1138 : Screw, machine-pan head close tolerance, short thread, offset cruciform.

(Rev.1).

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 5

NAS1151 to NAS1158 : Screw, machine-flat 100° head, close tolerance, short thread, offset

cruciform, 160 KSI. (Rev. 14).

NAS1241 : Rivet-solid, 100° flush head, aluminium alloy MS20426 Repair (Rev. 1).

NAS1242 : Rivet-solid, universal head, aluminium alloy, MS20470 repair.

NAS1303 to NAS1320 : Bolt, tension, hexagon head 160 KSI Ftu.

NAS1473 : Nut, self-locking, plate – Two lug, cap, floating.

NAS1474 : Nut, self-locking, plate – Two lug, cap, floating, reduced rivet spacing.

NAS1671 : Fastener-blind, Internally threaded, External sleeve, High temperature,

protruding head, self-locking

NAS1672 : Fastener-blind, Internally threaded, External sleeve, High temperature,

flush head, self-locking

NAS1726 : Nut, self-locking, captive washer, shear type, 450 degrees F and 800

degrees F.

NAS1727 : Nut, self-locking, aligning, 450 degrees F and 800 degrees F.

NAS1919 : Rivet, blind – General purpose, bulbed, protruding head, mechanically-

locked-spindle

NAS1921 : Rivet, blind – General purpose, bulbed, 100° flush head, mechanically-

locked-spindle

NAS6303 to NAS6320 : Bolt tension, hex head, close tolerance, A286 CRES, short threaded,

reduced major thread dia., self-locking and Non-lock.

NAS6403 to NAS6420 : Bolt tension, hex head, close tolerance, 6 Al- 4V Titanium alloy, short

threaded, reduced major thread diameter, self-locking.

NAS6603 to NAS6620 : Bolt, hex head, close tolerance, alloy steel, long thread, self-locking and

non-locking.

NAS6703 to NAS6720 : Bolt, hex, close tolerance, A286 CRES, long thread, self-locking and

non-locking.

NAS7503 : Bolt 100° head, cruciform recess, close tolerance, A286 CRES, short

thread, self-locking, and non-locking.

NFL21-215 : Fasteners – rivets, solid, universal head

NFL21-217 : 100 degrees countersunk head rivets

NSA2010 : Hole sizes and associated fits.

NSA2012 : Hole sizes and associated fits for over-sizing.

NSA2017 : Torque – Tightening.

NSA3530 : Tube – Blank for repair insert.

NSA5040 : Bolt – Hi-lok, medium head, CSK 100°, steel alloy, CRES, titanium.

NSA5041 : Bolt – Hi-lok, average flathead, steel alloy, CRES, titanium.

NSA5042 : Bolt – Shouldered, un-tightened fitting.

NSA5050 : Nut – Self-locking, captive washer.

NSA5092 : Screw – Medium countersunk head.

NSA5093 : Screw – Medium cheese-head, shearing.

NSA5100 : Retainer – Bearing, crimp-type for ball bearings and spherical plain

bearings.

NSA5114 : Retainer – Bearing, crimp-type, repair size.

NSA5118 : Bolt – Shouldered, repair sizes dia. + 1/64, for un-tightened fitting.

NSA5119 : Bolt – Shouldered, repair sizes dia. + 1/32, for un-tightened fitting.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 6

NSA5124 : Ring – Shouldered, repair.

NSA5154 : Screw – Medium cheese-head.

NSA5168 : Bolt – Steel alloy, 100° CSK head with MS33781 recess, for shear

application R min. = 910 Mpa up to +482 °C.

NSA5170 : Bolt – Steel alloy, 12-point, head for shear application Rc min. = 910 Mpa

up to +482 °C.

NSA5172 : Bolt – Steel alloy, 12-point head, for shear application

R min. = 1 076 Mpa up to +482 °C.

NSA5329 : Pin – Tapered, threaded, repair sizes dia. + 1/64 and dia. + 1/32.

NSA5333 : Bush – Shouldered, oversize.

NSA5334 : Ring – Plain, repair.

NSA5350 : Pin – Hi-lok, medium head, “bull nose”.

NSA5351 : Pin – Hi-lok, cylindrical head, “bull nose”.

NSA5356 : Pin – Hi-lok, average head, Ø 1/64, “bull nose”.

NSA5357 : Pin – Hi-lok, cylindrical head, Ø 1/64, “bull nose”.

NSA5358 : Pin – Hi-lok, average head, repair size Ø 1/32.

NSA5359 : Pin – Hi-lok, cylindrical head, repair size Ø 1/32.

NSA5368 : Washer – For repair size screws, for repair size taper-lok.

NSA5372 : Washer – For repair size screws, for repair size taper-lok.

NSA5373 : Nut – Double hexagon, self-locking.

NSA5378 : Bolt – 12-point socket head, in Inconel 718, R = 1 510 Mpa.

NSA5398 : Bolt – Tension, 12-point head, Inconel 718, repair size Ø 1/64, strength

class 1 500 Mpa.

NSA5399 : Bolt – Tension, 12-point head, Inconel 718, repair size Ø 1/32, strength

class 1 500 Mpa.

NSA5401 : Bolt – 100° CSK head, repair size dia. 1/64 torque-set, Rc min. = 910 Mpa

up to +482 °C.

NSA5402 : Bolt – 100° CSK head, repair size dia. 1/32 torque-set, Rc min. = 910 Mpa

up to +482 °C.

NSA5403 : Bolt – 12-point head, Rc. = 1 076 Mpa min., repair size dia. 1/64, alloy

steel.

NSA5404 : Bolt – 12-point head, Rc. = 1 076 Mpa min., repair size dia. 1/32, alloy

steel.

NSA5412 : Rivets, 100° countersunk head Aluminium alloy.

NSA5413 : Flat round head, Aluminium alloy.

NSA5414 : Monel rivets 100° CSK small head.

NSA5415 : Rivet – Monel reduced flat head.

NSA5435 : Rivet – Monel, metal, oversize, thin 100° countersunk head.

NSA5444 : Rivet – Monel, oversize, mushroom head.

NSA5452 : Bolt – 100° CSK head, with torque-set recess, Rc min. = 910 Mpa up to

+232 °C.

NSA5453 : Bolt – Dodecagonal, Rc = 910 Mpa.

NSA5468 : Fastener – Hi-lok, countersunk head, oversize diameter +1/64.

NSA5469 : Fastener – Hi-lok, countersunk head, oversize diameter +1/32.

NSA5488 : Bolt – Taper-lok, medium head, 100° CSK, 2nd oversize.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 7

NSA8145 : Bush – Self-lubricated, steel.

NSA8147 : Bearing – Journal, flanged, self-lubricating, steel.

NSA8195 : Bush – Shouldered, self-lubricated, oversize.

3 - SOLID RIVET

3.1 - General

The necessity of an over-sizing can result of two types of anomalies:

- Bores out of tolerance

- Removal of badly installed solid rivets

Defective solid rivets shall be removed by drilling in such a way that the hole and countersink are not

damaged.

The removal of installed solid rivets must be avoided if possible (ADET0078 to be consulted for the

acceptance criteria of riveting failures) to avoid to decrease by over-sizing the d/Φ

edge/diameter) and e/ Φ ratio (sheet thickness/diameter) and therefore to avoid parts deforming.

3.1.1 - Bores out of tolerance

Requires a reboring to the next larger size.

3.1.2 - Removal of badly installed solid rivets

The necessity of an over-sizing depends on the bore quality after removal;

1° - The tolerance of the hole and countersink has to be in accordance with the ADET0078.

AND

2° - Little damage to bore (no visual grooves or cracks):

The installation of solid rivet initially specified in bore presenting no visual damage is possible only if the

bore presents neither grooves nor cracks.

There is no limitation in number of reworked bores when the two requirements above are met.

If the bore is damaged, a reboring is essential and involves an over-sizing.

3.2 - General rules

Automatic installation:

- If a solid rivet automatically installed has to be replaced, the tolerance for “automatic hole installation”

indicated in the ADET0078 has to be used, even if the solid rivet will be manually (or automatically) installed

for repair.

The tolerance for the bore is linked to the nominal application.

Manually installation:

- If a solid rivet manually installed has to be replaced, the tolerance for “manual hole installation” indicated

in the ADET0078 has to be used. The solid rivet will be manually installed.

The tolerance for the bore is linked to the nominal application.

In case of insufficient distance from edge, the design office has to be consulted.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 8

3.3 – Material of solid rivet

- Solid rivets in 7050 aluminium class initially installed in automatic must be replaced by the same material

for repair whatever installation mode (manual or automatic), until the diameter 4,8mm and associated

oversize.

