Professional Documents

Culture Documents

5S Audit Checklist v2

Uploaded by

nhishamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5S Audit Checklist v2

Uploaded by

nhishamCopyright:

Available Formats

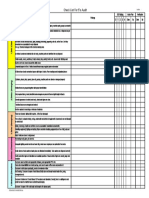

MA SEPANG MONTHLY 5S EVALUATION

MONTH SUPERVISOR SIGNATURE

DIV/DEPT/UNIT

5S REPRESENTATIVE

COMMENT

For each Audit statement, circle the mark that the best describes the condition based on the observations made.

(Untuk setiap kenyataan, bulatkan markah yang terbaik menggambarkan keadaan terhadap pemerhatian yang dilakukan)

Mark (Markah) Explanation (Penerangan)

1 Not at All

2 It is done but not systematically

3 Multiple evience showing its done systematically

4 Multiple evidence showing its doen systematically but not properly maintained

5 It is done systematically and maintained

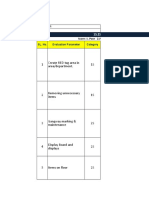

5S Description Questions Rating Comments

(Total Rating 100)

Floor area free of unwanted items 1 2 3 4 5

Top and insides of all cupboards, shelves, tables, etc free of unwanted items 1 2 3 4 5

All unnecessary items have been removed.

Sort / Sisih (Barangan yang tidak perlu telah disisihkan) Only the required Files/report is present in the area. Outdated or unnecessary memos, instructions, reports, posters, etc. are removed from 1 2 3 4 5

the area.

All tripping hazards such as electrical wires and equipment cables are removed from all working, standing, and walking areas. 1 2 3 4 5

Walls free of old posters, calendars, pictures, notices etc. 1 2 3 4 5

Files/Paperwork is properly labeled and has a clearly identified location that is away from work surfaces. 1 2 3 4 5

Any barriers to the movement due to

excessive items have been managed Equipment/machinery is labeled placed in a properly identified location. 1 2 3 4 5

Set in order/ Susun properly.

(Halangan terhadap pergerakan oleh Cables, wires, pipes etc. neat and straight 1 2 3 4 5

barangan yang berlebihan ditangani)

Any barriers to the movement due to excessive items have been managed properly. 1 2 3 4 5

Cleaning schedules available and displayed 1 2 3 4 5

Equipments and furnitures are clean , free

from dust, grease and oil.

Shine/ Sapu Floors, walls, windows doors etc. maintained at a high level of cleanliness 1 2 3 4 5

(Peralatan & Perabut adalah bersih & bebas

habuk, gris dan minyak)

Machines, equipment, tools, furniture maintained at a high level of cleanliness 1 2 3 4 5

Tools, equipment, paperwork, furniture, etc. is stored neatly in designated areas and are returned to their proper homes immediately after

1 2 3 4 5

use.

The signages and labels are available at

Standardization / appropriate location. The results of the previous audit are posted and clearly visible for the entire team. 1 2 3 4 5

Seragam (Tanda tunjuk arah dan label terdapat dan

berada di lokasi yang bersesuaian) Standard check lists is established and used to regularly inspect 5S 1 2 3 4 5

Labels, notices etc. are standardized 1 2 3 4 5

A member of management has participated in a 5S activity such as an audit or other activity 1 2 3 4 5

An efforts to sustain 5S are practices such

as 5S corner and information boards are The team took the initiative to make improvements to the workplace that were not identified during the last audit. 1 2 3 4 5

Sustain / Sentiasa created.

Amal (Usaha untuk mengekalkan amalan 5S

seperti Sudut 5S dan papan maklumat First 3S become a part of the daily work 1 2 3 4 5

diwujudkan)

5S posters and 5S points of work reminders displayed 1 2 3 4 5

Final Score

You might also like

- Lear 145 5S ChecklistsDocument10 pagesLear 145 5S ChecklistsEfrain PerezNo ratings yet

- Hazardous Materials Operating GuideDocument128 pagesHazardous Materials Operating GuidenhishamNo ratings yet

- Mobile Phone CloningDocument38 pagesMobile Phone CloningDevansh KumarNo ratings yet

- Hazardous Materials Incidents PDFDocument30 pagesHazardous Materials Incidents PDFnhishamNo ratings yet

- SQL Queries Interview Questions and Answers - Query ExamplesDocument25 pagesSQL Queries Interview Questions and Answers - Query Examplesiveraj67% (9)

