Professional Documents

Culture Documents

Factory Acceptance Test New Sample Report

Uploaded by

Jafarov VuqarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Factory Acceptance Test New Sample Report

Uploaded by

Jafarov VuqarCopyright:

Available Formats

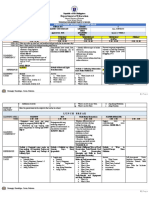

Electrical Control Cabinet (TAG22T3-100B) / 03 Apr

2019 / Sierra Blassingame

Factory Acceptance Test Checklist Conducted on 3rd Apr, 2019 By SafetyCulture Staff Complete

Inspection score Failed items Created actions

82.93% 7 2

Site

Sydney

Equipment

Electrical Control Cabinet (TAG22T3-100B)

Client

Bigwin Realty Corporation

Manufacturing Facility Location

JT Manufacturers 4790 Seneca Dr., Portland, OR 97205

Quality Manager

Sierra Blassingame

Conducted on

3rd Apr, 2019 8:01 AM +08

Private & Confidential Page 1/13

Failed items 7 Failed

Inspection / Factory Acceptance Test (FAT) / Pre-Factory Acceptance Test Checklist / Factory Acceptance Test Protocol

Recommended Spare Parts Lists Incomplete

Actions

Coordinate with fabrication manager and design engineers to gather the complete list of

Done

recommended spare parts for machinery maintenance.

Inspection / Factory Acceptance Test (FAT) / Pre-Factory Acceptance Test Checklist / Factory Acceptance Test

Preparation

Safety Inspection Incomplete

Are FAT personnel aware of the location of the first aid cabinet? No

Notes

Informed FAT personnel about the location of the first aid cabinet for proper emergency response

procedure.

Are machinery nameplates visible? No

Photos

Photo 9

Actions

The current location of the nameplate makes it hard for the operator to view. Add to and

Done

update the punch list.

Inspection / Factory Acceptance Test (FAT) / Factory Acceptance Test Checklist / Factory Acceptance Test Personnel

Are all FAT personnel equipped with the right PPE? No

Notes

Coordinated with health and safety officer for proper PPE of FAT personnel

Inspection / Factory Acceptance Test (FAT) / Factory Acceptance Test Checklist / Factory Acceptance Test of Equipment

Private & Confidential Page 2/13

Safety Fail

Maintenance Fail

Private & Confidential Page 3/13

Actions 2 Actions

SafetyCulture Staff created a High priority action

Done 4th Apr, 2019 8:00 AM +08

Relocate nameplate

The current location of the nameplate makes it hard for the operator to view. Add to and update the punch list.

Inspection / Factory Acceptance Test (FAT) / Pre-Factory Acceptance Test Checklist / Factory Acceptance Test

Preparation

Are machinery nameplates visible?

SafetyCulture Staff created a High priority action

Done 4th Apr, 2019 8:00 AM +08

Provide recommended spare parts list

Coordinate with fabrication manager and design engineers to gather the complete list of recommended spare parts for

machinery maintenance.

Inspection / Factory Acceptance Test (FAT) / Pre-Factory Acceptance Test Checklist / Factory Acceptance Test Protocol

Recommended Spare Parts Lists

Private & Confidential Page 4/13

Inspection 7 Failed 2 Actions 82.93%

Factory Acceptance Test (FAT)

Pre-Factory Acceptance Test Checklist

Factory Acceptance Test Protocol 1 Failed 1 Actions

Standard Work Procedures Complete

Certificates of Compliance Complete

Photos

Photo 1

Welding Processes Qualifications Complete

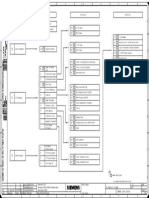

As-built Technical Drawings Complete

Photos

Photo 2

Instruments Calibration Certificates Complete

Equipment Data Sheets Complete

Materials Data Sheets Complete

Standard Maintenance Procedures Complete

Installation, Maintenance and Users’ Manuals Complete

Private & Confidential Page 5/13

Recommended Spare Parts Lists Incomplete

Actions

Coordinate with fabrication manager and design engineers to gather the complete list of

Done

recommended spare parts for machinery maintenance.