- Solid rivet in 2017A-T4 aluminum class (in delivery condition) initially installed in automatic or manual

must be replaced by the same material for repair whatever installation mode (manual or automatic), until

the diameter 4,8mm and associated oversize.

3.4 – Restriction

Solid rivet installation has to be stopped when causes of defects are not clearly identified.

The acceptable defects described in ADET0078 chapter 7 are limited to:

- The maximum number of solid rivets installed with acceptable defects shall not exceed 5% of the

total solid rivets installed on the frame or on the assembled part (junction).

- Solid rivets installed with acceptable defects shall not be adjacent: a minimum of five solid rivets

free of defects shall separate two solid rivets with acceptable defects.

The design office has to be consulted in any other case.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 9

3.5 - General case

SOLID RIVETS IN ALUMINIUM ALLOY TITANIUM OR NICKEL-

OUT OF PRIMARY IN PRIMARY COPPER ALLOY (MONEL)

STRUCTURE STRUCTURE SOLID RIVETS

Removal of solid rivets - Solid rivets in

non-damaged bores aluminium alloy of - Solid rivets in nickel-copper

out of tolerance - Solid rivets in aluminium alloy same type and alloy (monel) or titanium of

up to Ø + 0,3 mm of same type and diameter. material, with same type and diameter.

(Ø = solid rivet - No reboring. diameter

diameter) without immediately larger. - No reboring.

either groove or crack - Existence of solid

New bores out of - Solid rivets in aluminium alloy rivets in aluminium - Solid rivets in nickel-copper

tolerance of same type and diameter for intermediate alloy (monel) or titanium of

immediately larger. diameters same type and of diameter

Removal of solid rivets - Existence of solid rivets in (oversize): 2,8 and immediately larger.

damaged bores aluminium for intermediate 4,4mm (NAS1241,

diameter (oversize): 2,8 and NSA1242, - Existence of solid rivets in

4,4 mm (NAS1241, EN6069, EN6080, nickel-copper alloy (monel) of

NAS1242, EN6069, EN6080, EN6081, EN6101). intermediate diameter: 2,8 and

EN6081, EN6101). 4,4 mm (NSA5435, NSA5444).

Table 1

3.6 - Special case

Solid rivets with large diameter

When the oversizing rules mentioned above lead to exceed the installation limits, solid rivets should be

replaced by bolts in accordance with table hereafter.

SOLID RIVETS SOLID RIVETS TO BE REPLACED BY

PARTS

SPECIFIED ON

MATERIAL BOLT NUT FIT

DRAWING

Titanium or nickel-copper Aluminium alloy Hi-lite or bull-nose Steel

Interference

alloy (monel) Ø 4,8 Steel or titanium Ø 4,8 R1 Steel Clearance

Hi-lite or bull-nose

Ø 5,6

Ø 6,35

Clearance

Aluminium Hi-lite or bull-nose Aluminium

alloy

Ø 6,4 Aluminium alloy

Ø 6,35 R1 alloy or steel

Clearance

Hi-lite or bull-nose

Ø 7,9 Ø 7,92 R1

Clearance

Table 2

Height interference as per NSA2012.

Small clearance with small interference as per NSA2010, NSA2012.

Automatic installation or by C rivet as per NSA2012.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 10

3.7 - Slugs

A slug may be replaced by multi-punch rivet in the following conditions:

- Not more than 2 consecutive solid rivets.

- Not more than 5 % solid rivets at a junction.

If these conditions are not respected, replace slugs with HI-LITE installed with high interference.

(Bolt EN6114K and EN6115K, nuts ASNA2528 or ASNA2529).

3.8 - Non magnetic areas

In the non-magnetic areas, it is not possible to use nickel-copper alloy (monel) solid rivets or steel bolts.

Consequently, titanium solid rivets must mandatory be replaced by titanium solid rivets.

For repairs of 4,8 mm diameter, use either 5,6 mm diameter titanium rivets or 5,2mm and 5,6mm diameter

CRES repair bolts. In this last case, see important note (§ 3 – Nut to be used).

4 - BOLTS AND COLLARS OVERSIZING

4.1 - General

Three repair levels:

-Diameter + 1/64 (R1 or X): All bolts of a same junction can be replaced with no

agreement requested.

-Diameter + 1/32 (R2 or Y): With agreement request, which can be changed under

concession, as required.

-Diameter + 1/16 (only for Hi-lite and Pull In bolts from 15,9 mm diameter) (R3 or Z):

With agreement request, which can be changed under concession, as required.

If R3 or Z is not available, switch over to next larger diameter: Under concession.

Tapered threaded pins: 2 levels (see NSA5329).

In case of material change between nominal and oversize, an agreement from Materials and Processes

and stress department is mandatory for restricted temperature range area (ex: pylon).

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 11

4.2 - Nuts to be used

During switch over to over-sizes R1, R2 and R3, it is necessary to take into account the nut’s capacity to

absorb the increase in the bolt shank diameter. The condition differs according to the type of nut and bolt

initially foreseen.

1)The use of HI-LOK BULL-NOSE nuts and bolts systematically imposes using washers (see ADET0029).

2) For repair, lock-bolts systems shall be replaced by hi-lites with steel nuts in accordance with :

a. ADET0030 in term of nature of nuts,

b. ABD0078 in term of coatings.

3)For repair, taper lock and taper hi-lite systems shall be installed with ASNA2532 steel nuts.

4.3 - Nuts without counterbore

Switch over to over-sizes does not affect the type of nut to be used or the thickness of the washers normally

foreseen.

4.4 - Nuts with counterbore

In this case, it is necessary to take into account the counterbore diameter of the nut which can not absorb

the oversize bolt shank diameter.

Generally speaking, if the nut initially foreseen cannot be mounted, it is necessary to mount a nut with

identical material and finish.

The counterbore of nuts NAS1726, NAS1727, NSA5050, ASNA2531 and ASNA2532 does not

accommodate for oversize bolts R2 (Y) and R3 (Z); however, these nuts can be mounted on R2 (Y) and

R3 (Z) bolts using washer with 1,6 thickness 3,2 mm.

The Inconel nut ABS1831 accommodates the oversize bolt (X,Y) ABS1830.

4.5 - Captive nuts

Except otherwise specified (NAS1473 or 1474), the counterbore diameter of captive nuts is not compatible

with the oversize bolt shank diameter. In this case, it is necessary to choose a bolt length code number that

avoids all contact of the shank end with the nut seating.

4.6 - Washers under nuts

In the case when finished bolt system is used, and for economical purposes, the Design Office tolerates

that only one length code number is supplied out of two; in this case, installation of an additional washer is

admitted. Its definition is as follows:

- Types: NSA5368 or NSA5372.

- Material, thickness: See ADET0029.

More generally, please refer to ADET0029 for the use of washers (requirement, material and thickness).

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: U

Page: 12

4.7 - Blind bolts

Blind bolts shall be generally repaired by next nominal diameter. However oversize exists see table 3.

4.8 - Other requirements

The oversize bolt adjustment (clearance or interference) is the same as that of the nominal size bolt

provided in the plan; tolerances are given in NSA2012.

In the case of the blank system out, the finished bolt to be manufactured is that in the column adjacent

to the blank column in the tables hereafter.

Anti-corrosion installation conditions are those given in the definition documents of the areas under

consideration.

Tightening torques: see NSA2017, as per ADET0030, the oversize bolts shall be tightened with the

same tightening torque than the bolt indicated in Tables 3 and 4 in the column “Torque for oversize

same as”.

Production of bolts and nuts and threaded axes in our workshops as per ADET0034.

Inspection after installation: Refer ADET0059 and ABS1762 to identify the requirements.

