Professional Documents

Culture Documents

Coconut Oil PDF

Coconut Oil PDF

Uploaded by

Selva RajanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coconut Oil PDF

Coconut Oil PDF

Uploaded by

Selva RajanCopyright:

Available Formats

PROJECT PROFILE

PRODUCT: COCONUT OIL.

PRODUCTION CAPACITY

(PER ANNUM):

ITEM QTY. VALUE

Coconut oil 92.4 MT RS.27,72,000

Coconut powder for 100 MT RS. 50,000

PREPARED BY:

Business Development Department

Orissa State Financial Corporation

OMP Square, Cuttack-753 003

Tel. Phone : 2444192

E-mail : osfcho@osfcindia.com

INTRODUCTION:

Coconut Oil is prepared from coconuts by cooking the decorticated and

granulated coconuts having good oil content are preferred for this purpose. In

Tarini temple, devotees from all over Orissa send coconuts and huge quantities of

coconuts are collected. Those coconuts are offered to Devi Tarini and after that it is

decorticated manually and granulated to prepare lodu (sweets) but nowadays these

coconuts are sold to private parties and the money collected is utilised in the

development of temple. Those private parties are nowadays collected coconut oil

from granulated coconut and the deoiled coconut powder is again used in

preparation of lodus (sweets) with sugar syrup. The present profile is estimated to

set up a small scale unit for collection of coconut oil from coconut collected from

Tarini temple at Keonjhar.

MARKET POTENTIAL:

In Orissa, Coconut oil is mainly used for massaging before taking bath. It is

of light weight, low viscosity and of sweet essence and most suitable for

massaging purpose, coconut oil mixed with other ingredients like henna, shikakai,

trifala, synthetic essence to prepare hair oil. Though commercial preparation of

coconut oil from the coconuts produced in Orissa is not viable like in Karnataka,

Kerala, but in the present scheme raw coconut is available with very low cost,

which will help the entrepreneur to make it for commercial purpose by blending

with scented coconut oil.

BASIS AND PRESUMPTION:

1. Eight hours per day and 300 days per annum has been considered as the

working period.

2. 15% of oil can be collected from the coconuts available in the temple.

3. The unit will be set up in rental premises and will adopt manual process

to collect oil.

4. Blending and packaging will be carried out using machinery.

5. 12% rate of interest has been considered on total capital investment.

IMPLEMENTATION SCHEDULE:

Preparation of project report and regn. With DIC 1 month

Availability of finance 3 months

Procurement of machinery and equipment 1 month

Recruitment of staff and trial run 1 month

6 months

TECHNICAL ASPECTS:

Technology:

1. Coconuts are decorticated using decorticating equipment and then the

kernels are washed with hot water.

2. The washed coconut kernels are fed to the rotor and oil is expelled

through the sieves. Oil collected contains water. To remove water from

the oil it is cooked in Open cast iron pans.

3. During cooking, stirring is done with little pressing so that escalation of

oil will be easier.

4. When oil comes out the granulated or scrap form of coconut are screened

with screener and the oil mixed water is heated to evaporate water.

5. To that oil scented coconut oil is added and blended in a stirrer and then

packed in an automatic form, fill and seal machine in printed plastic

containers.

FINANCIAL ASPECTS:

Land: 5000 sq. ft. land with 1500 sq. ft. shed on rental basis: Rs.2500 P.M.

Machinery:

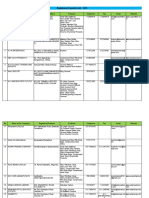

S.no. Specification Qty. Value

1. Cast iron pan 1000 lit. capacity (200 kg. four 1,20,000

Wt.)

