Professional Documents

Culture Documents

Tetralon FCP-MV-EN - 002

Uploaded by

Rogério RangelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tetralon FCP-MV-EN - 002

Uploaded by

Rogério RangelCopyright:

Available Formats

Multi-way ball valve

for process or transfer line

and all types of fluids

MV ©

Optional:

Gaskets:

OVERVIEW:

The multi-way ball valve is designed to close one or more circuits or distribute the

pressurised fluids to one or more ways. The MV valve comprises a body with 2 or 4 ways

and a key (cylindrical ball) which directs the fluid circulation. Its hygienic design ensures

there is no retention zone while providing maximum cleanability by hammering during

the CIP cycles.

This valve is intended for circuits carrying group 2 clear or viscous liquids (Article 9 of

the European directive 97/23/CE) and solid bearing liquids.

KEY BENEFITS:

Full flow (pigging version)

Minimisation of pressure losses

2 to 5 ways enabling line pooling for several products

Hygienic design

Numerous options to meet all types of requirements

APPLICATIONS:

Equipment adapted to the lines distributing all types of fluids, including viscous,

solid bearing and/or solidifying fluids (creams, chocolate, caramel, etc.)

Equipment especially adapted to lines with pigging systems: may be used as a

distribution or isolation valve or as intermediary station (pigging receiving version)

© alphaspirit - Fotolia.com

34-36, avenue Roger Hennequin - CS 10536 - 78190 Trappes Cedex (France)

Tel. +33 (0)1.30.16.15.00 | Fax. +33 (0)1.30.16.15.01 | Web. www.servinox.com

AVAILABLE VERSIONS: STANDARD DIMENSIONS IN MM:

DN25

The valve body can have 2 to 4 ways, as well as a key (cylindrical ball) which directs the fluid Sizes DN10 DN15 DN20

SMS25

DN32

flow:

A 25 28.5 31.5 34 40.5

MVA MVB MVC MVD MVH MVI B 20 24.5 26 29.5 35.5

C 55 63.6 78.1 78 78

E 64 55 98 115 101

F 71 71 110 135 146

DN40 DN50 DN80

Sizes SMS38 SMS51

SMS63.5 DN65

SMS76.1

A 49 57.5 65.5 65.5 78.5

B 43 50 58 58 67.5

C 96.2 107 123 117 139

E 155 155 198 198 250

On-off valve 90° T-key 90° L-key Distribution L-key 120° L-key 90° L/L-key 2 I/O F 160 205 265 265 295

Product entry rear

channel DN100

Sizes SMS104

DN125 DN150

A 89 - -

TECHNICAL SPECIFICATIONS:

B 81.5 110 134

Sizes: C 160 292 390

• SMS: 25mm (1’’), 38mm (1.1/2’’), 51mm (2’’), 63.5mm (2.1/2’’), 76.1mm (3’’), 104mm (4’’) E 265 - -

• DIN 11851: DN10, DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, F 295 - -

DN125, DN150

Connection: Male

Product pressure: Empty 10 bar Note: The MVH model is only available from DN25

Service temperature: From 1 °C to 120 °C

Materials:

• Parts in contact with the product: 1.4404 (316L) stainless steel

• Other parts: 1.4301 (304L) stainless steel

• Sealing: Rings PTFE (Polytetrafluoroethylene, eq. Teflon®) and EPDM (Ethylene

Propylene Diene Monomer) gaskets

Standard Ra of the valves is 0.8 μm interior.

The DN10 to DN65 standard valves have an operating lever. Models DN80 and DN100 have

a double operating lever. As of DN80, we recommend a pneumatic or electric actuator.

All the valves are marked on the lower part of the key; this indicates the exact position of

the ways.

Servinox makes every effort to update its documents in line with improvements to its products. This data sheet can therefore be updated with no prior notifications.

