Professional Documents

Culture Documents

11 5282 TM L11 Dock Scheduling v2016.1 PDF

11 5282 TM L11 Dock Scheduling v2016.1 PDF

Uploaded by

priya singarajuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 5282 TM L11 Dock Scheduling v2016.1 PDF

11 5282 TM L11 Dock Scheduling v2016.1 PDF

Uploaded by

priya singarajuCopyright:

Available Formats

Lesson 11: Dock Scheduling 11

Lesson Overview

In this lesson, you will learn about the concept of dock scheduling

and how it works in Transportation Manager (TM). You will also

learn how to create docks for your shipping locations and use the

Dock Schedule module in TM to view dock commitments and

capacities for docks.

Learning Objectives

After completing this lesson, you will be able to:

Explain the concept of dock scheduling

Perform dock scheduling in TM

JDA Software Group, Inc. July 2016 Page 539

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Dock Scheduling Overview

Shipping locations often have capacity constraints such as limited

docks or dock access. Multiple trucks arrive at the docks to load or

unload goods at the same time leading to dock congestion. How

can you avoid dock congestion?

Dock Scheduling can help you avoid dock congestion by arranging

a specific time and dock location for loading or unloading

shipments. It enables you to model dock facilities and create plan

outputs that take into account any physical and scheduling

constraints at the docks.

Dock scheduling is useful when scheduling inbound and outbound

movements from a facility where dock capacity is constrained.

This capacity is primarily constrained by the number of doors at

the facility. When there is more freight to load than available doors

at the location, trailers need to be scheduled. They must be loaded

in sequence such that once a trailer is full, it can be hooked and

taken away and a new trailer can take the door position to be

loaded with the next set of goods.

Apart, from modeling dock facilities to avoid congestion, docks

can also be modeled based on equipment type and type of

commodity.

Docks may also have physical limitations that prevent them from

servicing larger-sized equipment. For example, smaller docks in

urban areas may not have enough room to allow a longer van to

reverse and back into the door. Alternatively, a planner may not

want to send a straight truck with a lift gate into a facility that has

ample dock facilities for receiving trailers. Dock equipment type

Page 540 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

modeling allows users to create the inclusive list of equipment

types allowed at a dock.

Docks at larger facilities may only receive certain types of

commodities. For example, products that need refrigeration may be

located in a separate part of the building from ambient temperature

goods that can be stored anywhere in the warehouse. These

separate parts of a warehouse may even have their own shipping

and receiving hours. Dock commodity modeling enables you to

accommodate these types of constraints.

Dock Scheduling in TM

In TM, a dock is an entity that has to be associated with a shipping

location. If a shipping location supports docks, those docks can be

configured in TM to be booked as part of Dock Scheduling.

Docks can be set up for a Load-at, Consignee, Hub, or Distribution

Center (DC). Docks can be inbound, outbound, or both.

Docks can be scheduled for loads either manually or automatically

during optimization with the help of Transportation Planner (TP).

TP optimizes newly built and existing loads/trips. It also tries to

assign vehicles and schedule docks for these vehicles.

The Dock Scheduling feature allows you to define dock selection

constraints so that TP:

Excludes loads that use equipment types, which cannot be

handled by dock facilities at particular locations.

Schedules only as many loads as the location can handle when

supplied with many loads in the same time period with the

same equipment type. It also verifies that inappropriate docks

are not used for these loads.

Schedules only as many loads of each equipment type as the

location can handle when supplied with many loads with

different equipment types and the same time window. It tries to

allocate docks efficiently and use appropriate facilities to

handle each load or trip.

Schedules only loads that can be handled at a dock at one time,

based on the amount of contiguous space available on the dock

(if you specify dock length) and the length of the equipment.

JDA Software Group, Inc. July 2016 Page 541

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Terminology

Before we proceed to look at the dock scheduling workflow in TM,

here are a few terms you need to be familiar with while working

with dock schedules.

Time Slot: The Start Date/Time and End Date/Time for the usage

of a Dock space (door) for a load.

Booking: The assignment of a TM load to a time slot.

Dock Capacity: The maximum that a dock can handle in a given

time period for a day of the week.

Capacity schedules can be defined for each dock area. If a capacity

schedule is not defined for a dock, capacity at the dock is

unlimited.

Dock Commitment: A commitment created on a dock for a

specified time to fulfill loading/unloading activity at that dock.

Pre-Loading: Refers to loading a trailer at the first stop, then

waiting for a certain amount of time before the carrier comes to

pick up the loaded trailer. Pre-loading is applicable in a non-live

loading scenario as it separates the activity of actual loading from

the carrier pickup activity.

Post-Discharge: Refers to a loaded trailer dropped off by the

carrier at the last stop, and then waiting for a certain amount of

time before the trailer is unloaded. Post-discharge is applicable in a

non-live unloading scenario as it separates the activity of actual

unloading from the carrier drop-off activity.

Associated and Unassociated Dock Commitments: A dock

commitment that is associated to a specific load/stop is called an

associated dock commitment and a dock commitment that is not

associated to a specific load/stop is referred to as an unassociated

dock commitment. Authorized users can create both the types of

dock commitments.

Dock Commitment Eligible Start Times: Indicates at what

instance of the hour the dock starts loading or unloading.

Possible values can be by the hour, half-hour, by the tens, etc.

Dock Commitment Violation: Refers to error conditions for a

dock commitment.

There are multiple possible error conditions, such as commodity

violation, equipment type violation, inbound / outbound violation,

pre-loading/post-discharge time violation, dock activity violation,

and loading type violation.

Page 542 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

During optimization, dock commitment violation will not occur.

Only during manual dock scheduling, authorized users can

violate dock commitments. For example, a user can modify the

equipment type that a specific dock can handle, leading to an

equipment type violation.

Dock Scheduling: Setup Options

You need to configure TM to work with docks and dock schedules.

You can configure TM at two levels:

Global Defaults: Define user group defaults, enable/disable

cut off time, time interval for dock commitments, etc.

User Group Level: Define user/carrier permissions to manage

Dock Commitments/Slot Bookings.

Global Defaults Setup

To set up global defaults for dock scheduling,

1. Navigate to Environment > Global Settings.

2. In the System Configuration Operations section, click

Transaction Management.

3. On the Transaction Management page, click the Load 3 tab.

This tab specifies all the fields related to Dock Scheduling.

All information entered on this page will be setup as defaults while

creating user groups, docks, and unassociated dock commitments.

JDA Software Group, Inc. July 2016 Page 543

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

User Groups Setup

In a User Group setup, dock scheduling controls are maintained at

a user-group level. When creating a user group, defaults will be

established for the dock scheduling controls based on

corresponding fields in the Global Settings.

Page 544 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

While setting up user groups, you can assign permissions to

carriers and employees to work with dock schedules using the

following fields:

Eligible to Maintain Dock Commitment with Violations:

When this field is unchecked, users in the user group cannot

create/update/delete dock commitments that have violations,

nor can they create or modify a dock commitment that would

result in a new violation scenario.

