Professional Documents

Culture Documents

Curtain Wall Data Collection

Uploaded by

prachi surana0 ratings0% found this document useful (0 votes)

384 views1 pagedata collection for curtain walls of different types

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdata collection for curtain walls of different types

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

384 views1 pageCurtain Wall Data Collection

Uploaded by

prachi suranadata collection for curtain walls of different types

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

INTRODUCTION

•A curtain wall system is an outer covering of a building in which the

CURTAIN WALL

outer walls are non-structural, but merely keep the weather out and METAL CURTAIN WALLS

the occupants in.

• As the curtain wall is non-structural it can be made of a light 1. STICK TYPE CURTAIN WALLS

DATA COLLECTION

weight material, reducing construction costs.

• When glass is used as the curtain wall, a great advantage is that •Likely most common wall system especially

natural light can penetrate deeper within the building. on low-rise construction . COMPONENTS OF METAL CURTAIN WALLS

• The curtain wall façade does not carry any dead load weight from • Each component of wall is installed piece by piece in the

the building other than its own dead load weight. field. Installed with one- or two storey mullion lengths and

• The wall transfers horizontal wind loads that are incident upon it to horizontal rails equal in length to width of the infill panels 1. ANCHORS

the main building structure through connections at floors or • Field labour intensive and dependent • Curtain wall anchors connect the wall to the building and can

columns of the building. • Often utilize standard system be broadly grouped as both gravity and lateral load anchors

• A curtain wall is designed to resist air and water infiltration, sway • Minimum requirements for assembly facilities and (fixed) or as just lateral load anchors (slotted). Aside from

induced by wind and seismic forces acting on the building, and its shipping. their primary load carrying function anchors must be

own dead load weight forces. • Normally short lead time to arrive on-site, but longer designed to allow for adjustment to site conditions.

erection/close-in time on-site. THERE ARE TWO TYPES OF ANCHORS

TERMINOLOGIES IN A CURTAIN WALL • Difficult to accommodate in-plane movements due to 1. CONCRETE EMBEDED: This is a type in which

sway or seismic events. anchors are embedded in concrete

II. UNITIZED TYPE CURTAIN WALLS

2. MOUNTING LUG ASSEMBLY: In this type a lug is

•Most common to large high-rise buildings although found on buildings as Provided in which

low as four stories. The panel is fixed

• Large factory assembled framed units complete with spandrel panels and

often with vision lights installed.

Panels typically one-storey high by width of infill panels.

• Panels designed for sequential installation with interlocking split vertical

mullions and nesting horizontal rails at expansion joint.

• Significant fabrication facility and shipping requirement. 2. PROFILES

• More shop labour dependant and less field dependant than stick system •A wide range of cross sections or profiles is available from different

• Normally longer lead time to arrive on-site, but rapid erection with manufacturers.

minimum time to close in building once on-site. • Each manufacturer’s profile varies somewhat and incorporates different

• Design potential to accommodate in-plane movements due to sway and features, although common section widths and depths are found with

seismic events. most suppliers of standard systems.

MULLION AND PANEL SYSTEM 3. FASTENERS

•Mechanical fasteners such as screws and bolts

•It is combination of stick and unitized system where are used in the assembly of the curtain wall

mullion members are separately installed first and then framing, the fixing of the pressure plate and the

the preassembled framed units are placed between them. anchorage to the building.

•This system is often employed where mullion members • A wide variety of fastener types, thread types,

Aluminium Extrusions

are unusually deep or large in cross section , making it coatings and materials are available.

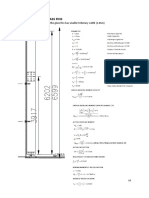

The extrusions are designed to resist seismic/wind loads in compliance with the requirements pertaining to the height of

impracticable to incorporate them as a part of

building. These extrusions are anodized to prevent corrosion and to improve aesthetics

preassembled unit.

Mullions

Mullions are provided basically to transfer the dead load of the Curtain wall. Mullion joint is preferred at the bracket location

•The preassembled unit used in this system may be one PRECAST RCC CURTAIN WALLS

storey in height or may be separated into a spandrel unit

and aluminium stiffeners are provided for extra strength. •Precast cladding or curtain walls are the most commonly used precast

and vision glass unit.

Transoms concrete components for building envelopes.

Transoms are aluminium sections provided in between the mullions horizontally. They are designed after due consideration of

the floor height and the false -ceiling height.

PANEL SYSTEM •This type of precast concrete panel does not transfer vertical loads but

simply encloses the space.

