Professional Documents

Culture Documents

QP

Uploaded by

good buddy0 ratings0% found this document useful (0 votes)

57 views3 pagesThis document contains a comprehensive exam for a Biochemical Engineering course. It includes 10 multi-part questions testing knowledge of topics like chemostat operation, fluidized bed reactor design, batch vs continuous culture, bioreactor design/operation, enzyme kinetics, sterilization, and more. Students are asked to determine parameters like required dilution rates, reactor volumes, cell concentrations, heat removal requirements, probabilities of sterilization, and effects on process economics.

Original Description:

Original Title

QP.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a comprehensive exam for a Biochemical Engineering course. It includes 10 multi-part questions testing knowledge of topics like chemostat operation, fluidized bed reactor design, batch vs continuous culture, bioreactor design/operation, enzyme kinetics, sterilization, and more. Students are asked to determine parameters like required dilution rates, reactor volumes, cell concentrations, heat removal requirements, probabilities of sterilization, and effects on process economics.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views3 pagesQP

Uploaded by

good buddyThis document contains a comprehensive exam for a Biochemical Engineering course. It includes 10 multi-part questions testing knowledge of topics like chemostat operation, fluidized bed reactor design, batch vs continuous culture, bioreactor design/operation, enzyme kinetics, sterilization, and more. Students are asked to determine parameters like required dilution rates, reactor volumes, cell concentrations, heat removal requirements, probabilities of sterilization, and effects on process economics.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

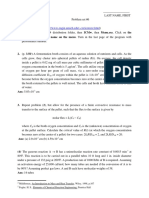

BITS PILANI, K. K.

BIRLA GOA CAMPUS, FIRST SEMESTER 2017 – 2018

COMPREHENSIVE EXAM (CLOSED BOOK)

BIOCHEMICAL ENGINEERING (CHE F421)

DATE: 14/05/2017 TIME: 9:00 pm – 12:00 pm MAX. MARKS: 40

Answer all the questions

1) Ethanol is to be used as a substrate for single-cell protein production in a chemostat. The available

equipment can achieve an oxygen transfer rate of 10 g O2/l. h. Assume kinetics of cell growth on

ethanol is of Monod type, with µm = 0.5 h–1, Ks = 30 mg/l, YX/S = 0.5 g cells/g EtOH, and YO2/S = 2 g

O2/g EtOH. We wish to operate the chemostat with an ethanol concentration in the feed of 22 g/L. We

also wish to maximize the biomass productivity and minimize the loss of unused ethanol in the effluent.

Determine the required dilution rate and whether sufficient oxygen can be provided. (3 marks).

2) Immobilized lactase packed in a multistage fluidized bed is being proposed for the continuous

production of glucose and galactose. Draw the operation schemes for multistage fluidized bed reactor to

achieve a uniform conversion rate? What are the advantages of fluidized bed reactor over packed bed

reactor for enzymatic reactions? (3 marks)

3) Discuss about various factors that dictate the choice of biomass cultivation method? (1 mark). Show

that biomass productivity from continuous culture is higher than that of batch productivity? (3 marks).

Compare the biomass productivities obtained from continuous and batch cultivation methods when final

biomass concentration is 30 times higher than initial biomass concentration, down time between the

batches is 10 h and maximum specific growth rate of 0.5 h-1 (1 mark)

4) An industrial waste-water stream is fed to a stirred-tank reactor continuously and the cells are recycled

back to the reactor from the bottom of the sedimentation tank placed after the reactor.

The following are given for the system:

F = 100 l/h; S0 = 5000 mg/l; µm = 0.25 h-1; Ks = 200 mg/l; α = 0.6; C = 2; YX/S = 0.4. The effluent

concentration is desired to be 100 mg/l.

a. Determine the required reactor volume. (2 marks)

b. Determine the cell concentration in the reactor and in the recycle stream. (2 marks)

c. If the residence time is 2 h in the sedimentation tank, determine the volume of the sedimentation tank

and cell concentration in the effluent of the sedimentation tank. (2 marks)

5) Citric acid is manufactured using submerged culture of Aspergillus niger in a batch reactor operated at

30 °C. Over a period of 2 days, 2500 kg glucose and 860 kg oxygen are consumed to produce 1500 kg

citric acid, 500 kg biomass, and other products. Ammonia is used as the nitrogen source. Power input

to the system by mechanical agitation of the broth is about 15 kW; approximately 100 kg of water is

evaporated over the culture period. Estimate the cooling requirements. (Δhv water at 30°C is 580.6 k cal

kg-1) (3 marks)

