Professional Documents

Culture Documents

10 5923 J Ijmc 20150506 01 PDF

10 5923 J Ijmc 20150506 01 PDF

Uploaded by

Eran LopezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 5923 J Ijmc 20150506 01 PDF

10 5923 J Ijmc 20150506 01 PDF

Uploaded by

Eran LopezCopyright:

Available Formats

International Journal of Materials and Chemistry 2015, 5(6): 123-126

DOI: 10.5923/j.ijmc.20150506.01

Production of Silica Gel from Clay

Ayegba C. O.*, Makinde T., Obigwa P., Orijajogun J.

Sheda Science and Technology Complex

Abstract The production of silica gel from the natural clay obtained from Kwali area council of Abuja was carried out

using alkaline extraction followed by acid precipitation. The alkaline extraction was investigated using 4%, 15%, 25% and

30% (wt) sodium hydroxide solution at various reaction times of 1hr 1½ hr, 2hrs, 2½ hrs, 3hrs, 4hrs, 5hrs,7hrs and 8hrs. The

highest yield of 15.25% silica gel for 25g of clay was recorded at 25% (wt) of the sodium hydroxide solution and reaction

times of 4hrs. The x ray diffraction analysis and characterization of the clay showed the predominance of quartz and illite.

There were also peaks showing the presence of kaolinite, goethite and rutile.

Keywords Silica Gel, Quartz, Diffraction, Extraction

at high temperatures and (Maeda and Komatsu 1996) studied

1. Introduction the semiconductor properties of silicon carbide produced

from rice hull. Semiconductor industries require pure silica,

Silica is extensively found in nature either as a major currently produced by smelting quartz in a high temperature

mineral in most igneous (e.g granite) or sedimentary (e.g furnace, to produce ultrapure polycrystalline silicon and

sand and sand stone) or metamorphic rocks (quartzite, silicon hydride.

gneiss). Silica is most commonly found in nature as quartz, Most of the research work carried out for the preparation

as well as in various living organism. It is produced by a of different grades and forms of silica gel exist in patent form

simple method based on alkaline extraction this is followed and no detailed experimental procedures are available (Hafiz

by acid precipitation, the gelatinous precipitate is washed, et al., 2009). This work is aimed at investigating the

then dehydrated to produce silica gel. The gel or colloid effectiveness of: (1) alkali extraction of silica from Kwali

consist mainly of hydrated silica (SiO2.nH2O). The term clay, and (2) washing silica gel with water, in reducing the

“Gel” merely indicates the condition of the material at one mineral content of silica produced by the alkali extraction.

stage of its manufacture. It is highly porous structure,

characterized by uniformity of the arrangement of the pores

and their sizes. The pore area of silica gel varies with the 2. Experimental Section

method of manufacture. Silica gel is widely used as a

desiccant. Its role as a catalyst support, as a flatting agent in 2.1. Materials and Method

coatings and as a selective adsorbent in column The clay used for the production of silica gel was obtained

chromatography is well established. It has the application in from Kwali in Kwali area council, Abuja Nigeria. The clay

modification of viscosities and thixotropy of the liquids. was ground into powder and sieved using a 250micron sieve.

Soluble silicates produced from silica are widely used in the 25g of the clay powder was then mixed with various

glass, ceramics, and cement as a major component and in concentration of aqueous Sodium hydroxide (4%, 15%, 25%

pharmaceuticals, cosmetics, and detergents industries as a and 30%) at liquid to solid ratio 2:1 in a 250ml circular flask.

bonding and adhesive agents (Anon., 1997); (Laxamana, The flask was placed on a heating mantle at a temperature of

1982). Silica also has been used as a major precursor for a 80°C and heated and agitated at various reaction time of

variety of inorganic and organometallic materials which 1hour, 1½ hour, 2hours and 2½ hour, 3hours, 4hours, 5hours,

have applications in synthetic chemistry as catalysts, and in 6hours, 7hours and 8hours. The mixture was removed from

thin films or coatings for electronic and optical materials the heating mantle and centrifuge. The liquid portion of the