4.9 - Tables of oversize bolts to be used

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 13

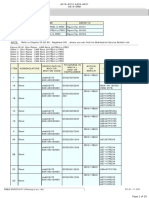

Table 3 – General case

Original bolt Oversize bolt Torque for Associated Washer to be used Observations

Type Shape Standard R1 (X) R2 (Y) R3 (Z) oversize same as nut (1) under nut (or collar) Installation instructions

NSA5040V EN6114TX EN6114TY (4) EN6114TZ(3) EN6114T

Hi-lok

COUNTERSUNK HEAD NSA5040 NSA5468 (2) NSA5469 (2) - NSA5040

NSA5040C NSA5468C (2) NSA5469C (2) - NSA5040C

ASNA2003V EN6114VX EN6114VY (4) EN6114VZ (3) EN6114V

Hi-lok NSA5041V EN6115KX EN6115KY (4) EN6115KZ(3)- EN6115K

PROTRUDING HEAD

NSA5041 EN6115-X EN6115-Y (4) EN6115-Z(3)- EN6115-

Hi-lok ASNA2004V EN6115TX EN6115TY (4) EN6115TZ(3) EN6115T

Hi-lok bull nose NSA5350 - - - -

COUNTERSUNK HEAD

NSA5350V NSA5356 (2) NSA5358 (2) - NSA5356/58

ASNA2008V EN6114TX EN6114TY (4) EN6114TZ(3) EN6114T

Hi-lok bull nose NSA5351- EN6115-X EN6115-Y (4) EN6115-Z(3) EN6115-

PROTRUDING HEAD NSA5351V EN6115TX EN6115TY (4) EN6115TZ(3) EN6115T NSA5368 or NSA5372

See

NSA5331V NSA5357 NSA5359 - NSA5357/59 Use the same ADET0029

nut as for ADET0059

ASNA2009V EN6115TX EN6115TY (4) EN6115TZ(3) EN6115T For R3 from Dash 10:

original bolt ADET0077

possibility to use

ASNA2026- EN6114-X EN6114-Y (4) EN6114-Z (3) EN6114- and § 4.2

DHS781 to 783

ASNA2026K EN6114KX EN6114KY (4) EN6114KZ (3) EN6114K

ASNA2026V EN6114VX EN6114VY (4) EN6114VZ (3) EN6114V

ASNA2026T EN6114TX EN6114TY (4) EN6114TZ (3) EN6114T

EN6114- EN6114-X EN6114-Y (4) EN6114-Z (3) EN6114-

Hi-lite EN6114K EN6114KX EN6114KY (4) EN6114KZ (3) EN6114K

COUNTERSUNK HEAD EN6114V EN6114VX EN6114VY (4) EN6114VZ (3) EN6114V

EN6114T EN6114TX EN6114TY (4) EN6114TZ (3) EN6114T

Hi-lite

EN6114L EN6114LX EN6114LY (4) EN6114LZ (3) EN6114L

EN6114M EN6114MX EN6114MY (4) EN6114MZ (3) EN6114M

EN6114B EN6114BX EN6114BY (4) EN6114BZ (3) EN6114B

ASNA2657V ASNA2657VX ASNA2657VY - ASNA2657V

ASNA2657K ASNA2657KX ASNA2657KY - ASNA2657K

ASNA2657T ASNA2657TX ASNA2657TY - ASNA2657T

ASNA2001V ASNA2001VX ASNA2001VY - ASNA2001V

ASNA2352T ASNA2001TX ASNA2001TY - ASNA2001T

(Standards continued on page 14)

(1) In case of non availability of the original nut, alternatives can be used according to F00713009.

(2) To be used as long as supplies last, after see table 4.

(3) R3 from Dash 10, below Dash 10 used the upper diameter for Z. Dash 3AX is the third oversize of Dash 3.

(5) Dash 3A is the second oversize of Dash 3.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 14

Table 3 – (Standards continued from page 13)

Original bolt Oversize bolt Torque for Associated Washer to be used Observations

Type Shape Standard R1 (X) R2 (Y) R3 (Z) oversize same as nut (1) under nut (or collar) Installation instructions

ASNA2027- EN6115-X EN6115-Y (5) EN6115-Z (3) EN6115-

ASNA2027K EN6115KX EN6115KY (5) EN6115KZ (3) EN6115K

ASNA2027V EN6115VX EN6115VY (5) EN6115VZ (3) EN6115V

ASNA2027T EN6115TX EN6115TY (5) EN6115TZ (3) EN6115T

EN6115- EN6115-X EN6115-Y (5) EN6115-Z (3) EN6115-

Hi-lite EN6115K EN6115KX EN6115KY (5) EN6115KZ (3) EN6115K

PROTRUDING HEAD EN6115V EN6115VX EN6115VY (5) EN6115VZ (3) EN6115V

NSA5368 or NSA5372

EN6115T EN6115TX EN6115TY (5) EN6115TZ (3) EN6115T See

Hi-lite Use the

EN6115L EN6115LX EN6115LY (5) EN6115LZ (3) EN6115L ADET0029

EN6115M EN6115MX EN6115MY (5) EN6115MZ (3) EN6115M same nut as

For EN6114 and ADET0059

EN6115P EN6115PX EN6115PY (5) EN6115PZ (3) EN6115P for original

EN6115 R3 from Dash ADET0077

EN6115B EN6115BX EN6115BY (5) EN6115BZ (3) EN6115B bolt

10: possibility to use and § 4.2

ABS0876K ABS0876KX ABS0876KY ABS0876KZ (3) ABS0876K DHS781 to 783

ABS0876L ABS0876LX ABS0876LY ABS0876LZ (3) ABS0876L

ABS0907K ABS0907KX ABS0907KY Not applicable ABS0907K

ABS0925K ABS0925KX ABS0925KY Not applicable ABS0925K

Hi-lite ABS0997K ABS0997KX ABS0997KY ABS0997KZ ABS0997K

Hi-lite PROTRUDING ROUND

HEAD ABS0997L ABS0997LX ABS0997LY ABS0997LZ ABS0997L

Taper lok NSA5488VxTxC

NSA5092 NSA5153V (2) - NSA5153V

COUNTERSUNK HEAD A(2)

NSA5488VxRxN

Taper lok ASNA2012V NSA5153VA (2) - NSA5153VA See ADET0188 and § 4.2

(2)

NSA5488VxKxC

ASNA2012K NSA5153K (2) - NSA5153K

A(2)

Taper Hi-lite ABS1418K ABS1418KX ABS1418KY - ABS1418K Use

COUNTERSUNK HEAD NSA5368X or

Taper ASNA2532- See

ABS1418V ABS1418VX ABS1418VY - ABS1418V NSA5372X

Hi-lite (4) AIPS01-02-002 and § 4.2

ABS1418- ABS1418-X ABS1418-Y - ABS1418-

Taper lok NSA5093V NSA5154V (2) - - NSA5154V

PROTRUDING HEAD

Taper lok ASNA2013V NSA5154VA (2) - - NSA5154VA See ADET0188 and § 4.2

ASNA2013K NSA5154K (2) - - ASNA2013K

(Standards continued on page 15)

(1) In case non-availability of original nut, alternatives can be used according to F00713009.

(2) To be used as long as supplies last, after see table 4.

(3) R3 from Dash 10, below Dash 10 used the upper diameter for Z. Dash 3AX is the third oversize of Dash 3.

(4) In some specific cases, others nuts can be used according to X51D06008986.

(5) Dash 3A is the second oversize of Dash 3.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 15

Table 3 – (Standards continued from page 14)

Original bolt Oversize bolt Torque for Washer to be Observations

Associated nut

oversize same as used under nut Installation

Type Shape Standard R1 (X) R2 (Y) R3 (Z) (1)

(or collar) instructions

Taper Hi-lite ABS0889- ABS0889-X ABS0889-Y - ABS0889- See

Taper PROTRUDING HEAD Use ASNA2532- NSA5368X or

AIPS01-02-002

Hi-lite ABS0889K ABS0889KX ABS0889KY - ABS0889K (4) NSA5372X

and § 4.2

Lockbolt GP

NAS1151E to

COUNTERSUNK HEAD ASNA2040C ASNA2314C ASNA2315C -

1158E

ASNA2040- ASNA2314- ASNA2315- - NAS1151 to 1158 See

Use NSA5050

ADET0029

NAS1131E to nut and

ASNA2316C (2) ASNA2317C (2) - NSA5368 or ADET0059

Lockbolt NAS1138E requirement

ASNA2054C NSA5372 ADET0077

Lockbolt GP NAS6303X to NAS6303Y to NAS6303 to according to §

- ADET0030

PROTRUDING HEAD 6320X 6320Y NAS6320 4.2

and see § 4.2

NAS1131- to

ASNA2316 (2) ASNA2317 (2) -

NAS1138-

ASNA2054-

NAS6703X to NAS6703Y to NAS6703 to

-

NAS6720X NAS6720Y NAS6720

ASNA2043- ASNA2657VX ASNA2657VY - ASNA2657V Use

Lockbolt LGP ASNA2528 or

ASNA2043A ASNA2657TX ASNA2657TY - ASNA2657T ASNA2529 and

COUNTERSUNK HEAD NSA5368 or

requirement

NSA5372 See

ASNA2043HK ASNA2657KX ASNA2657KY - ASNA2657K according to

ADET0029

§4.2

ADET0059

Lockbolt EN6050A ASNA2657VX ASNA2657VY - ASNA2657V Use

For R3 from Dash ADET0077

ASNA2048- EN6115VX EN6115VY (5) EN6115VZ(3) EN6115V ASNA2531-, or

10: possibility to ADET0030

Lockbolt LGP ASNA2532-, or

ASNA2048A EN6115TX EN6115TY (5) EN6115TZ(3) EN6115T use DHS781 to and see § 4.2

PROTRUDING HEAD ASNA2536 nut

783

ASNA2048HK EN6115KX EN6115KY (5) EN6115KZ(3) EN6115K and requirement

according to §

ABS0269- EN6115KX EN6115KY (5) EN6115KZ(3) EN6115K 4.2

(Standards continued on page 16)

(1) In case non availability of original nut, alternatives can be used according to F00713009.

