Professional Documents

Culture Documents

Engineer Manual TP PDF

Uploaded by

Angga IndrawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineer Manual TP PDF

Uploaded by

Angga IndrawanCopyright:

Available Formats

TP48300B and TP48600B V300R001

Engineer Manual

Issue 01

Date 2012-08-28

HUAWEI TECHNOLOGIES CO., LTD.

Copyright © Huawei Technologies Co., Ltd. 2012. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and feat ures are stipulated by the contract made bet ween Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchas e scope or the usage scope. Unless otherwis e specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. E very effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Issue 01 (2012-08-28) Huawei Proprietary and Confidential i

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual About This Document

About This Document

Purpose

This document describes Telecom Power 48300B and 48600B V300R001 in terms of its

positioning, benefits, architecture, application scenarios, installation, routine maintenance,

troubleshooting, and component replacement. Telecom Power 48300B and 48600B

V300R001 is combined by the TP48300B and TP48600B, and the combined power system is

short for it in this document.

Intended Audience

This document is intended for:

Technical support personnel

Maintenance personnel

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol Description

Alerts you to a high risk hazard that could, if not avoided,

result in serious injury or death.

Alerts you to a medium or low risk hazard that could, if not

avoided, result in moderate or minor injury.

Alerts you to a potentially hazardous situation that could, if not

avoided, result in equipment damage, data loss, performance

deterioration, or unanticipated results.

Provides a tip that may help you solve a problem or save time.

Provides additional information to emphasize or supplement

important points in the main text.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential ii

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual About This Document

Change History

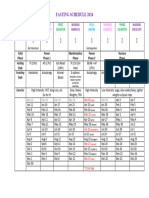

Date Version Description Author

2012-08-28 V1.0 Completed the initial Lin Quanxi (employee ID:

release. 00183858)

Issue 01 (2012-08-28) Huawei Proprietary and Confidential iii

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual Contents

Contents

About This Document.................................................................................................................... ii

1 Overview......................................................................................................................................... 1

1.1 Positioning ..........................................................................................................................................................................1

1.2 Benefits ................................................................................................................................................................................1

2 Architecture .................................................................................................................................... 3

2.1 Overview .............................................................................................................................................................................3

2.2 Hardware Co mponents......................................................................................................................................................4

2.2.1 Cabinet ......................................................................................................................................................................4

2.2.2 Rectifiers ...................................................................................................................................................................8

2.2.3 Monitoring System................................................................................................................................................11

3 Application Scenarios ................................................................................................................ 16

4 Installation.................................................................................................................................... 17

4.1 Preparations ......................................................................................................................................................................17

4.2 Equip ment Installat ion ....................................................................................................................................................19

4.3 Verify ing the Installation ................................................................................................................................................20

4.4 Po wering On and Co mmissioning the Combined Power System ...........................................................................20

4.5 Project Acceptance ..........................................................................................................................................................21

4.5.1 Acceptance for the Installation of the Co mbined Power System ..................................................................21

4.5.2 Acceptance Before Power-on ..............................................................................................................................22

4.5.3 Acceptance for Rectifiers .....................................................................................................................................22

4.5.4 Acceptance for the PMU ......................................................................................................................................23

4.5.5 Acceptance of Parameter Settings ......................................................................................................................23

4.5.6 Acceptance of System Functions and Performance .........................................................................................24

5 Routine Maintenance ................................................................................................................. 25

6 Troubleshooting .......................................................................................................................... 26

6.1 Rectifying Co mmon Faults ............................................................................................................................................26

7 Component Replacement .......................................................................................................... 31

8 FAQ ................................................................................................................................................ 33

A Appendix ..................................................................................................................................... 34

Issue 01 (2012-08-28) Huawei Proprietary and Confidential iv

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual Contents

A.1 A larm List.........................................................................................................................................................................34

B Acronyms and Abbreviations .................................................................................................. 37

Issue 01 (2012-08-28) Huawei Proprietary and Confidential v

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 1 Overview

1 Overview

1.1 Positioning

The combined power system is an indoor power system and supplies –48 V power for

communications equipment. The combined power system uses 50 A rectifiers. The TP48300B

can be configured with a maximum of six rectifiers to provide a maximum output current of

300 A. The TP48600B can be configured with a maximum of twelve rectifiers to provide a

maximum output current of 600 A.

1.2 Benefits

The combined power system supports easy installation, intelligent hibernation, and a wide AC

input voltage range. It also supports remote monitoring by communicating with the Network

Ecosystem (NetEco) if being configured with a Simple Network Management Protocol

(SNMP) module.

Easy Installation

The rectifiers are hot-swappable, which facilitates the system installation and maintenance.

This feature reduces the operating expense (OPEX).

Intelligent Hibernation

The combined power system can put one or more rectifiers in hibernation based on the actual

load power usage. This meets energy-saving purposes.

Network Management over the NetEco

The combined power system performs comprehensive power management and battery

management functions. The power monitoring unit (PMU) communicates with the rectifier

over an RS485 port, with Huawei communications equipment over a COM port, or with the

NetEco over an SNMP module.

The NetEco is a new-type intelligent element management system (EMS) developed by

Huawei. It works in client/server mode, which allows you to perform operations on the client

if you successfully log in to the server from the client.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 1

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 1 Overview

Wide AC Input Voltage Range

The AC input voltage of the combined power system ranges from 90 V AC to 290 V AC.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 2

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

2 Architecture

2.1 Overview

This section describes the model and functions of the combined power system.

Model Description

Figure 2-1 Model description (taking the TP48300B as an example)

TP 48 300 B

Type: major classification B

Maximum output current: 200 A

Output voltage: –48 V

Telecom Power

Functions

Table 2-1 Function description

Function Description

AC-DC The combined power system converts the AC input power into the

conversion –48 V DC for communications equipment.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 3

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Function Description

AC and DC The combined power system distributes AC and DC power.

distribution

Intelligent If the load is light, the combined power system automatically enables

hibernation of one or more rectifiers to enter hibernation mode.

rectifiers If the load is heavy, the combined power system automatically wakes

up the hibernated rectifiers.

This improves the efficiency of the combined power system.

Communication, The PMU performs functions of communication and alarm reporting,

control, and alarm supports remote monitoring, monitors and controls the operating

reporting status of the combined power system, and reports fault alarms in a

timely manner.