6) An enzyme is used to convert substrate to a commercial product in a 1600 L batch reactor. Vmax for the

enzyme is 0.9 g 1-1 h-l; Km is 1.5 g 1-1. Substrate concentration at the start of the reaction is 3 g l-1;

according to the stoichiometry of the reaction, conversion of 1 g substrate produces 1.2 g product. The

cost of operating the reactor including labour, maintenance, energy and other utilities is estimated at

$4800 per day. The cost of recovering the product depends on the extent of substrate conversion and the

resulting concentration of product in the final reaction mixture. For conversions

between 70% and 100%, the cost of downstream processing can be approximated using the equation:

C = 155 - 0.33X

where C is cost in $ per kg product treated and X is the percentage substrate conversion. The market

price for the product is $750 kg-1. Currently, the enzyme reactor is operated with 75% substrate

conversion; however it is proposed to increase this to 90%. Estimate the effect this will have on the

economics of the process. (5 marks)

7) A cylindrical stirred bioreactor of diameter and liquid height 2 m is equipped with a Rushton turbine of

diameter one-third the tank diameter. The bioreactor contains Newtonian culture broth with the same

density as water and viscosity 4 cP.

(a) If the specific power consumption must not exceed 1.5 kW m-3, determine the maximum allowable

stirrer speed. (1 mark)

(b) What is the mixing time at the stirrer speed determined in (a)? (1 mark)

(c) The tank is now aerated. In the presence of gas bubbles, the approximate relationship between the

ungassed turbulent power number (NP)’0 and the gassed turbulent power number (NP)’g is

(NP)’g = 0.5 (NP)’0 . What maximum stirrer speed is now possible in the sparged reactor? (1 mark)

8) An autoclave malfunctions, and the temperature reaches only 119.5°C. The sterilization time at the

maximum temperature was 20 min. The jar contains 10 l of complex medium that has 105 spores/l. At

121°C, kd = 1.0 min-1 and E0d = 90 kcal/g-mol. What is the probability that the medium was sterile? (3

marks)

9) The growth of baker’s yeast (Saccharomyces cerevisiae) on glucose may be simply described by the

following equation:

C6H12O6 + 3 O2 + 0.48 NH3 0.48 C6H10NO3 (yeast) + 4.32 H2O + 3.12 CO2

In a batch reactor of volume 105 L, the final desired yeast concentration is 50 g/L. Using the above

reaction stoichiometry:

(a) Determine the concentration and total amount of glucose and (NH4)2SO4 in the medium. (1 mark)

(b) Determine the yield factors YX/S (biomass/glucose) and YX/O2 (biomass/ oxygen). (1 mark)

(c) Determine the total amount of oxygen required. (1 mark)

(d) If the rate of growth at exponential phase is rX = 0.7 g/(L.h), determine the rate of oxygen

consumption, g O2/(L.h). (1 mark)

(e) Calculate the heat-removal requirements for the reactor. (1 mark)

10) The lowest yield of ATP /is in (0.5 mark)

A. fermentation

B. aerobic respiration

C. anaerobic respiration

D. same in (a), (b) and (c).

11) Answer true or false to the following statements (Answers with proper justification required)

a. In the design of the sterilizer, the deterministic and probabilistic approaches would yield similar

results as long as Nf >>1 (0.5 mark)

b. Dynamic method of kLa determinations is widely used because it can be used while a bioreactor

is in use and with little disturbance to its performance (0.5 mark)

c. In a batch culture, the specific oxygen consumption rate does not vary with time (0.5 mark)

d. While sparging air into the bubble column reactor at a rate above the transition gas flow rate Q T

bubbles size increases but bubbles are formed at constant frequency (0.5 mark)

e. In the case of un-gassed Newtonian fluids, under laminar regime, power requirement is directly

proportional to viscosity but independent of density (0.5 mark)

f. For product formation not directly coupled to energy metabolism, observed yield of product,

Y’P/X can be improved by increasing the mP (0.5 mark)

g. In an airlift reactor, equilibrium bubble size is independent of sparger design (0.5 mark)

You might also like

- Biohydrogen III: Renewable Energy System by Biological Solar Energy ConversionFrom EverandBiohydrogen III: Renewable Energy System by Biological Solar Energy ConversionNo ratings yet

- Medium Stoichiometry & KineticsDocument9 pagesMedium Stoichiometry & KineticsDzung Pham0% (1)

- Home Assignment 1: Mass & Energy BalancesDocument4 pagesHome Assignment 1: Mass & Energy BalancesAyush DubeyNo ratings yet