(2) To be used as long as Airbus France stocks last, after see table 4.

(3) R3 from Dash 10, below Dash 10 used the upper diameter for Z. Dash 3AX is the third oversize of Dash 3.

(4) In some specific case, others nuts can be used according to X51D06008986.

(5) Dash 3A is the second oversize of Dash 3.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 16

Table 3 – (Standards continued from page 15)

Original bolt Oversize bolt Torque for Observations

Associated Washer to be used

oversize same as Installation

Type Shape Standard R1 (X) R2 (Y) R3 (Z) nut (1) under nut (or collar)

instructions

Lockbolt XPL ABS1506V EN6115VX EN6115VY (3) EN6115VZ (2) EN6115V

PROTRUDING HEAD ABS1506K rep 3

ABS0907KX ABS0907KY ABS0907KZ (2) ABS0907K

to 9

ABS1506K rep 9

ABS0876KX ABS0876KY ABS0876KZ (2) ABS0876K

to 16

ABS1506T EN6115TX EN6115TY (3) EN6115TZ (2) EN6115T

ABS0998T EN6115TX EN6115TY (3) EN6115TZ (2) EN6115T

Use

ABS0998V EN6115VX EN6115VY (3) EN6115VZ (2) EN6115V ASNA2531-,

ABS0998K EN6115KX EN6115KY (3) EN6115KZ (2) EN6115K or NSA5368 or NSA5372 See

Lockbolt XPL ABS0995V EN6114VX EN6114VY (3) EN6114VZ (2) EN6114V ASNA2532-, ADET0029

COUNTERSUNK HEAD or ADET0059

Lockbolt ABS0995K EN6114KX EN6114KY (3) EN6114KZ (2) EN6114K ASNA2536 For R3 from Dash 10: ADET0077

ABS0995T EN6114TX EN6114TY (3) EN6114TZ (2) EN6114T nut and possibility to use ADET0030

requirement DHS781 to 783 and see § 4.2

ABS1504V - - - - according to

ABS1504K - - - - § 4.2

ABS1504T ASNA2001TX ASNA2001TY - ASNA2001T

ABS1720V EN6114VX EN6114VY (3) EN6114VZ (2) EN6114V

ABS1720K EN6114KX EN6114KY (3) EN6114KZ (2) EN6114K

ABS1720T EN6114TX EN6114TY (3) EN6114TZ (2) EN6114T

Lockbolt Huckcomp Use

PROTRUDING HEAD ASNA2531-,

ASNA2042 EN6115TX EN6115TY (3) EN6115TZ (2) EN6115T or

ASNA2532-, NSA5368 or NSA5372 See

or ADET0029

Lockbolt Huckcomp ASNA2041 ABS0873X ABS0873Y - ABS0873 ASNA2536 ADET0059

Lockbolt

COUNTERSUNK HEAD nut and For R3 from Dash 10: ADET0077

NAS1151E to requirement possibility to use ADET0030

ABS0094 ASNA2314C ASNA2315C -

1158E according to DHS781 to 783 and see § 4.2

ABS0095- EN6114TX EN6114TY (3) EN6114TZ (2) EN6114T § 4.2Use

steel nut as

ABS0095V EN6114VX EN6114VY (3) EN6114VZ (2) EN6114V per § 4.2

(Standards continued on page 17)

(1) In case non availability of original nut, alternatives can be used according to F00713009.

(2) R3 from Dash 10, below Dash 10 used the upper diameter for Z. Dash 3AX is the third oversize of Dash 3.

(3) Dash 3A is the second oversize of Dash 3.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 17

Table 3 - (Standards continued from page 16)

Original bolt Oversize bolt Torque for Washer to be used Observations

Associated

oversize same as under nut (or Installation

Type Shape Standard R1 (X) R2 (Y) R3 (Z) nut (1)

collar) instructions

Lockbolt LGP ASNA2391 EN6114VX EN6114VY (3) EN6114VZ (2) EN6114V

COUNTERSUNK HEAD

ABS0548VHK EN6114KX EN6114KY (3) EN6114KZ (2) EN6114K

Use

ABS0550VHK EN6114KX EN6114KY (3) EN6114KZ (2) EN6114K ASNA2531-, or

Lockbolt LGP ASNA2532-, or

PROTRUDING HEAD ASNA2392 EN6115VX EN6115VY (3) - EN6115V

ASNA2536 or NSA5368

See

and NSA5372

ABS0549VHK EN6115KX EN6115KY (3) EN6115KZ (2) EN6115K ADET0029

ASNA2528 (4)

ADET0059

Lockbolt or

Lockbolt LGPL Alu. ADET0077

ASNA2529 (4) For R3 from Dash

COUNTERSUNK HEAD ADET0030

EN6100 EN6114VX EN6114VY (3) EN6114VZ (2) EN6114V 10: possibility to use

and see § 4.2

nut and DHS781 to 783

requirement

Lockbolt LGPL Alu. according to

PROTRUDING HEAD § 4.2

EN6120 EN6115VX EN6115VY (3) EN6115VZ (2) EN6115V

(Standards continued on page 18)

(1) In case non availability of original nut, alternatives can be used according to F00713009.

(2) R3 from Dash 10, below Dash 10 used the upper diameter for Z. Dash 3AX is the third oversize of Dash 3.

(3) EN6114 and EN6115 Dash 3A is the second oversize of Dash 3. ASNA2391 and ASNA2392 dash 3 can be repaired by ASNA2391 Dash 3A and ASNA2392 Dash 3A respectively.

(4) Use ASNA2528 / ASNA2529 only for repair of ASNA2391 and ASNA2392. Do not use for repair of Lockbolts with Ti-collars.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 18

Table 3 - (Standards continued from page 17)

Original bolt Oversize bolt Washer to be used Observations Installation

Associated nut

Type Shape Standard R1 (X) R2 (Y) R3 (Z) under nut (or collar) instructions

Visu-Lok, Jo.Lok

COUNTERSUNK HEAD ASNA0081A rep

NAS1672 - -

3&4

Visu-Lok, Jo.Lok

PROTRUDING HEAD ASNA0082A rep

NAS1671 - -

3&4

Cherrymax,

Huckclinch, All max

COUNTERSUNK HEAD

ASNA0077 ASNA0077X - -

See

Blind bolt Cherrymax, N/A N/A ADET0134

Huckclinch, All max And see § 4.4

PROTRUDING HEAD

ASNA0078 ASNA0078X - -

Huck MLS

PROTRUDING HEAD NAS1919M ASNA0129 - -

NAS1919M. W ASNA0129C - -

Huck MLS

COUNTERSUNK HEAD NAS1921M ASNA0130 - -

NAS1921M. W ASNA0130C - -

(Standards continued on page 19)

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Table 3 - (Standards continued from page 18) Page: 19

Original bolt Oversize bolt Torque for Associated Washer to be used Observations Installation

Type Shape Standard R1 (X) R2 (Y) R3 (Z) oversize same as nut (1) under nut (or collar) instructions