Battery The PMU manages storage batteries effectively to ensure their proper

management operation.

2.2 Hardware Components

2.2.1 Cabinet

This section describes the appearance and features of the cabinet.

Appearance

The dimensions (H x W x D) of the combined power system is 1600 mm x 600 mm x 400 mm.

Figure 2-2 shows the TP48300B exterior and Figure 2-3 shows the TP48600B exterior. Figure

2-4 shows the TP48300B interior and Figure 2-5 shows the TP48600B interior.

You can install the cabinet on a concrete floor by tightening expansion bolts on the floor.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 4

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Figure 2-2 TP48300B exterior

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 5

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Figure 2-3 TP48600B exterior

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 6

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Figure 2-4 TP48300B interior

1. PM U 2. Ground 3. Surge protection device 4. AC input circuit breaker

terminal (SPD)

5. DC output 6. Battery 7. Load low voltage 8. Battery low voltage

positive busbar fuse disconnection (LLVD) fuse disconnection (BLVD) circu it

breaker

9. Rectifier

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 7

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Figure 2-5 TP48600B interior

1. PM U 2. Ground terminal 3. SPD 4. AC input circuit breaker

5. LLVD circuit breaker 6. DC output positive busbar 7. Battery fuse 8. LLVD fuse

9. BLVD circuit breaker 10. Rectifier

Benefits

All operations can be performed from the front of the cabinet.

The cabinet can be shipped together with boards.

2.2.2 Rectifiers

This section describes the appearance, technical specifications, and functions of a rectifier.

Rectifiers convert AC power into –48 V DC power. The TP48300B can be configured with

2–6 rectifiers and the TP48600B can be configured with 2–12 rectifiers as required.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 8

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Appearance

The front panel of a rectifier has a Run indicator, an Alarm indicator, and a Fault indicator.

Figure 2-6 shows a rectifier.

Figure 2-6 Rectifier

Technical Specifications

Table 2-2 lists the technical specifications of the rectifier.

Table 2-2 Rectifier technical specifications

Parameter Specification

Model R4850G1 R4850N1

Weight ≤ 3.2 kg ≤ 3.2 kg

Dimensions (H x W x D) 88.9 mm x 103 mm x 243 88.9 mm x 103 mm x

mm 243 mm

Environmental Operating –40°C to + 75°C –40°C to + 75°C

specifications temperature

Operating 5%–95% RH 5%–95% RH

humidity

Transportatio –40°C to + 75°C –40°C to + 75°C

n temperature

Storage –40°C to + 75°C –40°C to + 75°C

temperature

Storage 5%–95% RH 5%–95% RH

humidity

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 9

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Parameter Specification

Altitude 0–4000 m 0–4000 m

When the altitude ranges When the altitude

from 3000 m to 4000 m, the ranges from 3000 m to

operating temperature is 4000 m, the operating

decreased by 1°C for each temperature is decreased

additional 200 m. by 1°C for each

additional 200 m.

Cooling Fan-cooled Fan-cooled

mode

AC input Operating 85–300 V AC 85–300 V AC

voltage

Operating 45–66 Hz (rated frequency: 45–66 Hz (rated

frequency 50 Hz or 60 Hz) frequency: 50 Hz or 60

Hz)

Power factor ≥ 0.99 (≥ 50% load) ≥ 0.99 (≥ 50% load)

DC output Output 43.2–58 V DC (53.5 V DC 43.2–58 V DC (53.5 V

voltage by default) DC by default)

Output power 0–2900 W (176–300 V 0–2900 W (176–300

AC input) V AC input)

0–1200 W (85–175 V 0–1200 W (85–175

AC input) V AC input)

Efficiency > 96.0% (30%–60% load, > 91.5% (35%–60%

maximum efficiency: > load, maximum

96.2%) efficiency: > 92%)

Function

Input overvoltage and undervoltage protection

Input overcurrent protection

Output overvoltage protection

Output short circuit protection

Output current limiting protection

Overtemperature protection

Benefits

High power density

Stability

Intelligent hibernation

Hot swap

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 10

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

2.2.3 Monitoring System

The monitoring system consists of the PMU, panel, and SNMP module (optional).

PMU

The TP48300B and TP48600B both employ a PMU and the monitored objects can be added.

The PMU is installed on the cabinet door and is covered by an aluminum shell that is not

entirely closed. Cables are routed out of the left side of the aluminum shell. The movable

window can be removed to connect cables to ports. Figure 2-7 shows a PMU.

Figure 2-7 PMU

Table 2-3 PMU structural specifications

Item Description

Dimensions (W x D) 270 mm x 127.9 mm

Installation scenario On the cabinet door

Maintenance Replace the whole PMU.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 11

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Figure 2-8 shows the UIM panel.

Figure 2-8 UIM panel

Table 2-4 UIM port description

Port Type Silk Screen Description Remarks

Sensor port GATE Door status sensor port Reserved

SMOKE Smoke sensor port N/A

TEM_BAT Battery temperature sensor N/A

port

TEM2 Ambient temperature N/A

sensor port

TEM_HUM Temperature-Humidity Reserved

sensor port

WATER Water sensor port Reserved

Analog AIN Port for monitoring middle Battery detection

parameter voltage for a battery string

detection port

Boolean value DIN1 Port 1 for receiving N/A

detection port Boolean value input signals

DIN2 Port 2 for receiving N/A

Boolean value input signals

DIN3 Port 3 for receiving Monitors the AC

Boolean value input signals SPD.

DIN4 Port 4 for receiving Monitors the DC

Boolean value input signals SPD.

