Professional Documents

Culture Documents

Cryolor Asia Pasific

Uploaded by

Josh BiadnoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cryolor Asia Pasific

Uploaded by

Josh BiadnoCopyright:

Available Formats

Case Study

Architecturally Appealing Pre-engineered Steel Building

CRYOLOR ASIA PACIFIC (P) LIMITED

Location : Kadmalaiputtur, Chennai-Madurai Road, Tamil Nadu

Country : India

Client : CRYOLOR ASIA PACIFIC (P) LIMITED

Products Used : ECOBUILD™ BUILDING SYSTEMS

Project Details : 7,217 sq.mt

Architects : Architects United, Pune

Brief about the project: The project involved providing complete pre-engineered steel building solution for

Cryolor Asia Pacific (P) Limited, a French company manufacturing vessels for cryogenic gases. The scope of

work for Tata BlueScope Building Solutions included design, manufacture, supply, project management and

erection of the pre-engineered steel building by using the highest quality of materials and proven technology. On-

time completion, aesthetically pleasing as well as a functionally superior solution coupled with economy, were

the key requirements of Cryolor Asia Pacific (P) Limited.

Solution Offered

For this challenging project, Tata BlueScope Building Solutions recommended ECOBUILD™ Building Systems,

with TRIMDEK® 1015 roof which was fitted on convex and concave roof profile. The building thus designed has

a bold architectural form exclusively designed for Cryolor Asia Pacific (P) Limited.

The solution proposed by Tata BlueScope Building Solutions provides superior functionalities that include

different working heights of cranes, raw materials handling area, cable trays and mezzanine floor with higher

loads for process requirements.

E-mail: ecobuild@tatabluescopesteel.com; Website: www.tatabluescope-bs.com

Case Study

Architecturally Appealing Pre-engineered Steel Building

Building Description:

Building Name Size in Meters Total area in Sq.mt

Plant building for manufacturing 50 m Width X 184 m Length X 16 m Height

7217

cryogenic equipment’s With 25 MT & 10 MT EOT Cranes

Applicable Standards of Practice:

1. The loads have been applied on the structure in accordance with:

a. Metal Building Systems Manual 1996 by MBMA “Metal Building Manufacturer’s Association”.

b. IS-1893-2002 (Part –1) Indian Standard Criteria for Earthquake Resistant Design of Structures (Part-1

General Provisions and Buildings)

2. Hot rolled sections and built up components have been designed in accordance with: AISC-1989, 9th

Edition (Allowable Stress Design)

3. Cold formed components have been designed in accordance with: AISI -1996 “American Iron and Steel

Institute” (Allowable Stress Design)

4. Welding has been applied in accordance with AWS D1.1.2006 “American Welding Society” Structural

Welding Code - Steel Manual, 2000 Edition.

5. Fabrication and Erection Tolerance applied in accordance with Metal Building Systems manual, 2006 by

MBMA “Metal Building Manufacturer’s Association”.

Design Basis:

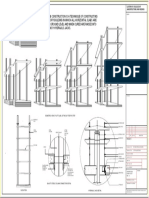

Lateral Stability: The main frame rafters and exterior columns are connected to each other using moment type

connections and hence the lateral stability of the building is provided through the frame action of the main rigid

frames. Main frames are designed as two dimensional. Rigid frame columns along sidewalls are designed as

fixed-based and the columns at interior locations are pinned-based. The frame is designed with segmental arch

action in order to meet profile configuration.

Initial Frame Profile

Final frame profile

Value Engineering in Building Cross Section meeting both Functional and Architectural

Requirements Interior View of Cryolor Asia Pacific (P) Limited

Longitudinal Stability: Longitudinal stability of a building is provided through multi–tiered cross braced bays of

the building in its roof, side walls and interior walls. The analysis and design has been carried out by MBS (Metal

Building Software), USA.

