Professional Documents

Culture Documents

PDS 15asg PDF

PDS 15asg PDF

Uploaded by

Erwin MalmsteinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDS 15asg PDF

PDS 15asg PDF

Uploaded by

Erwin MalmsteinCopyright:

Available Formats

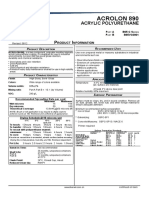

Product Data

HEMPEL'S 15ASG

15AS9: BASE : CURING 950SG

Description: HEMPEL’S 15ASG is a two-component, abrasion resistant, pure epoxy primer with excellent

anticorrosive properties. The product has optimised performance properties for different harsh

service conditions.

Recommended use: As a self-primed high performance coating system for atmospheric or in water service, including

water ballast tanks. HEMPEL’S 15ASG is also suitable for tugs and barges. HEMPEL’S 15ASG

is intended for all year application down to -10°C/14°F and for applications where fast recoating

and handling is required.

Features: Excellent anticorrosive and very good mechanical properties. Curing down to -10°C/14°F.

Service temperature: Maximum, dry exposure only: 120°C/248°F.

Ballast water service. Resists normal ambient temperatures at sea (Avoid long-term exposure to

negative temperature gradients). Other liquids: Contact HEMPEL

Availability: Not Included In Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Shade Nos./Colours: 67120/Dark Brown

Finish: Semi-Flat

Volume solids, %: 72 ± 2

Theoretical spreading rate: 5.8 m2/l [232.6 sq.ft/US gallon] - 125 micron/5 mils

Flash point: 35 °C [95.0 °F]

Specific gravity: 1.5 kg/litre [12.2 lbs/US gallon]

Dry to touch: 4.0 approx. hour(s) 20°C/68°F

9.0 approx. hour(s) 5°C/41°F

Fully cured: 5 day(s) 20°C/68°F

15 day(s) 5°C/41°F

VOC content: 268 g/l [2.2 lbs/US gallon]

*other shades according to assortment list.

APPLICATION DETAILS: The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

Version, mixed product: 15ASG

Mixing ratio: BASE 15AS9: CURING 950SG

3.0 : 1.0 by volume

Application method: Airless spray / Brush / Roller

Thinner (max. vol.): 08450 (5%) / 08450 (5%) / 08450 (5%)

Pot life (Airless spray): 2 hour(s) 20°C/68°F

Pot life (Brush): 2 hour(s) 20°C/68°F

Induction time: - see REMARKS overleaf

Nozzle orifice: 0.021 - 0.025 "

Nozzle pressure: 250 bar [3625 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL'S TOOL CLEANER 99610

Indicated film thickness, dry: 125 micron [5 mils]

Indicated film thickness, wet: 175 micron [5 mils]

Overcoat interval, min: see REMARKS overleaf

Overcoat interval, max: see REMARKS overleaf

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint

- containers, consult HEMPEL Safety Data Sheets and follow all local or national safety

regulations.

Date of issue: September 2016 Page: 1/2

Product Data

HEMPEL'S 15ASG

SURFACE PREPARATION: New steel: Remove oil and grease, etc. with suitable detergent. Remove salt and other

contaminants by (high pressure) fresh water cleaning. Abrasive blasting to Sa 2 1/2 (ISO 8501-

1:2007) is recommended. For temporary protection, if required, use a suitable shopprimer. All

damage of shopprimer and contamination from storage and fabrication should be thoroughly

cleaned prior to final painting. For repair and touch-up use: HEMPEL’S 15ASG.

Concrete: Remove slip agent and other possible contaminants by emulsion washing followed by

high pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and

uniform surface, preferably by abrasive blasting, possibly by other mechanical treatment or acid

etching. Seal surface with suitable sealer, as per relevant painting specification.

Steel, maintenance: Remove oil and grease, etc. with suitable detergent. Remove salt and other

contaminants by (high pressure) fresh water cleaning. Clean damaged areas thoroughly by power

tool cleaning to St 3 (minor areas) or by abrasive blasting to min. Sa 2, preferably to Sa 2½.