DIN5 Port 5 for receiving N/A

Boolean value input signals

DIN6 Port 6 for receiving N/A

Boolean value input signals

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 12

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Port Type Silk Screen Description Remarks

DIN7 Port 7 for receiving N/A

Boolean value input signals

Dry contact ALM1 Port for reporting AC N/A

output port power failure alarms

ALM2 Port for reporting DC N/A

undervoltage alarms

ALM3 Port for reporting rectifier N/A

fault alarms

ALM4 Port for reporting fuse N/A

blown alarms

ALM5 Port for reporting PMU N/A

fault alarms

Electronic label PELU Port for inputting electronic Reserved

port labels

Communications COM Port for communicating N/A

port with the EMS

Table 2-5 PMU functions

Function Description

Power management Intelligent rectifier hibernation

Adjusting rectifier output voltage and limit threshold

Switching between equalized charging and floating charging

Controlling power-on and power-off of storage batteries and

loads

Supporting buzzer alarms

Site mains quality

Intelligent battery Management of storage batteries inside the power cabinet

management and outdoor battery cabinet

Battery temperature compensation, charge current limiting,

battery capacity calculation, and battery protection

Battery detection

Controlling storage batteries in manual or automatic mode

Battery operating temperature

Amount of electricity discharged by storage batteries.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 13

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Function Description

Alarm reporting and Generating audible and visual alarms and reports the alarms

recording to the host

Typically, the alarm severity is classified into critical and

minor, but it can also be customized.

Recording a maximum of 1000 historical alarms.

Communication Providing local management and alarm reporting.

Communicating with the host and third-party equipment.

Communicating with the NetEco over an SNMP module.

Dry contact output Providing five dry contact output ports.

Setting the dry contact outputs for associating with alarm

signals. When an alarm is generated, an alarm signal is sent

through the corresponding dry contacts.

Boolean value input Providing seven Boolean value input ports.

Sensor port Various sensor ports

Panel

The panel has indicators, buttons, and a liquid crystal display (LCD). The panel is positioned

on the front door of the cabinet and is connected to the monitoring board over a flat cable.

Figure 2-9 shows a PMU panel.

Figure 2-9 Panel

Table 2-6 Indicator description

Item Color Meaning State Description

RUN Green Run indicator Off The PMU is faulty or has no

indicator DC input.

Blinking at 0.5 The PMU communicates with

Hz the host normally.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 14

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 2 Arch itecture

Item Color Meaning State Description

Blinking at 4 The PMU communicates with

Hz the host abnormally.

ALM Red Alarm Off No alarm is generated.

indicator indicator

Steady on A critical alarm is generated.

Table 2-7 Button description

Button Description

▲ or ▼ Allows you to turn to the previous or next

menu and set parameter values.

Cancel Allows you to return to the previous menu.

Enter Allows you to enter the main menu from the

standby screen, to enter a submenu from the

main menu, or to save the settings of a

submenu item.

SNMP Module (Optional)

An SNMP module coverts RS485 into TCP/IP. With the FE port provided by the SNMP

module, the combined power system can communicate with the NetEco over an Ethernet.

Figure 2-10 shows the network diagram of the SNMP module.

The SNMP module is optional for the combined power system and can be installed in the

power cabinet.

Figure 2-10 Network diagram for the SNMP module

System power SNM P module Network management system (NM S)

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 15

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 3 Application Scenarios

3 Application Scenarios

The combined power system can be installed in indoor base stations or equipment rooms

depending on the number of configured rectifiers.

Typical Application

The combined power system, AC power source, automatic transfer switch (ATS), alternating

current distribution box (ACDB), and storage batteries are combined to form a site energy

solution. Figure 3-1 shows the position of the combined power system in a typical site

solution.

Figure 3-1 Position of the combined power system in a typical site solution

AC load

D.G.

DC load

TP48300B

ATS ACDB

and

TP48600B

Mains Storage

DC batteries

AC

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 16

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

4 Installation

Figure 4-1 shows the installation flowchart for the combined power system.

Figure 4-1 Installation flowchart for the combined power system

Preparation Install the power cabinet Install the battery cabinet

Install the storage battery

and sensor

Power on the system Connect system

End Verify the system installation

for commissioning cables

4.1 Preparations

Getting Familiar with the Site

Get familiar with the site environment, determine the installation position, and check that

there is enough space for installation and maintenance.

Project Survey

Conduct a survey to determine the length of an AC input power cable. Determine the

installation position of the combined power system to ensure that installation and maintenance

space is allowed.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 17

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

Tools

Table 4-1 Tools

Tool Picture Function

Multimeter Used to measure electrical

properties.

Phillips screwdriver (M3 Used to connect cables and

and M6) tighten screws.

Flat-head screwdriver (M3 Used to connect cables and

and M6) tighten screws.

Socket wrench Used to tighten bolts.

Torque wrench Used to tighten bolts.

Adjustable wrench Used to tighten bolts.

Hex key (M5) Used to tighten bolts.

Crimping tools Used to crimp cord end

terminals.

Diagonal pliers Used to cut cables.

Wire stripper Used to peel cables.

Polyvinyl chloride (PVC) Used to insulate cables.

insulation tape

Fuse extracting unit Used to install or remove

fuses.

Brush Used to clean shells and

panels and apply paint.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 18

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

Tool Picture Function

Sandpaper Used to remove rust.

Cotton cloth Used to clean shells and

panels.

Protective gloves Used to protect hands.

Painting Used to prevent rust.

4.2 Equipment Installation

For details about how to install the combined power system, see the TP48300B and

TP48600B Quick Installation Guide (V300R001).

Note the following during installation:

1. Check that the delivered cabinet is intact.

2. Check that the delivery configurations are consistent with the system configurations.

3. Route cables as required in the quick installation guide because the cabinet has a

compact structure. Otherwise, improper cable routing may cause a maintenance trouble.

4. Connect negative battery cables and then positive battery cables. This is because

positive battery cables to the TP48300B are grounded. If you connect positive

battery cables before negative cables, the storage batteries will be short-circuited

when a screwdriver touches the shell.

5. After installing the cabinet, block cable holes by using sealing mud.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 19

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

4.3 Verifying the Installation

After installing the combined power system, verify the installation by observing components

and using instruments.

Table 4-2 describes the installation checklist.

Table 4-2 Installation checklist

Item Method Expected Result

Cabinet Observing the All the components are installed.

installation cabinet The cabinet is installed securely.

Cable Observing the cable Cables are connected securely and correctly.

connection Working ground and protection ground

(PGND) cables are connected correctly.

Cable layout Observing the cable Cable layout is designed for future cable

routing.

Storage Observing the Battery terminals are connected correctly.

batteries storage batteries

Circuit breakers Using a multimeter Input circuit breakers and load circuit breakers

are OFF.

Short circuits Using a multimeter The live and neutral wires are not

short-circuited.

