Professional Documents

Culture Documents

1156-PT-038 (306) RP 1317

Uploaded by

el_sharkawy2011Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1156-PT-038 (306) RP 1317

Uploaded by

el_sharkawy2011Copyright:

Available Formats

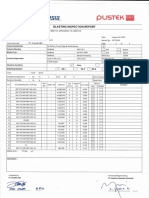

Report No 38

LIQUID PENETRANT

Test Date 10/7/2019

EXAMINATION REPORT

Sheet 1 of 1

Job No. : 1156/19 Project : BAPCO MODERNZATION PROGRAM Client : TECNICAS REUNIDAS TECHNICAL

Dwg No. : A1-33135-306 Material Type : Carbon steel

Weld Thickness : 10 mm Material Thickness: 10 mm Welding Process : FCAW

Surface Conditions : Burshing Surface Temperature : 25 Heat Treatment : None

Reference Procedure / Specifications: ASF-PT-001 Rev. 5 Acceptance Criteria : AWS D1.1 2015

Technique Description Penetrant used

Precleaning Method : Chemetall S-76 Penetrant Method : a S/R W/W P/E

Penetrant Application : Spraying

Dwell Time : 5-10 Min Penetrant Type : 240

Excess Penetrant Removing : Wiping With Lint free Cloth

Developing Application : Spraying Cleaner/Remover : S 76

Developing Time : 12 Min

Viewing Conditions : Visible Light Developer Type : LD 7

Black Light Intensity : N/A

Post Cleaning : Cleaning With S-76 Manufacturer : Chemetall

Welding Tested

Item No. POS QTY Welder ID Interpretation Result Remarks

Position Length

RP1317 . 1 309 No defect found ACC OK

RP1360 1 227 No defect found ACC OK

RP1314 1 161 No defect found ACC OK

RP1315 1 309 No defect found ACC OK

RP1364 2 227 No defect found ACC OK

10% Structure

1F

ASF Examiner THIRD PARTY CLIENT

Name M-ELSHAHAT

Signature

Level II

Date 10/7/2019

You might also like

- CatalougeDocument21 pagesCatalougea_zf2001100% (2)

- Visual Inspection ReportDocument5 pagesVisual Inspection ReportOmar WardehNo ratings yet

- PROTEM Completo PDFDocument44 pagesPROTEM Completo PDFMarcelo AguileraNo ratings yet

- Basf MasterEmaco 8100 APDocument49 pagesBasf MasterEmaco 8100 APabdul majeedNo ratings yet

- Tugas Metalurgi LasDocument16 pagesTugas Metalurgi LasMizan100% (2)

- AM Series 45-200 D170 Rev D-W OM PDFDocument15 pagesAM Series 45-200 D170 Rev D-W OM PDFNestor SalasNo ratings yet

- Saudi Sadara Inspection Checklist CoverDocument1 pageSaudi Sadara Inspection Checklist CoverArshad MahmoodNo ratings yet

- Aramco Balance Material Site IssuesDocument12 pagesAramco Balance Material Site IssuesVinay Yadav100% (1)

- Cummins L8.9 Oil Pressure InformationDocument1 pageCummins L8.9 Oil Pressure InformationThomasRudyNo ratings yet

- GSB-Form-58 Non Conforming Report (NCR)Document1 pageGSB-Form-58 Non Conforming Report (NCR)Made GileeNo ratings yet

- Preliminary Inspection Report of Line # 80-SCL-6016600-BB31C at VCM Plant UNIT-60 (Pipe Rack)Document3 pagesPreliminary Inspection Report of Line # 80-SCL-6016600-BB31C at VCM Plant UNIT-60 (Pipe Rack)Anonymous YRyGcKPNo ratings yet

- Pre Ot - Request For Site Driver - January-2021Document1 pagePre Ot - Request For Site Driver - January-2021Gurumoorthy RajavijayanNo ratings yet

- CV-DNV Format - Selva KumarDocument31 pagesCV-DNV Format - Selva KumarBaraneedharanNo ratings yet

- MGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031Document9 pagesMGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031velmurug_balaNo ratings yet

- Tools Register: NO Nama Barang Satuan JumlahDocument5 pagesTools Register: NO Nama Barang Satuan JumlahdennisjuntakNo ratings yet

- 20 Catalog Krisbow 9 WeldingDocument14 pages20 Catalog Krisbow 9 WeldingEnrique da MattaNo ratings yet

- Brosur BridgestoneDocument12 pagesBrosur BridgestoneWahyuni SalmanNo ratings yet