E-mail: ecobuild@tatabluescopesteel.com; Website: www.tatabluescope-bs.com

Key Challenges :

Integration of structure and services to meet functional needs:

The pre-engineered steel building solution was customised taking into account following functional and

operational needs:

Sr. No. Key Needs Innovative Solution

1. Different working heights of cranes Due to differential height of cranes in the adjacent

width module, either the height could be increased or

irregular profile of building width could be considered.

The team instead suggested innovative profile of

building which meets the functional as well as

structural requirements. The solution proposed was

also architecturally appealing.

2. Raw material handling area with crane Functional requirement was to have a crane to receive

raw materials. The area can be enclosed at a later

stage. Structurally, we proposed similar profile frame

with the provision of fixing the roof sheeting at a later

stage and with nearly the same amount of steel being

used.

3. Mezzanine Floor with Monorail Crane Mezzanine floor roof was designed with same roof

profile for architectural requirement and heavy storage

loads on mezzanine floor. The structural members

have been designed with monorail crane movement.

4. Cable Tray Supporting Structure Cable trays have been designed with cold form

sections and have been factory made, instead of

commonly used hot-rolled angles and channels.

5. Maintaining suitable ambient Use of Super Polynum Thermal Reflective Insulation

temperature in Tropical weather in roof system.

Favorable Environmental Impact:

· Material Selection: The building is made of Steel which is a 100% Recyclable material. The Building

System is re-locatable and adaptable for reuse.

· Sustainable Site: 100% off site fabrication helps in maintaining the flora & fauna at site.

· Energy Efficiency & Indoor Air Quality: Use of Super Polynum Thermal Insulation, Skylight panels

and Wind Driven Turbo Vents conserves electrical energy and enhances Indoor Air Quality.

· Innovation in Design: Value engineering in building design optimises usage of steel.

E-mail: ecobuild@tatabluescopesteel.com; Website: www.tatabluescope-bs.com

Case Study

Architecturally Appealing Pre-engineered Steel Building

Convex and

Concave Roof

Profile: The long

straight lengths of

unique TRIMDEK®

1015 panel is

spring curved on

site without the

aid of additional

mechanical curving

equipment in order

to match special

shape of building

profile

Results:

1. The outcome is an eye-catching building on Chennai - Madurai road, in Tamil Nadu. The building is

completed safely and meets the parameters for Green Buildings.

2. The bold curved profile of the structure is not only aesthetically unique, but also meets the rigid requirements

of height put forth by process planner.

3: Innovative approach in structural design helped in weight reduction and cost optimisation of steel

structure.

Customer appreciation:

An award for Design Skills, a commendation for turning a beautiful but difficult

Award for Design Skills design into reality and creating a wonder in steel.

E-mail: ecobuild@tatabluescopesteel.com; Website: www.tatabluescope-bs.com

You might also like

- BROC Mackam Dab en v1.0Document2 pagesBROC Mackam Dab en v1.0jangri1098No ratings yet

- Building Case StudyDocument49 pagesBuilding Case StudyJaskiratNo ratings yet

- Plastic PackagingDocument47 pagesPlastic PackagingRajaSekarsajja100% (1)

- TM 9-1651 Data Transmission System m3, January 1942Document78 pagesTM 9-1651 Data Transmission System m3, January 1942Advocate100% (1)

- Lucsuhin National High School Daily Lesson Plan on Accounting ConceptsDocument6 pagesLucsuhin National High School Daily Lesson Plan on Accounting ConceptsALMA ACUNANo ratings yet

- Lesson Plan (Climatology s3)Document2 pagesLesson Plan (Climatology s3)Dipu GeorgeNo ratings yet

- Thermo-Physical-Optical Property Database of Construction MaterialsDocument31 pagesThermo-Physical-Optical Property Database of Construction MaterialsSabyasachi Naik (Zico)No ratings yet

- Business Plan For Mobile Food CourtDocument13 pagesBusiness Plan For Mobile Food CourtMd. Al- AminNo ratings yet