- Passenger Elevator Operation ManualDocument24 pagesPassenger Elevator Operation ManualJahn Ray B. Lanozo100% (1)

- Pigging ProcedureDocument11 pagesPigging ProcedureEndika Alfan100% (9)

- 1S2S3S - Check SheetDocument1 page1S2S3S - Check SheetManoj KaushikNo ratings yet

- Maintain Training FacilitiesDocument14 pagesMaintain Training FacilitiesKen Balintay100% (1)

- 5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not NeededDocument2 pages5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not Neededsaeed ahmedNo ratings yet

- 5S Audit Checklist 2019 Rev 01Document3 pages5S Audit Checklist 2019 Rev 01SUGUNABALAKUMARNo ratings yet

- UntitledDocument385 pagesUntitledDelta BravoNo ratings yet

- 145 5S ChecklistsDocument10 pages145 5S Checklistsyogesh prajapatiNo ratings yet

- Oxylog Ve300Document134 pagesOxylog Ve300davidNo ratings yet

- Examples of Autonomous Maintenance Review Sheets LeanManufacturing - OnlineDocument15 pagesExamples of Autonomous Maintenance Review Sheets LeanManufacturing - Onlinesuzhou cNo ratings yet

- 5S-Manufacturing-Assessment v3.1Document2 pages5S-Manufacturing-Assessment v3.1MIKEHENDRICKNo ratings yet

- Housekeeping ScheduleDocument14 pagesHousekeeping ScheduleMark Stephen PerilloNo ratings yet

- Time Management - Top 18 Advantages and Disadvantages - WiseStepDocument5 pagesTime Management - Top 18 Advantages and Disadvantages - WiseStepnhishamNo ratings yet

- 5S Audit: Scoring Rubric: Score Description of Scoring CriteriaDocument4 pages5S Audit: Scoring Rubric: Score Description of Scoring CriteriaAhmed EssamNo ratings yet

- 5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreDocument2 pages5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreGeeTheWhizz100% (1)

- 6S Audit Checklist 2015Document2 pages6S Audit Checklist 2015Aisyah Nabilah Johary100% (7)

- UntitledDocument250 pagesUntitlednhishamNo ratings yet

- 5s Audit Check SheetDocument1 page5s Audit Check SheetDevendra Singh100% (1)

- 5S Score Warehouse Audit OMEX ConsultingDocument10 pages5S Score Warehouse Audit OMEX ConsultingNiel DariusNo ratings yet

- 5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreDocument4 pages5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreCaroline Eliza MendesNo ratings yet

- Risk Based Process Safety 1679636677Document87 pagesRisk Based Process Safety 1679636677nhishamNo ratings yet

- Virgin Galactic Profile & Performance Business ReportDocument10 pagesVirgin Galactic Profile & Performance Business ReportLoic PitoisNo ratings yet

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFradhajaladiNo ratings yet

- Css-5s Audit ScorecardDocument4 pagesCss-5s Audit ScorecardTarunaiNo ratings yet

- Check List For 5s Audit For UtyDocument1 pageCheck List For 5s Audit For Utysiruslara6491No ratings yet

- Monitoring 5s ProgressDocument76 pagesMonitoring 5s ProgressDamienNo ratings yet

- 6S Audit Report No 4Document17 pages6S Audit Report No 4Zul DiansyahNo ratings yet

- Office 5S - AdminDocument2 pagesOffice 5S - AdminavpmailsNo ratings yet

- Monitoring and Evaluation Sheet For The Progress of 5S-Kaizen ActivitiesDocument4 pagesMonitoring and Evaluation Sheet For The Progress of 5S-Kaizen ActivitiesanludfiNo ratings yet

- 5S Accounting 12-2-05 Ed Sosnowski - 1Document1 page5S Accounting 12-2-05 Ed Sosnowski - 1Pratik SharmaNo ratings yet

- 5s GuideDocument1 page5s Guidesklim ericNo ratings yet

- 5s KaizenDocument5 pages5s KaizenSÜMME AÇIKGÖZNo ratings yet

- Monitoring and Evaluation Sheet For The Progress of 5-S ActivitiesDocument5 pagesMonitoring and Evaluation Sheet For The Progress of 5-S ActivitiesDANTENo ratings yet