- List of Problems-Lec29Document1 pageList of Problems-Lec29Sachin MogerNo ratings yet

- Hydraulic Charateristic and Their Effects On Working Performance of Compartmentalized Anaerobic ReactorDocument6 pagesHydraulic Charateristic and Their Effects On Working Performance of Compartmentalized Anaerobic ReactorThiagoSilvaOliverNo ratings yet

- Unsw Sydney School of Chemical Engineering Sample Paper Ceic 2005 Chemical Reaction EngineeringDocument6 pagesUnsw Sydney School of Chemical Engineering Sample Paper Ceic 2005 Chemical Reaction EngineeringJoshua JohnNo ratings yet

- Bpe-Ii Tutorial-3 - 2024Document2 pagesBpe-Ii Tutorial-3 - 2024125010211No ratings yet

- CHE4171: Biochemical Engineering: TUTOTRIAL Solution Guide (WEEK 3 T3)Document4 pagesCHE4171: Biochemical Engineering: TUTOTRIAL Solution Guide (WEEK 3 T3)HannahNo ratings yet

- Unit Conversions 1.1-1.4 Exercises-2Document5 pagesUnit Conversions 1.1-1.4 Exercises-2Jackson MakgolengNo ratings yet

- Uasb, MBBR Domestic WastewaterDocument10 pagesUasb, MBBR Domestic WastewaterIbarra ChavezNo ratings yet

- BTech degree exam bioprocess calculationsDocument4 pagesBTech degree exam bioprocess calculationsAnonymous 5lZJ470No ratings yet

- Optimize ethanol production from yeast in a continuous fermenterDocument17 pagesOptimize ethanol production from yeast in a continuous fermenterrhia81% (16)

- Biochemical AssDocument1 pageBiochemical AssbezNo ratings yet

- Set3ans 10Document5 pagesSet3ans 10amalinaishahNo ratings yet

- T7 - Mid-Semister Revisit and SterilizationDocument4 pagesT7 - Mid-Semister Revisit and SterilizationFishNo ratings yet

- Transport Phenomenon Question Paper (M.tech)Document3 pagesTransport Phenomenon Question Paper (M.tech)Kiran SheelavantNo ratings yet

- Homework 2 - 2020 - 01 - Sent (v4)Document4 pagesHomework 2 - 2020 - 01 - Sent (v4)DeividNo ratings yet

- Problemas A Resolver TareaDocument8 pagesProblemas A Resolver TareaRuben Marquez0% (1)

- Healthcare Insulin ProblemDocument16 pagesHealthcare Insulin ProblemTaufiq JaiNo ratings yet

- 1st Assess SumsquesDocument5 pages1st Assess Sumsquesmsg2deepak0% (1)

- Haramaya University Haramaya Institute of Technology Department of Chemical Engineering Introduction To Biochemical Engineering Worksheet 2Document3 pagesHaramaya University Haramaya Institute of Technology Department of Chemical Engineering Introduction To Biochemical Engineering Worksheet 2workisaNo ratings yet

- Chem Engg Paper-IIDocument6 pagesChem Engg Paper-IIambaneh tzeraNo ratings yet

- HomeworkDocument3 pagesHomeworkJudluzNo ratings yet

- Chemical Engineering Calculations - Midterm ExamDocument12 pagesChemical Engineering Calculations - Midterm ExamJohnNo ratings yet

- Assignment 1 BRD BT5071-2022Document3 pagesAssignment 1 BRD BT5071-2022Subhrojyoti GhoshNo ratings yet

- Bio Degradation of Distillery Spent WashDocument20 pagesBio Degradation of Distillery Spent Wash9219561870No ratings yet

- Sewage Treatment in A Rotating Biological Contactor (RBC) SystemDocument16 pagesSewage Treatment in A Rotating Biological Contactor (RBC) SystemBelen CRNo ratings yet

- Assignment L01 (Thursday, 11.30 Am)Document9 pagesAssignment L01 (Thursday, 11.30 Am)MawareNo ratings yet

- L7 ManuscriptDocument12 pagesL7 ManuscriptNURSYAHIRAH MOHD NAZIRNo ratings yet

- Cro Tut8Document13 pagesCro Tut8Ernst SmitNo ratings yet

- Insulin ADocument16 pagesInsulin ACarlos JimaNo ratings yet

- NIT TIRUCHIRAPPALLI PROCESS CALCULATIONS END SEMESTER EXAMDocument2 pagesNIT TIRUCHIRAPPALLI PROCESS CALCULATIONS END SEMESTER EXAMSujalNo ratings yet