Improved surface preparation will improve the performance of the paint.

As an alternative to dry cleaning, water jetting to sound, well adhering coat and/or to steel. Intact

coat must appear with roughened surface after the water jetting. By water jetting to steel,

cleanliness shall be: (minimum) WJ-2 Acceptable flash rust degree before application: FR-2,

preferably FR-1. Feather edges to sound and intact areas. Dust off residues. Touch up to full film

thickness.

APPLICATION CONDITIONS: Use only where application and curing can proceed at temperatures above: -10°C/14°F. Apply

only on a dry and clean surface with a temperature min. 3°C/5°F above the dew point to avoid

condensation. In confined spaces provide adequate ventilation during application and drying.

PRECEDING COAT: None, or as per specification. When diluted to 25-30%, the product can be used as blast primer

preceding a full coat application of the product.

SUBSEQUENT COAT: According to specification.

Colours/Colour stability Has a tendency to yellow after application. This will have no influence on the performance. The natural

Weathering/service temperatures: tendency of epoxy coatings to chalk in outdoor exposure and to become more sensitive to mechanical

damage and chemical exposure at elevated temperatures is also reflected in this product.

Induction time: To facilitate proper application properties, it is recommended to allow the thoroughly mixed BASE and

CURING AGENT to pre-react before application.

Film thicknesses/thinning: May be specified in another film thickness than indicated depending on purpose and area of use. This

Note: will alter spreading rate and may influence drying time and over-coating interval. Normal range dry is:

100-200 micron/4-8 mils. For ballast tanks servicing at newbuilding stage minimum specified DFT is: 2 x

160 micron.

Overcoating: Overcoating intervals related to later conditions of exposure: If the maximum overcoating interval

is exceeded, roughening of the surface is necessary to ensure intercoat adhesion. Before

overcoating after exposure in contaminated environment, clean the surface thoroughly with high

pressure fresh water hosing and allow drying.

A specification supersedes any guideline overcoat intervals indicated in the table.

ENVIRONMENT Immersion

-10°C (14°F) 0°C (32°F) 20°C (86°F)

Surface Temperature:

Min. Max. Min. Max. Min. Max.

HEMPADUR 27 h 90 d 13 h 63 d 3h 14 d

NR = Not Recommended, Ext. = Extended, m = minute(s), h = hour(s), d = day(s)

Note: HEMPEL’S 15ASG is for professional use only.

ISSUED BY: HEMPEL R&D SINGAPORE 15ASG67120

Disclaimer to Second page

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: September 2016 Page: 2/2

You might also like

- 5E Enchanted EmporiumDocument19 pages5E Enchanted EmporiumDavid KristNo ratings yet

- Chugoku Paint Color (RAL)Document3 pagesChugoku Paint Color (RAL)Catur Pribadi100% (2)

- Hempaprime Multi 500 Summer 45950Document3 pagesHempaprime Multi 500 Summer 45950omar alkarabliehNo ratings yet

- Pds Hempadur Glass Flake 35851 En-GbDocument2 pagesPds Hempadur Glass Flake 35851 En-Gbkalpesh parmarNo ratings yet

- Jotun Jotamastic Brochure MarineDocument20 pagesJotun Jotamastic Brochure MarineGabriel PanaNo ratings yet

- FTALIT (115-Xxx) Kansai PaintDocument1 pageFTALIT (115-Xxx) Kansai Paintrezky_baskoro4230No ratings yet

- Pure Epoxies Vs Epoxy Mastics For Maintenance PDFDocument4 pagesPure Epoxies Vs Epoxy Mastics For Maintenance PDF003086100% (1)

- Origins of The Idea of AntipodesDocument18 pagesOrigins of The Idea of AntipodesDjumboDjettNo ratings yet

- 30.disorders of Pigmentation - PPT (Compatibility Mode) PDFDocument5 pages30.disorders of Pigmentation - PPT (Compatibility Mode) PDFavitrivardhayantiNo ratings yet