2. Rotor cum screener to expel oil four 4,000

3. Decorticator five 500

4. Aluminium Disc 500 lit. capacity four 20,000

5. Stirrer with motor 1 HP (for blending 1 no. 10,000

purpose)

6. Other necessary equipments for cooking LS 5,000

7. Automatic filling machine for liquid one 70,000

8. Office furniture 10,000

2,39,500

Pre-operative expenditure:

Wooden chulla four nos. 2,000

Project profile 200

Travel 2,000

Regn. With Sales tax 2,000

Packing advance for plastic containers, cartons 15,000

Stationery 300

Telephone connection 3,000

Other misc. exp. 5,000

29,500

Fixed capital Investment:

Machinery 2,39,500

Pre-operative expr. 29,500

2,69,000/-

Working capital Analysis:

Raw coconuts 60 tons @ Rs.2000/Ton 1,20,000

Scented coconut oil 500 lit. @ 60/lit. 30,000

Packing materials (plastic containers, cartons,etc.) 20,000

1,70,000

Utilities:

Wood 30 quintals @ Rs.120/qtl. 3600

Electricity 300 KWH @ Rs.3.00 900

4,500

Staff and Labour:

Skilled labour 5 nos. 10,000

Unskilled labour 5 nos. 7,500

Salesman 1 no. 3,000

Accountant 1 no. 2,500

Peon 1 no. 2,000

25,000

Other expr. :

Rent 2500

Transport and travel 2000

Telephone 400

Stationery 100

Publicity 1000

Sale tips 1000

Other misc. expr. 2000

Taxes and levies 500

9,500

Working capital P.M. = 1,70,000 + 4500 + 25,000 + 9500 = Rs.2,09,000/-

Total capital Investment:

Fixed capital 2,69,000

Working capital 2,09,000

4,78,000

Cost of production (Per annum):

Depreciation on machinery and equipments @ 10% 22,950

Depreciation on furniture @ 20% 2,000

Recurring expenditure (per annum) 25,08,000

Interest on total cap. Investment @ 14% 66,920

25,99,870/-

Turnover (Per annum):

Assuming 20% wastage in outer cover and 15% of oil content, coconut oil

prepared 7.7 ton per month.

Item Quantity/Rate Value

Coconut oil 92.4 MT @ Rs.30,000/ton 27,72,000

Coconut powder for 100 MT @ Rs.500/ton 50,000

Lodu. 28,22,000

PROFIT:

= 28,22,000 - 25,99,870 = 2,22,130/-

Net profit ratio = Profit x 100 = 7.8%

Turnover

Rate of return = Profit x 100 = 46%

Investment

BREAK EVEN ANALYSIS:

Fixed cost (Per annum):

Total depreciation 24,950

Interest @ 14% 66,920

40% salary 1,20,000

40% other exp. Except rent 33,600

Rent 30,000

2,75,470/-

B.E.P. = FC x 100 = 55%

FC + profit

ADDRESSES OF MACHINERY SUPPLIERS:

1. M/s.Chemaco., 408, Jessore Road, Bus stop, Barat colony, Kolkata.

2. M/s.Jai Machinery, 9, Ezra Street, Kolkata.

You might also like

- Project Report On Ground Nut Oil (Cold Pressed)Document4 pagesProject Report On Ground Nut Oil (Cold Pressed)EIRI Board of Consultants and PublishersNo ratings yet

- Load Declaration FormDocument2 pagesLoad Declaration Formhunky110% (1)

- Desiccated CoconutDocument8 pagesDesiccated CoconutYohanes Slamet WidodoNo ratings yet

- Onion Dehydration: Project ProfileDocument4 pagesOnion Dehydration: Project ProfileMallikarjunReddyObbineniNo ratings yet

- Besan Mill ProjectDocument14 pagesBesan Mill Projectshreyans01100% (1)

- Business OverviewDocument10 pagesBusiness OverviewD J Ben Uzee100% (1)

- Project Report On Egg Tray From PulpDocument5 pagesProject Report On Egg Tray From PulpEIRI Board of Consultants and Publishers0% (1)

- Vastu Tips For Diagonal PlotDocument19 pagesVastu Tips For Diagonal Plothunky1175% (4)

- International Marketing Business Plan: Coconut Husk TilesDocument24 pagesInternational Marketing Business Plan: Coconut Husk TilesBea MendozaNo ratings yet

- Coconut Products: 1.0 Product and Its ApplicationsDocument6 pagesCoconut Products: 1.0 Product and Its ApplicationsAgri NetNo ratings yet

- Oil MillDocument8 pagesOil Millmanish.eer2394No ratings yet

- Coco Flour Flow ChartDocument3 pagesCoco Flour Flow ChartWilliam PulupaNo ratings yet