- Indira Paryavahan BhawanDocument26 pagesIndira Paryavahan BhawanPiyush Janardan KhadeNo ratings yet

- Water Supply in High Rise BuildingsDocument8 pagesWater Supply in High Rise BuildingsVaishnavi Parmar100% (1)

- Case Study of Hvac System in A Sustainable Building PDFDocument70 pagesCase Study of Hvac System in A Sustainable Building PDFguru jiNo ratings yet

- HOUSEKEEPING SESSION PLANDocument2 pagesHOUSEKEEPING SESSION PLANScarlette Beauty Enriquez100% (1)

- Average Weather Guide for CuttackDocument41 pagesAverage Weather Guide for CuttackUtkarsh SharmaNo ratings yet

- Structural Systems: Lamella DomesDocument19 pagesStructural Systems: Lamella DomesMohammad KHNo ratings yet

- Green Building III AssignmentDocument9 pagesGreen Building III AssignmentBorelli Ravi Shankar ReddyNo ratings yet

- Brookfeilds Case Study: Building Services-3Document13 pagesBrookfeilds Case Study: Building Services-3VishnuNo ratings yet

- Specialized Air Conditioning SystemDocument6 pagesSpecialized Air Conditioning SystemSACHIDANANDA SNo ratings yet

- Saving Money and Energy: Godrej Bhavan Case StudyDocument11 pagesSaving Money and Energy: Godrej Bhavan Case StudySai Ujjwala VemuriNo ratings yet

- A Comparative Study Energy Performance Analysis of Conventional Office Buildings at LucknowDocument11 pagesA Comparative Study Energy Performance Analysis of Conventional Office Buildings at LucknowFarheen Bano100% (1)

- Report 6-Folded Plates Case StudyDocument6 pagesReport 6-Folded Plates Case StudySoham SatamNo ratings yet

- COMMON ACOUSTICAL DEFECTS AND SOLUTIONSDocument25 pagesCOMMON ACOUSTICAL DEFECTS AND SOLUTIONSParth Gupta0% (1)

- Climate ConsultantDocument186 pagesClimate ConsultantAkila KarthikaNo ratings yet

- Green Building Design Case Studies: Asia Shabbir 1-2-BAR-005-14Document6 pagesGreen Building Design Case Studies: Asia Shabbir 1-2-BAR-005-14nikita singhalNo ratings yet

- PneumaticDocument45 pagesPneumaticTanuj BhardwajNo ratings yet

- Smart Luxury Housing Blends Technology and AmenitiesDocument71 pagesSmart Luxury Housing Blends Technology and AmenitiesPrajapati Ankit100% (1)

- Capitaspring Tower, SingaporeDocument43 pagesCapitaspring Tower, SingaporeAnanya SinghNo ratings yet

- Micro-Climate Analysis of Bhopal for Passive DesignDocument5 pagesMicro-Climate Analysis of Bhopal for Passive DesignDrishti AgarwalNo ratings yet

- Low Energy Traditional Architecture of LucknowDocument7 pagesLow Energy Traditional Architecture of LucknowRus NaniNo ratings yet

- Brochure - INSDAG Architecture Award Competition 2023Document10 pagesBrochure - INSDAG Architecture Award Competition 2023ebinhorrison sNo ratings yet

- GROUP 1 Burj KhalifaDocument1 pageGROUP 1 Burj Khalifanurman.1707235No ratings yet

- Tubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsDocument3 pagesTubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsKranthi Kumar Chowdary ManamNo ratings yet

- Dipshikha Meti SchoolDocument13 pagesDipshikha Meti SchoolNasrinNaharTuliNo ratings yet

- Encon Basement VentilationDocument15 pagesEncon Basement VentilationcyruskuleiNo ratings yet

- St2110 Design of Tall Buildings 1st LessonDocument42 pagesSt2110 Design of Tall Buildings 1st Lessonrenganathank87No ratings yet