- The Role of The Project ManagerDocument4 pagesThe Role of The Project Managerjohn onesmoNo ratings yet

- Hempadur Mastic 45880 Product Data SheetDocument3 pagesHempadur Mastic 45880 Product Data SheetDeepak YadavNo ratings yet

- Company Profile - PT Warna Indah Samatex PDFDocument21 pagesCompany Profile - PT Warna Indah Samatex PDFJeffrey Liandi100% (1)

- Coating Types and Its UsesDocument14 pagesCoating Types and Its Usesdubaisrinivasulu100% (1)

- Painting Procedures of Pertamina SurabayaDocument13 pagesPainting Procedures of Pertamina SurabayaUdinHermansyahNo ratings yet

- Split Plummer Block Housings SNVDocument84 pagesSplit Plummer Block Housings SNVKharimul AzizNo ratings yet

- Protective CoatingDocument4 pagesProtective CoatingfairmatechemicalNo ratings yet

- 6DLDocument1 page6DLAnonymous NxpnI6jCNo ratings yet

- Colour Card 21Document2 pagesColour Card 21Jorge SalgadoNo ratings yet

- Marathon XHB - TDSDocument5 pagesMarathon XHB - TDSDamar WardhanaNo ratings yet

- JOTUN Color Sheet PDFDocument2 pagesJOTUN Color Sheet PDFphuocquocNo ratings yet

- Pts Ip Paint SystemDocument51 pagesPts Ip Paint SystemshiqinmkNo ratings yet

- Rules BKI For Non Metalic MaterialsDocument67 pagesRules BKI For Non Metalic MaterialsTimoteus Hasudungan SitinjakNo ratings yet

- Sigma Cover 510Document4 pagesSigma Cover 510supriadi90315100% (1)

- Nitocote AC: Weather Resistant Flexible Acrylic CoatingDocument2 pagesNitocote AC: Weather Resistant Flexible Acrylic CoatingWahlee SatuNo ratings yet

- Repairing & Protective Coating System For Cooling Tower: SP Concare Pvt. LTDDocument6 pagesRepairing & Protective Coating System For Cooling Tower: SP Concare Pvt. LTDAnkita Baban Gavade100% (1)

- KCT-1903 - Ship ParticullarDocument1 pageKCT-1903 - Ship Particullarariskustiawan77No ratings yet

- 1A-Acrolon 890Document2 pages1A-Acrolon 890Stuart PhamNo ratings yet

- SPECK Boiler Feed Water PumpsDocument16 pagesSPECK Boiler Feed Water Pumpsmaxh blumNo ratings yet

- Kovax Catalogue 2019Document28 pagesKovax Catalogue 2019Viraj AmleNo ratings yet

- Data Sheet Polyken 980 & 955Document4 pagesData Sheet Polyken 980 & 955Teguh SilaNo ratings yet

- Chockfast Orange Resin GhsDocument8 pagesChockfast Orange Resin GhsRizky RamadhanNo ratings yet

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruNo ratings yet

- Meditran SX Sae 15w 40 API CH 4Document1 pageMeditran SX Sae 15w 40 API CH 4Aam HudsonNo ratings yet

- Kansai Paint System Guide: Environmental CorrosivelyDocument16 pagesKansai Paint System Guide: Environmental Corrosivelyscribdfreeasus100% (1)

- Coating Equivalent List KCCDocument3 pagesCoating Equivalent List KCCchrismas_g100% (1)

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- Omyacarb 6Document1 pageOmyacarb 6Arifin HN100% (1)

- Eutronic Arc Spray Gun 4 HF: Operating Manual & Spare Parts ListsDocument44 pagesEutronic Arc Spray Gun 4 HF: Operating Manual & Spare Parts ListsRafael Rivera50% (2)

- KCC DataSheet LT313ENGDocument2 pagesKCC DataSheet LT313ENGNasir AnsariNo ratings yet

- Ficha Tecnica Shell Oil 9156 PDFDocument1 pageFicha Tecnica Shell Oil 9156 PDFcarlos arturo piedrahitaNo ratings yet

- Conplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionDocument3 pagesConplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionAditya KrisnandaNo ratings yet

- Korethan Topcoat UT6585 (Two-Component) : Physical PropertiesDocument2 pagesKorethan Topcoat UT6585 (Two-Component) : Physical PropertiesTrịnh Minh KhoaNo ratings yet

- Enhanced Qualitative Method For Long Life Anti Fouling Painting - PPT 2Document31 pagesEnhanced Qualitative Method For Long Life Anti Fouling Painting - PPT 2Oladokun SulaimanNo ratings yet

- Teflon Ptfe Disp 30 Product InfoDocument2 pagesTeflon Ptfe Disp 30 Product InfoThusith WijayawardenaNo ratings yet

- FP 6LDocument1 pageFP 6LAQUILES CARRERANo ratings yet

- Bitumen Paint Data SheetDocument2 pagesBitumen Paint Data SheetAPPI NAIDUNo ratings yet

- Alkyd Topcoat Technical Data Sheet Jotun PaintDocument4 pagesAlkyd Topcoat Technical Data Sheet Jotun PaintGurdeep Sungh Arora0% (1)

- COM SU 5191 C February 2017Document91 pagesCOM SU 5191 C February 2017suriya100% (1)

- CMP0000599 - PC - Katalog Bevananda PDFDocument8 pagesCMP0000599 - PC - Katalog Bevananda PDFRieskeIswardhanyNo ratings yet

- SHCP2668Document2 pagesSHCP2668Herwandi AlwiNo ratings yet

- Painting Procedure AlkydDocument7 pagesPainting Procedure AlkydSyaiful Arif WicaksonoNo ratings yet

- Jota Armour Brochure 2007Document6 pagesJota Armour Brochure 2007yudiar2008No ratings yet

- PDS HEMPATHANE FAST DRY 55750 en-GBDocument2 pagesPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawNo ratings yet

- Paint Specification HamadourDocument2 pagesPaint Specification HamadourAbdul Majid LodhiNo ratings yet

- 151SGDocument2 pages151SGdcsamaraweeraNo ratings yet

- PDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBDocument2 pagesPDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBEli KhawNo ratings yet

- Product Data: Hempadur Multi-Strength 35530Document2 pagesProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarNo ratings yet

- HEMPADUR MULTI-STRENGTH 35530 BlackDocument2 pagesHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- In 1st-PDS Hempadur 15570 en-GB PDFDocument3 pagesIn 1st-PDS Hempadur 15570 en-GB PDFdcsamaraweeraNo ratings yet

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Hempadur 85671Document2 pagesHempadur 85671EkoAndriAntoNo ratings yet

- Pds Hempadur 85671Document2 pagesPds Hempadur 85671Namta GeorgeNo ratings yet

- PDS Hempathane HS 55610 en-GBDocument3 pagesPDS Hempathane HS 55610 en-GBAnonymous HPlNDhM6ejNo ratings yet

- Main Switchboard (H-8001) Rev 2Document19 pagesMain Switchboard (H-8001) Rev 2wahyuNo ratings yet

- Hempel ShopprimersDocument7 pagesHempel ShopprimerswahyuNo ratings yet

- Untitled 1Document1 pageUntitled 1wahyuNo ratings yet

- D01 Equipment Number Calculation R0 PDFDocument2 pagesD01 Equipment Number Calculation R0 PDFwahyuNo ratings yet

- 30千瓦发电机组外形图 机载 2019 PDFDocument1 page30千瓦发电机组外形图 机载 2019 PDFwahyuNo ratings yet

- Untitled Document PDFDocument1 pageUntitled Document PDFwahyuNo ratings yet

- Lesson 1 - Rocks and Minerals GoodDocument5 pagesLesson 1 - Rocks and Minerals Goodapi-314775182No ratings yet

- Advanced Machining Processes of Metallic Materials: Theory, ... - Page 5Document1 pageAdvanced Machining Processes of Metallic Materials: Theory, ... - Page 5jcetmechanicalNo ratings yet