Training Materials Complete

FAT Procedure Complete

Photos

Photo 3 Photo 4 Photo 5 Photo 6 Photo 7

Photo 8

Private & Confidential Page 6/13

Factory Acceptance Test Preparation 3 Failed 1 Actions

Hazard Identification Complete

Safety Inspection Incomplete

Are guard doors accessible and easy to use? Yes

Are emergency stop buttons in good locations? Yes

Are fire alarms functioning correctly? Yes

Are fire extinguishers in place and clearly marked? Yes

Are FAT personnel aware of the location of the first aid cabinet? No

Notes

Informed FAT personnel about the location of the first aid cabinet for proper emergency response

procedure.

Are emergency numbers displayed? Yes

Are safety switches installed? Yes

Are adequate machine guards in place? Yes

Are there adequate equipment and material labels? Yes

Are machinery nameplates visible? No

Photos

Photo 9

Actions

The current location of the nameplate makes it hard for the operator to view. Add to and

Done

update the punch list.

Ergonomic Assessment Complete

Private & Confidential Page 7/13

Factory Acceptance Test Checklist

Factory Acceptance Test Personnel 1 Failed

Were pre-tests conducted? Yes

Do the design engineers and fabrication manager agree that the Yes

equipment is ready for FAT?

Are operators and maintenance personnel present? Yes

Is the client aware of the acceptance criteria? Yes

Are all FAT personnel equipped with the right PPE? No

Notes

Coordinated with health and safety officer for proper PPE of FAT personnel

Factory Acceptance Test of Equipment 2 Failed

Startup process Pass

Safety Fail

Control System Pass

User Interface Pass

Ergonomics Pass

Performance Pass

Shutdown process Pass

Maintenance Fail

Regulatory/Sanitary Design Pass

Conformance to Specifications Pass

Post-Factory Acceptance Test Checklist

Punch List Complete

Completion

Private & Confidential Page 8/13

Additional observations

Nameplates relocated to be visible to the operator and pass the safety criteria. Recommended spare parts

list completed for maintenance personnel and pass the maintenance criteria.

The equipment has been produced according to the specifications of the client. Since the equipment

reliability has been verified, it is scheduled for delivery and installation at the site of the client.

Full Name and Signature of Quality Manager

Sierra Blassingame

3rd Apr, 2019 9:41 AM +08

Full Name and Signature of Client Representative

Ruth Chundler

3rd Apr, 2019 9:42 AM +08

Full Name and Signature of Head of Design Engineers

Ryan Samaniego

3rd Apr, 2019 9:42 AM +08

Full Name and Signature of Fabrication Manager

James Beaufort

3rd Apr, 2019 9:43 AM +08

Full Name and Signature of Maintenance Coordinator

Deborah Peachey

3rd Apr, 2019 9:44 AM +08

Private & Confidential Page 9/13

Full Name and Signature of Head Operator

Hansen Lubbock

3rd Apr, 2019 9:45 AM +08

Private & Confidential Page 10/13

Photos 9 Photos

Photo 2

Photo 1

Photo 4

Photo 3

Private & Confidential Page 11/13

Photo 6

Photo 5

Photo 7

Photo 8

Private & Confidential Page 12/13

Photo 9

Private & Confidential Page 13/13

You might also like

- Sat Psat Word GamesDocument166 pagesSat Psat Word Gamesapi-360773187No ratings yet

- Ahmad Bilal CV - I&C EngineerDocument5 pagesAhmad Bilal CV - I&C EngineerMuhammad Faizan WaraichNo ratings yet

- FAT Test Procedure NKT Flexible Hose PDFDocument10 pagesFAT Test Procedure NKT Flexible Hose PDFTomasPavlovicNo ratings yet

- Vampire Stories in GreeceDocument21 pagesVampire Stories in GreeceΓιώργος ΣάρδηςNo ratings yet