- Modular CoordinationDocument107 pagesModular Coordinationchamil_dananjayaNo ratings yet

- Indira Paryavaran Bhawan Net Zero Energy BuildingDocument26 pagesIndira Paryavaran Bhawan Net Zero Energy BuildingAjay JainNo ratings yet

- Modern Wedding Hall Garden DesignDocument3 pagesModern Wedding Hall Garden DesignMendoza, Kyle S.No ratings yet

- Indira Paryavaran BhawanDocument5 pagesIndira Paryavaran BhawanKanika MaheshwariNo ratings yet

- Sustainable Arch. - Avasara Academy PuneDocument19 pagesSustainable Arch. - Avasara Academy PuneGurusha MengiNo ratings yet

- Lights-Market SurveyDocument29 pagesLights-Market Survey1965 Aliptha ShettyNo ratings yet

- ProjectDocument16 pagesProjectAkshay HalyalNo ratings yet

- 126-Apt Housing Project with Large Garden SpaceDocument9 pages126-Apt Housing Project with Large Garden SpaceHasiba BarisaNo ratings yet

- VGU Architecture Campus Achieves SustainabilityDocument13 pagesVGU Architecture Campus Achieves SustainabilityIsha KarodiNo ratings yet

- RCC Folded Plates ShortDocument2 pagesRCC Folded Plates ShortdeepshikhaNo ratings yet

- North Light Truss (Autosaved)Document13 pagesNorth Light Truss (Autosaved)Fidha SulfiNo ratings yet

- Sudha HouseDocument6 pagesSudha HouseAarshia Punavia JainNo ratings yet

- Agri-Koli Cultural Centre auditorium case studyDocument18 pagesAgri-Koli Cultural Centre auditorium case studyROSHAN BANIKNo ratings yet

- Vocational Centre at KhurjaDocument45 pagesVocational Centre at KhurjaNAZEEF KHANNo ratings yet

- Luxury 12-Seat Pneumatic Cinema SystemDocument4 pagesLuxury 12-Seat Pneumatic Cinema SystemmathangghiNo ratings yet

- Spaze Tower - It Park: Case Study OnDocument17 pagesSpaze Tower - It Park: Case Study OnPrashanth HosamaneNo ratings yet

- Warm Humid Climate 1. OrientationDocument4 pagesWarm Humid Climate 1. OrientationmariyaNo ratings yet

- HaveliDocument22 pagesHaveliSaeara Saju CNo ratings yet

- 3.7 Detailed Specification For Woodwork For Doors, Windows Frames and Shutters A) DoorsDocument4 pages3.7 Detailed Specification For Woodwork For Doors, Windows Frames and Shutters A) DoorssahilNo ratings yet

- Final Updated Composite Climate 21-10-2020Document39 pagesFinal Updated Composite Climate 21-10-2020Zehra UmarNo ratings yet

- Suzlon One EarthDocument34 pagesSuzlon One EarthNazeeha NazneenNo ratings yet

- False Ceiling: Integrated Market Survey and Theoretical PresentationDocument29 pagesFalse Ceiling: Integrated Market Survey and Theoretical PresentationShruti TareNo ratings yet

- SANNDocument1 pageSANNSanchita Jha100% (1)

- Hotdry MahendraDocument5 pagesHotdry MahendraNeha Goyal100% (1)

- ITC Green Centre, Gurgaon: General InformationDocument7 pagesITC Green Centre, Gurgaon: General Informationbintang avgustaNo ratings yet

- Composite ClimateDocument10 pagesComposite ClimatevaibhavNo ratings yet

- ECBC Implementation Experience - A Case Study on UPERC BuildingDocument21 pagesECBC Implementation Experience - A Case Study on UPERC BuildingAanchal MishraNo ratings yet

- Folded Plate StructureDocument18 pagesFolded Plate StructuresushmakNo ratings yet