- Product Knowledge (2) (26-8) 2-1Document38 pagesProduct Knowledge (2) (26-8) 2-1zeyad1234ali0No ratings yet

- PermutationsDocument1 pagePermutationsaugustuswgNo ratings yet

- Current Affairs: Princeton Business Park (Behind SIDBI), Ashok Marg, HAZRATGANJ, Lucknow M: 9838380700Document2 pagesCurrent Affairs: Princeton Business Park (Behind SIDBI), Ashok Marg, HAZRATGANJ, Lucknow M: 9838380700Arvind SrivastavaNo ratings yet

- 3GPP TS 29.060: Technical SpecificationDocument151 pages3GPP TS 29.060: Technical SpecificationnyksriNo ratings yet

- Table of Liturgical DaysDocument1 pageTable of Liturgical DaysIanNo ratings yet

- Pronouns Class8Document6 pagesPronouns Class8agentofdarknessNo ratings yet

- Introduction To Society, Community and Education Dr. Mike Kelvin Nicole N. Buted at The End of This Module, Pre-Service Teachers Should Be Able ToDocument7 pagesIntroduction To Society, Community and Education Dr. Mike Kelvin Nicole N. Buted at The End of This Module, Pre-Service Teachers Should Be Able ToName S. CruzNo ratings yet

- BullyingDocument35 pagesBullyingArnel OlsimNo ratings yet

- Natres Case DigestDocument6 pagesNatres Case Digestamareia yapNo ratings yet

- Magic Titles Worth NotingDocument204 pagesMagic Titles Worth NotingVan Kochkarian0% (1)

- Advanced Introduction To Post Keynesian Economics - J. E. King Edward Elgar Publishing (2015) (Elgar Advanced Introductions)Document169 pagesAdvanced Introduction To Post Keynesian Economics - J. E. King Edward Elgar Publishing (2015) (Elgar Advanced Introductions)Lucas Jean de Miranda CoelhoNo ratings yet

- Collaborative Approaches To The Digital in English StudiesDocument314 pagesCollaborative Approaches To The Digital in English StudiesJames SmithNo ratings yet

- The Speech MechanismDocument5 pagesThe Speech MechanismSittie HijaraNo ratings yet

- Rewired:: Crafting A Compelling Customer ExperienceDocument11 pagesRewired:: Crafting A Compelling Customer ExperienceBophelo Edgar SejesoNo ratings yet

- Foundations of Tibetan TantraDocument29 pagesFoundations of Tibetan TantrachristianthomaskohlNo ratings yet

- CLass-III Summer Holiday HomeworkDocument14 pagesCLass-III Summer Holiday HomeworkShivam VermaNo ratings yet

- Oral Communication Module4Document4 pagesOral Communication Module4Jonalyn AndalloNo ratings yet

- DBMS Normalization Normalization: Types of Normal FormsDocument17 pagesDBMS Normalization Normalization: Types of Normal FormsAnick KhanNo ratings yet

- Sculptures and Architecture Saketh Reddy Roll No A03 Lovely School of ArchitectureDocument7 pagesSculptures and Architecture Saketh Reddy Roll No A03 Lovely School of ArchitecturesakethNo ratings yet

- Competence in Competency-Based Supervision PracticeDocument10 pagesCompetence in Competency-Based Supervision PracticeENSNo ratings yet

- Literature Review Presenter Dr. S. M. Shafiqul Islam Professor of StatisticsDocument10 pagesLiterature Review Presenter Dr. S. M. Shafiqul Islam Professor of StatisticsDevid LuizNo ratings yet

- Zulfiqar Ali Bhutto Notes From Death CellDocument69 pagesZulfiqar Ali Bhutto Notes From Death CellSani Panhwar100% (10)

- ASBU Methodology Summary of Block 0 Modules H. SudarshanDocument17 pagesASBU Methodology Summary of Block 0 Modules H. SudarshanvasidhartaNo ratings yet