(Lender and Ruiter, 1990; Brinker and Scherer, 1990). mixture was separated and the pH adjusted to 4 with

(Mizuki et al., 1993) and (Krishnaro and Godkhindi 1992) hydrochloric acid. The liquid was neutralized with ammonia

investigated the formation of silicon carbide from rice hulls solution and then centrifuge to separate the precipitate (gel)

from the solution. The gel was washed several times with

* Corresponding author:

clemsking@yahoo.co.uk (Ayegba C. O.)

deionized water to remove sodium chloride. Complete

Published online at http://journal.sapub.org/ijmc removal of the salt was verified by the X-ray diffraction

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved analysis. The sample was then dried in the oven at 105°C and

124 Ayegba C. O. et al.: Production of Silica Gel from Clay

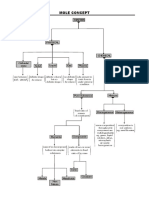

quantified. Figure 1 is a process diagram for the production N2 = normality of iodine

of soluble sodium silicate. N1 = normality of sodium thiosulphate

DF = dilution factor

2.2. Characterizations I = volume of iodine (ml)

The X-ray diffraction analysis of the silica gel produced H = volume of 5% HCl (ml)

and the clay (powder) were carried out to determine their the F = filtrate (ml)

phases present, the x ray diffraction analysis was carried out

using multipurpose x-ray Diffractometer (Panalytical). The

yield of silica gel produced at various concentration of 3. Results and Discussion

sodium hydroxide was determined from equation (1):

3.1. Effect of Reaction Time on Yield of Silica Gel

m2 Reaction Weight of Concentration Silica gel Yield

Yield = *100 (1)

m1 time (hr) clay (g) of NaOH (%) (g) (%)

1½ 25 25 0.897 3.6

Where

2 25 25 1.511 6.04

m1 = mass of clay (g)

2½ 25 25 1.911 7.64

m2 = mass of silica gel produced (g)

The iodine number of the silica gel was determined using 3 25 25 1.269 5..80

ASTM method. The iodine number was calculated using 4 25 25 3.820 15.30

equation (2) 5 25 25 3.811 15.24

[A − (DF)(B)(S)] 7 25 25 3.645 14.58

Iodine Number = (2) 8 25 25 3.800 15.2

M

A = (N2)(1269.3) The effect of reaction time on the yield of silica gel from

H+I kwali clay was investigated by varying the reaction time one

DF = and half hour to 8hours. The highest yield of silica gel was

F obtained at the reaction time of 4hours. (XU YING-MEI et

B = (N1)(126.93) al., 2010) reported a reaction time of 3hour.

Figure 1. Flow diagram for the production of soluble sodium silicate

International Journal of Materials and Chemistry 2015, 5(6): 123-126 125

3.2. Effect of NaOH Concentration of on the Yield of Silica Gel

Reaction time (hr) Weight of clay (g) Concentration of NaOH (%) Weight of silica gel (g)

2 25 4 1.496

2 25 15 2.867

2 25 25 3.820

2 25 30 3.816

2 25 40 3.821

3.3. X-ray Analysis

Figure 2. XRD of Clay

Figure 3. XRD of Silica Gel

126 Ayegba C. O. et al.: Production of Silica Gel from Clay

The interpretation of the diffractogram was done by properties of a good quality commercially available silica gel

carrying out search and match on highscore software

(panalytical). The highscore compares diffractograms with

reference diffractograms by using different colouration to ACKNOWLEDGEMENTS

identify different phases in a sample.

The result of search and match on the highscore identified The authors are grateful to the Sheda Science and

quarzt and kaolinite as the predominant phases with scores of Technology Complex, Abuja for facilities and sponsorship

58 and 42 respectively. Peaks at 23.036°, 26.702°, 40.374°, of this project.