The power cables between the RTN+ and

–48 V busbars are not short-circuited.

4.4 Powering On and Commissioning the Combined

Power System

Powering On the Combined Power System

For details, see the TP48300B and TP48600B V300R001 User Guide.

Joint Commissioning with an EMS

For details, see the TP48300B and TP48600B V300R001 User Guide.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 20

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

4.5 Project Acceptance

4.5.1 Acceptance for the Installation of the Combined Power

System

Objective

To verify that the combined power system is installed based on engineering specifications and that the

combined power system does not experience any installation faults during operation

Prerequisite

The power system is installed properly. All input and output power cables and signal cables are connected.

No. Item Expected Result

01 Consistency between the system The system configuration, including models and

configuration and the delivery number of modules, complies with the contract.

configuration

02 Rack arrangement Racks are arranged neatly and front panels are on the

same plane.

03 Paint and electroplated layer No paint or electroplated layer flakes off, and the

cabinet surface is intact.

04 Cabinet installation All the four expansion bolts are installed and

tightened.

05 Cable layout Cables are routed properly and meet engineering

requirements.

06 Cable connections All input power cables, output power cables, and

battery cables are connected securely.

07 Cable labels Both ends of a cable are labeled. Labels are clear and

correct, and provide concise and understandable cable

description in English.

08 Connections of working ground Ground cables are connected between the ground bar

and PGND cables in the combined power system and a ground bar in the

equipment room.

09 Distances between cable ties Distances between cable ties are even, and no burr is

found.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 21

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

4.5.2 Acceptance Before Power-on

Objective

To verify that the combined power system is ready for power-on

Prerequisite

The power system is installed properly. All input and output power cables and signal cables are connected.

No. Item Expected Result

01 AC input power cables and DC AC input power cables and DC output power cables

output power cables are connected correctly based on labels.

02 Battery terminal connection Storage batteries are connected correctly.

03 Cables between the combined The positive battery terminal connects to the RTN+

power system and storage batteries busbar on the combined power system. The negative

battery terminal connects to the NEG– busbar on the

combined power system.

04 Short circuits The live wire and neutral wire of the input power

cable are not short circuited. The positive terminal and

negative terminal of the output power cable are not

short circuited.

05 Input circuit breakers and load Input circuit breakers and load circuit breakers are

circuit breakers OFF.

4.5.3 Acceptance for Rectifiers

Objective

To verify that rectifiers are installed correctly and work properly

Prerequisite

The combined power system is started.

No. Item Expected Result

01 Rectifier installation Rectifiers are installed securely, and screws on the

front panel are tightened.

02 Rectifier installation sequence Rectifiers are installed first in slot 1, then slot 2, and

so on.

03 Indicators If an indicator displays an alarm, locate the cause and

rectify the fault based on the troubleshooting or

maintenance manual.

04 Rectifier fan The fan is working properly. Fan blades are not

blocked or do not generate abnormal sounds. It is a

normal condition that the fan does not work when the

rectifier temperature is low.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 22

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

4.5.4 Acceptance for the PMU

Objective

To verify that the PMU is installed correctly and works properly

Prerequisite

The combined power system is started.

No. Item Expected Result

01 Screws on the front panel of the The PMU is installed securely, and screws on the

PMU front panel are tightened.

02 Information displayed on the LCD Information displayed on the LCD is correct and

normal, and no garbled character is displayed.

03 Buttons All buttons can be operated properly.

04 Communication between the PMU The PMU can normally communicate with the host or

and northbound interface EMS, and can report correct system information. The

communication is normal if the data of the system

voltage, load current, and battery current on the host is

consistent with that on the LCD.

You do not have to check this item if there is no

northbound equipment.

4.5.5 Acceptance of Parameter Settings

Objective

To verify that parameters are set correctly, without affecting the performance of the TP48300B and TP4860B

and storage batteries

Prerequisite

The combined power system is started.

No. Item Expected Result

01 Equalized charging voltage The default voltage is 56.5 V. The voltage can be

adjusted based on customer requirements.

02 Float voltage The default voltage is 53.5 V. The voltage can be

adjusted based on customer requirements.

03 System type (The system may The system type of the PMU must be consistent with

fail to run properly if the type is the actual system type. For details about the parameter

incorrectly configured.) settings, see the quick installation guide.

04 Battery capacity (Battery TP48300B-N20A5 and TP48300B-L20A5: 300 Ah

lifespan will be shortened if the (by default)

parameter is incorrectly set.) TP48300B-N20A6 and TP48300B-N20B1: 600 Ah

(by default)

The parameter value is consistent with the actual

battery capacity.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 23

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 4 Installat ion

05 Charge current limiting The default charge current limiting coefficient is

coefficient 0.15C. The coefficient can be adjusted based on

customer requirements.

06 BLVD voltage The default BLVD voltage is 43.2 V. The voltage can

be adjusted based on customer requirements.

07 Hibernation function The hibernation function is disabled by default.

If the hibernation function is enabled, one or more

rectifiers are hibernated based on the load current.

08 Time The time on the PMU is consistent with the local time.

4.5.6 Acceptance of System Functions and Performance

Objective

To verify that the combined power system functions and performance are as specified and meet requirements

Prerequisite

The combined power system is started.

No. Item Expected Result

01 Output voltage Observe the output voltage on the LCD, and check

that the output voltage is within a range of 43.2 V to

57.6 V by using a multimeter.

02 Load current Observe the load current on the LCD, and use a clamp

meter to measure the current. If the load current is

greater than 50 A, the measurement error must be less

than ±1%.

If the load current is less than 50 A, the error may

reach 0.5 A.

03 Battery current Observe the battery current on the LCD, and use a

clamp meter to measure the current. If the battery

current is greater than 50 A, the measurement error

must be less than ±1%.

If the battery current is less than 50 A, the error may

reach 0.5 A.

04 AC input voltage Difference between the AC input voltage and the

actual voltage is less than 5 V.

05 AC power failure alarm An alarm is displayed on the LCD when an AC power

failure occurs.

06 Battery fuse blown alarm When a battery fuse blows, an alarm is displayed on

the LCD and the alarm indicator blinks.