- 5S Format3 B REVDocument2 pages5S Format3 B REVSIVA966No ratings yet

- ChecklistDocument6 pagesChecklistElla JoyceNo ratings yet

- 5S Audit SheetDocument1 page5S Audit SheetSiddharth GuptaNo ratings yet

- Criteria Very Poor Poor Good Very Good Excellent Comments/Actions To Be TakenDocument5 pagesCriteria Very Poor Poor Good Very Good Excellent Comments/Actions To Be TakenCrispin HungNo ratings yet

- 5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Document6 pages5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Dian PeshevNo ratings yet

- SEC Standards - 1.8 - 5-Star Safety and Health Management System - Good HousekeepingDocument4 pagesSEC Standards - 1.8 - 5-Star Safety and Health Management System - Good HousekeepingAhmad Shawky El MadhalyNo ratings yet

- Audit FormatDocument2 pagesAudit Formatmrajbhar792No ratings yet

- Maintain Training FacilitiesDocument14 pagesMaintain Training FacilitiesArlynPorrasBonifacioNo ratings yet

- Monitoring and Evaluation Sheet For The Progress of 5-S ActivitiesDocument5 pagesMonitoring and Evaluation Sheet For The Progress of 5-S Activitieskevin ostos julcaNo ratings yet

- CBV MTFDocument13 pagesCBV MTFEduardo TomasNo ratings yet

- FormatosDocument8 pagesFormatosJuan Pablo GarzonNo ratings yet

- 5S Audit Check List (ICS Customised )Document4 pages5S Audit Check List (ICS Customised )Integrated ConsultancyNo ratings yet

- O 5SCL20 5S Audit Checklist Template USDocument4 pagesO 5SCL20 5S Audit Checklist Template USDamienNo ratings yet

- Audit 5 SDocument6 pagesAudit 5 SGleone KaiserinNo ratings yet

- Equipment Type Equipment Code Location Operation ProcedureDocument11 pagesEquipment Type Equipment Code Location Operation ProcedureKhiezher GoyonanNo ratings yet

- Maintain - Training - Facilities Muah MuahDocument19 pagesMaintain - Training - Facilities Muah MuahSalvador MiraNo ratings yet

- Supplemental Material:: Program Administration For 5S Roll-OutDocument21 pagesSupplemental Material:: Program Administration For 5S Roll-Outahmed nawazNo ratings yet

- 5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreDocument4 pages5S Audit Checklist: Sort Set in Order Shine Standardize Sustain Total Total Score No. of Questions Average ScoreJamsari SulaimanNo ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- Office 5 SformDocument2 pagesOffice 5 Sformfrenz2kiranNo ratings yet

- 6S Scan Diagnostic Sheet-ExampleDocument2 pages6S Scan Diagnostic Sheet-ExampleHardi BanuareaNo ratings yet

- 3 Manufacturing 5S ChecklistDocument10 pages3 Manufacturing 5S ChecklistBANCHISFOOD S.ANo ratings yet

- 5 SDocument2 pages5 SKristine GraceNo ratings yet

- Lear 145 5S - ChecklistsDocument10 pagesLear 145 5S - ChecklistsCarlos HernandezNo ratings yet

- 5s AuditchecklistDocument8 pages5s AuditchecklistDINESH SHARMANo ratings yet

- 5 Saud It ChecklistDocument5 pages5 Saud It Checklistclara_cahuaNo ratings yet

- 1S, 2S & 3S Check List: DepartmentDocument4 pages1S, 2S & 3S Check List: DepartmentBharathNo ratings yet

- 5s Audit Summary Score SheetDocument1 page5s Audit Summary Score SheetubraghuNo ratings yet

- 5s Audit Checklist NewDocument2 pages5s Audit Checklist NewdrkefyalewtayeNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistAtul Sharma100% (1)

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFTJOSNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistIan MardiansyahNo ratings yet

- UPLOADDocument7 pagesUPLOADMf TsdcNo ratings yet

- FRM PG Article June 2010 Smoke ExtractDocument4 pagesFRM PG Article June 2010 Smoke ExtractnhishamNo ratings yet

- Volume 4 - Water and Flood Response Text Digital v7 WebDocument50 pagesVolume 4 - Water and Flood Response Text Digital v7 WebnhishamNo ratings yet

- Fire Protection Aircraft Passenger Cabin PDFDocument6 pagesFire Protection Aircraft Passenger Cabin PDFnhishamNo ratings yet