- Mass Balance Tutorial 2 - 2021 Fin-StuDocument2 pagesMass Balance Tutorial 2 - 2021 Fin-StuToanique HeadmanNo ratings yet

- Problem set for batch and continuous reactor kineticsDocument4 pagesProblem set for batch and continuous reactor kineticsThalia RodriguezNo ratings yet

- Ie 50471 A 023Document6 pagesIe 50471 A 023Sedef ŞıraNo ratings yet

- CHE 304 (Spring 2010) Problem Set #6 SolutionsDocument4 pagesCHE 304 (Spring 2010) Problem Set #6 SolutionsNatália FerreiraNo ratings yet

- BITS Pilani, KK Birla Goa Campus Midterm Test-Semester II (2017-2018)Document2 pagesBITS Pilani, KK Birla Goa Campus Midterm Test-Semester II (2017-2018)Hritik LalNo ratings yet

- Batch Manufacture of Propylene GlycolDocument6 pagesBatch Manufacture of Propylene Glycolprassna_kamat1573No ratings yet

- Board-Exam May2223242019Document11 pagesBoard-Exam May2223242019Jonnah Faye MojaresNo ratings yet

- Anaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterDocument3 pagesAnaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterNurul RazakNo ratings yet

- Cre-II EndtermDocument2 pagesCre-II Endtermbt21cme061No ratings yet

- Simulation of Anaerobic Digestion of Cattle Manure PDFDocument8 pagesSimulation of Anaerobic Digestion of Cattle Manure PDFely_hernandez2010No ratings yet

- Anaerobic Processes (Chapter 10) : AdvantagesDocument13 pagesAnaerobic Processes (Chapter 10) : AdvantagesΔημητρηςΣαρακυρουNo ratings yet

- Production Hydrogen ModelDocument6 pagesProduction Hydrogen ModelJean OrellanaNo ratings yet

- RBC in Doua TrepteDocument15 pagesRBC in Doua TrepteRoxana AvramNo ratings yet

- Rbc in Doua TrepteDocument15 pagesRbc in Doua TrepteApex LoftNo ratings yet

- Biochemical Engineering Sample ProblemsDocument5 pagesBiochemical Engineering Sample ProblemsVan Vesper Dulliyao100% (1)

- Bioprocess Lab Manual GuideDocument27 pagesBioprocess Lab Manual GuideFatih RushdiNo ratings yet

- ExChEL Group Study Session 17 - ChE Calc IDocument4 pagesExChEL Group Study Session 17 - ChE Calc IRochelle Louise SampagaNo ratings yet

- BPE B.Tech NOVEMBER 2011Document6 pagesBPE B.Tech NOVEMBER 2011Thirunavukkarasu ANo ratings yet

- Problem Set 3Document2 pagesProblem Set 3Nigel Kow0% (1)

- Torkian 2003Document11 pagesTorkian 2003Walther Millones QuesquenNo ratings yet

- CHEN 509 Tutorial Revised - 2024Document5 pagesCHEN 509 Tutorial Revised - 2024Enemona ShellengNo ratings yet

- Production of ethylene glycol from a semibatch reactorDocument3 pagesProduction of ethylene glycol from a semibatch reactorJose David D SNo ratings yet

- Proposal OutlineDocument7 pagesProposal OutlineNaveen RajahNo ratings yet

- AELTERMAN Et Al 2006 Microbial Fuel Cells For Wastewater TreatmentDocument7 pagesAELTERMAN Et Al 2006 Microbial Fuel Cells For Wastewater TreatmentEr Mohammad ImranNo ratings yet

- Ejercicios Diseño de BiorreactoresDocument2 pagesEjercicios Diseño de BiorreactoresJuli OsorioNo ratings yet

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationFrom EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Vision VAMDocument64 pagesVision VAMgood buddyNo ratings yet

- Vision Sept 2021Document113 pagesVision Sept 2021Yash MhadgutNo ratings yet

- BITS Pilani Laplace Transforms NotesDocument19 pagesBITS Pilani Laplace Transforms Notesgood buddyNo ratings yet

- Exp - P4 - First and Second Order SystemsDocument9 pagesExp - P4 - First and Second Order SystemsSayan BiswasNo ratings yet

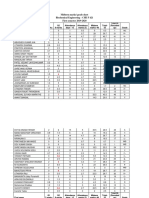

- Midterm Grades BiochemicalDocument2 pagesMidterm Grades Biochemicalgood buddyNo ratings yet

- Enzyme Kinetics GuideDocument37 pagesEnzyme Kinetics Guidekumar ankitNo ratings yet