- E & I Construction SuperintendentDocument8 pagesE & I Construction SuperintendentMohammad SaifullahNo ratings yet

- FACTORY TEST EQUIPMENTDocument1 pageFACTORY TEST EQUIPMENTBalakrishnan S NadarNo ratings yet

- FATDocument36 pagesFATSanjay Kumar ChaubeyNo ratings yet

- Gateway A2 Test 1BDocument3 pagesGateway A2 Test 1BNewteacher29100% (6)

- Field Instrument Installation ChecklistDocument1 pageField Instrument Installation ChecklistAbarajithan RajendranNo ratings yet

- Saudi Arabian Engineering Standards Saes J 9021Document30 pagesSaudi Arabian Engineering Standards Saes J 9021sarvesh14111984100% (1)

- Pressure Relieving Device Inspection ProcedureDocument2 pagesPressure Relieving Device Inspection Procedurecamasa2011No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWNo ratings yet

- Factory Acceptance Testing Guideline Process PDFDocument16 pagesFactory Acceptance Testing Guideline Process PDFAmira Guembri100% (1)

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Method Statement Loop CheckDocument4 pagesMethod Statement Loop CheckMohamed Rafih100% (1)

- IEC-62382 Electrical and Instrumentation Loop CheckDocument24 pagesIEC-62382 Electrical and Instrumentation Loop CheckFreddy100% (7)

- VVISUAL INSPECTION Check CHECKLIST PDFDocument2 pagesVVISUAL INSPECTION Check CHECKLIST PDFDanny BoysieNo ratings yet

- Supplier Self Audit FormDocument5 pagesSupplier Self Audit FormAllison Porter100% (2)

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 34-SAMSS-623 Programmable Controller Based ESD SystemsDocument31 pages34-SAMSS-623 Programmable Controller Based ESD Systemscherif yahyaouiNo ratings yet

- Factory Acceptance Tests – A Winning CombinationDocument9 pagesFactory Acceptance Tests – A Winning Combinationmahesh5277No ratings yet

- SAES-N-001 PDF Download - Basic Criteria, Industrial Insulation - PDFYARDocument7 pagesSAES-N-001 PDF Download - Basic Criteria, Industrial Insulation - PDFYARZahidRafique100% (1)

- Loop Checking and Field Instrument Testing ProcedureDocument7 pagesLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- Instr 12306 Perform Pressure & Leak Test, Tubing & PipingDocument19 pagesInstr 12306 Perform Pressure & Leak Test, Tubing & PipingMeliana Butar-ButarNo ratings yet

- Research Project On Capital PunishmentDocument6 pagesResearch Project On Capital PunishmentNitwit NoddyNo ratings yet

- Factory Acceptance Test PDFDocument2 pagesFactory Acceptance Test PDFStephanie0% (3)

- Instrumentation Inspection and Quality Control InterviewDocument3 pagesInstrumentation Inspection and Quality Control InterviewzhangyiliNo ratings yet

- P-5000T - Loop Folder PDFDocument15 pagesP-5000T - Loop Folder PDFSrikant SuruNo ratings yet

- Junction Box and Local Control Panel Quality Control and Inspection Report FormDocument1 pageJunction Box and Local Control Panel Quality Control and Inspection Report FormJpa YudiNo ratings yet

- Gap Control For Socket Weld Back Welded Threaded FittingsDocument12 pagesGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- The FAT Test ProcedureDocument1 pageThe FAT Test Procedurenisha_khanNo ratings yet

- IEC 60079-11 equipment intrinsic safety updatesDocument6 pagesIEC 60079-11 equipment intrinsic safety updatesQuynh ElectricalNo ratings yet

- Forming Plurals of NounsDocument5 pagesForming Plurals of NounsCathy GalNo ratings yet

- Biraogo vs. Philippine Truth CommissionDocument3 pagesBiraogo vs. Philippine Truth CommissionJulesMillanarNo ratings yet

- Loop Checking ProcessDocument19 pagesLoop Checking ProcesskoangyakNo ratings yet