34-36, avenue Roger Hennequin - CS 10536 - 78190 Trappes Cedex (France)

Servinox is an ISO 9001:2008 certified company

Tel. +33 (0)1.30.16.15.00 | Fax. +33 (0)1.30.16.15.01 | Web. www.servinox.com

OPTIONS:

• Compliant with "ATEX 94/9/CE zones 1 & 2, gas and dust"

• Handle operating stop: avoid any risk of fluid mix and uncontrolled operations

• Position detection for controller (inductive sensors)

• Automatic version

• Accessories (EV, ED, detection, etc.)

• Pigging distribution or receiving versions

• Heating element

• Intensive cleaning version

• Other connections: To weld, clamp, female, flange

• Sealing - other materials available for rings: Polyethylene, PTFE glass-filled, PTFE filled

Stainless steel

• Sealing- other materials available for gaskets: NBR (Nitrile rubber), FKM (Fluorocarbon

rubber, eq. Viton®), VMQ (Silicone), VMQ PTFE encapsulated (Polytetrafluoroethy-

lene, eq. Teflon®), FFKM (Perfluoroelastomer, eq. Kalrez®)

• Sealing USP Class VI compliant

• Specific surface state

• Other construction materials nuances

• Customised equipment: please contact us

GUARANTEE:

12 months from the date of shipment (except in the case of special conditions)

COMPLIANCE:

• Elastomer gaskets compliant with FDA CFR 21.177.2600 and 1935/2004/EC ruling

• Optional: Gaskets USP Class VI compliant

• Optional: Compliant with "ATEX 94/9/EC zones 1 & 2, gas and dust"

SERVINOX follows the recommendations of international guidelines and standards relative

to hygienic design and construction, in particular those of the EHEDG and 3-A.

FCP-MV-EN/002

Servinox makes every effort to update its documents in line with improvements to its products.

This data sheet can therefore be updated with no prior notifications.

Servinox is an ISO 9001:2008 certified company

You might also like

- Unit 2 - Chapter 2 - Macromolecules NotesDocument41 pagesUnit 2 - Chapter 2 - Macromolecules Notesapi-375285021No ratings yet

- Manual InstructionsDocument34 pagesManual InstructionsАндрей100% (4)

- MANN Filters For LiquidsDocument48 pagesMANN Filters For LiquidsRoccinanteNo ratings yet

- Swro PretreatmentDocument8 pagesSwro PretreatmentprakashNo ratings yet

- SSV Divider ValvesDocument28 pagesSSV Divider ValvesRock SayboltNo ratings yet

- Transfluid Clutch in 1412TPDocument4 pagesTransfluid Clutch in 1412TPSivaNo ratings yet

- G10 Lesson1 DLPDocument15 pagesG10 Lesson1 DLPAngeles, Mark Allen CNo ratings yet

- BASF CoatingDocument18 pagesBASF Coatingchinmoy100% (1)

- Dual-Line Lubrication Systems: Product CatalogueDocument84 pagesDual-Line Lubrication Systems: Product CataloguedinomounarymaminaNo ratings yet

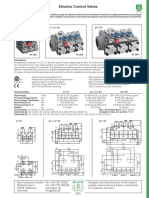

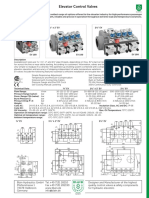

- Elevator Control Valves: EN ISO 9001Document4 pagesElevator Control Valves: EN ISO 9001Bantu BantuNo ratings yet

- SSM Monoblock Leaflet L4 4 April2017Document1 pageSSM Monoblock Leaflet L4 4 April2017Mohammad ShahidNo ratings yet

- Selector Valves (SVDXXX) - Rv00Document3 pagesSelector Valves (SVDXXX) - Rv00Lý Thái ThuầnNo ratings yet