Silicone Sealants •Panel system is similar to preassembled unitized system except that •Cladding components are designed to resist wind, seismic forces

Silicone sealants are used to prevent the passage of moisture, air, dust and heat through all the joints. The putties formulated it consists of homogenous units formed from sheet metal or castings generated by their own weight and forces required to transfer the weight

from linseed and other organic oils were the first generation sealants that perform satisfactory for 5 to 7 years. Mastics with few joints except at glass periphery. of the panel to the support.

formulated from butyl and other synthetic oils, were improvement over putties. Their greater flexibility and movement •Mullions are omitted and connections are made to floor

permitted the use of aluminium and vinyl frames in place of wood •Panels may be small units, one or two storey in height with or

Setting blocks without openings for glazing.

Setting blocks are used to provide support in the relation to the size of glass, glazing techniques and condition of use. Setting • Units may be glazed during shop assembly or glazed after panels

blocks, which are rot-proof, non-absorbent and load bearing, capable of maintaining the requisite edge clearance without are installed on buildings.

presenting local areas of stress to the glass through being incompressible or non resilient should be used. • The panel system is economical when large numbers of identical

panels are to be used.

• The costs for in shop or site labor are both minimized.

TYPES OF CURTAIN WALLS

1. METAL CURTAIN WALLS

2. WINDOW WALLS

3. R.C.C CURTAIN WALLS

4. SPECIAL PURPOSE CURTAIN WALLS CONNECTION DETAILS BETWEEN PANELS

COLUMN COVER AND SPANDREL SYSTEM

1. METAL CURTAIN WALLS

•Panel system is similar to preassembled unitized system except that it

•An exterior curtain wall which may consist entirely or principally of metal, or may be a combination of metal, glass

consists of homogenous units formed from sheet metal or castings with

and other surfacing materials supported by or within a metal framework.

few joints except at glass periphery.

•Mullions are omitted and connections are made to floor

2. WINDOW WALLS

•Panels may be small units, one or two storey in height with or without

openings for glazing.

•A type of metal curtain wall installed between floors or between floor and roof and typically composed of vertical and

• Units may be glazed during shop assembly or glazed after panels are

horizontal framing members, containing operable sash or ventilators, fixed lights or opaque panels or any combination

installed on buildings.

thereof.

• The panel system is economical when large numbers of identical panels

are to be used.

3. RCC OR PRECAST CURTAIN WALLS • The costs for in shop or site labor are both minimized.

•Precast cladding or curtain walls are the most commonly used precast concrete components for building envelopes.

This type of precast concrete panel does not transfer vertical loads but simply encloses the space.

CONNECTION OF PANELS AT INTERMEDIATE FLOOR LEVELS

PRACHI .S. SURANA

ADVANCED BUILDING TECHNOLOGY A ND CONSTRUCTION - II -FOURTH YEAR - C

You might also like

- Advanced Structural Systems: Curtain WallsDocument13 pagesAdvanced Structural Systems: Curtain WallsSajid QuaziNo ratings yet

- Calculation Profile Curtain WallDocument91 pagesCalculation Profile Curtain WallEren BoyaciNo ratings yet

- TD - 50175 - Curtain Wall DetailsDocument1 pageTD - 50175 - Curtain Wall DetailsHasitha AthukoralaNo ratings yet

- 04 4012 00 PDFDocument38 pages04 4012 00 PDFrmdarisaNo ratings yet

- Unitized Curtain Wall SystemDocument38 pagesUnitized Curtain Wall Systems.senthil nathan100% (1)

- Glass Aluminum Curtain Wall SystemsDocument20 pagesGlass Aluminum Curtain Wall Systemsliuqian100% (1)

- DOUBLE SKIN FACADES FOR OFFICE BUILDINGS IN HOT AND DRY FinalDocument63 pagesDOUBLE SKIN FACADES FOR OFFICE BUILDINGS IN HOT AND DRY FinalharishNo ratings yet

- Facade ExamplesDocument10 pagesFacade ExamplesAmro Ahmad Ali100% (1)

- Kawneer Curtain Wall SystemDocument35 pagesKawneer Curtain Wall SystemCyrill GlennNo ratings yet

- HALFEN Curtain Wall Support SystemsDocument36 pagesHALFEN Curtain Wall Support Systemsvinthf100% (2)

- Curtain Wall Stick SystemDocument15 pagesCurtain Wall Stick SystemAnonymous PWdOlxY100% (2)

- Facade MaintenanceDocument8 pagesFacade Maintenanceanil100% (1)

- Building Material Science - GlassDocument53 pagesBuilding Material Science - GlassMuskaan Chowdhary100% (2)

- Curtain WallDocument32 pagesCurtain WallParas Gulia100% (6)

- Check For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Document5 pagesCheck For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Laurence SarmientoNo ratings yet