Dock Commitment Date/Time Access: The value defined at

user-group level will control whether users in the user group

are allowed to edit the start date, end date, and end time for a

dock commitment. Possible values include:

o All (Can edit Start Date/Time, Duration, and End

Date/Time)

o Start Date/Time Only (Duration and End Date/Time cannot

be edited)

o Start Time Only (Start Date, Duration, and End Date/Time

cannot be edited)

Eligible to Maintain Unassociated Dock Commitments:

When this field is unchecked, users in the user group cannot

create/update/delete unassociated dock commitments.

Enforce Minimum Lead Time for Editing Dock

Commitments: When this field is checked, users in the user

group cannot modify dock commitments where the start

date/time is less than xxx hours in the future, where xxx refers

to the minimum lead time for editing dock commitments for

the applicable dock (specified in Global defaults). For example,

if the dock commitment is from 10:30 A.M. to 11:30 A.M., and

if this field is checked, then the user cannot modify the dock

commitment outside the specified time, say before 10:30 A.M.

Enforce Cut-Off Time for Next Business Day for Dock

Commitments: When this field is checked, if a value is

defined for the cut off time for the next business day for editing

dock commitments for the applicable dock (specified in Global

Defaults), users in this user group cannot modify dock

commitments if the date portion of the start date/time for the

dock commitment is equal to the date for the next business day

for the dock and the current time (adjusted to the time zone

context for the dock's location) is greater than the cutoff time

for the dock.

Enforce Maximum Days Dock Commitment Start Date

Change: When this field is selected, users in the user group

JDA Software Group, Inc. July 2016 Page 545

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

will not be able to create/update/delete dock commitments if

either of the following statements is true or would be true if the

transaction were allowed to proceed:

o The start date is more than xxx days later than the

default start date, where xxx refers to the maximum

number of days (later) for the dock.

o The start date is more than yyy days earlier than the

default start date, where yyy refers to the maximum

number of days (earlier) defined for the dock.

Enforce Live/Non-Live Violations: When this field is

selected, users in the user group will not be able to

create/update/delete dock commitments if the live/non-live

violation condition is currently applicable or would be

applicable if the transaction were allowed to proceed.

Enforce Dock Selection Constraint Violations: When this

field is selected, users in the user group will not be able to

create/update/delete dock commitments if the dock

commitment constraint violation condition is currently

applicable or would be applicable if the transaction were

allowed to proceed.

Page 546 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Working with Dock Schedules

Now that you have an understanding of the concept of dock

scheduling and setup options for dock scheduling in TM, let’s

learn to work with dock schedules.

Creating Docks

To work with dock schedules, the first step is to create or set up a

dock for a shipping location in TM.

To create a dock:

1. Navigate to the System Entities > Principal > Docks.

The List of Docks page is displayed which lists the docks for all

shipping locations.

2. Click New to create a dock.

JDA Software Group, Inc. July 2016 Page 547

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

3. On the Create Dock page, type the information required to

create a dock.

Page 548 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Let us look at some of the fields available on the Create Dock

page:

Location Type and Location ID: Used to associate the dock

to an existing shipping location

As mentioned earlier, you can create docks for Load-at,

Consignee, DC or a Hub.

Dock ID: A unique ID to identify the dock

Dock Type: Can be Inbound, Outbound, or both

Inbound docks can be used only at DROP stops and outbound

docks can be used only at PICK stops. The dock type ‘BOTH’

allows the dock to be used at both PICK and DROP locations.

Priority: Indicates the dock priority

These are relative values for docks at a shipping location.

While building loads, the dock with the highest priority will be

picked before other docks for the same location. Lowest

numeric value indicates highest priority.

Enabled for Optimization: Indicates whether the dock be

considered by optimization strategies, which are used to assign

dock commitments to stops.

If selected, the dock will be available for manual dock

assignment as well as dock assignment by TP.

If this check box is not selected, the dock will be available for

manual dock assignment, but will not be considered by TP.

Inbound / Outbound Environment: Indicates whether the

dock will be used for live (carrier waits for the goods to be

loaded/removed from the trailer) and/or non-live (carrier does

not wait while the goods are loaded onto a trailer) activity

Dock Commitment Eligible Start Times: Controls the

eligible start times for dock commitments for the dock

Potential values are: Hourly on the Hour, Hourly on the Half

Hour, On the Half Hour, On the Quarter Hour, On the

Twenties, and On the Tens.

Activity Type: Indicates the activity type of the dock.

o Carrier: Corresponds to existing behavior for carrier

picks, drops, pick-and-drops, live and non-live.

o Internal: For pre-loading and post-discharge only;

carrier cannot access.

o Both: Can be used for carrier and internal pre-loading

and post-discharge.

JDA Software Group, Inc. July 2016 Page 549

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Dock Length: The minimum horizontal distance measured on

the center line of the dock between the two farthest points on

the dock

The total length for the equipment at the dock at any given

moment should not be greater than the value specified in the

field

For each dock you set up, you can also specify:

Business hours

Fixed and Variable loading / unloading time rates

Equipment types

Excluded Commodities

Excluded Loading Types

The business hours and loading/unloading times of the dock are

used for all scheduling considerations.

The equipment types maintained at the dock are used for all rating

considerations. Docks inherit shipping location properties;

however, the Business Hours and Loading/Unloading times of a

dock usually vary from the settings provided at shipping location

level. A list of loading types that cannot be managed at a dock can

also be defined. This allows for proper allocation of equipment to

the loading types.

After you set up a dock, you can either place it on hold or activate

it as required.

In addition to creating docks using the above method, you can

also create docks for existing shipping locations. To create

docks for existing shipping locations:

1. Navigate to the List of Shipping Locations page.

2. Search and select the shipping location.

3. Click More…> Docks> New to open the Create Dock

page.

Page 550 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

In the next few topics, you will look at the key operations you can

perform using the Dock Schedule module.

Viewing Locations with Docks

While planning for pickup or delivery from shipping locations, you

may need to view the list of all shipping locations with docks so

that you can model and schedule docks to handle loads.

In the Dock Schedule module, you can view a list of all shipping

locations with docks on the List of Locations with Docks page.

This list displays all shipping locations for which at least one dock

has been defined. Using this page, you can also view the dock

schedule for a shipping location.

To view the dock schedule for a shipping location:

1. Navigate to Dock Schedule > Locations with Docks.

The List of Locations with Docks page is displayed.

2. Select a shipping location.

3. Click Dock Schedule.

The Dock schedule is displayed.

Viewing Dock Commitments

To plan towards future capacity allocation without violating

committed capacity, you need visibility to the previously planned

commitments. You can use the Dock Schedule module to view

dock commitments across multiple docks and locations on the List

of Dock Commitments page.

JDA Software Group, Inc. July 2016 Page 551

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

When a dock commitment is planned for pre-loading or post-

discharge activities, it is an internal dock commitment. Internal

docks can never be used for carrier dock commitments.

Dock commitments are automatically computed and recorded by

TP, based on the dock information supplied by TM. This process

takes into account any pre-existing dock commitments.

TP will create only one dock commitment for a load/stop, so

duplicate dock commitments will not exist.

Authorized users can also manually create and modify dock

commitments using this page.