- CIM603PDFDocument3 pagesCIM603PDFMagalaNo ratings yet

- Ev100 gb-1Document6 pagesEv100 gb-1Geoffrey PearmainNo ratings yet

- OLED65EF9500 WebOS 2.0 4K UHD OLED TV T-CON BOARD LAYOUTDocument3 pagesOLED65EF9500 WebOS 2.0 4K UHD OLED TV T-CON BOARD LAYOUTEliecer RdguezNo ratings yet

- 99026-SV Valve-BDocument4 pages99026-SV Valve-Bpabloperezmtz1No ratings yet

- DS Variable Area Flow MetersDocument6 pagesDS Variable Area Flow MetersJoel VargasNo ratings yet

- Selector ValvesDocument23 pagesSelector Valveswalk111No ratings yet

- LKRK Static Spray Balls Product LeafletDocument4 pagesLKRK Static Spray Balls Product LeafletalejandroNo ratings yet

- Hydreco@: HydraulicsDocument12 pagesHydreco@: HydraulicsMauricio Hermosilla OrellanaNo ratings yet

- Siemens Flow SwitchDocument6 pagesSiemens Flow Switcheng.abdullrahmanNo ratings yet

- DtEC Valve Trays - ADDS 231112Document1 pageDtEC Valve Trays - ADDS 231112a0aryanNo ratings yet

- HPVM Series: Hydraulic Pilot ControlsDocument4 pagesHPVM Series: Hydraulic Pilot ControlsMichael AkhramovichNo ratings yet

- Elevator Control Valves: EN ISO 9001Document6 pagesElevator Control Valves: EN ISO 9001DaceDropNo ratings yet

- Qm30dy 24Document5 pagesQm30dy 24joelpalzaNo ratings yet

- A Polyhydron Group Company: DescriptionDocument2 pagesA Polyhydron Group Company: DescriptionRenjithSivaNo ratings yet

- Qm75dy HDocument5 pagesQm75dy HSamsung KzoomNo ratings yet

- Grundfos Valves: Non-Return Valves and Foot ValvesDocument10 pagesGrundfos Valves: Non-Return Valves and Foot ValvesFernando RochaNo ratings yet

- Grundfosliterature 829855Document26 pagesGrundfosliterature 829855Service GamberiniNo ratings yet

- Ev100 GBDocument6 pagesEv100 GBCarlos PalmaNo ratings yet

- Actuador VC On-Off HoneywellDocument4 pagesActuador VC On-Off HoneywellGrafter TermocuplasNo ratings yet

- Electrical Machines DesignsDocument5 pagesElectrical Machines DesignsHafiz SalmanNo ratings yet

- Solenoid Valve, Metal, NAMUR: ConstructionDocument4 pagesSolenoid Valve, Metal, NAMUR: ConstructionEdmar Vilela de SouzaNo ratings yet

- Selector Valves SVDXXX - Rv06Document4 pagesSelector Valves SVDXXX - Rv06fatmhnjarymarfNo ratings yet

- TP, Tpe, TPD, TpedDocument20 pagesTP, Tpe, TPD, TpedGergely DancsNo ratings yet

- EIC E 1012 0 Double Locking Check ValveDocument2 pagesEIC E 1012 0 Double Locking Check ValvePasu_08No ratings yet

- Solenoid Valve: Selector TableDocument130 pagesSolenoid Valve: Selector TablePatricio ValenciaNo ratings yet

- KICE INDUSTRIES Spout ManualDocument48 pagesKICE INDUSTRIES Spout ManualcharlesmpsNo ratings yet

- Type MP07 Pneumatic Modules, ContinuedDocument1 pageType MP07 Pneumatic Modules, ContinuedIlham RomadhoniNo ratings yet

- WWDPDocument1 pageWWDPJose ItzmoyotlNo ratings yet

- Control Valve Pn16: Series Vla300 and Vlb300Document5 pagesControl Valve Pn16: Series Vla300 and Vlb300SultanNo ratings yet