- 1cvvecu5i 859848Document10 pages1cvvecu5i 859848nhishamNo ratings yet

- Aviation Nouns and VerbsDocument9 pagesAviation Nouns and VerbsnhishamNo ratings yet

- TTT Accreditation ProcessDocument1 pageTTT Accreditation ProcessnhishamNo ratings yet

- A4 Landscape 6 Storyboard TemplateDocument1 pageA4 Landscape 6 Storyboard TemplatenhishamNo ratings yet

- 1 Custom Lanyard Template PDFDocument1 page1 Custom Lanyard Template PDFnhishamNo ratings yet

- Materials: Retro-Reflectivity / Fluorescence OutershellDocument7 pagesMaterials: Retro-Reflectivity / Fluorescence OutershellnhishamNo ratings yet

- Cept FinalDocument14 pagesCept FinalVighnesh MalagiNo ratings yet

- Review of The Householder's Guide To Community Defence Against Bureaucratic Aggression (1973)Document2 pagesReview of The Householder's Guide To Community Defence Against Bureaucratic Aggression (1973)Regular BookshelfNo ratings yet

- Lesson 2 - Língua Inglesa 7Document21 pagesLesson 2 - Língua Inglesa 7Shara Maria Venâncio SilvaNo ratings yet

- Snigdha Chaturvedi PDFDocument5 pagesSnigdha Chaturvedi PDFHitesh KohliNo ratings yet

- Fender Re-Issue 62 Jazzmaster Wiring DiagramDocument1 pageFender Re-Issue 62 Jazzmaster Wiring DiagrambenitoNo ratings yet

- Clapham - Creativity TrainingDocument11 pagesClapham - Creativity TrainingNevenka JakšićNo ratings yet

- Chapter 6Document32 pagesChapter 6John Rick DayondonNo ratings yet

- Nutrition, Food Cravings and Aversions in PregnancyDocument9 pagesNutrition, Food Cravings and Aversions in PregnancyKanneaufii KaramelNo ratings yet

- Conscious Sedation PaediatricsDocument44 pagesConscious Sedation PaediatricsReeta TaxakNo ratings yet

- Verilog HDL: Special ClassesDocument11 pagesVerilog HDL: Special ClassesUnique ProNo ratings yet

- A View From Elkab The Tomb and Statues oDocument87 pagesA View From Elkab The Tomb and Statues oBeatriz FélixNo ratings yet

- Smart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Document1 pageSmart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Eeman AkbarNo ratings yet

- Chapter 3 - Instructional PlanningDocument30 pagesChapter 3 - Instructional PlanningMadelyne BenitezNo ratings yet

- Jisicom - Smart System of Fast Internet Access Development Using Backbone Network MethodDocument9 pagesJisicom - Smart System of Fast Internet Access Development Using Backbone Network MethodVerdi YasinNo ratings yet

- Cse205 Computer-Architecture-And-Organization TH 2.00 Ac26Document2 pagesCse205 Computer-Architecture-And-Organization TH 2.00 Ac26Ravi ThejaNo ratings yet

- CE6306-Strength of Materials NotesDocument16 pagesCE6306-Strength of Materials NotesTrishul SampathNo ratings yet

- QMM Epgdm 1Document113 pagesQMM Epgdm 1manish guptaNo ratings yet

- Database NotesDocument4 pagesDatabase NotesKanishka SeneviratneNo ratings yet

- Momentum - Action High Intensity 2022Document24 pagesMomentum - Action High Intensity 2022GabrielNo ratings yet

- Jess's Heart Is Racing at 100 Miles Per Hour.Document3 pagesJess's Heart Is Racing at 100 Miles Per Hour.vexagon wallowNo ratings yet

- Avamar - ADS Data Erasure-YES - I Understand All Data Will Be Lost by Performing This Procedure!Document30 pagesAvamar - ADS Data Erasure-YES - I Understand All Data Will Be Lost by Performing This Procedure!dansegui.mir4No ratings yet

- Pyneng Readthedocs Io en LatestDocument702 pagesPyneng Readthedocs Io en LatestNgọc Duy VõNo ratings yet

- Councillor Danny Thorpe: Leader, Royal Borough of GreenwichDocument2 pagesCouncillor Danny Thorpe: Leader, Royal Borough of GreenwichDr-Syed Ali TarekNo ratings yet