Countersunk NAS1151VA to

- - - -

(CSK) bolt NAS1158VA

ASNA2315C 5 NAS1151E to

NAS1151V to ASNA2314C (2) (2) -

1158E

NAS1158V

ASNA2001TX ASNA2001TY - ASNA2001T

NAS1151E to

NAS1151 to ASNA2314 (2) ASNA2315 (2) -

1158E

NAS1158

ASNA2001VX ASNA2001VY - ASNA2001V

NAS1151E to Use the

NAS1151E to ASNA2314C (2) ASNA2315C (2) - NSA5368 or NSA5372

1158E same nut as

NAS1158E Code E Mandatory

ASNA2001TX ASNA2001TY - ASNA2001T for original

CRES washer

CSK NAS1151EP to bolt

ASNA2001VX ASNA2001VY - ASNA2001V

bolt NAS1158EP

ASNA2001V ASNA2001VX ASNA2001VY - ASNA2001V

ASNA2001T ASNA2001TX ASNA2001TY - ASNA2001T

NSA5168* NSA5401* NSA5402* - NSA5168

NSA5452* ASNA2060* ASNA2062* - NSA5452

ASNA0092- ASNA0095 ASNA0097 - ASNA0092

ASNA0092P ASNA0095P ASNA0097P - ASNA0092P

ASNA0124 ASNA0141 ASNA0142 - ASNA0124 ADET0029

CSK bolt Use the ADET0059

ABS0950V ABS0950VX ABS0950VY - ABS0950V

same nut as ADET0077

NSA5368 or NSA5372 and § 4.2

for original

NAS7503U NAS7503UX NAS7503UY - NAS7503U bolt

Round head bolt NAS1133V to NAS1133E to

ASNA2316C ASNA2317C -

NAS1138V NAS1138E

NAS1131VA to

- - - -

NAS1138VA

NAS1131 to NAS1131 to Use the

ASNA2316 ASNA2317 -

Round head NAS1138 NAS1138 same nut as

NSA5368 or NSA5372

bolt NAS1131 to for original

ASNA2016V ASNA2316 ASNA2317 - bolt

NAS1138

NAS1133E to

ASNA2016T ASNA2316C ASNA2317C -

NAS1138E

NAS1131E to NAS1133E to

ASNA2316C ASNA2317C

NAS1138E NAS1138E

Shouldered bolt NSA5042- NSA5118- NSA5119- - NSA5042

NSA5042C NSA5118C NSA5119C - NSA5042C Use the

Shouldered NSA5042E NSA5118E NSA5119E - NSA5042E same nut as

NSA5368 or NSA5372

bolt NSA5042A NSA5118A NSA5119A - NSA5042A for original

NSA5042T NSA5118T NSA5119T - NSA5042T bolt

NSA5042V NSA5118V NSA5119V - NSA5042V

(Standards continued on page 20)

(1) In case non availability of original nut, alternatives can be used according to F00713009.

(2) To be used only in case of temperature restriction not permitting usage of titanium bolt. If area not subjected to temperature, see table 4.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 20

Table 3 – (Standards continued from page 19)

Original bolt Oversize bolt Torque for Observations

Associated Washer to be used

oversize same as Installation

Type Shape Standard R1 (X) R2 (Y) R3 (Z) nut (1) under nut (or collar)

instructions

Hexagonal head bolt NAS6403 to

ABS0114TX ABS0114TY - ABS0114T

NAS6420

NAS1303 to

ASNA2318 ASNA2319 -

NAS1320

ASNA2000 ASNA2318 ASNA2319 -

Use the same

ABS0114- ABS0114-X ABS0114-Y - ABS0114-

Head bolt nut as for NSA5368 to NSA5372

ABS0114V ABS0114VX ABS0114VY - ABS0114V

original bolt

ABS0114T ABS0114TX ABS0114TY - ABS0114T

ADET0029

NAS6603 to NAS6603X to NAS6603Y to NAS6603 to

- ADET0059

NAS6620 6620X 6620Y NAS6620

ADET0077

NAS6703 to NAS6703X to NAS6703Y to NAS6703 to

- and § 4.2

NAS6720 6720X 6720Y NAS6720

Bi-hexagonal shear bolt NSA5170 NSA5403 NSA5404 - NSA5170 NSA5368 or NSA5372

NSA5172 NSA5403 NSA5404 - NSA5172 Code E

NSA5453 ASNA2061 ASNA2063 - NSA5453 Use the same NSA5368 or

Shear bolt ASNA0093 ASNA0096 ASNA0098 - ASNA0093 nut as for NSA5372, Code E or

ASNA0093P ASNA0096P ASNA0098P - ASNA0093P original bolt EW

NSA5368 or NSA5372

ASNA0123 ASNA0139 ASNA0140 - ASNA0123

Code E

Original bolt Oversize bolt Torque for Associated To be used washer Observation

oversize same as nut (1) (or collar) Installation

Type Shape Standard Under Under instructions

R1 (X) R2 (Y) R3 (Z)

nut head

Bi-hexagonal tension bolt Use

NASM21250 NSA5398A NSA5399A - NSA5378A ASNA0094- or NSA5368 or

NSA5373A NSA5372, Mandatory

NASM21250 BSA228X BSA228Y - NASM21250 Code E or EW CRES washer

NSA5378A NSA5398A NSA5399A - NSA5378A See

ASNA2394 ADET0085

NSA5378 NSA5398 NSA5399 - NSA5378 Use the same NSA5368 or

Tension nut as for NSA5372 Code

bolt ASNA0122 NSA5398 NSA5399 - NSA5378 original bolt E

ABS0927 - - - -

ABS0927A - - - -

NASM21250 ABS1830M (X) ABS1830M (Y) - NASM21250

ASNA2394

NSA5378A ABS1830M (X) ABS1830M (Y) - NSA5378A Washer not

ABS1831 or

NSA5378 ABS1830P (X) ABS1830P (Y) - NSA5378 necessary

NSA5379

ABS1830 ABS1830 (X) ABS1830 (Y) ABS1830

(End)

(1) In case non availability of original nut, alternatives can be used according to F00713009.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Note: When using a blank for manufacturing a replacement bolt in compliance with A/DET0034, the shape of the bolt produced must be the same as the shape of the original finished bolt. Page: 21

- Two non-conformities are tolerated: a. Protruding head: H-head allowed in place of cylindrical head. b. Recess on thread side: Slot allowed in place of hexagonal recess.

Table 4 – Particular case

Original bolt Oversize bolt Torque for Observations

Associated Washer to be used

oversize same as Installation

Type Shape Standard R1 (X) R2 (Y) R3 (Z) nut (1) under nut (or collar)

instructions

Hi-lok

NSA5040V EN6114X EN6114Y EN6114Z(2) EN6114

COUNTERSUNK HEAD

NSA5040 EN6114X EN6114Y EN6114Z(2) EN6114

ASNA2003V EN6114X EN6114Y EN6114Z(2) EN6114

Hi-lok

PROTRUDING HEAD NSA5041V EN6115X EN6115Y EN6115Z(2) EN6115

NSA5368 or NSA5372 See

NSA5041 EN6115X EN6115Y EN6115Z(2) EN6115 Use the

ADET0029

same nut as

Hi-lok For R3 from Dash 10: ADET0059

Hi-lok bull nose NSA5350 EN6114X EN6114Y EN6114Z(2) EN6114 for original

possibility to use ADET0077

COUNTERSUNK HEAD bolt

NSA5350V EN6114X EN6114Y EN6114Z(2) EN6114 DHS781 to 783 and § 4.2

ASNA2008V EN6114X EN6114Y EN6114Z(2) EN6114

Hi-lok bull nose NSA5351- EN6115X EN6115Y EN6115Z(2) EN6115

PROTRUDING HEAD

NSA5331V EN6115X EN6115Y EN6115Z(2) EN6115

ASNA2009V EN6115X EN6115Y EN6115Z(2) EN6115

Taper Hi-lite ASNA2012V

Taper ABS1418VX ABS1418VY - ABS1418V See

COUNTERSUNK HEAD AIPS01-02-002

Hi-lite

ASNA2012K ABS1418KX ABS1418KY - ABS1418K and § 4.2

Use

NSA5368X or

Taper lok ASNA2013K ABS0889K ASNA2532-

ABS0889KX ABS0889KY - NSA5372X

PROTRUDING HEAD (3)

See ADET0188

Taper lok ASNA2013V ABS1418VX ABS1418VY - ABS1418V

and § 4.2

ASNA2012K ABS1418KX ABS1418KY - ABS1418K

CSK Countersunk NAS1151V to

ASNA2001TX ASNA2001TY - ASNA2001T Use the

bolt (CSK) bolt NAS1158V ADET0029

same nut as NSA5368 or NSA5372

NAS1151 to ADET0059

ASNA2001VX ASNA2001VY - ASNA2001V for original Code E Mandatory

NAS1158 ADET0077

bolt CRES washer

NAS1151E to and § 4.2

ASNA2001TX ASNA2001TY - ASNA2001T

NAS1158E

(1) In case non availability of original nut, alternatives can be used according to F00713009.