- Series BBV-2 5-Valve Block and Bleed Manifold: Specifications - Installation and Operating InstructionsDocument4 pagesSeries BBV-2 5-Valve Block and Bleed Manifold: Specifications - Installation and Operating InstructionsGuillermo de la Fuente SantiagoNo ratings yet

- 12-PB EU SevereServiceControlValves R1 2020-03Document24 pages12-PB EU SevereServiceControlValves R1 2020-03nandkishorNo ratings yet

- SKF Lub Dual LineDocument84 pagesSKF Lub Dual LinevietkhamNo ratings yet

- HV-VCV: HV VCV Lines For The Insulation With Cross-Linked Polyethylene (XLPE)Document5 pagesHV-VCV: HV VCV Lines For The Insulation With Cross-Linked Polyethylene (XLPE)Sourav BhattacharyaNo ratings yet

- Eaton Industrial Valves Catalog E VLVI SS001 E en UsDocument203 pagesEaton Industrial Valves Catalog E VLVI SS001 E en UsPtbbi TubanNo ratings yet

- Alu Piston PUMPDocument24 pagesAlu Piston PUMPv8wfm8d8r7No ratings yet

- Fluidotehnic Lubrication - 42 DistributorsDocument11 pagesFluidotehnic Lubrication - 42 Distributorsli geneNo ratings yet

- Pipe Bolt Dimensions (Reference: Recommended Data) : Diaphragm ValveDocument4 pagesPipe Bolt Dimensions (Reference: Recommended Data) : Diaphragm ValveHoàng DũngNo ratings yet

- Automatic Lub SystemsDocument86 pagesAutomatic Lub SystemsSb KumarNo ratings yet

- Automatic ValvesDocument33 pagesAutomatic ValvesManjeet kumarNo ratings yet

- MSV Oil-Sealed Rotary Screw VacuumDocument8 pagesMSV Oil-Sealed Rotary Screw VacuumAlvaro G R MelgarNo ratings yet

- Ball Valve Thread EndDocument2 pagesBall Valve Thread EndBernard Bonnin CervantesNo ratings yet

- 377 U TungDrillTwistedDocument30 pages377 U TungDrillTwistedmartin.riosNo ratings yet

- MVP Multi-Valve PlatformDocument3 pagesMVP Multi-Valve PlatformGabriel Rincón RodríguezNo ratings yet

- Belimo Pressure Independent Control Valve Range - Piccv: Technical DatabookDocument21 pagesBelimo Pressure Independent Control Valve Range - Piccv: Technical DatabookHoàngViệtAnhNo ratings yet

- Gfps Datasheet 561 562 Cone Check Valve enDocument8 pagesGfps Datasheet 561 562 Cone Check Valve encarnaticshankNo ratings yet

- Features & Options: Main Dimensions Hydraulic DiagramDocument2 pagesFeatures & Options: Main Dimensions Hydraulic DiagramGerman BetancurNo ratings yet

- Zawory enDocument14 pagesZawory enadiNo ratings yet

- Esbe SERIES ARA600 Prop: Series MG, G, F, H, HG, BIV, T, TMDocument8 pagesEsbe SERIES ARA600 Prop: Series MG, G, F, H, HG, BIV, T, TMkardoszoltanNo ratings yet

- Atlantic ValvulaDocument8 pagesAtlantic ValvulaHector DiazNo ratings yet

- Haloalkanes and HaloarenesDocument14 pagesHaloalkanes and HaloarenesKalpesh BishnoiNo ratings yet

- Proteoglycans and Glycoproteins: DR - Nuruddin Mohammed NurDocument39 pagesProteoglycans and Glycoproteins: DR - Nuruddin Mohammed NurIffah IrdinaNo ratings yet

- Aldehydes and KetonesDocument6 pagesAldehydes and KetonesMira JaoNo ratings yet

- 978 1 62100 769 2 - ch1Document45 pages978 1 62100 769 2 - ch1João RodriguesNo ratings yet