- Gana Glazing Manual (Latest)Document105 pagesGana Glazing Manual (Latest)rozleNo ratings yet

- Curtain Wall SystemsDocument28 pagesCurtain Wall SystemsKarvy Yadav90% (10)

- Eckersley O'callaghan: Structural and Facade EngineersDocument17 pagesEckersley O'callaghan: Structural and Facade EngineersDivyesh Mistry100% (1)

- Saflex Structural GuideDocument51 pagesSaflex Structural Guidemercab15No ratings yet

- Contemporary Curtain Wall ArchitectureDocument264 pagesContemporary Curtain Wall Architecturelee ching0% (1)

- Curtain GlazingDocument14 pagesCurtain GlazingsuhailNo ratings yet

- A421-A426 Curtain WallDocument8 pagesA421-A426 Curtain WallronniedakingpouNo ratings yet

- Bro Facade Systems Specification Guide PDFDocument48 pagesBro Facade Systems Specification Guide PDFabinavdevaNo ratings yet

- Curtain WallDocument9 pagesCurtain WallHansanee MagoNo ratings yet

- Element Facades LRDocument17 pagesElement Facades LRkothaunghtike100% (1)

- Curtain WallDocument3 pagesCurtain WalljitenderaNo ratings yet

- Design Components For Structural GlazingDocument8 pagesDesign Components For Structural GlazingnonspodNo ratings yet

- North American Glazing GuidelinesDocument10 pagesNorth American Glazing GuidelinesAyça Bayram OzcanlarNo ratings yet

- SAS Curtain Wall BrochureDocument28 pagesSAS Curtain Wall BrochureAngga RamadhanNo ratings yet

- CWDC 1 08 GasketsDocument59 pagesCWDC 1 08 GasketsJoni StulicNo ratings yet

- Static Calculation CWDocument64 pagesStatic Calculation CWR KNo ratings yet

- CWCT - Shadow Box Technical NoteDocument1 pageCWCT - Shadow Box Technical NotebatteekhNo ratings yet

- Building FacadesDocument23 pagesBuilding FacadesSHAHID THAKUR0% (1)

- Curtain WallDocument96 pagesCurtain WallJay100% (1)

- WernerSobek TripleZeroDocument2 pagesWernerSobek TripleZerocharbonelleNo ratings yet

- Facade-Alumimum & Glazing Works Scope-Technical SpecificationsDocument5 pagesFacade-Alumimum & Glazing Works Scope-Technical SpecificationsHasnain SafdarNo ratings yet

- Curtain Wall Glass Thickness DesignDocument2 pagesCurtain Wall Glass Thickness DesignKoala BNo ratings yet

- Glass Fixing DetailsDocument16 pagesGlass Fixing Detailsprasaddha100% (2)

- Application DetailsDocument4 pagesApplication Detailsregina_cdeguzmanNo ratings yet

- jgj102-2003 CurtainWall PDFDocument94 pagesjgj102-2003 CurtainWall PDFtonyNo ratings yet

- Frameless Glass PartitionDocument30 pagesFrameless Glass PartitionFashionable JewelleryNo ratings yet

- Curtain Walls ReportDocument13 pagesCurtain Walls ReportAshwini Bramhane100% (3)

- Curtain WallDocument20 pagesCurtain WallAkshay Borati50% (2)

- Curtain WallDocument38 pagesCurtain Walledbern20005873100% (4)

- Curtain Wall Fabrication Manual 1 2Document69 pagesCurtain Wall Fabrication Manual 1 2Suruthi Dasan67% (3)

- Kalzip StructuralDocument44 pagesKalzip StructuralZoranNo ratings yet

- Principles of Curtain WallingDocument16 pagesPrinciples of Curtain Wallingjewon100% (1)

- Advanced Glazing SystemsDocument45 pagesAdvanced Glazing SystemsSwati Singh100% (1)

- Dynamic Watertightness Tests For Curtain WallingDocument4 pagesDynamic Watertightness Tests For Curtain WallingHCStepNo ratings yet

- GlazingsDocument23 pagesGlazingsKinkar BhattacharjeeNo ratings yet

- Silicon Structural GlazingDocument30 pagesSilicon Structural Glazingedbern20005873No ratings yet

- Spider GlazingDocument23 pagesSpider GlazingSethusweet SethuramanNo ratings yet

- Earthquake ResistanceDocument3 pagesEarthquake ResistancesmaranikaNo ratings yet

- Wall ConstructionDocument6 pagesWall ConstructionAnn Cyrilla Coney Corporal100% (1)

- DiaphragmWalls Barretes PDFDocument4 pagesDiaphragmWalls Barretes PDFAnonymous 6vZfB9pfzaNo ratings yet