(2) R3 from Dash 10, below Dash 10 used the upper diameter for Z. Dash 3AX is the third oversize of Dash 3.

(3) In some specific case, others nuts can be used according to X51D06008986.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 22

4.10 – Non magnetic areas

In this case use CRES oversize nuts and bolts.

The use of CRES bolts and nuts in aluminium alloy structures may induce its corrosion by galvanic coupling;

this is why the following precautions should be observed:

- Wet installation of the CRES bolt.

- Heads bolts and nuts shall be painted.

IMPORTANT NOTE: Such precautions are furthermore imposed by the technical protection sheets specific

to each aircraft.

4.11 – Assemblies containing carbon

- Bolts:

In this case CRES oversize bolts are used.

- Nut:

Generally speaking, use CRES nuts.

Cadmium plated steel or aluminium alloy nuts are prohibited on carbon parts.

- Admitted nut with captive washer (See § 4.3):

Generally, type NSA5368 or NSA5372, material as per § 4.3.

- Precaution to be taken:

See important note in § 4.5.2.

5 - REPAIR BUSHINGS

5.1 – Bushings installed with tight fit (using press of liquid nitrogen)

These bushings, in most cases, flush on both surfaces (smooth bushings without shoulder) are intended to

protect the bores for removable parts.

They are in 35 NC6 (R = 112 to 123 hbars) or in the material of origin.

Examples:

- Bushings for mast shackles N 18

A-546 10071-204

A-546 10071-206

- Bushings for external fittings N 12 (mast)

A-546 10053-203

A-546 10053-204

- Bushings installed H 7 P 6 A-538.31.946 for gantry beam fitting installation.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 23

Definition of over-sizing or “repair sizes” is different according to whether it concerns:

- thin bushings e 1,5

- thick bushings e > 1,5

and whether the male element installed from the inside, will or will not have oversizing

possibilities.

5.2 – Over-sizing and “repair sizes” for bushings for bolts Ø 25,4

These bushings can tolerate a bore over-sizing of + 0,4.

For a second repair, it is necessary to change the bushing, replacing it by a repair bushing with external

over-sizing of 0,2 – 0,4 – 0,6 – 0,8 – 1 or 1,4 ; the two first levels being usable in manufacture without

concession, except where specified on the drawing.

The new bushing can tolerate an over-sizing of its bore allowing the possibility of further repair.

The tolerances of the bores corresponding to the oversized bushings shall be the same as for original

bushings.

To summarize, the following repairs may be carried out:

- internal reboring to + 04,

- replacement of the bushing

- internal reboring of the oversized bushing to + 0,4

- repair bushings NSA5124, 5333 and 5334

5.3 – Bushings “repair sizes” for bolts Ø > 25,4

These bushings can tolerate successive reborings of:

- first repair: + 0,4

- second repair: + 0,8

or undergo the instructions set out in paragraph 4.1.1 with an external over-sizing of the

bush of 2,4.

5.4 – Specific cases: large diameter thick bushings

This applies to bushings equipping the shackles of the mast. Two solutions can be envisaged:

Over-sizing: - internal

external

1st solution – Internal diameter (solution not recommended)

These bushings can tolerate several successive reborings of internal diameter:

+ 0,2 + 0,4 + 0,6 + 0,8

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 24

This repair type has the following disadvantages:

- Large diameter reboring difficult.

62H7 X 55H7 .................... for 10042

62H7 ........................... for 10053

- Creation of male repair elements corresponding to the different reborings.

2nd solution

Installation of bushings with external over-sizing and internal bore maintained at initial size.

While this repair type does not require any male oversized elements, on the other hand, it produces the

following difficulties:

- removal of a large diameter nitrogen shrunk-in bushing,

- H7 reboring of part,

- H6 or H7 reboring of the repair bushing after nitrogen shrink-in.

5.5 – Single attachment assembly without original bushing

Two repair levels for each bushing.

- For Ø < 12,7 2 bushings thickness: 0,6 and 0,8

- For 12,7 < Ø < 25,4 2 bushings thickness: 0,8 and 1

- For Ø > 25,4 2 bushings thickness: 1,2 and 1,5

For first repair level only, and for each of these blanks, no concession.

These repair bushings are taken from blanks NSA3530.

5.6 – Bushings installed with Loctite

Examples:

- Hinge bushing of Main Landing Gear

Plan No. A53831788A53831994

- LG drag strut attachment bushing

Plan No. A53831826

In the event of damage to the bore of these bushings, proceed to dismantling of these parts, either by

heating, or by impact, according to the grade of loc-tite used.

Four successive over-sizings are foreseen:

+ 0,2 + 0,4 + 0,6 + 0,8

Four repair levels and marking procedure acceptance, see the following paragraph, as well as for addition

of a stamp on the drawings.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 25

5.7 – Removable bushings and sockets

These are used, for example, for hinges and control of movable elements.

These bushings must be considered removable, even when the fit on the external diameter is of H 7 k6

quality.

Four successive over-sizings are foreseen:

+ 0,2 + 0,4 + 0,6 + 0,8

5.8 – Crimping bushings for roller bearings and ball joints

These are the NSA5100.

Over-sizing retained are as per NSA5114.

+ 0,2 + 0,4 + 0,6 + 0,8

5.9 – Self-lubricated bushings

These are bushings NSA8145 (smooth) and NSA8147 (shouldered).

The over-sizings retained are:

0,127 and 0,254

as per NSA8194 and NSA8195.

Installation with or without loc-tite, with or without interference.

5.10 – Repair bushing marking

They are identified by one, two, three or four notches according to whether they are assigned to the first,

second, third or fourth repair level.

Identification of oversized bore bushings shall be made using two grooves in X shape.

These notches shall be underlined by a mark of black paint to make them easily seen.

The procedure will be carried out:

- for shoulder bushings, on the shoulder section.

- for smooth bushings, on the end section.

5.11 – Indications to be used on drawings

The different assemblies will be identified in a table giving acceptable repair levels with ring identification

and corresponding bore (see ASN-D0001-013).

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 26

AMENDMENT RECORD SHEET

Modified

Issue Modification summary Justification

paragraph

A.03.85

B.01.86 Bolts and nuts over-sizing paragraph entirely

amended.

C.04.86 Page 4 In paragraph 3.1: Diameter + 1/32: changed Made conform to

“With waiver” by “With agreement request, which IQ.DA 14.04

can be changed into a waiver, as required”.

D.06.86 Page 10 Added : ASN-A2026TX and TY ATR 72

ASNA2027TX and TY

ASNA2001TX and TY

ABS 0114TX and TY

ASNA2352

ASNA2358TX and TY

E.02.87 3.5.1 For tension bolt added associated nut ASN- No item code No. 6 on

A0094. NSA5373

F.03.87 3.5.3 For ASNA2026T and 2027T, sizes R1 and R2

become NSA5356T, NSA5358T and NSA5357T,

NSA5359T.

4.1.2 Paragraph 3.1 now reads 4.1.1.

G.01.88 3.5.2 Code C added. Internal memo.

3.5.3 Jro/RCz/JB531/032/88

H.07.88 3.5.1 Bolt castings deleted for BULL NOSE and HI- Note 437.156/88

3.5.2 LITE.

3.5.3

3.5.1 Note added.

J.12.89 3.2.2.1 Nuts ASNA2028-2029-2031-2036-2032-2038 DMJ 168035

replaced by ASNA2528-2529-2531-2536-2532

and 2538.

3.5.3 ASNA2701 and 2702 added.

3.5.1 IF.To 980, ABS0548 and ABS0549 added.

NSA5042 “C” and “E”, NSA5118 and NSA5119

“C” and “E” added. NAS6603 to 6620 added.

3.5.2 IF.To 852 added.

Note: Modification to the last standard issue are indicated by a vertical

line in the margin.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 27

AMENDMENT RECORD SHEET

Modified

Issue Modification summary Justification

paragraph

K.11.90 Amended standard. A/DET/CG request

§ 2 and § 3.5.3 modified.

L.02.03 ASNA2657 added in chapters 3.5.2 and 3.5.3.

437.121/88 changed to 437.156/88 in column Following mistake

“justification” for issue H.

M.10.03 Standard fully amended. Update

N.12.04 Oversize bolt R3 added. A380

EN 6080 added in Table 1.

ASNA2048 added for “Lockbolt LGP” in Table 4.

Over-sizing from ASNA to ABS and ABS to NSA

for taper-locks added.

Nuts ASNA2531 and ASNA2532 added.

To reduce washer’s references, use of

NSA5372X and NSA5368X.