From the List of Dock Commitments page, you can view the

Dock Commitment Gantt Chart, the capacity for docks, and load

related information for each item in the list. You can also identify

dock commitments with violations or view activity across a set of

shipping locations.

In the next few topics, you will learn how to perform these tasks.

The List of Dock Commitments page displays both associated

and unassociated dock commitments.

Dock Commitment Gantt Chart

The Dock Commitment Gantt Chart page displays the

commitments for all docks defined for a specific shipping location

and dates in a Gantt chart format.

To view the Dock Commitment Gantt Chart for a dock

commitment:

1. Navigate to Dock Schedule > Dock Commitments.

2. On the List of Dock Commitments page, select a dock

commitment.

3. Click Dock Schedule.

Page 552 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

The Dock Commitment Gantt Chart is displayed for the selected

dock commitment.

As shown in the following image, individual docks for a location

are displayed on the list portion of the page. When docks are

selected, the chart on the page is loaded with dock commitments

that partially or fully overlap the applicable date horizon for each

dock.

You can change the date horizon by specifying a new date in the

Jump field or by using the Next/Previous buttons below the dock

schedule portion of the page.

Now, let us understand how to read the Gantt chart displayed in the

following image.

JDA Software Group, Inc. July 2016 Page 553

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Looking at the chart portion of the page, you can determine the

business hours for a dock and identify the activities of a dock.

Lines and bars displayed on the chart determine the type of dock

activity.

The following are the elements on a Gantt chart:

Blank Slots: Empty cells that indicate the slots open for

booking

Green Bar: Indicates that there are no problems with the dock

commitment

Red Triangle on the upper right corner of the Green Bar:

Indicates unassociated Dock Commitment

Animated (Blinking) Line: Is displayed when the chart is

accessed from the context of a specific load/stop or dock

commitment

Thin Red Line: Indicates when the dock is closed

It will help you identify the business hours of a dock.

Docks can be booked even when they are closed by having the

right permissions at user group level.

Yellow Bar: Indicates that scheduling results are not currently

valid for the applicable load or trip, suggesting that a potential

problem exists. This is applicable only for dock commitments

that are associated with a load/stop or load or trips where

scheduling is active.

Yellow Line: Indicates that loading/unloading duration for the

associated Location Throughput Group capacity is reached or

is over the maximum.

Page 554 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Red Bar: Indicates that a violation exists for the dock

commitment

The most likely problem is that the Start and End Date/Time

range for the dock commitment overlaps with the date/time

range for at least one other commitment for the same dock.

Gray Bar: Indicates that the Dock commitment is assigned to

another division, logistics group, or carrier

Limited information is available for these dock commitments.

Thin Dark Yellow Line: Indicates that the dock has no

additional capacity

Dark Green Triangle on the upper right corner of the bars

indicates a carrier dock commitment linked to an internal dock

commitment, or vice versa

Information about a booked slot (for example, Load ID, Start

Date/Time, End Date/Time) can be displayed by hovering the

mouse over the bar representing the commitment.

If you have logged on as a carrier user, internal dock

commitments are grayed out, does not blink or display green

triangle. Also, the hover-over text shows limited information.

You can also view trailer activities in a Dock Commitment Gantt

Chart if the Display Trailer Activity Icons on Dock Gantt

Chart is selected in Global Settings. The colored bars will

display either or X characters representing whether the trailer

activities have been performed.

Execute an Action

on a Dock

Commitment

To execute an action for a specific dock commitment, such as

viewing its properties, or to perform an operation, you must first

click the bar representing the dock commitment. Once a bar has

been selected, the box is displayed in bold.

In the following image, we will look at the Properties of the green

colored bar (highlighted element on the chart).

JDA Software Group, Inc. July 2016 Page 555

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

You can also perform various tasks on the Gantt chart elements

or a dock commitment using the Operations button.

You can view the properties of a load, the shipments assigned

to a load, and the list of stops (itinerary) for a load. You can also

swap commitments for two dock commitments (of equal and

unequal durations) using the Swap operation.

Creating a Dock

Commitment

As mentioned earlier, authorized users can also create a dock

commitment.

To create a dock commitment:

1. Navigate to the List of Dock Commitments page.

2. Click New to create a dock commitment.

The Create Dock Commitment page is displayed where you can

create associated and unassociated dock commitments.

When creating a dock commitment, once a Load ID and Stop

Number have been provided, the Start Date/Time field is

automatically populated based on the stop.

Page 556 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

In the Activity Type field, you can specify whether the dock

commitment you are creating is for carrier pick, drop, and pick-

and-drop, live and non-live (carrier dock commitment), or for pre-

loading or post-discharge activities (internal dock commitment).

You can also create/update a dock commitment from the Dock

Commitment Gantt Chart. Double-click any grid cell of the chart,

to open the Create Dock Commitment page. The Dock ID,

Start Date and Start Time fields would have been populated

depending on the cell you clicked.

For example, if you double-clicked on a cell representing

DOCK2 on October 15th, 2015 14:00 – 15:00, then DOCK2,

10/15/2015 14:00 are the defaults for Dock ID, Start Date, and

Start Time fields.

JDA Software Group, Inc. July 2016 Page 557

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Location Throughput Capacity (LTC) Overview

You have learned how to create docks for shipping locations and

view dock commitments. In this section, you will learn about an

important feature of Dock Scheduling known as Location

Throughput Capacity (LTC).

TM supports advanced dock scheduling capabilities that represent

capacity constraints at the dock better. LTC is the functionality

used in TM to create restrictions on the number of loads, pallets,

total weight, total volume, and so on that docks can handle on a

daily or hourly basis. Multiple docks in a location can be

associated to an LTC group and you can create as many LTC

groups as required for a location.

In addition to setting up LTC groups, you can also manage

capacity by utilizing “capacity restrictions”, which are of two

types:

Day of the Week or Specific Date: Indicates that the capacity that

is defined for a day of the week or a specific date will be formally

recognized as the capacity during optimization

Examples include:

Day of the week: “Thursday- Tuesday” before Black Friday

Specific date: Only for one calendar date (Dec 30th) – Gift

Returns etc.

Daily/Hourly: Indicates whether the capacity for the location

throughput group will be available per hour or per day

For example, if the capacity is six loads and interval is hourly, the

defined capacity will be available for each hour between the start

time and end time for each date within the date range or on each

occurrence of the day of the week within the date range.

Page 558 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

You can work with LTC using the List of Capacity for Location

Throughput Groups page in the System Entities module.

Each shipping location and dock could potentially be associated

with multiple location throughput groups. If a location or dock

does not refer to any location throughput groups, there will be

no matching of resource capacity to resource requirements for

activity that occurs at the shipping location or dock.

Creating a Location

Throughput Group

To set up capacity restrictions for a dock, you need to first create a

Location Throughput Group (LTG) for one or more docks and then

specify capacity restrictions for the group.

To create a LTG:

1. Navigate to System Entities > Miscellaneous > Location

Throughput Groups.

The List of Location Throughput Groups page is displayed.

JDA Software Group, Inc. July 2016 Page 559

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

2. Click New.

The Create Location Throughput Group page is displayed

where you can enter details to create a group.