45.838°, 50.220°, 54.953°, 60.034°, 62.304°, and 76.037°

showed the presence of quartz in the clay. And peaks at

12.186°, 19.844°, 25.081°, and 42.478° showed the presence

of kaolinite. The x ray diffraction analysis of the clay showed REFERENCES

the predominance of quartz and illite. Also the diffractogram

was compare to previous work reported by (Souza et al., [1] Anon., (1997). Soluble Silicates and their Applications.

Crossfield Publication, Crossfield, Warrington, UK, Issue No.

2013). Using the technique of peak position (2thetha) and 2.

intensity of peaks, kaolinite, goethite and rutile seem to be

present. [2] Laxamana, N.B., (1982). Binders from rice hull ash low-cost

The X-ray diffraction pattern shown in Figure 1 reveals housing materials. Forbride-Dig. College: Forest Products

Research and Industries Development Commission 11,

that the X-ray diffaction studies of the silica gel indicated 27-30.

relatively high disordered structure of silica. It also shows

that the silica gel is completely free of sodium chloride, [3] Brinker, C.J., Scherer, G.W., (1990). Applications. In:

proving the effectiveness of the extraction process. Sol-Gel Science, The Physics and Chemistry of Sol-Gel

Processing. Academic Press, San Diego, CA, pp. 839-880.

3.4. Iodine Number [4] Lender, P.W., Ruiter, R., (1990). Novel inorganic materials

Iodine number indicates the extent of surface area existing and heterogeneous catalysis: Preparation and properties of

high surface area silicon carbide and silicon oxynitrides. In:

in the silica gel sample and hence are important parameters Sheats, J.E., Carraher, C.E., Pittman, C.U., Eldin, M., Currell,

for assessing the usefulness of the sample for its industrial B. (Eds.), Inorganic and Metal-Containing Polymeric

applications as a desiccant and catalyst support. The iodine Materials, Plenum Press, New York, pp. 187-195.

number of 21.95mg/gI2 was obtained for the silica gel

[5] Mizuki, E., Okumura, S., Saito, H., Muro, S., (1993).

produced. This value is close to iodine number of Formation of silicon carbide from rice husks using enzymatic

23.87mg/gI2 for commercial granular silica gel. Also (Hafiz methods for carbon control. Biores. Technol. 44, 47-51.\

et al., 2009) reported 23.60mg/gI2.

[6] Maeda, E., Komatsu, M., (1996). The thermoelectric

performance of silicon carbide semiconductor made from rice

hull. Mater. Res.Soc. Symp. Proc. 410, 77-82.

4. Conclusions

[7] Krishnaro, R.V., Godkhindi, M.M., (1992). Distribution of

Non indicating (white) amorphous silica gel has been silica in rice husk and its effect on formation of silicon

prepared successfully. The clay used for this work is widely carbide. Ceramics Intl. 18, 243-249.

avalaible in kwali, Abuja, Nigeria. This investigation has [8] Xu Ying-Mei, Qi Ji, He De-Min, Wang Dong-Mei, Chen

indicated that there is a great scope for their exploitation as Hui-Ying, (2010). Guan Jun, Zhang Qiu-Min. Preparation of

the raw materials for the production of silica gel on industrial Amorphous Silica From Oil Shale residue and Surface

scale in the country. Modification by Silane Coupling Agent. Oil Shale, Vol. 27,

This investigation shows that the quantity of silica gel No. 1, pp. 37–46.

produced increased with the increase in reaction time with [9] Souza A. E.; Teixeira S. R.; Santos G. T. A.; Longo E. (2013).

the optimum quantity of 3.82g of silica gel obtained per 25g Addition of sedimentary rock to kaolinitic clays: influence on

of clay in 4hrs. also the quantity of silica gel produced sintering process Cerâmica vol.59 no.349.

increased with the concentration of sodium hydroxide with [10] Hafiz Asghar Ali, Arshad Chughtai and Abdul Sattar, (2009).

the optimum quantity obtained at 25% of sodium hydroxide. Synthesis of quality silica gel; Optimization of parameters

The silica gel produced shows close resemblance to the Journal of Faculty of Engineering & Technology, pages xx-xx.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 8 White Oil OfferDocument9 pages8 White Oil Offervivek dakavarapuNo ratings yet