P.05.06 Standard updated with:

- New tables including all the assemblies to be

used (bolts and nuts),

- New possibilities of repair for lockbolts,

- New instructions for taper-lock and taper-lite,

- New instructions for tension assembly.

Q.03.07 2 Update of standard list Update

3.1 Solid rivets over-sizing paragraph entirely

modified.

4.4 Blind bolts over-sizing paragraph added.

4.6 Table 3 updated with:

- Lockbolt ABS0998T, K or V with protruding

head and oversize bolt EN6115T, K or V modified

- Nuts ASNA0094- and NSA5373A added for

NASM21250

- Lockbolt ABS0550VHK, ASNA2041,

ASNA2042, ABS0094, ABS0095, ABS0269,

ABS1720 added

Note: Modification to the last standard issue are indicated by a vertical

line in the margin.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 28

AMENDMENT RECORD SHEET

Modified

Issue Modification summary Justification

paragraph

- Blind bolts ASNA0081, ASNA0082, ASNA0077,

ASNA0078, NAS1919, NAS1921

- Nuts to be used more specified.

Table 4 updated with:

- CSK screw NAS1151 to NAS1158

- Lockbolt ASNA2054

- Nuts to be used more specified.

R.02.10 3.2 Paragraph clarified Update

3.3 Maximum diameter 28récised.

4.6 Use of ADET0029 specified for general cases.

4 Table 3 updated:

- Notes added for second oversize of dash 3.

- Possibility added for repair of ASNA2391 Dash

3 and ASNA2392 Dash 3 by ASNA2391 Dash 3A

and ASNA2392 Dash 3A respectively.

- For EN6114 and EN6115 dash 3 R3: possibility

to use dash 3AX.

- For EN6114 and EN6115 R3 from Dash 10:

possibility added to use DHS781 to 783 washers

under the nut.

- MS21250 repaired by BS A228.

- Reference screw for tightening torque of

oversize bolts

S.12.13 4 Table 3 updated:

-Replacement of CRES nut to Al nuts for

installation with ASNA2657

-Note 2 for NAS1151 to 1158 replacement

modified

T.11.15 Page 1 Document applicability information added Update

2 - ABS1830 & ABS1831 added (CPPR 4905)

Note: Modification to the last standard issue are indicated by a vertical

line in the margin.

AIRBUS FRANCE 1985. All rights reserved

ASNA2180

Issue: Nov 15

Page: 29

AMENDMENT RECORD SHEET

Modified

Issue Modification summary Justification

paragraph

- Term “Screw” changed as “Bolt” (for NSA5378

3.6 in page 6)

3.7 - Term “Screw” changed as “Bolt” (Table 2)

- Term “strong” changed as “high”

- Term “Screw” changed as “Bolt”

- EN6114V replaced by EN6114K

3.8 - EN6115V replaced by EN6115K

4.1 - Term “Screw” changed as “Bolt”

- Term “ESW” replaced by “Materials and

Processes”

4.4

- Line added: “The Inconel nut ABS1831

accommodates the oversize bolt ABS1830.”

4.6

- Line deleted: “NAS1473 or 1474 NSA5368 or

NSA5372 ADET0029”

4.8

- ADET0059 and ABS1762 added as reference

for inspection after installation

4.9

- Term “Screw” changed as “Bolt” (under Table 3

& Note)

- Table 3 updated with EN6114B**, EN6115B**,

EN6115P** and ABS1830 part number

- Term “Screw” changed as “Bolt” (Table 4)

U.01.17 4.9 - Table 3: Added of nuts ASNA2528 and 2529 for

4.9 repair of Lockbolts ASNA2391 and ASNA2392.

- Table 3: Added of under nuts NSA5368 or

NSA5372 Code E and “use the same washer as

the original washer” for repair of tension bolt

ABS1830.

V.11.21 4.9 - Table 3: Added ABS1830 (X) and ABS1831 (Y)

for the repair of bolts NASM21250, NSA5378 and

NSA5378A

Note: Modification to the last standard issue are indicated by a vertical

line in the margin.

AIRBUS FRANCE 1985. All rights reserved

You might also like

- Daihatsu Sirion Part and PrizeDocument15 pagesDaihatsu Sirion Part and PrizeAgus HanantoNo ratings yet

- Nissan Engine MR20DE Repair Manual DownloadDocument218 pagesNissan Engine MR20DE Repair Manual DownloadMohammed Elkuni100% (8)

- Nammiaca 000039Document1,157 pagesNammiaca 000039gangadhark196No ratings yet

- 1241 WS1 PDFDocument114 pages1241 WS1 PDFleejo100% (1)

- Goodrich Proprietary - This Document Is Subject To The Controls and Restrictions On The Title Page. U.S. Export Classification: EAR 9E991Document152 pagesGoodrich Proprietary - This Document Is Subject To The Controls and Restrictions On The Title Page. U.S. Export Classification: EAR 9E991duythienddt100% (1)

- RDN 307 - Rev. 60 CFM56 5BDocument1,342 pagesRDN 307 - Rev. 60 CFM56 5BDaniel Gomez100% (2)

- SRM CFM56-5B - A318 - 319 - 320 - 321 (RDN 307) R65Document1,396 pagesSRM CFM56-5B - A318 - 319 - 320 - 321 (RDN 307) R65Andres Mendez50% (2)

- A318/A319/A320/A321: Service BulletinDocument521 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Adams Rite Control Module ManualDocument82 pagesAdams Rite Control Module ManualSyed Zeeshan UddinNo ratings yet

- Ads Ts20 Ags SpecsDocument120 pagesAds Ts20 Ags Specsdsgaviation100% (1)

- N Fastener 0000000004 00Document374 pagesN Fastener 0000000004 00librolibro1100% (1)

- 205a1-Ipb-Ch53 FuselageDocument318 pages205a1-Ipb-Ch53 FuselageWilson BarbosaNo ratings yet

- Nasm21250 (MS21250, Nas624 .. Nas644)Document4 pagesNasm21250 (MS21250, Nas624 .. Nas644)Bogdan RusuNo ratings yet

- Struct Inspection Manual 3-22-11Document246 pagesStruct Inspection Manual 3-22-11DAVINCI100% (1)

- TDS0028 Module 3 PDFDocument47 pagesTDS0028 Module 3 PDFPusca LiviuNo ratings yet

- ATA 32 Landing Gear PDFDocument1,508 pagesATA 32 Landing Gear PDFDaniel Santiago Montaño Suarez100% (2)

- Ipc R45Document1,931 pagesIpc R45Danilo Souto100% (1)

- D12.Parts Catalogue.2013Document1,169 pagesD12.Parts Catalogue.2013PETRNo ratings yet

- Pretreatment of Polyamide - APSDocument12 pagesPretreatment of Polyamide - APSolegprikhodko2809No ratings yet

- Rtlo 15610B T2 0510Document38 pagesRtlo 15610B T2 0510Orlando Wong100% (1)

- @airbus: Airbus S.A.SDocument206 pages@airbus: Airbus S.A.SDmitriy PognaievNo ratings yet

- Abs 0114Document11 pagesAbs 0114kevin seine100% (2)

- Fape3 - CMM - 014 Sliding Table and Foot RestDocument284 pagesFape3 - CMM - 014 Sliding Table and Foot Restsaid PalaoNo ratings yet

- Mammto 000001Document11 pagesMammto 000001RAMIRO MARTINEZ SALINASNo ratings yet

- Task 53-00-14-300-002Document5 pagesTask 53-00-14-300-002mashobih hussururNo ratings yet

- Nipcxf 000026Document852 pagesNipcxf 000026Arron ChanNo ratings yet

- CNW A320Document83 pagesCNW A320ollieknightNo ratings yet

- TO 1C-130H-4-00-1: 1 September 1999Document688 pagesTO 1C-130H-4-00-1: 1 September 1999Mohamed HassanNo ratings yet

- Kholer 9EOZD Manual PartsDocument76 pagesKholer 9EOZD Manual Partsleopoldo larezNo ratings yet

- Nipcxf 000013Document654 pagesNipcxf 000013Arron ChanNo ratings yet

- 6gc Steering Manifold PDFDocument183 pages6gc Steering Manifold PDFThai Nguyen100% (1)

- 711300Document704 pages711300duythienddt100% (1)

- Structural Repair Manual Chapter 55 List of Effective PagesDocument3,828 pagesStructural Repair Manual Chapter 55 List of Effective PagesJhoshua AvilaNo ratings yet

- ASNA2536-collars CortaduraDocument6 pagesASNA2536-collars CortaduraCurro Espadafor Fernandez AmigoNo ratings yet