07 Load fuse blown alarm When a load fuse blows, an alarm is displayed on the

LCD and the alarm indicator blinks.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 24

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 5 Routine Maintenance

5 Routine Maintenance

Routine Maintenance

The combined power system is maintained every six months. If faults are identified, clear

them immediately.

Table 5-1 describes the routine maintenance checklist.

Table 5-1 Routine maintenance checklist

Item Content

Check That Check Repair When Troubleshooting

Method Method

Electrical The output voltage is Using a The BLVD or LLVD See chapter 6

connection normal. multimeter voltage exceeds the "Troubleshooting. "

threshold.

Indicators Indicators are in the Observing the Alarms are generated.

normal state. indicators

Appearance The paint and the Observing the The surface is Repaint or repair the

electroplated coating cabinet damaged or distorted. surface.

on the surface of the

cabinet are in good

condition.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 25

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 6 Troubleshooting

6 Troubleshooting

6.1 Rectifying Common Faults

Table 6-1 describes common faults and troubleshooting measures.

Table 6-1 Common faults and troubleshooting methods

Symptom Possible Cause Troubleshooting Method

AC open phase The AC input power 1. Check whether the AC input power cable is connected

cable is faulty. properly. If it is not connected properly, reconnect it. If

the insulation layer deteriorates, replace the AC input

The mains or D.G.

power cable.

fails.

2. Use a multimeter to check whether the AC input

voltage is lower than 180 V AC and whether an AC

undervoltage alarm is generated. If yes, check whether

short circuits or electrical leaks occur in the AC input

loop. If a short circuit or electrical leakage occurs,

replace the AC input power cable.

3. If the AC input is from the mains, contact the mains

supplier. If the AC input is from a D.G., check and

repair the D.G. by referring to the D.G. User Manual.

AC power failure The AC input power 1. If the AC input power cable is not connected properly,

cable is faulty. reconnect it.

The mains or D.G. 2. If the AC input power is unavailable, check whether

fails. open or short circuits occur in the AC input loop. If the

AC input loop is normal, contact the mains supplier. If

the AC input is from a D.G., check and repair the D.G.

by referring to the D.G. User Manual.

3. If the power failure is for a short time, use storage

batteries to power DC loads. If the power failure is for

a long time, use another power supply.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 26

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 6 Troubleshooting

Symptom Possible Cause Troubleshooting Method

AC overvoltage or The alarm threshold 1. Adjust the AC overvoltage or undervoltage alarm

undervoltage for AC overvoltage threshold to a proper value.

or undervoltage is 2. If the AC input is from the mains, contact the mains

not properly set on supplier. If the AC input is from a D.G., check and

the PMU. repair the D.G. by referring to the D.G. User Manual.

The mains or D.G.

fails.

DC overvoltage or The DC overvoltage 1. Adjust the DC overvoltage or undervoltage alarm

undervoltage or undervoltage threshold to a proper value.

alarm threshold is 2. If storage batteries supply power properly, remove all

not set properly on rectifiers and then install them one by one. If an

the PMU. overvoltage alarm is generated when you install a

rectifier, replace this rectifier.

Charge overcurrent Rectifier 1. Check whether the rectifier is installed in the subrack

communication fails and whether the rectifier is properly connected. Install

the rectifier in the correct subrack. If the rectifier has

The battery loop is

poor contact with the subrack, reseat it and secure it to

faulty. the subrack.

2. Check whether the battery loop is faulty or

short-circuited.

3. Replace faulty storage batteries.

Load disconnection The load circuit 1. Check whether the load detection cable is connected

breaker is OFF. properly.

The contactor is 2. Check whether the load circuit breaker is OFF. If the

faulty. circuit breaker is OFF, switch it to ON.

3. Check whether the contactor is faulty and whether the

The PMU load

contactor can be connected or disconnected. If the

disconnection

contactor is faulty or cannot be connected or

voltage is greater disconnected, replace the contactor.

than the maximum

value. 4. If the LLVD voltage is greater than the maximum

value, adjust the voltage to the normal range.

The load power is

5. Check whether the load power is greater than the

greater than the

configured rectifier power. If yes, add rectifiers. If the

configured rectifier

load power is greater than the maximum power

power, causing a low

supported by the combined power system, reduce the

output voltage. loads.

Battery voltage The battery 1. If the mains fails or the battery voltage is below the

disconnection parameters are not BLVD threshold, contact the mains supplier.

properly set on the 2. Enable the BLVD function on the PMU.

PMU. 3. Check the battery cables and connectors, and replace

The contactor is faulty ones.

faulty. 4. Check whether the contactor is faulty and whether the

contactor can be connected or disconnected. If the

contactor is faulty or cannot be connected or

disconnected, replace the contactor.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 27

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 6 Troubleshooting

Symptom Possible Cause Troubleshooting Method

Battery loop broken The battery loop is 1. Check the battery cables and connectors on the battery

alarm faulty. loop, and replace faulty ones.

The contactor is 2. Check whether the contactor is faulty and whether the

faulty. contactor can be connected or disconnected. If the

contactor is faulty or cannot be connected or

Storage batteries are disconnected, replace the contactor.

faulty.

3. Replace faulty storage batteries.

Overtemperature or The alarm threshold 1. Check whether the alarm threshold for ambient

undertemperature for ambient temperatures is properly set on the PMU.

(This alarm can be temperature is not 2. Repair the TCU in the shelter if it is faulty. After the

generated only when properly set on the temperature inside the shelter is adjusted to a normal

an ambient PMU. range, the alarm is automatically cleared.

temperature sensor is The temperature 3. If the alarm persists, repair the temperature sensor.

installed.) inside the shelter

where the ambient

temperature sensor is

installed is beyond a

normal range.

The battery

temperature sensor is

faulty.

Overhigh or over low The alarm threshold 1. Check whether the alarm threshold for ambient

ambient humidity for ambient humidity humidity is properly set on the PMU.

(This alarm can be is not set properly on 2. If there is water in the shelter, remove water by using a

the PMU. dry cotton cloth or dehumidifier.

generated only when

a humidity sensor is The shelter where the 3. If the ambient humidity is within a proper range but the

installed.) humidity sensor is alarm persists, check the humidity sensor. If the

installed is beyond a humidity sensor is faulty, replace it.

normal range.

The humidity sensor

is faulty.