Let us look at some of the important fields on this page:

Location Type and Location ID: Used to associate the LTG

to an existing shipping location

Location Throughput Group ID: A unique ID to identify the

LTG

Location Throughput Group Unit Type: Used to track

demand vs. capacity for the Location Throughput Group

Values can be loading/unloading duration, loads, weight,

pallets, pieces, and volume.

Location Throughput Group Level: Indicates whether

tracking of demand vs. capacity will be managed at shipping

location or dock level for the Location Throughput Group

Page 560 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Activity Type: Specifies the activity type: inbound only,

outbound only, or both inbound and outbound

Location Throughput Group Capacity Interval: Indicates

whether capacity for the Location Throughput Group will be

available per hour or per day

Activity Inclusion: Used to specify the activity types to be

accounted for, such as Carrier Live Only, Carrier Live and

Internal, Carrier Non-Live Only, and Internal Only.

Throughput capacity does not consider the wait time between

the completion of the pre-loading and carrier pick-up, or

between the completion of the carrier drop-off and the start of

the post-discharge unloading.

Specifying Location

Throughput Group

Capacity

Once you set up the LTG, you can specify capacity restrictions for

the group.

To set up capacity for a group:

1. Navigate to the List of Location Throughput Groups page.

2. Select the LTG for which you want to specify capacity

restrictions.

3. Click More… and select Capacity.

The List of Capacity for Location Throughput Groups page

is displayed.

4. Click New.

The Create Capacity for Location Throughput Group page is

displayed.

JDA Software Group, Inc. July 2016 Page 561

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Let us look at some important fields on this page.

Day/Dates/Times: In this section, you can provide capacity

restrictions for a specific day of the week between start and end

dates and time. For example, every Tuesday for four weeks

between 8 A.M and 6 P.M.

You can also specify a fixed date and time. For example,

December 25, between 9 A.M and 6 P.M.

Maximum Quantity: Indicates the maximum quantity allowed

per hour or per day for each date between the start and end

time in the date range or on each occurrence of the applicable

day of the week within the start and end dates

The quantity you specify here is in relation to the unit type you

defined for the corresponding LTG. For example, if the LTG

unit type is loads, the quantity is in relation with the number of

loads; if the LTG unit type is pallets, the quantity is in relation

with the number of pallets.

Target Quantity: Similar to maximum quantity, you can also

specify target quantity allowed per hour/day or day of the

week. When target quantity exceeds, the target penalty amount

is incurred for each capacity unit in excess of the target.

Penalty Amount when Target Violated: Indicates the target

quantity violation penalty amount

When target quantity exceeds, the target penalty amount is

incurred for each capacity unit in excess of the target.

Page 562 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Viewing Location

Throughput

Capacities

You have learned about LTC and how to work with LTC groups.

In this section, you will understand how to view/modify capacities

for multiple Location Throughput Groups within a location for a

specific date.

After you have scheduled docks through TP or manually, you can

check if the capacities you specified for the Location Throughput

Groups of a dock have been honored while building loads.

In the Dock Schedule module, the Specific Date Capacities page

can be used to simultaneously maintain multiple capacity entries

concurrently on a single page. This page opens in the Smartbench

UI.

The following information can be viewed on the Specific Date

Capacities page:

You can use the Select Docks icon to filter the records

based on the selection of docks.

The Location Throughput Groups will be enabled for Daily or

Hourly capacity based on the values you specified while

creating the group.

A thin red line is displayed at the top of the cell representing

the duration when the location will be closed.

The Maximum, Actual, and Available rows are displayed for

each Location Throughput Group that you created. The Actual

quantity is the total demand for all dock commitments for the

docks that are associated with the Location Throughput Group.

The Available quantity is the net of Maximum and Actual.

The hyperlink for the Actual value displays the associated dock

commitment details.

To access the Specific Date Capacities page and view capacities

for multiple Location Throughput Groups:

1. Navigate to the List of Dock Commitments page.

JDA Software Group, Inc. July 2016 Page 563

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

2. Select a dock commitment and click Capacity.

The Specific Date Capacities page is displayed.

3. View and modify capacities as required. Press ENTER or click

on any cell in a different row to save your changes.

4. Click Return to return to the previous page in the TM UI.

On pressing ENTER, save logic is triggered that validates

whether the maximum quantity is greater than or equal to

corresponding target quantity. If a violation exists, an error

message will be presented and the contents of the cells will be

reset (the most recent edits will be lost).

Using the Quantity Basis and Availability Basis fields on the

Capacity List Customization page, users can indicate whether

they want to view Maximum capacity only, Target capacity only,

or both capacities.

Page 564 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Dock Scheduling Methods

As mentioned earlier, docks can be scheduled for loads either

manually or automatically during optimization.

Let us look at both the methods.

Manual Dock Scheduling

In manual dock scheduling, after building the load, the dock is

manually booked for a load stop.

To perform manual dock scheduling:

1. Navigate to the List of Dock Commitments page and click

New.

2. Enter details on the Create Dock Commitment page to

manually create a dock commitment. The same page can also

be obtained by double clicking the desired time slot on the

Gantt chart.

Dock Scheduling via Optimization

TP can also schedule docks for the loads created in an optimization

request. This can be done by the following two ways:

1. Generic Settings from the parameter file used for optimization:

By including the parameter ‘UseDocks = TRUE’ in the

parameter file, docks will be booked (with default settings)

wherever possible, after loads are built by TP.

2. Specific Settings present in the strategy file used for

optimization: Customized settings for Dock Scheduling can be

provided by defining the ‘TryDockScheduling’ Strategy in the

strategy file.

JDA Software Group, Inc. July 2016 Page 565

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Lesson Review

In this lesson, we have covered:

Dock Scheduling in TM

Dock Schedule terminology

How to configure Dock schedules

Creating docks and viewing dock commitments

Manual dock scheduling and dock scheduling via optimization

Page 566 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Hands-On Exercises

In these exercises, you will practice:

Creating docks

Creating LTGs

Assigning docks to the Groups

Setting up Capacity for the docks

Optimizing shipments and building loads

Viewing dock commitments and capacity for the loads

Case Study

ABC wants to ship loads to the Chicago Distribution Center. A few

shipments are coming from Orlando, Florida and few from within

Chicago. The Chicago Distribution Center has five docks to

manage inbound and outbound shipments.

The docks have no capacity restrictions.

Dock Business Hours – 8 AM to 5 PM (Monday-Friday)

Exercise 13.1

Step 1: Create Docks

First, you will create docks for the Chicago distribution center

shipping location (CHICDOCK-IL).

1. Navigate to System Entities > Principal > Docks.

The List of Docks page is displayed.

You will notice that two docks are already created for the

Chicago distribution center, DOCK01 and DOCK02.

JDA Software Group, Inc. July 2016 Page 567

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

2. Click New to create a dock for this location.

3. On the Create Dock page, specify the following information:

Location Type: Distribution Center

Location ID: CHICDOCK-IL (Refresh)

Dock ID: DOCK03

Description: DOCK03

Inbound/Outbound Environment: Live Only

Activity Type: Both

4. Click Submit.

Page 568 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

5. Similarly, create two more docks called DOCK04 and

DOCK05 for the CHICDOCK-IL distribution center.