- Nce 003452Document939 pagesNce 003452Misbah ZaidiNo ratings yet

- Nammiaca 000011Document656 pagesNammiaca 000011gangadhark19650% (2)

- @A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerDocument31 pages@A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerFabian Andres Soto Lineros (LATAM)No ratings yet

- Asna 2531 2006-09 K 2Document7 pagesAsna 2531 2006-09 K 2Speeder JohnNo ratings yet

- Must Change Item in PohDocument23 pagesMust Change Item in Pohmailbkrao100% (1)

- Rectification of Met Material by Shot PeeningDocument9 pagesRectification of Met Material by Shot Peeningolegprikhodko2809No ratings yet

- 51-49-00 - Description - Standard Torque ValuesDocument14 pages51-49-00 - Description - Standard Torque ValuesMarijaNo ratings yet

- CMM 25 24 76 3K723 20100315 005Document246 pagesCMM 25 24 76 3K723 20100315 005ırmak erolNo ratings yet

- (A318 - A319 - A320 - A321) : Nose Jacking Single AisleDocument7 pages(A318 - A319 - A320 - A321) : Nose Jacking Single AisleJivendra KumarNo ratings yet

- Asna2025: Docmaster: Uncontrolled Copy When PrintedDocument5 pagesAsna2025: Docmaster: Uncontrolled Copy When Printedpym31No ratings yet

- General Limits: Airbus Directive (ABD)Document11 pagesGeneral Limits: Airbus Directive (ABD)Rissi CH100% (1)

- Portable Water-Solution Fire Extinguisher P/N M892480-1: Page T-1 OCT 15/02Document32 pagesPortable Water-Solution Fire Extinguisher P/N M892480-1: Page T-1 OCT 15/02Isaac Angel VasquezNo ratings yet

- Aims03 08 007Document7 pagesAims03 08 007Jorge OrtegaNo ratings yet

- Abs 0056Document17 pagesAbs 0056darrow dori100% (1)

- 25 25 14Document258 pages25 25 14Shah M. ArifNo ratings yet

- Technical Notes (TN) : AirbusDocument76 pagesTechnical Notes (TN) : AirbusHossein RashediNo ratings yet

- Asna 2050Document9 pagesAsna 2050Carlos Arévalo100% (1)

- CMM Recaro Seat PT4400-406Document191 pagesCMM Recaro Seat PT4400-406EssamNo ratings yet

- EN6114Document14 pagesEN6114akayirNo ratings yet

- A318-A319-A320-A321 - (A319-SRM) (53-21-11 Pageblock 001 SKIN PLATES - SKIN PLATES)Document29 pagesA318-A319-A320-A321 - (A319-SRM) (53-21-11 Pageblock 001 SKIN PLATES - SKIN PLATES)Violet Paris100% (1)

- Hasil Review Maintenance Roll Calender MHV KusterDocument5 pagesHasil Review Maintenance Roll Calender MHV KusterrajapalasaNo ratings yet

- Aero Stock ListDocument1,543 pagesAero Stock ListGaynor Morgan67% (3)

- B767 Illustrated Parts Catalog (IPC) Supplement: Polaris Aviation SolutionsDocument208 pagesB767 Illustrated Parts Catalog (IPC) Supplement: Polaris Aviation SolutionsfinlanfinNo ratings yet

- Oxygengenerators MixabilityDocument37 pagesOxygengenerators MixabilityJános RédeiNo ratings yet

- Cherry Part Number ConversionsDocument2 pagesCherry Part Number ConversionsMueed LiaqatNo ratings yet

- TYE Insert Cross Reference ListDocument11 pagesTYE Insert Cross Reference ListJesse KrebsNo ratings yet

- Component Maintenance Manual: Container Type H1Document73 pagesComponent Maintenance Manual: Container Type H1John CenaNo ratings yet

- Airbus A320 200 WBM ALK Rev 003H Jul 05 2006 - 1238255754Document475 pagesAirbus A320 200 WBM ALK Rev 003H Jul 05 2006 - 1238255754Manuel Hervas HermosoNo ratings yet

- Tables 7-12Document6 pagesTables 7-12blackhawkNo ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet

- Spectrum™ Convertible 1006500 Series Passenger Seats For Lan Chile A319 AircraftDocument296 pagesSpectrum™ Convertible 1006500 Series Passenger Seats For Lan Chile A319 Aircraftlibrolibro1100% (1)

- Catalog Ass en - Produse NoiDocument28 pagesCatalog Ass en - Produse NoiBirciu ValiNo ratings yet

- DS 966001-2 ANSI Safety Relief Valve Threaded ARI-SAFE-FN 966 968 969 REYCO RL14 RL40 RL41Document22 pagesDS 966001-2 ANSI Safety Relief Valve Threaded ARI-SAFE-FN 966 968 969 REYCO RL14 RL40 RL41Carlos Alberto OspinaNo ratings yet

- Sapag: Sapag Series 8400 and 8500 Safety Relief Valves For API-526 Process ApplicationsDocument8 pagesSapag: Sapag Series 8400 and 8500 Safety Relief Valves For API-526 Process ApplicationsAbdeldjalil AchourNo ratings yet

- XcarveDocument5 pagesXcarveLucas MuñozNo ratings yet

- Engine Control SystemDocument443 pagesEngine Control SystemAhmed MohammedNo ratings yet

- 11.3.2 Critical Sparepart & Inventory List - Kazo JaxDocument11 pages11.3.2 Critical Sparepart & Inventory List - Kazo JaxJOHAN SIAHAANNo ratings yet

- Make and Program Your Own Robots For The Commodore 64 and VIC 20Document50 pagesMake and Program Your Own Robots For The Commodore 64 and VIC 20turboc201No ratings yet

- Mechanics Tools & Storage: CatalogDocument100 pagesMechanics Tools & Storage: CatalogMahmoud SalehNo ratings yet

- Lubrication & Cooling Systems OverviewDocument34 pagesLubrication & Cooling Systems OverviewLudo PiętakNo ratings yet

- Legrand Cable Lighting & Data Trunking TechnicalDocument35 pagesLegrand Cable Lighting & Data Trunking TechnicalboltgingerkoppyNo ratings yet

- 1) MOTORE EURO 3 - en SAMEDocument72 pages1) MOTORE EURO 3 - en SAMERadek BabuszkiewiczNo ratings yet

- Firstlook Manual SenxDocument22 pagesFirstlook Manual SenxschraeubleNo ratings yet

- Perkins Engine 1106C-E60TAG4 SERIES SPARE PARTSDocument2 pagesPerkins Engine 1106C-E60TAG4 SERIES SPARE PARTSIbrahim YunusNo ratings yet

- Wa0006Document9 pagesWa0006GabrielNo ratings yet

- Micro-Project Report Group No-06Document18 pagesMicro-Project Report Group No-06Parth Maldhure0% (1)

- Hitemp Ec: Installation Guide For Aluminum Conductor Steel Supported (Acss and Acss/Tw)Document2 pagesHitemp Ec: Installation Guide For Aluminum Conductor Steel Supported (Acss and Acss/Tw)rajensamaNo ratings yet

- PDF Valve Adjustment PDF - CompressDocument9 pagesPDF Valve Adjustment PDF - Compressjavier gelvezNo ratings yet

- Measuring Slip TitleDocument18 pagesMeasuring Slip TitleSRNSNo ratings yet

- Bearing SDocument60 pagesBearing SsrikanthsmashNo ratings yet

- Takeuchi Track Loader Engine V3800di T 3b Tltu 1 Parts ManualDocument10 pagesTakeuchi Track Loader Engine V3800di T 3b Tltu 1 Parts ManualWillis100% (46)

- Shandong XSY Bearing Co., Ltd. Products AlbumDocument105 pagesShandong XSY Bearing Co., Ltd. Products AlbumRahul KatariyaNo ratings yet

- Power Train: 6Y-2303 Clutch Gp-TransmissionDocument19 pagesPower Train: 6Y-2303 Clutch Gp-TransmissionDANIEL VARGAS RODRIGUEZNo ratings yet

- Fundamentals of Rotating EquipmentDocument61 pagesFundamentals of Rotating EquipmentFery HartantoNo ratings yet

- NTC45LED Floodlight Operating ProcedureDocument9 pagesNTC45LED Floodlight Operating ProcedureDerrickNo ratings yet

- February2024 INCALDVD CoverLetterDocument4 pagesFebruary2024 INCALDVD CoverLetterSuministros MantenimientoNo ratings yet