- RFI RecordDocument16 pagesRFI RecordmyraNo ratings yet

- EP 2 Grease PDFDocument2 pagesEP 2 Grease PDFTayyab IftikharNo ratings yet

- Technical & Price Proposal On Line Leak Sealing On Straight Pipe 2 Inchi PDFDocument5 pagesTechnical & Price Proposal On Line Leak Sealing On Straight Pipe 2 Inchi PDFandistwn99No ratings yet

- Sop & Jsa For Pipe LeakageDocument1 pageSop & Jsa For Pipe LeakageSoumya ChatterjeeNo ratings yet

- Xtreme King BulldogDocument12 pagesXtreme King BulldogGustavo Eduardo Vargas RaynholdsNo ratings yet

- GSB Form 221 Purchase RequestDocument2 pagesGSB Form 221 Purchase RequestMade GileeNo ratings yet

- Technical Service Report: PT Pama Persada Nusantara Distric Topb Kalimantan TengahDocument18 pagesTechnical Service Report: PT Pama Persada Nusantara Distric Topb Kalimantan TengahNanang AgustyaNo ratings yet

- Hydrogen Attack PDFDocument11 pagesHydrogen Attack PDFChanoNo ratings yet

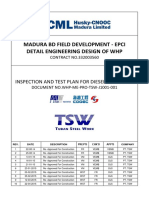

- Inspection Test Plan FOR Fabrication: Pt. Dwikappa Asri UtamaDocument27 pagesInspection Test Plan FOR Fabrication: Pt. Dwikappa Asri UtamaDwikappa Asri UtamaNo ratings yet

- Pm01988 Ge WG 5 1-8'' 10k SSV - Phase IDocument2 pagesPm01988 Ge WG 5 1-8'' 10k SSV - Phase IAbu UmarNo ratings yet

- Msds Chemical List 2021Document1 pageMsds Chemical List 2021Bayu Irawan sgiNo ratings yet

- GSB-Form-247 Dimension Inspection Report (Nozzle)Document1 pageGSB-Form-247 Dimension Inspection Report (Nozzle)Made GileeNo ratings yet

- Blasting ProcedureDocument3 pagesBlasting ProcedureFaiz ZainudinNo ratings yet

- Summary ReportDocument24 pagesSummary ReportRonniNo ratings yet

- Electrode Issue SlipDocument1 pageElectrode Issue SlipHasan ShahriarNo ratings yet

- GRACO King 45-1 PartsDocument10 pagesGRACO King 45-1 Partssamgivp2869No ratings yet

- Suould PDFDocument2 pagesSuould PDFMarta Beatriz Verbel ArroyoNo ratings yet

- Prosedur Penetran TestingDocument11 pagesProsedur Penetran TestingIkhsan DalimuntheNo ratings yet

- MC-7 HSE Inspection 04 May 2014Document9 pagesMC-7 HSE Inspection 04 May 2014Pokiko MikotoNo ratings yet

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument5 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- HIRAC For Project Retubing ACHEDocument2 pagesHIRAC For Project Retubing ACHEragilNo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument8 pagesTuv India Private Limited: Inspection Visit ReportAbhay KarandeNo ratings yet

- Sfa-5.6Document20 pagesSfa-5.6vannie_yundaNo ratings yet

- YS-EWO-BEC-0102 Detail Engineering For Sanitary System Connection From Berth 71, 72 To Berth 69 Pit (Sump)Document23 pagesYS-EWO-BEC-0102 Detail Engineering For Sanitary System Connection From Berth 71, 72 To Berth 69 Pit (Sump)AdnanNo ratings yet

- ASTM A106 Working PresureDocument4 pagesASTM A106 Working PresureAnkon MukherjeeNo ratings yet

- 3PS Gaw 003Document5 pages3PS Gaw 003ravi00098No ratings yet

- TM-81 Condenser Cleaner 5125Document6 pagesTM-81 Condenser Cleaner 5125gshdavidNo ratings yet

- Eng052 20erw 000 Qa WQS 0015 000 - 01Document6 pagesEng052 20erw 000 Qa WQS 0015 000 - 01Mohammed ShehinNo ratings yet

- IEC62109 CertificateDocument3 pagesIEC62109 CertificateJulio CesarNo ratings yet

- 5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-BDocument8 pages5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-Bammar mughalNo ratings yet

- Inspection CertificateDocument1 pageInspection CertificateAtanasio PerezNo ratings yet

- Report Blasting PDFDocument22 pagesReport Blasting PDFLord MobileNo ratings yet