For this exercise, we will use only DOCK01, DOCK02 and

DOCK03, so we need to place DOCK04 and DOCK05 on hold. To

do so:

6. Select DOCK04 and DOCK05.

7. Click More…, and select Hold.

The Dock Status for the two docks changes to On Hold.

JDA Software Group, Inc. July 2016 Page 569

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

As mentioned in the case study, you need to set up business hours

for DOCK01, DOCK02, and DOCK03 from 8 A.M. to 5 P.M.

from Monday to Friday. To do so, follow these steps:

8. Select DOCK01.

9. Click More…, and select Business Hours.

10. On the Update Business Hours page, type 08:00 and 17:00 in

the Range 1 From and Range 1 To boxes respectively, for all

the Days of Week from Monday to Friday.

Ensure there are no hours for Saturday and Sunday.

11. Click Submit.

12. Follow step 8 to step 11 for DOCK02 and DOCK03.

Page 570 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Step 2: View Shipments

A few shipments have already been created for this exercise. You

need to build loads for these shipments.

1. Navigate to Shipment Processing > Shipments.

2. On the List of Shipments page, in the Shipment ID search

box, type DOCK%.

Six shipments will be displayed.

Step 3: Load Building

The next steps are to assign the shipments to a plan, select the

shipments for optimization, and optimize the shipments.

The user must be authorized to work with Plan 1003 and the

plan should be set as the current plan.

1. Navigate to Load Build > User Plan Authorization.

2. On the List of User Plan Authorizations page, select the

Plan ID 1003, and click Authorize.

3. Type 1003 in the Plan ID box, and TRAIN01 in the User ID

box.

4. Select the Select as the current Plan for User check box.

5. Click Submit.

1. Navigate to Load Build > Work with Plan > Shipments >

Unassigned.

2. In the Shipment ID search box, type DOCK%.

3. Select Shipment IDs DOCK001, DOCK003, and DOCK005

check boxes.

4. Click Select for Optimization.

JDA Software Group, Inc. July 2016 Page 571

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

You will receive a message that 3 shipment(s) are selected for

optimization.

5. Navigate to Load Build >Work with Plan > Control.

6. On the Load Build Control page, click Optimize.

7. Change the Scheduled Date/Time to a past date to avoid

scheduling issues.

8. From the Constraint Override File list, select Dock Exercise.

9. Click Submit.

Page 572 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

The override files available in the Constraints Override File list

are added to the List of Optimizer Constraints page.

You will receive a message that the optimization request is

created.

10. Now, navigate to Load Build >Work with Plan >Loads.

On the List of Loads Attached to Plan page, you will notice that

three loads have been built and dock scheduled.

JDA Software Group, Inc. July 2016 Page 573

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Step 4: Dock Commitments

After the loads are built, you can view the dock commitments for

the new loads.

1. Navigate to Dock Schedule > Dock Commitments.

The List of Dock Commitments page is displayed. Notice that

there are three associated commitments created, one for each load.

2. Select the first commitment for DOCK01 and click Dock

Schedule.

The Dock Commitment Gantt Chart page is displayed.

Are the business hours displayed correctly for the docks?

_________________________________

What is the information in the green colored bars?

_____________________________________________________

Page 574 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

3. Similarly view the dock schedules for the other dock

commitments and note down your observations

______________________________________________________

Exercise 13.2

The Chicago Distribution Center is operating during the last week

of December, however as the staff to handle its operations is low

for the week, they have to place capacity restrictions on some

docks.

On December 30th 2016: Dock 1 can receive one load.

On December 30th 2016: Dock 2 and 3 can receive 50 and 40

pallets respectively.

Step 1: Location Throughput Groups Set Up

As you have already created docks for the CHICHDOCK-IL

location in the previous exercise, in this step you will create LTGs

and associate them with the docks.

You need to create three LTGs, one for loads and two for pallets.

You also need to set up capacity for the groups according to the

conditions specified in the case study.

To set up location throughput groups:

1. Navigate to System Entities > Miscellaneous > Location

Throughput Groups.

The List of Location Throughput Groups page is displayed.

You will notice that one LTG has already been created.

2. Select the CHICDOCK-IL-TPG ID, and click Properties.

JDA Software Group, Inc. July 2016 Page 575

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

3. Notice the following:

a. LTG Unit Type is Loads

b. LTG Level is Dock

c. LTG Capacity Interval is set to Daily.

4. Click Cancel to return to the List of Location Throughput

Groups page.

5. On the List of Location Throughput Groups page, click New

to create a second LTG for pallets.

Page 576 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

6. On the Create Location Throughput Group page, specify the

following information as per the case study:

Field Value

Location Type Distribution Center

Location ID CHICDOCK-IL (Refresh)

Location Throughput Group ID CHICDOCK-IL-TPG2

Description CHICDOCK-IL Dock

Throughput2

LTG Unit type Pallets

LTG Level Dock

Activity Type Both

LTG Capacity Interval Daily

Date Based Capacity Required Selected

Enforce Full Page Date/Time Selected

Constraints

Activity Inclusion All

7. Click Submit.

JDA Software Group, Inc. July 2016 Page 577

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

8. Similarly, create one more location throughput group

CHICDOCK-IL-TPG3 for pallets.

Next, you will associate the docks to the Location Throughput

Groups.

DOCK01 is associated to CHICDOCK-IL-TPG, DOCK02 is

associated to CHICDOCK-IL-TPG2, and DOCK03 is associated to

CHICDOCL-IL-TPG3.

DOCK01 is already associated to CHICHDOCK-IL-TPG.

9. Select the CHICHDOCK-IL-TPG LTG.

10. Click More…, and select Docks from the list.

You can see that DOCK01 has been associated to this LTG.

11. Click Cancel to return to the List of Location Throughput

Groups page.

Next, you will associate DOCK02 with CHICHDOCK-IL-TPG2.

12. Select the CHICHDOCK-IL-TPG2 LTG.

13. Click More..., and select Docks.

Page 578 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

14. On the Docks for LTG page, add DOCK02 and click Submit.

Click the add new row icon to add new rows.

15. Repeat steps 12 to 14 to associate DOCK03 with LTG

CHICDOCK-IL-TPG3.

You will now set up the capacity for each LTG.

16. Select CHICHDOCK-IL-TPG.

17. Click More…, and select Capacity.

JDA Software Group, Inc. July 2016 Page 579

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

The List of Capacity for Location Throughput Group page is

displayed.

18. Click New to define a capacity.

19. On the Create Capacity for Location Throughput Group

page, specify the following information and click Submit:

Page 580 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Field Value

Start Date 12/30/2016

End Date 12/30/2016

Open Time 00:00

Close Time 23:59

Maximum Quantity 1 (As per case study)

Target Quantity 1

JDA Software Group, Inc. July 2016 Page 581

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

20. Click Return to return to the List of Location Throughput

Groups page.

21. Select CHICHDOCK-IL-TPG2.

22. Click More…and select Capacity to set up the capacity for

this group.

Page 582 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

The List of Capacity for Location Throughput Group page is

displayed.