- Coconut ProductionDocument14 pagesCoconut ProductionCharith LiyanageNo ratings yet

- Plate LeafDocument3 pagesPlate LeafAbdul RahmanNo ratings yet

- Project Report On Grape Squash ManufacturingDocument13 pagesProject Report On Grape Squash ManufacturingPhanisreeNo ratings yet

- Coconut Oil MillingDocument3 pagesCoconut Oil MillingRichwil John Magadan100% (1)

- Virgin Coconut Oil Fresh Dry Process Wet Milling Route FULL PDFDocument79 pagesVirgin Coconut Oil Fresh Dry Process Wet Milling Route FULL PDFadelio mercadejasNo ratings yet

- Project On Hollow BricksDocument13 pagesProject On Hollow BricksSindhu Amal100% (1)

- Mustard Oil KanpurDocument10 pagesMustard Oil KanpurVinay YadavNo ratings yet

- Vittal Papermachine ProjectDocument20 pagesVittal Papermachine ProjectMir Muzamil AliNo ratings yet

- Charcoal Briquettes Production and Distribution Business PlanDocument14 pagesCharcoal Briquettes Production and Distribution Business PlanEmmanuel Bibandor100% (1)

- Project Profile On Manufacturing of Palm PlateDocument9 pagesProject Profile On Manufacturing of Palm PlateGangaraboina Praveen MudirajNo ratings yet

- Plywood Project Report by Yogesh AgrawalDocument22 pagesPlywood Project Report by Yogesh AgrawalYOGESH AGRAWALNo ratings yet

- Project Profile On Groundnut Oil and Oil Cake ManuafcuringDocument2 pagesProject Profile On Groundnut Oil and Oil Cake ManuafcuringprtmNo ratings yet

- Jute BagDocument9 pagesJute Bagafham84No ratings yet

- A Project ReportDocument24 pagesA Project ReportshariquesayeedNo ratings yet

- Sample Project From Udyami PDFDocument11 pagesSample Project From Udyami PDFBabu Viswanath MNo ratings yet

- Bio Mass Briquette PDFDocument17 pagesBio Mass Briquette PDFJigna PatelNo ratings yet

- Surgical Bandage-Ok-35-R PDFDocument2 pagesSurgical Bandage-Ok-35-R PDFSuresh KaushikNo ratings yet

- Profile On Activated Carbon PlantDocument5 pagesProfile On Activated Carbon PlantsolomonNo ratings yet

- Project Proposal On Poverty ReductionDocument7 pagesProject Proposal On Poverty Reductionhugen mutondoroNo ratings yet

- Project Profile On Petroleum JellyDocument10 pagesProject Profile On Petroleum JellymahahajNo ratings yet

- Project Profile On Mini Flour Mill UnitDocument10 pagesProject Profile On Mini Flour Mill UnitGolden Shower தமிழ்No ratings yet

- Plaster of ParisDocument5 pagesPlaster of ParisAniket Salvi100% (1)

- Plant Desin Report For Spice ProductionDocument7 pagesPlant Desin Report For Spice ProductionUmar Mohammad Mir0% (1)

- Briquette Proposal PlanDocument20 pagesBriquette Proposal PlanCyprian AendeNo ratings yet

- Dal MillDocument14 pagesDal MillAMBESHNo ratings yet

- Project On National Horticulture BoardDocument9 pagesProject On National Horticulture Boardrupeshmore145No ratings yet

- Dairy Farm Project-Self WorkDocument12 pagesDairy Farm Project-Self WorkPankaj Narendrasinh RajNo ratings yet

- Mini Rice MillDocument3 pagesMini Rice Millcheat2vin100% (1)

- 8.3.19 Synthesis of Organic Compost Using Dry and Wet Waste of The SurroundingDocument21 pages8.3.19 Synthesis of Organic Compost Using Dry and Wet Waste of The SurroundingAmit HanatNo ratings yet

- Groundnutdpr 04.08.23Document17 pagesGroundnutdpr 04.08.23TNRTP SALEMNo ratings yet