Battery Temperature inside 1. Check whether the alarm threshold for battery

overtemperature or the battery temperatures is properly set on the PMU.

undertemperature compartment is 2. If the temperature inside the battery compartment is

greater than the greater than the maximum value, lower the

maximum value. temperature. The alarm is cleared automatically after

the temperature drops to a normal range.

The alarm threshold

for battery 3. If the charge current is greater than the maximum

temperature is not value, change equalized charging into float charging

properly set on the and check whether the charge current is lowered. If the

PMU. charge current is still greater than the maximum value,

reduce the charge current. If the battery temperature is

The battery charge

still greater than the maximum value, replace faulty

current is greater storage batteries.

than the maximum

value.

The battery

temperature sensor is

faulty.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 28

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 6 Troubleshooting

Symptom Possible Cause Troubleshooting Method

Door status alarm The cabinet door is 1. Close the cabinet door.

(This alarm can be open. 2. If the alarm persists after the cabinet door is closed,

generated only when The door status check and repair the door status sensor.

a door status sensor is sensor is faulty.

installed.)

Water alarm There is water in the 1. If there is water in the shelter, remove water by using a

shelter. dry cotton cloth or dehumidifier.

(This alarm can be

generated only when The water sensor is 2. If there is no water but the alarm persists, check and

a water sensor is faulty. repair the water sensor.

installed.)

Smoke alarm There is smoke in the 1. If there is smoke in the shelter, put out the fire

shelter. immediately and open the shelter door for ventilation.

(This alarm can be

generated only when The smoke sensor is 2. If there is no smoke but the alarm persists, check and

repair the smoke sensor.

a smoke sensor is faulty.

installed.)

Rectifier fault alarm The rectifier is in 1. Check the Fault indicator on the rectifier panel. If the

poor contact. indicator is blinking red, the rectifier is faulty. Replace

the rectifier.

The rectifier is

faulty. 2. Disconnect the AC power supplies to the rectifier, and

then restart the rectifier after a period of time. If the

alarm persists, replace the rectifier.

Rectifier protection The rectifier input 1. Check whether the mains voltage is higher than the

voltage is beyond a rectifier AC overvoltage threshold (300 V) or lower

normal range. than the rectifier AC undervoltage threshold (85 V). If

the power grid is in an overvoltage or undervoltage

The rectifier is

condition for a long period of time, contact the mains

faulty.

supplier to improve the power grid.

2. If the rectifier input voltage is within a normal range

but the alarm persists, replace the rectifier.

Failed communication The signal cable to 1. Check whether the rectifier is installed in the subrack

between the rectifier the rectifier is not and whether the rectifier is properly connected. Install

and the PMU connected properly. the rectifier in the correct subrack. If the rectifier has

poor contact with the subrack, reseat it and secure it to

The rectifier is not

the subrack.

installed in the

2. If the alarm persists, replace the rectifier.

subrack.

The rectifier is in

poor contact.

The rectifier is

faulty.

D.G. faults The signal cable to 1. Check whether the signal cable to the D.G. is connected

the D.G. is not properly.

connected properly. 2. Check whether D.G. startup is disabled on the PMU

The D.G. parameter and whether the D.G. has been started manually. If yes,

is not set properly on shut down the D.G. Then the D.G. fault alarm is

the PMU. cleared.

3. Check whether the D.G. is faulty. If it is faulty, repair

The D.G. is faulty. the D.G. by referring to the D.G. User Manual.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 29

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 6 Troubleshooting

Symptom Possible Cause Troubleshooting Method

Load fuse blown The load circuit breaker 1. Switch on the load circuit breaker.

is OFF. 2. If the load circuit breaker trips immediately after being

switched to ON, check whether the load power on the

branch is greater than the maximum value or a short

circuit occurs. If yes, rectify the load loop fault.

AC SPD faults The AC SPD is If the indication window on the AC SPD turns red, replace

faulty. the SPD. If it does not turn red, replace the AC SPD

The UIM is faulty. detection cable if it is damaged or broken and connect it

properly. If the cable is connected properly and in good

condition, replace the PMU because the alarm loop is

faulty.

DC SPD faults The DC SPD is faulty. 1. Connect the DC SPD detection cable properly.

2. If the cable is connected properly, replace the DC SPD.

After a fault is rectified, the corresponding alarm is automatically cleared on the PM U and the alarm

information is stored in the alarm history.

After replacing a PM U, reset parameters.

The PM U and rectifiers are hot-swappable.

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 30

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 7 Co mponent Replacement

7 Component Replacement

This chapter describes how to replace an AC SPD and a circuit breaker.

Replacing an AC SPD

Remove the faulty AC SPD.

Install a new SPD.