- FAT Procedure (En)Document2 pagesFAT Procedure (En)wado11No ratings yet

- NCR - SampleDocument7 pagesNCR - SamplecamycaxNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Stock Market Course ContentDocument12 pagesStock Market Course ContentSrikanth SanipiniNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeNo ratings yet

- Factory Acceptance Testing (FAT): Key StepsDocument4 pagesFactory Acceptance Testing (FAT): Key StepsKhaled KamalNo ratings yet

- Instrument Loop CheckDocument3 pagesInstrument Loop Checknayum100% (1)

- SAIC-J - 6501 - Rev 0Document7 pagesSAIC-J - 6501 - Rev 0Adel KlkNo ratings yet

- BR COREnew Rulebook v1.5 ENG-nobackground-lowDocument40 pagesBR COREnew Rulebook v1.5 ENG-nobackground-lowDavid Miller0% (1)

- Hangnails and HomoeopathyDocument7 pagesHangnails and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNo ratings yet

- 3.1 Fat Document BSL Tata Olp PLC SystemDocument6 pages3.1 Fat Document BSL Tata Olp PLC Systemkoushik42000No ratings yet

- Mam 880 PDFDocument26 pagesMam 880 PDFUhule Peter100% (2)

- Sri Sathya Sai Bhagavatam Part IDocument300 pagesSri Sathya Sai Bhagavatam Part ITumuluru Krishna Murty67% (6)

- Chapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionDocument6 pagesChapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Factory Acceptance Test For RDDocument3 pagesFactory Acceptance Test For RDUmair Awan100% (1)

- Sumerian LexiconDocument159 pagesSumerian LexiconDeclan WarnerNo ratings yet

- Preservation Check Sheet PRODDocument2 pagesPreservation Check Sheet PRODBảo Hạnh Phúc Bảo Hạnh PhúcNo ratings yet

- Instrument Cables SpecificationDocument12 pagesInstrument Cables Specificationdon121don121No ratings yet

- Comment Resolution Sheet 19009 Welding DossierDocument1 pageComment Resolution Sheet 19009 Welding DossierDheeraj E MohananNo ratings yet

- Testing and Commissioning of Electrical EquipmentDocument2 pagesTesting and Commissioning of Electrical EquipmentGuna PriyaNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202nadeem shaikhNo ratings yet

- Mechanical Completion Certificate for Export PumpsDocument1 pageMechanical Completion Certificate for Export PumpsDeonNo ratings yet

- 60.35-001 - 1994 Pressure GuagesDocument3 pages60.35-001 - 1994 Pressure GuagespradeepNo ratings yet

- CommissioningDocument4 pagesCommissioningowaise007No ratings yet

- DCI JK5 Fire Protection Site Acceptance TestDocument14 pagesDCI JK5 Fire Protection Site Acceptance TestAwaludin Angga WNo ratings yet

- SCOPE OF WORK AND TECHNICAL SPECIFICATIONSDocument40 pagesSCOPE OF WORK AND TECHNICAL SPECIFICATIONSPerfectionistSushantNo ratings yet

- Saudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestDocument4 pagesSaudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestRashid Arshad100% (1)

- QC Inspector Functions Tests AnswersDocument8 pagesQC Inspector Functions Tests Answerszhangyili50% (2)

- PC-EI-MS-02 Instrument Air Piping & Tubing System InstallationDocument9 pagesPC-EI-MS-02 Instrument Air Piping & Tubing System InstallationMark Anthony AlanoNo ratings yet

- ASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1Document23 pagesASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1John PaulNo ratings yet

- Instrument Cable Test MethodsDocument3 pagesInstrument Cable Test MethodsParesh Ghodasara100% (1)

- TFR CommissioningDocument24 pagesTFR CommissioningKrishna DNo ratings yet

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning Checklistsmehul10941No ratings yet

- Industrial Pressure TestersDocument2 pagesIndustrial Pressure Testerssmab2162094No ratings yet