- Course 3 QuestDocument25 pagesCourse 3 Questgood buddyNo ratings yet

- Course 4 Faecal Sludge ManagemDocument8 pagesCourse 4 Faecal Sludge Managemgood buddyNo ratings yet

- 3d Printing of Concrete StructuresDocument110 pages3d Printing of Concrete StructuresGabriel ComerlatoNo ratings yet

- Module 2 (Physics)Document4 pagesModule 2 (Physics)Miguel Oliveira100% (1)

- Aashto - LRFD of Steel Beam Bridges Fatigue and FractureDocument56 pagesAashto - LRFD of Steel Beam Bridges Fatigue and Fractureg401992100% (1)

- Troubleshoot 4-20 mA loopsDocument14 pagesTroubleshoot 4-20 mA loopsrozzillaNo ratings yet

- LeHTN PDFDocument220 pagesLeHTN PDFjasimabdNo ratings yet

- Sunswinger Pendulum Sunswinger Pendulum Sunswinger Pendulum: ® Skill Level: Beginner (Soldering Req'D)Document22 pagesSunswinger Pendulum Sunswinger Pendulum Sunswinger Pendulum: ® Skill Level: Beginner (Soldering Req'D)Andronic SebastianNo ratings yet

- Chapter 1 Chem ReviewerDocument4 pagesChapter 1 Chem ReviewerMatt DLSNo ratings yet

- Heat Engines Vol 3Document280 pagesHeat Engines Vol 3Ramana Rao SusarlaNo ratings yet

- Ta 7-5-10 GB Ta-CmiDocument4 pagesTa 7-5-10 GB Ta-Cmivan_dall_2No ratings yet

- Flame Radiation in Gas Turbines: Understanding Factors That Impact Combustor RadiationDocument18 pagesFlame Radiation in Gas Turbines: Understanding Factors That Impact Combustor RadiationReza KH100% (1)

- Processing Data BASF B 4406Document3 pagesProcessing Data BASF B 4406sygabrielaNo ratings yet

- Enrtl-Rk Rate Based Nh3 ModelDocument22 pagesEnrtl-Rk Rate Based Nh3 ModelsamandondonNo ratings yet

- ND II MECH, 2ND TERM 2011/2012 RESULTDocument15 pagesND II MECH, 2ND TERM 2011/2012 RESULTtaridanNo ratings yet

- Basics of VibrationDocument22 pagesBasics of VibrationPrashant Puri0% (1)

- PSC1501 Assignment 4Document5 pagesPSC1501 Assignment 4Koketso MashangoaneNo ratings yet

- Final Project (Team)Document5 pagesFinal Project (Team)bintangNo ratings yet

- Dpi 150Document4 pagesDpi 150Chirag SharmaNo ratings yet

- Understanding the Properties and Applications of Cemented CarbideDocument20 pagesUnderstanding the Properties and Applications of Cemented Carbidemp87_ingNo ratings yet

- Strength-Durability Correlation of OsteosynthesisDocument17 pagesStrength-Durability Correlation of OsteosynthesisdeniNo ratings yet

- Inert Gas NarcosisDocument8 pagesInert Gas NarcosisKanan Langin-HooperNo ratings yet

- Data Modulus ElastisitasDocument5 pagesData Modulus ElastisitasYohan S.No ratings yet

- Indian Night Vision TechDocument10 pagesIndian Night Vision Techshashank_shrNo ratings yet

- FluentDocument13 pagesFluentMilan Krishna Singha SarkarNo ratings yet

- Why Is Bandwidth Expressed in 3db and Not in 4db or 5db?: 2 AnswersDocument5 pagesWhy Is Bandwidth Expressed in 3db and Not in 4db or 5db?: 2 AnswersRajeev Mohan VermaNo ratings yet

- TM1800 Circuit Breaker Analyzer System: ProgrammaDocument10 pagesTM1800 Circuit Breaker Analyzer System: ProgrammaMuhammad NurhudaNo ratings yet

- Full Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full ChapterDocument36 pagesFull Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full Chapterrabate.toiler.vv5s088% (16)

- Condenser Design Calculation SummaryDocument11 pagesCondenser Design Calculation SummaryAlMakhie0% (1)

- SC Eng Guide Screw Conveyor ExampleDocument9 pagesSC Eng Guide Screw Conveyor ExampleTifanny FlorentinaNo ratings yet

- Apm2558nu 2Document10 pagesApm2558nu 2minhchatnguyenNo ratings yet

- Special Magic Squares of Order Six and EightDocument13 pagesSpecial Magic Squares of Order Six and EightIJDIWCNo ratings yet