Figure 7-1 Replacing an AC SPD

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 31

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 7 Co mponent Replacement

Replacing a Circuit Breaker

Figure 7-2 Removing a circuit breaker

Figure 7-3 Installing a circuit breaker

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 32

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual 8 FA Q

8 FAQ

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 33

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual A Appendix

A Appendix

A.1 Alarm List

Table A-1 Default alarm list

No. Alarm Name Alarm Generation Alarm Severity Associated Relay

Site summary

1 Internal PMU fault alarm Enabled Major N/A

2 DC overvoltage alarm Enabled Critical N/A

3 DC undervoltage alarm Enabled Critical 3

4 AC power failure alarm Enabled Major 1

5 AC overvoltage alarm Enabled Minor N/A

6 AC undervoltage alarm Enabled Minor N/A

7 Door status sensor alarm Enabled Minor 2

8 Load fuse blown alarm Enabled Major N/A

9 AC SPD fault alarm Enabled Minor N/A

10 Alarm for powering on Enabled Major N/A

storage batteries manually

11 Alarm for the AC SPD on Disabled Major N/A

the inverter

12 Inverter fault alarm Enabled Major N/A

13 DI 5 alarm Enabled Minor N/A

14 DI 6 alarm Enabled Minor N/A

15 DC SPD fault alarm Enabled Minor N/A

Rectifier

1 Communication Enabled Major N/A

interruption alarm

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 34

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual A Appendix

No. Alarm Name Alarm Generation Alarm Severity Associated Relay

2 Rectifier protection alarm Enabled Minor N/A

3 Rectifier fault alarm Enabled Major 4

Battery summary

1 Abnormal battery current Disabled Critical N/A

alarm

2 Alarm for battery Disabled Warning N/A

temperature compensation

activation

3 Battery discharge alarm Enabled Warning N/A

4 Battery loop broken alarm Enabled Critical N/A

5 High battery temperature Enabled Minor N/A

alarm

6 Battery overtemperature Enabled Major N/A

alarm

7 Low battery temperature Enabled Minor N/A

alarm

8 LVD2 disconnection alarm Enabled Major N/A

9 Alarm for disconnection of Enabled Warning N/A

battery temperature sensor

1

10 Alarm for faults of battery Enabled Minor N/A

temperature sensor 1

Rectifier summary

1 Alarm for not detecting Enabled Warning N/A

rectifiers

2 Alarm for the activation of Enabled Warning N/A

rectifier redundancy

3 Alarm for insufficient Enabled Warning N/A

rectifier redundancy

4 Alarm for rectifier loading Enabled Minor N/A

failure

VRLA battery

1 Alarm for reporting that the Disable Warning N/A

battery current exceeded the

limit

2 Alarm for charge Enabled Major N/A

overcurrent

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 35

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual A Appendix

No. Alarm Name Alarm Generation Alarm Severity Associated Relay

3 Alarm for not detecting Enabled Critical N/A

storage batteries

Temperature control module

1 Alarm for high temperature Enabled Minor N/A

of the TCU

2 Alarm for low temperature Enabled Minor N/A

of the TCU

3 Battery temperature sensor Enabled Minor N/A

fault alarm

4 Fan fault alarm Enabled Minor N/A

5 Communication Enabled Major N/A

interruption alarm

Lithium ion battery

1 Communication Enabled Major N/A

interruption alarm

2 Fault alarm Enabled Major N/A

3 Protection alarm Enabled Major N/A

4 Minor alarm Enabled Minor N/A

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 36

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual B Acrony ms and Abbreviations

B Acronyms and Abbreviations

3G the third generation

3GPP2 3rd Generation Partnership Project 2

A-E

BOSS business and operation support system

ETSI European Telecommunications Standards Institute

F-J

GIS geographical information system

IDEA integrated data environment of applications

K- O

MDSP mobile data service center

MM multimedia message

OSS operation support system

P-T

SGIP short message gateway interface protocol

SMSC short message service center

SP service provider

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 37

Copyright © Huawei Technologies Co., Ltd.

TP48300B and TP48600B V300R001

Engineer Manual B Acrony ms and Abbreviations

U- Z

URL uniform resource locator

USSD unstructured supplementary service data

WAP wireless Application Protocol

WAP GW wireless Application Protocol Gateway

Issue 01 (2012-08-28) Huawei Proprietary and Confidential 38

Copyright © Huawei Technologies Co., Ltd.

You might also like

- 2010-12 600 800 Rush Switchback RMK Service Manual PDFDocument430 pages2010-12 600 800 Rush Switchback RMK Service Manual PDFBrianCook73% (11)

- Huawei DC1 - TP48300A-DX15A1 & Extension User ManualDocument87 pagesHuawei DC1 - TP48300A-DX15A1 & Extension User ManualF. B. I.No ratings yet

- Trial Installation Lithium Battery With ZXDU68 W001 CabinetDocument10 pagesTrial Installation Lithium Battery With ZXDU68 W001 CabinetAndika Alvi Sahri100% (2)

- APM30 Installation GuideDocument25 pagesAPM30 Installation GuideRomulo100% (7)

- FLexi BTS Battary SystemDocument12 pagesFLexi BTS Battary SystemАнатолий Петьков100% (1)

- Термобокс Huawei MTS9000A Telecom Power User Manual (Russia, Veon, MTS9304A-HD10A1, MTS93...Document112 pagesТермобокс Huawei MTS9000A Telecom Power User Manual (Russia, Veon, MTS9304A-HD10A1, MTS93...Vanek50550% (2)

- Mind Map On The History of Science, Technology and SocietyDocument1 pageMind Map On The History of Science, Technology and SocietyJohn Michael Vincent CarreonNo ratings yet

- Handbook of Zen, Mindfulness and Spiritual Health PDFDocument324 pagesHandbook of Zen, Mindfulness and Spiritual Health PDFMatthew Grayson100% (3)

- Oracle Unified Method (OUM) White Paper - Oracle's Full Lifecycle Method For Deploying Oracle-Based Business Solutions - GeneralDocument17 pagesOracle Unified Method (OUM) White Paper - Oracle's Full Lifecycle Method For Deploying Oracle-Based Business Solutions - GeneralAndreea Mirosnicencu100% (1)

- NSX 100-630 User ManualDocument152 pagesNSX 100-630 User Manualagra04100% (1)

- Klein & Kulick Scandolous ActsDocument20 pagesKlein & Kulick Scandolous ActsClaudia Costa GarcíaNo ratings yet

- Edmonson - Pageantry Overture - AnalysisDocument3 pagesEdmonson - Pageantry Overture - Analysisapi-426112870No ratings yet

- (PDF) Biochemistry and Molecular Biology of Plants: Book DetailsDocument1 page(PDF) Biochemistry and Molecular Biology of Plants: Book DetailsArchana PatraNo ratings yet

- Huawei PDFDocument54 pagesHuawei PDFSilvestre ClementinoNo ratings yet

- Manual HuaweiDocument80 pagesManual HuaweiCarlos olmosNo ratings yet

- PowerCube 1000 V300R007C10 User Manual PDFDocument320 pagesPowerCube 1000 V300R007C10 User Manual PDFhammoumi100% (2)

- Huawei ETP48200Document71 pagesHuawei ETP48200Тахир ИзмайловNo ratings yet

- Tp48300b-n16b2 Tp48600b-n16b2 User ManualDocument53 pagesTp48300b-n16b2 Tp48600b-n16b2 User ManualAbhishek SrivastavaNo ratings yet

- PowerCube 1000 User ManualDocument341 pagesPowerCube 1000 User ManualDavid Chokani100% (1)

- Huawei PDFDocument146 pagesHuawei PDFDarwin Padilla TenorioNo ratings yet

- PowerCube 1000 (With An ICC500-HA) Quick Installation Guide (V300R002C00 - 024 Reusing Existing DG & ATS)Document20 pagesPowerCube 1000 (With An ICC500-HA) Quick Installation Guide (V300R002C00 - 024 Reusing Existing DG & ATS)Shakeb Amir100% (6)