- Welding and Cutting ProcedureDocument7 pagesWelding and Cutting ProceduredennisjuntakNo ratings yet

- Calibration & Measurement Report 0001Document4 pagesCalibration & Measurement Report 0001Sothy NanthiniNo ratings yet

- PF-0004-009-QA-955-0001 Rev D Code 1Document27 pagesPF-0004-009-QA-955-0001 Rev D Code 1Rıdvan UyarNo ratings yet

- Annual OkDocument22 pagesAnnual OkdennisjuntakNo ratings yet

- T-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Document110 pagesT-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Akansha SharmaNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- 04.12.2014 Udated Bar-Chart Common S D - Timeline - Copy12042014Document13 pages04.12.2014 Udated Bar-Chart Common S D - Timeline - Copy12042014Naushad AhamedNo ratings yet

- Check List For Arc Welding Machine: Description DayDocument2 pagesCheck List For Arc Welding Machine: Description DayAhmad Ishfahis Shofhal JamilNo ratings yet

- Msds. FSC-7CDocument3 pagesMsds. FSC-7CSagu LempengNo ratings yet

- CV Marmat BaruDocument26 pagesCV Marmat Barudonal sinagaNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- Din 7168-91 PDFDocument7 pagesDin 7168-91 PDFAndres Afanador MuñozNo ratings yet

- OpTransactionHistoryUX522-08-2022 23 - 27 - 53Document1 pageOpTransactionHistoryUX522-08-2022 23 - 27 - 53el_sharkawy2011No ratings yet

- 1 Dec2008Document9 pages1 Dec2008el_sharkawy2011No ratings yet

- Duplex Stainless Steel Quality - ASTM A923 Vs ISO 17781: HistoryDocument4 pagesDuplex Stainless Steel Quality - ASTM A923 Vs ISO 17781: HistoryshojiNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- As Run Sheet PQR 051 PDF FreeDocument14 pagesAs Run Sheet PQR 051 PDF Freeel_sharkawy2011No ratings yet

- Welding Guidelines For Duplex, Super Duplex and Hyper Duplex Stainless SteelsDocument8 pagesWelding Guidelines For Duplex, Super Duplex and Hyper Duplex Stainless Steelsel_sharkawy2011No ratings yet

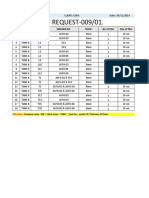

- Welders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJDocument3 pagesWelders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJel_sharkawy2011No ratings yet

- Welding of Duplex Stainless SteelDocument7 pagesWelding of Duplex Stainless Steelel_sharkawy2011No ratings yet

- Duplex Stainless Steels Welding Guidelines EN Juin 2019 WebDocument56 pagesDuplex Stainless Steels Welding Guidelines EN Juin 2019 WebMohamed YousufNo ratings yet

- Astm A923Document9 pagesAstm A923utreshwarmiskinNo ratings yet

- A Avesta-2507-P100 Ss en 5Document1 pageA Avesta-2507-P100 Ss en 5el_sharkawy2011No ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- PCP Workshop Special Items List Fainal 001 QuotedDocument17 pagesPCP Workshop Special Items List Fainal 001 Quotedel_sharkawy2011No ratings yet

- Humidity and Temperature FormDocument6 pagesHumidity and Temperature Formel_sharkawy2011No ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Humidity and Temperature FormDocument6 pagesHumidity and Temperature Formel_sharkawy2011No ratings yet

- Calibration Wekding EquipmentsDocument4 pagesCalibration Wekding Equipmentsel_sharkawy2011No ratings yet

- Working IsoDocument2 pagesWorking Isoel_sharkawy2011No ratings yet

- Liquid Penetrant Report: SER Iso No SH# SP# Joint No Joint Type DIA Welder Stamp Evaluation Remarks 1 2 3 4 5 6 7 8 9 10Document1 pageLiquid Penetrant Report: SER Iso No SH# SP# Joint No Joint Type DIA Welder Stamp Evaluation Remarks 1 2 3 4 5 6 7 8 9 10el_sharkawy2011No ratings yet

- PCP Workshop Special Items List Fainal 001 QuotedDocument17 pagesPCP Workshop Special Items List Fainal 001 Quotedel_sharkawy2011No ratings yet

- Measuring and Testing Equipment List: Page 1 of 2Document2 pagesMeasuring and Testing Equipment List: Page 1 of 2el_sharkawy2011No ratings yet