- Case Study HousingDocument47 pagesCase Study HousingAsmita SubediNo ratings yet

- RMIT Design Hub Case StudyDocument4 pagesRMIT Design Hub Case StudyGregg AustriaNo ratings yet

- COST-EFFECTIVE PEB BUILDINGDocument4 pagesCOST-EFFECTIVE PEB BUILDINGSandeep SolankiNo ratings yet

- AAMI Park Case StudyDocument3 pagesAAMI Park Case StudyKennedy TuguinayNo ratings yet

- Absorbance at 405Nm: United States PatentDocument20 pagesAbsorbance at 405Nm: United States Patentfelipe_fismed4429No ratings yet

- Somya Bhasin 24years Pune: Professional ExperienceDocument2 pagesSomya Bhasin 24years Pune: Professional ExperienceS1626No ratings yet

- Updated Scar Management Practical Guidelines Non-IDocument10 pagesUpdated Scar Management Practical Guidelines Non-IChilo PrimaNo ratings yet

- Meritor 210 220 230 240 2SpeedSingleAxlesDocument27 pagesMeritor 210 220 230 240 2SpeedSingleAxlesYhojan DiazNo ratings yet

- Segilola Gold ProjectDocument11 pagesSegilola Gold ProjectaishaNo ratings yet

- Iwan Lab Guide v1.1 FinalDocument63 pagesIwan Lab Guide v1.1 FinalRicardo SicheranNo ratings yet

- PE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Document6 pagesPE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Prince ImmanuelNo ratings yet

- Bus Crash LawsuitDocument7 pagesBus Crash LawsuitNewsTeam20No ratings yet

- Combined SGMA 591Document46 pagesCombined SGMA 591Steve BallerNo ratings yet

- Re-registering a vehicle in Karnataka - A step-by-step guideDocument4 pagesRe-registering a vehicle in Karnataka - A step-by-step guideHidayathulla HasanNo ratings yet

- Filiation and Support ClaimsDocument3 pagesFiliation and Support ClaimsEugene BalagotNo ratings yet

- Lb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDocument2 pagesLb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDaniel Oliveira Freitas RochaNo ratings yet

- Benetton CaseDocument23 pagesBenetton CaseNnifer AnefiNo ratings yet

- Internship Report On: "Training and Development of Bengal Group of Industries."Document47 pagesInternship Report On: "Training and Development of Bengal Group of Industries."Lucy NguyenNo ratings yet

- Subhra Ranjan IR Updated Notes @upscmaterials PDFDocument216 pagesSubhra Ranjan IR Updated Notes @upscmaterials PDFSachin SrivastavaNo ratings yet

- IWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesDocument83 pagesIWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesAsnake TegenawNo ratings yet

- Welcome To All: Fundamental Analysis Economic AnalysisDocument11 pagesWelcome To All: Fundamental Analysis Economic AnalysisMD.RUMON BAKSHINo ratings yet

- MB1 - The Australian Economy PA 7092016Document8 pagesMB1 - The Australian Economy PA 7092016ninja980117No ratings yet

- Document - University Admission SystemDocument100 pagesDocument - University Admission SystemNaresh SharmaNo ratings yet

- Rolling ResistanceDocument12 pagesRolling Resistancemu_rajesh3415No ratings yet

- OPTION STRATEGIES PAYOFF CALCULATOR v2Document9 pagesOPTION STRATEGIES PAYOFF CALCULATOR v2Jay KewatNo ratings yet

- An SAP Consultant - ABAP - ALV Blocked List1Document3 pagesAn SAP Consultant - ABAP - ALV Blocked List1Shikhar AgarwalNo ratings yet

- ExcelDocument1 pageExcelJosh KempNo ratings yet

- Flexible Instruction Delivery Plan Template CONTENT 5Document2 pagesFlexible Instruction Delivery Plan Template CONTENT 5Edward Barber100% (3)