- 6 - ShearwallDocument80 pages6 - Shearwallc a r I o c o n s u e g r aNo ratings yet

- Curtainwall 130910145437 Phpapp01Document42 pagesCurtainwall 130910145437 Phpapp01Nikki DeleñaNo ratings yet

- Earthquake Resistant ConstructionDocument31 pagesEarthquake Resistant ConstructionPrasad ArsulNo ratings yet

- AP Precast Double Wall Product Wall NATDocument4 pagesAP Precast Double Wall Product Wall NATFirnanda PutraNo ratings yet

- Rubiks CubeDocument36 pagesRubiks CubequalchedunoNo ratings yet

- Saroj Bluebells RERA Area StatementDocument10 pagesSaroj Bluebells RERA Area StatementVeena SNo ratings yet

- SingleRAN GSM UMTS LTE - New Product Introduction v2.0Document9 pagesSingleRAN GSM UMTS LTE - New Product Introduction v2.0angicar100% (3)

- How To Use secureCRT Startup Log FileDocument17 pagesHow To Use secureCRT Startup Log FileMecael DesuyoNo ratings yet

- Cacti Host Template Mikrotik 0.8.8a Rev1Document103 pagesCacti Host Template Mikrotik 0.8.8a Rev1aedinNo ratings yet

- Christiansee, K. Et Al. (Eds.) (2019), The Grand ProjetDocument326 pagesChristiansee, K. Et Al. (Eds.) (2019), The Grand ProjetAlexandra MeraNo ratings yet

- Profil - Ball - Return AMF 82-90XL PDFDocument48 pagesProfil - Ball - Return AMF 82-90XL PDFblurmuruganNo ratings yet

- How To Smart Home PDF orDocument79 pagesHow To Smart Home PDF orAndrei Horhoianu100% (1)

- Types of BricksDocument1 pageTypes of BricksBrijesh KumarNo ratings yet

- Hygene EPIHANIOU Faucets INT EN-1 PDFDocument55 pagesHygene EPIHANIOU Faucets INT EN-1 PDFattikourisNo ratings yet

- Case Study - Floating HousesDocument6 pagesCase Study - Floating HousesAkari MeiNo ratings yet

- D8 Catalog Digital Update 20190521Document80 pagesD8 Catalog Digital Update 20190521Tuan QuangNo ratings yet

- Elasticsearch PyDocument107 pagesElasticsearch Pysrinivas eevuriNo ratings yet

- Himel Productos 10 1Document58 pagesHimel Productos 10 1yasserfouda100% (1)

- Introduction To Art and ArchitectureDocument3 pagesIntroduction To Art and ArchitectureLakshmi VennelaNo ratings yet

- Staad Example NewDocument58 pagesStaad Example Newsusarlasaicharan100% (1)

- 8255ADocument3 pages8255Ababa212No ratings yet

- C Annun8 009Document26 pagesC Annun8 009Youssef EBNo ratings yet

- Olar Energy The Renewable Source of Energy: Prepared ByDocument28 pagesOlar Energy The Renewable Source of Energy: Prepared ByNilaya SinghNo ratings yet

- Om FTKC NewDocument60 pagesOm FTKC Newbeni.nass8593No ratings yet

- Making Ubuntu Unity Look Beautiful by Enabling TransparencyDocument3 pagesMaking Ubuntu Unity Look Beautiful by Enabling TransparencyEnlighten LightNo ratings yet

- Schedule of Poultry Building in Sariaya (As of Feb 10,2021)Document6 pagesSchedule of Poultry Building in Sariaya (As of Feb 10,2021)Jhunie FlorestaNo ratings yet

- Analysis of Contemporary Architecture: Frank Lloyd Wright's Taliesin WestDocument3 pagesAnalysis of Contemporary Architecture: Frank Lloyd Wright's Taliesin WestJireh GraceNo ratings yet

- Comparisons Between Three Open Source Operating SystemDocument4 pagesComparisons Between Three Open Source Operating SystemحسينالصديقNo ratings yet

- 24Kv Secogear: Metal-Clad Switchgear Instruction ManualDocument53 pages24Kv Secogear: Metal-Clad Switchgear Instruction Manualleidy vidalNo ratings yet

- How PCI Express WorksDocument11 pagesHow PCI Express WorksNick.mkNo ratings yet

- Modem RouterDocument108 pagesModem RouterHahnPutraNo ratings yet

- Geometry in Islamic ArtDocument21 pagesGeometry in Islamic ArtGülüş Art GeometryNo ratings yet

- Design of Davit Arm & SupportDocument4 pagesDesign of Davit Arm & Supportorode franklynNo ratings yet

- D198 PDFDocument20 pagesD198 PDFArnold RojasNo ratings yet