- Dehydrated Drumstick (Moringa Olifera) Powder: Profile No.: 95 NIC Code:21009Document8 pagesDehydrated Drumstick (Moringa Olifera) Powder: Profile No.: 95 NIC Code:21009Sabhaya ChiragNo ratings yet

- Corn MillingDocument4 pagesCorn Millingonetwoone s50% (1)

- Dairy Farming Project Report For 2.4.8.10,20,50, Cows, Farming ..Document4 pagesDairy Farming Project Report For 2.4.8.10,20,50, Cows, Farming ..Jamil erfanNo ratings yet

- Manual On Aqua EngDocument102 pagesManual On Aqua EngGIMRIL ATESNo ratings yet

- Project Report Tent PDFDocument10 pagesProject Report Tent PDFBasant KumarNo ratings yet

- Project Report PDFDocument11 pagesProject Report PDFamit22505No ratings yet

- Full Automatic Incense Stick Making MachineDocument9 pagesFull Automatic Incense Stick Making Machineprince kumarNo ratings yet

- PROJECT REPORT Converted CompressedDocument21 pagesPROJECT REPORT Converted CompressedVarun Jain0% (1)

- Banana Farming ProjectDocument3 pagesBanana Farming ProjectDmmi Fzco100% (1)

- Paper Bags and PouchesDocument9 pagesPaper Bags and Pouchessam krNo ratings yet

- Model Proj On Sheep Breeding FarmDocument4 pagesModel Proj On Sheep Breeding FarmSreenbabu0% (1)

- Centrifugal ExtractorDocument5 pagesCentrifugal ExtractorShivaniNo ratings yet

- MILLING ProcessDocument27 pagesMILLING ProcessSakinala Raj KumarNo ratings yet

- Sugarcane TechnologiesDocument136 pagesSugarcane TechnologiesVaibhav DafaleNo ratings yet

- Solvent Extraction For Jatropha OilDocument4 pagesSolvent Extraction For Jatropha OilRichard AmorinNo ratings yet

- Sample Project of Mini Oil MillDocument6 pagesSample Project of Mini Oil MillLajpat Lala0% (3)

- Agarbati ProjectDocument8 pagesAgarbati ProjectvachhanikapilNo ratings yet

- Eco Friendly Shoe Uppre Leather 2011Document12 pagesEco Friendly Shoe Uppre Leather 2011Namrit ZatakiyaNo ratings yet

- Herbal Hair OilDocument12 pagesHerbal Hair Oilrcool_rahul0039341No ratings yet

- Innovative Technology in Coconut Processing SectorDocument101 pagesInnovative Technology in Coconut Processing Sectorkhoafnn100% (1)

- Floor Is + 2'-6" Height From Road and Roof Height Is 11'-0" Clear From FloorDocument1 pageFloor Is + 2'-6" Height From Road and Roof Height Is 11'-0" Clear From Floorhunky11No ratings yet

- DR Fixit Piditop 333 105 1Document3 pagesDR Fixit Piditop 333 105 1hunky11No ratings yet

- Vastu Tips For Diagonal Plot JAJPURDocument5 pagesVastu Tips For Diagonal Plot JAJPURhunky11No ratings yet

- Exit Google Chrome CompletelyDocument1 pageExit Google Chrome Completelyhunky11No ratings yet

- SK Riaz F.floorDocument1 pageSK Riaz F.floorhunky11No ratings yet

- Bikash Ku - JenaDocument1 pageBikash Ku - Jenahunky11No ratings yet

- SK Riaz GfloorDocument1 pageSK Riaz Gfloorhunky11No ratings yet

- Rashtrapati BhavanDocument7 pagesRashtrapati Bhavanhunky11100% (1)

- S.g.plan Ground FloorDocument1 pageS.g.plan Ground Floorhunky11No ratings yet

- Age of Empires II: The Conquerors Cheats & Codes: Cheat ListDocument4 pagesAge of Empires II: The Conquerors Cheats & Codes: Cheat Listhunky11No ratings yet

- Profilling of Coconut MilkDocument42 pagesProfilling of Coconut MilkMichael Rio Adhipratama100% (1)

- Scale and Slug CaterpillarDocument66 pagesScale and Slug CaterpillarPca Zdn100% (1)