- Expansion Joint Waterstops, Internal:, Black, LECOTRIL DIN 18541Document2 pagesExpansion Joint Waterstops, Internal:, Black, LECOTRIL DIN 18541Dilhara WickramaarachchiNo ratings yet

- Solid Biomass Fuels For Cooking - Beyond Firewood and Charcoal. GIZ 2017 PDFDocument96 pagesSolid Biomass Fuels For Cooking - Beyond Firewood and Charcoal. GIZ 2017 PDFBirimumaso DavidNo ratings yet

- Batch 14Document22 pagesBatch 14Sreenivas NaruNo ratings yet

- Citronella - Review With Cover Page v2Document19 pagesCitronella - Review With Cover Page v2Kim ThảoNo ratings yet

- Cfas Lot314141 V1 Exp.2020 01Document16 pagesCfas Lot314141 V1 Exp.2020 01freedNo ratings yet

- Report On Wet Air OxidationDocument83 pagesReport On Wet Air OxidationAnkita RoyNo ratings yet

- Student Expt 8 EngDocument9 pagesStudent Expt 8 EngArpit SinghNo ratings yet

- b28109788 PDFDocument822 pagesb28109788 PDFSiddhartha KumarNo ratings yet

- Chemistry SCIENCE Paper - 2: (Two Hours)Document9 pagesChemistry SCIENCE Paper - 2: (Two Hours)Puja AgarwalNo ratings yet

- Plastic Degradation by Microorganism: MethodologyDocument1 pagePlastic Degradation by Microorganism: MethodologyPurvi SoniNo ratings yet

- Part - I: Subjective Questions: Section (A) : Electrophile, Nucleophile, Nucleophilicity, Leaving Group Ability SolventDocument18 pagesPart - I: Subjective Questions: Section (A) : Electrophile, Nucleophile, Nucleophilicity, Leaving Group Ability SolventRavi kumarNo ratings yet

- 9701 s07 QP 4Document16 pages9701 s07 QP 4Krishna GangaramNo ratings yet

- Innovene Pe ProductsDocument25 pagesInnovene Pe Productsghasem_726990287No ratings yet

- Korir Et Al. (2014) The Fortification of Tea With Sweeteners and Milk and Its Effect On in Vitro PDFDocument9 pagesKorir Et Al. (2014) The Fortification of Tea With Sweeteners and Milk and Its Effect On in Vitro PDFYvonne TongNo ratings yet

- 15th Group ElementsDocument36 pages15th Group ElementsReyanNo ratings yet

- Battery Recycling Technologies Recycling Waste LitDocument16 pagesBattery Recycling Technologies Recycling Waste LitYong JiangNo ratings yet

- Product Line FlottecDocument0 pagesProduct Line Flottecrichard gutierrezNo ratings yet

- 0138E DimeticonDocument1 page0138E DimeticonnakitaNo ratings yet

- TroxerutinDocument3 pagesTroxerutincarlosNo ratings yet

- Biodegradable Polymers, Current Trends of Research and Their Applications, A ReviewDocument43 pagesBiodegradable Polymers, Current Trends of Research and Their Applications, A ReviewShiji BalesNo ratings yet

- Alifiah 5 LampiranDocument24 pagesAlifiah 5 LampiranalfiiNo ratings yet

- Journal of Coordination Chemistry Volume 43 Issue 4 1998 (Doi 10.1080/00958979808230447) Hida, Sven Roman, Paul J. Bowden, Allen A. Atwood, Jim D. - Synthesis of Tri (M Â Sulfonatedphenyl) PhospDocument5 pagesJournal of Coordination Chemistry Volume 43 Issue 4 1998 (Doi 10.1080/00958979808230447) Hida, Sven Roman, Paul J. Bowden, Allen A. Atwood, Jim D. - Synthesis of Tri (M Â Sulfonatedphenyl) Phospjfjd6889No ratings yet