23. Click New to define a capacity.

24. On the Create Capacity for Location Throughput Group

page, specify the following information and click Submit:

Field Value

Start Date 12/30/2016

End Date 12/30/2016

Open Time 00:00

Close Time 23:59

Maximum Quantity 50 (As per case study)

Target Quantity 50

JDA Software Group, Inc. July 2016 Page 583

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

25. Click Return to return to the List of Location Throughput

Groups page.

26. Select CHICHDOCK-IL-TPG3.

27. Click More…and select Capacity to set up the capacity for

this group.

28. On the Create Capacity for Location Throughput Group

page, specify the following information and click Submit:

Field Value

Start Date 12/30/2016

End Date 12/30/2016

Open Time 00:00

Close Time 23:59

Maximum Quantity 40 (As per case study)

Target Quantity 40

Page 584 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Step 2: Update Shipments Details

The next step is to update existing shipments and build loads using

these shipments. This is similar to the steps performed in the

previous exercise.

1. Navigate to Shipment Processing > Shipments to view the

List of Shipments page.

2. Search using the DOCK% Shipment ID, six shipments will be

displayed.

For a few of these shipments, let us edit the shipment pickup and

delivery windows and also the number of pallets in the container.

3. Select DOCK002 and click Shipment Details.

4. On the List of Shipment Details page, select the shipment

detail ID, and click Properties.

JDA Software Group, Inc. July 2016 Page 585

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

5. On the Shipment Detail Properties page, change the

Quantity of pallets to 60, and click Submit.

6. Click Return to return to the List of Shipments page.

7. Now select DOCK002 again, and click Properties.

8. Change the Pickup and Delivery dates to:

Pickup From: 12/29/2016 00:00 Pickup To: 12/29/2016 23:58

Delivery From: 12/29/2016 23:58 Delivery To: 12/30/2016

23:59

Page 586 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

9. Click Submit.

10. Similarly, for shipment DOCK004, modify the shipment

details and change the Quantity of pallets to 38 and for

DOCK006 modify the Quantity of pallets to 45.

JDA Software Group, Inc. July 2016 Page 587

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

11. Also, modify the shipment pickup and delivery windows for

both DOCK004 and DOCK006 to:

Pickup From: 12/27/2016 00:00 Pickup To: 12/27/2015 23:58

Delivery From: 12/30/2015 00:00 Delivery To: 12/30/2016

23:59

Step 3: Build Loads

The next step is to select the shipments for optimization, and

optimize the shipments. During Load execution we need to ensure

that the Dock Throughput/ Allocation is respected by TP as it

builds the loads.

1. Navigate to Load Build > Work with Plan > Shipments >

Unassigned.

2. Select Shipment ID’s DOCK002, DOCK004, and DOCK006

and click Select for Optimization.

3. As you performed in the previous exercise, navigate to Load

Build >Work with Plan > Control.

4. On the Load Build Control page, click Optimize.

Page 588 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

5. Change the Scheduled Date/Time to a past date to avoid

scheduling issues.

6. Select the Constraint Override File as Dock Exercise from

the list.

7. Click Submit.

You will receive a message that the optimization request is created.

8. Next, navigate to Load Build >Work with Plan >Loads.

9. On the List of Loads Attached to Plan page, you will notice

that three new loads have been built and dock scheduled.

Note down the Load IDs.

JDA Software Group, Inc. July 2016 Page 589

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Step 4: View Dock Commitments

After the loads are built, you can view the dock commitments for

the new loads.

1. Navigate to Dock Schedule > Dock Commitments.

The List of Dock Commitments page is displayed. Notice that

there are three new commitments created, one for each load.

You will now check if the capacity restrictions were respected by

the TP while building loads.

2. Select the first dock commitment and click Capacity.

The Specific Date Capacities page is displayed.

What date are the capacities listed for?

_________________________________

What are the Maximum, Actual and Available values for

CHICDOCK-IL-TPG?

____________________________________________

What are the load and stop information for this LTG?

_____________________________________________________

What are the Maximum, Actual and Available values for

CHICDOCK-IL-TPG2?

Page 590 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

____________________________________________________

What are the load and stop information for this LTG?

_____________________________________________________

What are the Maximum, Actual and Available values for

CHICDOCK-IL-TPG3?

____________________________________________________

What are the load and stop information for this LTG?

_____________________________________________________

JDA Software Group, Inc. July 2016 Page 591

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Page 592 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

LESSON 11

Dock Scheduling

Review Questions

1. Docks can be set up for which of the following shipping

locations?

A. Only Load-at and Consignee

B. Only Distribution Center and Hub

C. Load-at, Consignee, Distribution Center, and Hub

D. Load-at, Consignee and Distribution Center

2. Match the terms in Column A to their definitions in Column

B.

Column A: Terms Column B: Definitions

a. Booking 1. The Start Date/Time and End

Date/Time for usage of a dock space

for a load.

b. Dock 2. The assignment of a TM load to a

Scheduling time slot.

c. Time Slot 3. Arranging a specific time and dock

location for loading or unloading

shipments.

_______________________________________________

3. What do the following elements on the Dock Commitment

Gantt Chart represent?

Blank Slots: ________________________________

Green Bar: _________________________________

Thin Red Line: ______________________________

4. What are the two types of capacity restrictions available?

____________________________________________

JDA Software Group, Inc. July 2016 Page 593

JDA University www.jdalearn.com

TRANSPORTATION MANAGER

Page 594 JDA Software Group, Inc. July 2016

www.jdalearn.com JDA University

You might also like

- Download pdf Thorp And Covichs Freshwater Invertebrates Keys To Neotropical Hexapoda 4Th Edition Neusa Hamada ebook full chapterDocument53 pagesDownload pdf Thorp And Covichs Freshwater Invertebrates Keys To Neotropical Hexapoda 4Th Edition Neusa Hamada ebook full chapterjosefina.johnson864No ratings yet

- Omnicell ServerDocument3 pagesOmnicell Serverapi-340750408No ratings yet

- Berthing PlanDocument44 pagesBerthing PlanPatel Tushar100% (1)

- Conventional and Emerging Container Terminal ConfigurationsDocument4 pagesConventional and Emerging Container Terminal Configurationsangelica16No ratings yet

- Unit 12-Heavy Lift & Project Cargoes PDFDocument88 pagesUnit 12-Heavy Lift & Project Cargoes PDFBisrat100% (3)

- Actividadndenaprendizajen9nKATERINEnRAMIREZ 306290d2884dd16Document7 pagesActividadndenaprendizajen9nKATERINEnRAMIREZ 306290d2884dd16Michael Arevalo DuarteNo ratings yet

- A Monolithic Approach To Vehicle Routing and Operations Scheduling of A Cross-Dock SystemDocument22 pagesA Monolithic Approach To Vehicle Routing and Operations Scheduling of A Cross-Dock SystemAhmad BuchoriNo ratings yet

- Evidencia 2 Workshop Understanding The Distribution Center LayoutDocument4 pagesEvidencia 2 Workshop Understanding The Distribution Center LayoutOscar MarinNo ratings yet

- Heavy Containers Over Light ContainersDocument4 pagesHeavy Containers Over Light Containersliao_marcoNo ratings yet