- Keto Fat Bombs: Sweet and Savory Fat-Fueling Snacks!Document12 pagesKeto Fat Bombs: Sweet and Savory Fat-Fueling Snacks!Locke LamoraNo ratings yet

- Ex Situ Analysis of The Bioinsecticidal Potency of Coconut (Cocos Nucifera) Oil Extract Against Green Leafhopper (Cicadella Viridis) On Rice PlantsDocument65 pagesEx Situ Analysis of The Bioinsecticidal Potency of Coconut (Cocos Nucifera) Oil Extract Against Green Leafhopper (Cicadella Viridis) On Rice PlantsJohn lebron SalumbidesNo ratings yet

- Registered Exporter List - 2019: No. Name of The Company Registered Address Products Telephone Fax Email WebsiteDocument64 pagesRegistered Exporter List - 2019: No. Name of The Company Registered Address Products Telephone Fax Email WebsiteBismillah SugehNo ratings yet

- CPAR Presentation No.1 2nd QuarterDocument19 pagesCPAR Presentation No.1 2nd QuarterDave Miranda LopezNo ratings yet

- Buko Pandan SaladDocument10 pagesBuko Pandan SaladDanielle Cezarra Fabella50% (2)

- Coco Foods Processing Plant Pre-Feasibility PresentationDocument16 pagesCoco Foods Processing Plant Pre-Feasibility PresentationGeorge Tumaob Calaor100% (6)

- Medicinal Plants MasterDocument490 pagesMedicinal Plants MasterNguyen Le Xuan BachNo ratings yet

- Chapter 23 AgricultureDocument7 pagesChapter 23 AgricultureEllen MaskariñoNo ratings yet

- 1.1 Overview of Coconut: Design and Fabrication of Coconut Fiber Extraction MachineDocument59 pages1.1 Overview of Coconut: Design and Fabrication of Coconut Fiber Extraction Machineabhishek mNo ratings yet

- 11th Plan HorticultureDocument552 pages11th Plan Horticulturemalikflori4650100% (1)

- RLDocument16 pagesRLFrancheska Pave CabundocNo ratings yet

- Ardra - MBA FINAL PROJECTDocument90 pagesArdra - MBA FINAL PROJECTKochuthresia JosephNo ratings yet

- Coconut VarietiesDocument6 pagesCoconut VarietiesJBNo ratings yet

- 04 Produce Organic Concoctions and ExtractsDocument48 pages04 Produce Organic Concoctions and ExtractsAlma Chavez Cubilla83% (18)

- Marketing Plan of Coconut Oil in IndonesDocument45 pagesMarketing Plan of Coconut Oil in IndonesHussainNo ratings yet

- Coconut IndustryDocument2 pagesCoconut Industryka bayani100% (1)

- Leads 3Document14 pagesLeads 3AltheaGeniloNo ratings yet

- Madhavaram HistoryDocument2 pagesMadhavaram HistoryTAMILARASINo ratings yet

- Black Widow Cookbook The Unique Marvel Mo - Luke SackDocument71 pagesBlack Widow Cookbook The Unique Marvel Mo - Luke SackCatherine CaoNo ratings yet

- Coconut Husk PDFDocument6 pagesCoconut Husk PDFMaxine FernandezNo ratings yet

- Pelatihan EPT 2021 - Reading SectionDocument22 pagesPelatihan EPT 2021 - Reading SectionIhsan BayuNo ratings yet

- Design FrameworkDocument3 pagesDesign Frameworknetinetnet78No ratings yet

- Strategic Management MBA 7002Document20 pagesStrategic Management MBA 7002cover edgeNo ratings yet

- Topic 22Document10 pagesTopic 22Jhade Danes BalanlayNo ratings yet

- 2nd Grading Test EPP 6Document5 pages2nd Grading Test EPP 6Art EaseNo ratings yet

- Chemical & Microbiological Analyses of Coconut Products & By-Products A. Laboratory Tests For SamplesDocument7 pagesChemical & Microbiological Analyses of Coconut Products & By-Products A. Laboratory Tests For SamplesBowo Aank ApriantoNo ratings yet

- MansdrfDocument2 pagesMansdrfmansi bavliyaNo ratings yet