- Electrical Control Cabinet (TAG22T3 100B) 7 Mar 2023 Sierra BlassingameDocument10 pagesElectrical Control Cabinet (TAG22T3 100B) 7 Mar 2023 Sierra BlassingameMohamed AminNo ratings yet

- Factory Acceptance Test Checklist - SafetyCultureDocument9 pagesFactory Acceptance Test Checklist - SafetyCultureMAT-LIONNo ratings yet

- B Report # EFI-MF-9-NP-2020Document3 pagesB Report # EFI-MF-9-NP-2020ghulamrasool726No ratings yet

- 7sd52 53 Catalog Sip E7Document38 pages7sd52 53 Catalog Sip E7Suresh Kumar PariharNo ratings yet

- Rapid Pressure Rise Relay Response CurvesDocument4 pagesRapid Pressure Rise Relay Response CurvesTarun Bhateja0% (1)

- Binary Input, 64 Channels, LED's: General InformationDocument2 pagesBinary Input, 64 Channels, LED's: General InformationJafarov VuqarNo ratings yet

- Sudden Pressure Relay Applications and Considerations for Power Transformer ProtectionDocument72 pagesSudden Pressure Relay Applications and Considerations for Power Transformer ProtectionMuhammad AftabuzzamanNo ratings yet

- Qualitrol 900 910Document6 pagesQualitrol 900 910chennupati999No ratings yet

- Digsi 5 QN0012Document2 pagesDigsi 5 QN0012Michael Parohinog GregasNo ratings yet

- Teleprotection Scheme With SIPROTEC 5 DevicesDocument12 pagesTeleprotection Scheme With SIPROTEC 5 DevicesCarlos Roberto Hernandez FerrerNo ratings yet

- ELCAD Manual Version 7.0.0 PDFDocument40 pagesELCAD Manual Version 7.0.0 PDFsalasineNo ratings yet

- K2C003HLH: Product Data SheetDocument3 pagesK2C003HLH: Product Data SheetJafarov VuqarNo ratings yet

- Circuit DiagramDocument1 pageCircuit DiagramJafarov VuqarNo ratings yet

- Schneider Electric Industries: Date: Thursday, September 16, 2021Document2 pagesSchneider Electric Industries: Date: Thursday, September 16, 2021Jafarov VuqarNo ratings yet

- Connections and Settings: I/O Adapter 520ADD02Document6 pagesConnections and Settings: I/O Adapter 520ADD02Jafarov VuqarNo ratings yet

- Energ Heat-Shrink-Technology Brochure 16 EuDocument8 pagesEnerg Heat-Shrink-Technology Brochure 16 EuJafarov VuqarNo ratings yet

- EDS-505A/508A/516A Series: 5, 8, and 16-Port Managed Ethernet SwitchesDocument3 pagesEDS-505A/508A/516A Series: 5, 8, and 16-Port Managed Ethernet SwitchesJafarov VuqarNo ratings yet

- DG DT MOXA Device Configuration 01 00Document8 pagesDG DT MOXA Device Configuration 01 00Jafarov VuqarNo ratings yet

- Materials Hydro One CompressDocument779 pagesMaterials Hydro One CompressJafarov VuqarNo ratings yet

- DG DT MOXA Device Configuration 01 00Document8 pagesDG DT MOXA Device Configuration 01 00Jafarov VuqarNo ratings yet

- DG DT - MOXA NPORT DriverConfiguration - 01 00Document4 pagesDG DT - MOXA NPORT DriverConfiguration - 01 00Jafarov VuqarNo ratings yet

- DG DT - MOXA NPORT DriverConfiguration - 01 00 PDFDocument6 pagesDG DT - MOXA NPORT DriverConfiguration - 01 00 PDFElbrus AbdulezimovNo ratings yet

- Nport S8455I Series User'S Manual: Second Edition, July 2012Document166 pagesNport S8455I Series User'S Manual: Second Edition, July 2012Jafarov VuqarNo ratings yet

- Simatic: S7-PLCSIM V5.4 Including SP8 Update 1 Simulation Software ReadmeDocument19 pagesSimatic: S7-PLCSIM V5.4 Including SP8 Update 1 Simulation Software ReadmeJafarov VuqarNo ratings yet