- An Integrated Quay Crane Assignment and Scheduling ProblemDocument9 pagesAn Integrated Quay Crane Assignment and Scheduling ProblemAshish Edwin HansdaArtsNo ratings yet

- Areas - and May Have Additional: 1. Loading DockDocument4 pagesAreas - and May Have Additional: 1. Loading DockDuvan CastiblancoNo ratings yet

- Workshop: Understanding The Distribution Center LayoutDocument6 pagesWorkshop: Understanding The Distribution Center LayoutMayerlis EscorciaNo ratings yet

- Workshop Understanding The Distribution Center Layout: RECEIVING Dock, Also CalledDocument7 pagesWorkshop Understanding The Distribution Center Layout: RECEIVING Dock, Also Calledeliana estefany espinosa carmonaNo ratings yet

- Actividad de Aprendizaje 9 Evidencia 2: Presentado Por: Alejandro Mejía. 1108933280Document6 pagesActividad de Aprendizaje 9 Evidencia 2: Presentado Por: Alejandro Mejía. 1108933280Lina PedrazaNo ratings yet

- Berth Planning July 2004Document33 pagesBerth Planning July 2004Estelle LiliaNo ratings yet

- 2022 XRoyOmmerenKosterGharehgozli S0191261522000893Document30 pages2022 XRoyOmmerenKosterGharehgozli S0191261522000893Hậu PhạmNo ratings yet

- Actividad 9 Evidencia - 2 - Workshop - Understanding - The - Distribution - Center - Layout - V2Document8 pagesActividad 9 Evidencia - 2 - Workshop - Understanding - The - Distribution - Center - Layout - V2alexandra patiñoNo ratings yet

- Poms 2023 10 19Document20 pagesPoms 2023 10 19g1305626957No ratings yet

- All Distribution Centers Have Three Main: AreasDocument5 pagesAll Distribution Centers Have Three Main: Areasandrea galvis narvaezNo ratings yet

- Workshop Understanding The Distribution Center LayoutDocument7 pagesWorkshop Understanding The Distribution Center LayoutMario HerediaNo ratings yet

- D1 IHC Training Simulators For Dredging and OffshoreDocument3 pagesD1 IHC Training Simulators For Dredging and OffshoreSig Baha100% (1)

- A Simulation Study On A Workload-Based Operation Planning Method in Container TerminalsDocument11 pagesA Simulation Study On A Workload-Based Operation Planning Method in Container TerminalssajjadNo ratings yet

- Operational Control For Stacker/reclaimers: January 2013Document7 pagesOperational Control For Stacker/reclaimers: January 2013Anonymous qPt2MHzXTNo ratings yet

- RoutingAndLogistics 1 VehicleRoutingDocument49 pagesRoutingAndLogistics 1 VehicleRoutingkaren_jofre100% (1)

- WhitePaper TheStowagePlan StowagePlanning PDFDocument3 pagesWhitePaper TheStowagePlan StowagePlanning PDFSeamen 777No ratings yet

- A New Approach To The Container Positioning ProblemDocument25 pagesA New Approach To The Container Positioning ProblemLouis WakumNo ratings yet

- Li, X., & Ding, Y. (2022). Collaborative optimization of truck appointment systemDocument13 pagesLi, X., & Ding, Y. (2022). Collaborative optimization of truck appointment systemAlhamdani zikrullahNo ratings yet

- Conceptual Planning of Jebel Ali New Container TerminalDocument8 pagesConceptual Planning of Jebel Ali New Container TerminalAlejandro GarnicaNo ratings yet

- Containers Fundamentals Module 09Document4 pagesContainers Fundamentals Module 09Patricio CaneloNo ratings yet

- Actividad de Aprendizaje 9 Evid. InglesDocument7 pagesActividad de Aprendizaje 9 Evid. InglesJorge ManjarresNo ratings yet

- Asef Vaziri PDFDocument9 pagesAsef Vaziri PDFmaxamaxaNo ratings yet

- An Expanded Robust Optimisation Approach For The Berth Allocation Problem Considering Uncertain Operation TimeDocument16 pagesAn Expanded Robust Optimisation Approach For The Berth Allocation Problem Considering Uncertain Operation Timefengshuai duNo ratings yet

- Optimizing Warehouse Efficiency: Red Cedar Technology, IncDocument7 pagesOptimizing Warehouse Efficiency: Red Cedar Technology, IncanfiboleNo ratings yet

- DRYDOCK An Interactive Computer ProgramDocument16 pagesDRYDOCK An Interactive Computer ProgramMichael McburnsNo ratings yet

- A Slot Reallocation Model For Containership Schedule AdjustmentDocument10 pagesA Slot Reallocation Model For Containership Schedule AdjustmentanaNo ratings yet

- What Is Advanced Outfitting in ShipbuildingDocument5 pagesWhat Is Advanced Outfitting in ShipbuildingsuryaNo ratings yet

- Seasonal Slot Allocation Planning For A Container Liner Shipping ServiceDocument9 pagesSeasonal Slot Allocation Planning For A Container Liner Shipping ServiceFeShAdoWNo ratings yet

- SSRN Id4382754Document35 pagesSSRN Id4382754Hemil ShahNo ratings yet

- Evidencia 2 Workshop Understanding The Distribution Center Layout V2Document7 pagesEvidencia 2 Workshop Understanding The Distribution Center Layout V2Diego Andres Correa FigueroaNo ratings yet

- 01.1 A Combined Ship Scheduling and Allocation ProblemDocument9 pages01.1 A Combined Ship Scheduling and Allocation ProblemMarcelo FerreiraNo ratings yet

- DockerTraining Nirmallya Day5Document33 pagesDockerTraining Nirmallya Day5Janaki sweetNo ratings yet

- Robust Ship Scheduling With Multiple Time Windows: Marielle Christiansen, Kjetil FagerholtDocument15 pagesRobust Ship Scheduling With Multiple Time Windows: Marielle Christiansen, Kjetil FagerholtcameliaNo ratings yet

- Expert Systems With Applications: S.H. Chung, K.L. ChoyDocument9 pagesExpert Systems With Applications: S.H. Chung, K.L. ChoyImane TorbiNo ratings yet

- Systems 11 00412Document22 pagesSystems 11 00412Seksun MoryadeeNo ratings yet

- Tecnologo en Gestion Logistica Ficha:2387830: Nilson Chamorro Martínez Keiner Cantillo PadillaDocument7 pagesTecnologo en Gestion Logistica Ficha:2387830: Nilson Chamorro Martínez Keiner Cantillo PadillaNilson ChamoNo ratings yet

- Enhancing Container Terminal Productivity: A Co-Maker Approach Between Carriers and OperatorsDocument3 pagesEnhancing Container Terminal Productivity: A Co-Maker Approach Between Carriers and OperatorsAdn AdinaNo ratings yet

- Actividad 2 Planeacion 9Document8 pagesActividad 2 Planeacion 9yezid rojasNo ratings yet

- Actividad de Aprendizaje 9 Evidencia 2: Workshop: Understanding The Distribution Center LayoutDocument7 pagesActividad de Aprendizaje 9 Evidencia 2: Workshop: Understanding The Distribution Center LayoutJazmin GomezNo ratings yet