- Eslam Abdelhameed Asme Ix IdDocument1 pageEslam Abdelhameed Asme Ix Idel_sharkawy2011No ratings yet

- Iso PDFDocument1 pageIso PDFel_sharkawy2011No ratings yet

- RFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20Document1 pageRFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20el_sharkawy2011No ratings yet

- Corregation Test Sample #1Document2 pagesCorregation Test Sample #1el_sharkawy2011No ratings yet

- RT Request-003-1&-2Document2 pagesRT Request-003-1&-2el_sharkawy2011No ratings yet

- Tanks RT REQUESTDocument4 pagesTanks RT REQUESTel_sharkawy2011No ratings yet

- 7-Material ASME VIIIDocument23 pages7-Material ASME VIIIel_sharkawy2011No ratings yet

- MT ReportDocument11 pagesMT Reportel_sharkawy2011100% (1)

- WEG Coatings Industrial Maintenance 50021180 Brochure en PDFDocument20 pagesWEG Coatings Industrial Maintenance 50021180 Brochure en PDFsabari ramasamyNo ratings yet

- Curtain WallDocument18 pagesCurtain WallTushar JainNo ratings yet

- Arcam's EBMDocument10 pagesArcam's EBMFrancis XavierNo ratings yet

- Pla RubricsDocument89 pagesPla Rubricsapi-313716520No ratings yet

- Construction Electrical Boq NewDocument7 pagesConstruction Electrical Boq Newmudassir mNo ratings yet

- List of Pending Activities (Ground Floor)Document2 pagesList of Pending Activities (Ground Floor)Abdur RehmanNo ratings yet

- Shard Place: Design ArchitectDocument1 pageShard Place: Design ArchitectfereetNo ratings yet

- Econ Ball Valves Carbon Steel Stainless SteelDocument1 pageEcon Ball Valves Carbon Steel Stainless SteelChristianGuerreroNo ratings yet

- BridgeDocument4 pagesBridgeRoxana AylasNo ratings yet

- Fora 400Document4 pagesFora 400PeterWayNo ratings yet

- Installation Instructions W10436749 RevC PDFDocument36 pagesInstallation Instructions W10436749 RevC PDFCarlos Alberto VentreNo ratings yet

- Model GXLO Series SprinklersDocument5 pagesModel GXLO Series SprinklersAbed HajjoNo ratings yet

- ACI PRC-201.1-08 Guide For Conducting A Visual Inspection of Concrete in ServiceDocument19 pagesACI PRC-201.1-08 Guide For Conducting A Visual Inspection of Concrete in ServiceGikoNo ratings yet

- AENOR Product Certificate: PlasticsDocument2 pagesAENOR Product Certificate: PlasticsEliud RodriguezNo ratings yet

- Moisture Methods Plastic EN PDFDocument24 pagesMoisture Methods Plastic EN PDFAttef BedaweNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Effect of Grain Size and Heat Treatment Upon Impact ToughnessDocument14 pagesEffect of Grain Size and Heat Treatment Upon Impact Toughnessmass3444No ratings yet

- Hart Cooley 2206GS CatalogDocument142 pagesHart Cooley 2206GS Catalogyapoh91026No ratings yet

- Iv Report Malabar CementsDocument12 pagesIv Report Malabar CementsSafanaNo ratings yet

- BRTS IIB (Durga Pura Elevated Road, Jaipur)Document24 pagesBRTS IIB (Durga Pura Elevated Road, Jaipur)Devendra SharmaNo ratings yet

- Bidding Form Santos 1Document8 pagesBidding Form Santos 1Eldrianne Louie OponNo ratings yet

- Kitz DJ E-234-03 PDFDocument16 pagesKitz DJ E-234-03 PDFYudi KurniawanNo ratings yet

- Flowchart PekerjaanDocument14 pagesFlowchart PekerjaankurniawanNo ratings yet

- Safe N Silent Data Sheet inDocument2 pagesSafe N Silent Data Sheet inApoorv MahajanNo ratings yet

- M Beam Details1Document5 pagesM Beam Details1AATVIK SHRIVASTAVANo ratings yet

- Katalog CaravanDocument19 pagesKatalog CaravanOctavian GrecuNo ratings yet

- Sustainable Building TechnologiesDocument9 pagesSustainable Building TechnologiesprashuboyNo ratings yet

- Flexible Sprinkler Connection Type - Unbraided: Info@newage-India - in WWW - Newage-India - inDocument9 pagesFlexible Sprinkler Connection Type - Unbraided: Info@newage-India - in WWW - Newage-India - inAdmin NewAgeNo ratings yet