- ReadMe 2 Replace DLLDocument1 pageReadMe 2 Replace DLLJafarov VuqarNo ratings yet

- Presentation Hesy English 2013Document28 pagesPresentation Hesy English 2013Jafarov Vuqar100% (1)

- Shanghai Durable Machinery Co., LTD.: Atlas Copco Bolaite Air CompressorDocument18 pagesShanghai Durable Machinery Co., LTD.: Atlas Copco Bolaite Air CompressorJafarov VuqarNo ratings yet

- EULADocument7 pagesEULAChinnu RainNo ratings yet

- Nport S8455/S8458 Series: Combo Switch / Serial Device ServersDocument4 pagesNport S8455/S8458 Series: Combo Switch / Serial Device ServersJafarov VuqarNo ratings yet

- Data Sheet 6ED1052-1HB00-0BA8: Product Is No Longer AvailableDocument1 pageData Sheet 6ED1052-1HB00-0BA8: Product Is No Longer AvailableJafarov VuqarNo ratings yet

- Logo System Manual en-US en-USDocument372 pagesLogo System Manual en-US en-UScportilloNo ratings yet

- Plattischemic Stroke Lesson PlanDocument18 pagesPlattischemic Stroke Lesson Planapi-216258123100% (3)

- Kyle Capodice Ecet Candidate ResumeDocument1 pageKyle Capodice Ecet Candidate Resumeapi-394690479No ratings yet

- Society of Radiographers - PDFDocument9 pagesSociety of Radiographers - PDFOsama AhmedNo ratings yet

- MAXsys 2510 Meterin FamilyDocument52 pagesMAXsys 2510 Meterin FamilyAbel NinaNo ratings yet

- Late 18th and Early 19thDocument82 pagesLate 18th and Early 19thGrace CordelinNo ratings yet

- EM Complete NotesDocument191 pagesEM Complete NoteswsbwaqhpwpvcwuhajkNo ratings yet

- Housing Inequality Causes and SolutionsDocument5 pagesHousing Inequality Causes and SolutionsFredrickNo ratings yet

- Faculty of Health and Medical Sciences: Academic Terms and Fee Schedule For 2022Document3 pagesFaculty of Health and Medical Sciences: Academic Terms and Fee Schedule For 2022Sadwi MulatsihNo ratings yet

- Course Registration Slip MBA 2023Document3 pagesCourse Registration Slip MBA 2023Piyush RaghuwanshiNo ratings yet

- Digital Mining Technology CAS-GPS Light Vehicle System Technical SpecificationDocument5 pagesDigital Mining Technology CAS-GPS Light Vehicle System Technical SpecificationAbhinandan PadhaNo ratings yet

- Manocha Icile Feasibility StudyDocument95 pagesManocha Icile Feasibility StudyAlmadin KeñoraNo ratings yet

- Railways MedicalDocument73 pagesRailways MedicalGaurav KapoorNo ratings yet

- En Subject C08Document13 pagesEn Subject C08jmolfigueiraNo ratings yet

- Download 3000+ Books by Acharya Pt. Shriram SharmaDocument89 pagesDownload 3000+ Books by Acharya Pt. Shriram SharmaAllWorld GaayatreeParivaar SaharunpurNo ratings yet

- UntitledDocument421 pagesUntitledtunggal KecerNo ratings yet

- Pdic LawDocument30 pagesPdic LawDadangNo ratings yet

- Grade 6 Quarter 3 WHLP WEEK 4Document3 pagesGrade 6 Quarter 3 WHLP WEEK 4JaneDandanNo ratings yet

- XMLvsJSON-40charDocument7 pagesXMLvsJSON-40charPrakashNo ratings yet

- MS For SprinklerDocument78 pagesMS For Sprinklerkarthy ganesanNo ratings yet

- Mrs. Dunia Halawi HarbDocument18 pagesMrs. Dunia Halawi HarbsallykamareddineNo ratings yet