- Evidencia 2 Workshop Understanding The Distribution Center LayoutDocument7 pagesEvidencia 2 Workshop Understanding The Distribution Center Layoutluis castroNo ratings yet

- Actividad de Aprendizaje 9 Evidencia 2: Workshop: Understanding The Distribution Center LayoutDocument7 pagesActividad de Aprendizaje 9 Evidencia 2: Workshop: Understanding The Distribution Center LayoutJazmin GomezNo ratings yet

- Workshop Understanding PDFDocument8 pagesWorkshop Understanding PDFHanny SanmartinNo ratings yet

- Learning Activity 9 Evidence 2 Workshop Understanding The Distribution Center LayoutDocument11 pagesLearning Activity 9 Evidence 2 Workshop Understanding The Distribution Center LayoutHarrison SalamancaNo ratings yet

- Autostore TOS For Vietnam (Final) - enDocument39 pagesAutostore TOS For Vietnam (Final) - enhọc giỏiNo ratings yet

- Inventory Management by OptimizationDocument11 pagesInventory Management by Optimizationgary311098No ratings yet

- 1 s2.0 S0950705118304763 MainDocument18 pages1 s2.0 S0950705118304763 Mainroi.ho2706No ratings yet

- Brochure Damen Floating Drydocks 06 2015Document4 pagesBrochure Damen Floating Drydocks 06 2015osamaNo ratings yet

- Workshop Understanding The Distribution Center LayouTDocument8 pagesWorkshop Understanding The Distribution Center LayouTcarlos suarezNo ratings yet

- Paper RPuisa Revision1Document22 pagesPaper RPuisa Revision1AugustoChagasNo ratings yet

- Docker: The Complete Guide to the Most Widely Used Virtualization Technology. Create Containers and Deploy them to Production Safely and Securely.: Docker & Kubernetes, #1From EverandDocker: The Complete Guide to the Most Widely Used Virtualization Technology. Create Containers and Deploy them to Production Safely and Securely.: Docker & Kubernetes, #1No ratings yet

- The Art of Docker: Streamline App Development and Deployment with Containerization (Computer Programming)From EverandThe Art of Docker: Streamline App Development and Deployment with Containerization (Computer Programming)No ratings yet

- Software Containers: The Complete Guide to Virtualization Technology. Create, Use and Deploy Scalable Software with Docker and Kubernetes. Includes Docker and Kubernetes.From EverandSoftware Containers: The Complete Guide to Virtualization Technology. Create, Use and Deploy Scalable Software with Docker and Kubernetes. Includes Docker and Kubernetes.No ratings yet

- 1 Cumulative Frequency CurvesDocument19 pages1 Cumulative Frequency Curvespradyummmna9856No ratings yet

- Continuity and DifferentiabilityDocument125 pagesContinuity and DifferentiabilityYugansh AroraNo ratings yet

- The Doctrine of Logos Within Ibn Arabi Mystical PDocument25 pagesThe Doctrine of Logos Within Ibn Arabi Mystical PAndreaNo ratings yet

- MIL-Q-9858 Quality Program RequirementsDocument11 pagesMIL-Q-9858 Quality Program RequirementsJay MillerNo ratings yet

- 3.2 Thursday - 01 - 02 - 18. Dr. Herbert Musonga Monitoring and Oversight of Land Use Planning KIP2018Document33 pages3.2 Thursday - 01 - 02 - 18. Dr. Herbert Musonga Monitoring and Oversight of Land Use Planning KIP2018Trevor DanielsNo ratings yet

- 14 Case Studies Fall 2021Document19 pages14 Case Studies Fall 2021sgdrgsfNo ratings yet

- Undersize Collecting Conveyor Example Technical Specification R00Document20 pagesUndersize Collecting Conveyor Example Technical Specification R00bashok20No ratings yet

- RDA and The Semantic Web, Linked Data Environment: Barbara TillettDocument7 pagesRDA and The Semantic Web, Linked Data Environment: Barbara TillettPEDRO NESTARES BELLEZANo ratings yet

- EAA Interview With Yu Hua, Author of To Live (Huo Zhe)Document3 pagesEAA Interview With Yu Hua, Author of To Live (Huo Zhe)elio35No ratings yet

- Digital Media and VR Art Creation For MetaverseDocument4 pagesDigital Media and VR Art Creation For MetaverseJuan HerreraNo ratings yet

- Assignment 2 - 2021 24Document2 pagesAssignment 2 - 2021 24Sakshi BargeNo ratings yet

- Proposal 108pc CMM Fixtures Kit - Parts List by STE Sahatool EngineeringDocument5 pagesProposal 108pc CMM Fixtures Kit - Parts List by STE Sahatool Engineeringmarketing1889No ratings yet

- Lecture 7Document71 pagesLecture 7adrienleeNo ratings yet

- Lab Script Exp 3 (Fourier Synthesis)Document12 pagesLab Script Exp 3 (Fourier Synthesis)mouazam KhalidNo ratings yet

- Java Object Oriented ProgrammingDocument81 pagesJava Object Oriented ProgrammingsyafiqNo ratings yet

- Review of Road Network Design: A Case Study of Kiri Kasama LGA - Jigawa StateDocument8 pagesReview of Road Network Design: A Case Study of Kiri Kasama LGA - Jigawa StateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Life of RizalDocument2 pagesLife of RizalArian Keith AquinoNo ratings yet

- En Iso 10081-2-2005 PDFDocument10 pagesEn Iso 10081-2-2005 PDFdong ganNo ratings yet

- Bode PlotDocument49 pagesBode PlotKart HikNo ratings yet

- B. 14.1 AB WKSHT HW Also Add Your Turn Problems P 440 To This For HWDocument2 pagesB. 14.1 AB WKSHT HW Also Add Your Turn Problems P 440 To This For HWShaira ClamorNo ratings yet

- Anger Awareness Versus Anger DeficiencyDocument8 pagesAnger Awareness Versus Anger DeficiencyJohn ShivaNo ratings yet

- REF615 Product GuideDocument92 pagesREF615 Product GuideSatish KumarNo ratings yet

- Ieltspracticetestsplus2 ReadingDocument98 pagesIeltspracticetestsplus2 ReadingRed RiverNo ratings yet

- SynMatrix Application Note 6 Synthesize MatrixDocument15 pagesSynMatrix Application Note 6 Synthesize MatrixHüseyin Nuri GülmezNo ratings yet

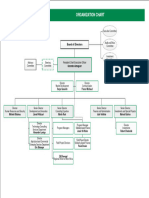

- Organization ChartDocument1 pageOrganization Chartm_azabNo ratings yet

- Lateral Earth PressureDocument29 pagesLateral Earth PressureAaquib MahfuzNo ratings yet

- D.el - Ed. First Year Result January - 2023 (2016-Syllabus)Document2 pagesD.el - Ed. First Year Result January - 2023 (2016-Syllabus)Nishat Afroz100% (1)

- Variability of Subgrade Reaction Modulus On Flexible Mat FoundationDocument22 pagesVariability of Subgrade Reaction Modulus On Flexible Mat FoundationGermar PorquerinoNo ratings yet