- MSDS LBLA Glue SuperheroDocument7 pagesMSDS LBLA Glue SuperherotiffyoloNo ratings yet

- Metal and Non Metal NotesDocument13 pagesMetal and Non Metal NotesShabad SinghNo ratings yet

- Polygon PP-R Pricelist 2018Document7 pagesPolygon PP-R Pricelist 2018pepito manalotoNo ratings yet

- Bahagian ADocument22 pagesBahagian AWan HaziqNo ratings yet

- Instr-Tes200 en PDFDocument2 pagesInstr-Tes200 en PDFDaniel IliescuNo ratings yet

- Technical Data Sheet Simona PP-H AlphaplusDocument1 pageTechnical Data Sheet Simona PP-H AlphaplusBilel MahjoubNo ratings yet

- PH - Buffers 1 QPDocument12 pagesPH - Buffers 1 QPRoshae SinclairNo ratings yet

- Bolt Grade Markings and Strength ChartDocument2 pagesBolt Grade Markings and Strength ChartGregory GaschteffNo ratings yet

- Jet-Lube Marine Grade Anti-SeizeDocument1 pageJet-Lube Marine Grade Anti-SeizeDon HowardNo ratings yet

- WPS BargeDocument1 pageWPS BargeBouzaida MaherNo ratings yet

- Thermo-Physiological Comfort of Printed CoolMax FabricDocument7 pagesThermo-Physiological Comfort of Printed CoolMax Fabricbasma ahmedNo ratings yet

- Pds CPD Sika Duoflex SL UsDocument4 pagesPds CPD Sika Duoflex SL UsJohnNo ratings yet

- Saf-T Vent Ci+ Al-429cDocument42 pagesSaf-T Vent Ci+ Al-429cAlex BogomolnyNo ratings yet

- Saline WaterDocument20 pagesSaline WaterAdroNo ratings yet

- Properties of Cu S and Zno Films Deposited by Radio Frequency Magnetron SputteringDocument27 pagesProperties of Cu S and Zno Films Deposited by Radio Frequency Magnetron SputteringThahirah AriefNo ratings yet

- Kim Lighting Concept 5000 Series Brochure 1981Document20 pagesKim Lighting Concept 5000 Series Brochure 1981Alan MastersNo ratings yet

- Hydraulic Oil H 22 32 46 68 100 150Document1 pageHydraulic Oil H 22 32 46 68 100 150GTMNo ratings yet

- Quick Delivery - ProductCutSheet - SE1-12-432-A4X-QD - 20200929034630 PDFDocument2 pagesQuick Delivery - ProductCutSheet - SE1-12-432-A4X-QD - 20200929034630 PDFzumrottNo ratings yet

- Shrinkage TestDocument12 pagesShrinkage TestAlsonChinNo ratings yet

- AGROADJENGDocument20 pagesAGROADJENGLuís Felipe MinelloNo ratings yet

- 2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetDocument4 pages2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetAlfonso BlancoNo ratings yet

- Materials Testing Manual Part 9: ConcreteDocument62 pagesMaterials Testing Manual Part 9: ConcreteBartoFreitasNo ratings yet

- Chem AnswersDocument8 pagesChem AnswersEunielyn SecretoNo ratings yet

- Adhesive GlueDocument14 pagesAdhesive GlueVenkadesh SubramanianNo ratings yet

- The Empirical Formula of Magnesium OxideDocument3 pagesThe Empirical Formula of Magnesium Oxideみゆ マイクロ100% (2)

- G1814BCDocument2 pagesG1814BCeisenbarger5607No ratings yet

- Cal Tube ListDocument109 pagesCal Tube Listafiqhashim89No ratings yet

- Stochiometry-Jeemain Guru PDFDocument19 pagesStochiometry-Jeemain Guru PDFhimanshu yadavNo ratings yet

- Plumbing Fixture ScheduleDocument3 pagesPlumbing Fixture SchedulejacksondcplNo ratings yet