- Delta TPS Brochure 13-05-2019Document27 pagesDelta TPS Brochure 13-05-2019thepimpo100% (1)

- ICC500 Power Cube ManualDocument47 pagesICC500 Power Cube Manualmukaram1128100% (1)

- 19-Inch Rack Installation Guide (01) (PDF) - enDocument164 pages19-Inch Rack Installation Guide (01) (PDF) - enюрий ермошенкоNo ratings yet

- TP48300B & TP48600B Maintenance Guide (V100R001 - 02)Document44 pagesTP48300B & TP48600B Maintenance Guide (V100R001 - 02)Alvaro Avila Sanchez0% (1)

- Emerson Candeo RectifierDocument166 pagesEmerson Candeo RectifierPablo SanabriaNo ratings yet

- ManualDocument43 pagesManualВадик НоунэймNo ratings yet

- ISitePower Integrated Smart Site V100R001C00 User Manual (ICC1000-A1-E1)Document180 pagesISitePower Integrated Smart Site V100R001C00 User Manual (ICC1000-A1-E1)Jefri Yan SipahutarNo ratings yet

- TP48300-A-N07A3 Maintenance Guide (V100R001 - 04)Document53 pagesTP48300-A-N07A3 Maintenance Guide (V100R001 - 04)SamirTam0% (1)

- PowerCube 1000 V300R008C00 Installation Guide (RuralStar Pro Solar Power Supply Solution) PDFDocument140 pagesPowerCube 1000 V300R008C00 Installation Guide (RuralStar Pro Solar Power Supply Solution) PDFمحمد المجهولNo ratings yet

- MTS9300A V100R002C01 Telecom Power Installation GuideDocument73 pagesMTS9300A V100R002C01 Telecom Power Installation GuideVanek505No ratings yet

- Rectifier PS4890 DescriptionDocument57 pagesRectifier PS4890 DescriptionMuhammad Rauf AkramNo ratings yet

- UMG8900Document0 pagesUMG8900Americo HuertaNo ratings yet

- MTS9300A V100R002C01 Telecom Power User ManualDocument61 pagesMTS9300A V100R002C01 Telecom Power User ManualVanek505No ratings yet

- Etisalat Wireless Network Modernization Project IntroductionDocument57 pagesEtisalat Wireless Network Modernization Project IntroductionDerbyNo ratings yet

- Inverter DJN1000-S V100R001 User Manual 04Document22 pagesInverter DJN1000-S V100R001 User Manual 04hammoumi100% (1)

- 01 - Equipment Cabinet ICC330-H7-C1 Datasheet 01 - (20170613)Document2 pages01 - Equipment Cabinet ICC330-H7-C1 Datasheet 01 - (20170613)alexdaniel666100% (1)

- SCC800-S1 SmartSite Management System V100R003C00 Installation GuideDocument192 pagesSCC800-S1 SmartSite Management System V100R003C00 Installation GuideHamza Osama100% (1)

- Huawei Power CubeDocument36 pagesHuawei Power CubeSathish Kumar TRNo ratings yet

- BTS3900 (Ver.D) Installation Guide (V100R009C00 - 03) (PDF) - enDocument175 pagesBTS3900 (Ver.D) Installation Guide (V100R009C00 - 03) (PDF) - enEugeneNo ratings yet

- BTS Antenna System Installation Guide RET V300R009 01Document143 pagesBTS Antenna System Installation Guide RET V300R009 01Moo Ping100% (1)

- Huawei BTS3900 Family Security Level DocumentationDocument23 pagesHuawei BTS3900 Family Security Level Documentationtal_evolution100% (3)

- ESM-4810A1 Energy Storage Module User ManualDocument31 pagesESM-4810A1 Energy Storage Module User ManualOscar SosaNo ratings yet

- EPS100D-N01D1 Indoor DC Blade Power Supply User ManualDocument47 pagesEPS100D-N01D1 Indoor DC Blade Power Supply User ManualEvandroti RBNo ratings yet

- Base Station Cabinets and Subracks (Including The BBU Subrack) Configuration (SRAN12.1 - 02) PDFDocument81 pagesBase Station Cabinets and Subracks (Including The BBU Subrack) Configuration (SRAN12.1 - 02) PDFanthonyNo ratings yet

- Engineering Preparations Key PointsDocument17 pagesEngineering Preparations Key PointsImran MalikNo ratings yet

- RTN 905 1E&2E V100R006C10 Commissioning Guide 02. (Configure Basic) PDFDocument180 pagesRTN 905 1E&2E V100R006C10 Commissioning Guide 02. (Configure Basic) PDFROUERN VannakNo ratings yet

- Claro Battery Soft-Lock ActivationDocument10 pagesClaro Battery Soft-Lock ActivationAntonio MilianNo ratings yet

- MTS9000A V100R002C30 Telecom Power Installation Guide (MTS9514A-DM20E1, MTS9514A-DM16E1)Document87 pagesMTS9000A V100R002C30 Telecom Power Installation Guide (MTS9514A-DM20E1, MTS9514A-DM16E1)محمد المجهولNo ratings yet

- BBU3900 Installation Guide 19Document58 pagesBBU3900 Installation Guide 19slavunNo ratings yet

- ZXDU68 W201 (V5.0R05M04) DC Power System Product DescriptionDocument48 pagesZXDU68 W201 (V5.0R05M04) DC Power System Product DescriptionDariomf FuenteNo ratings yet

- 8 ZXSDR R8862A Quick Installation Guide - R1.0 - CH - ENDocument30 pages8 ZXSDR R8862A Quick Installation Guide - R1.0 - CH - ENAndrie Purna FNo ratings yet

- 12 - 1553-lza7016011uen.a-NCU-user Manual EMERSON PDFDocument170 pages12 - 1553-lza7016011uen.a-NCU-user Manual EMERSON PDFMamadou Soumahoro100% (2)

- ISitePower Integrated Smart Site V100R001C00 User Manual (ICC1000-A1-E1)Document181 pagesISitePower Integrated Smart Site V100R001C00 User Manual (ICC1000-A1-E1)rudi amsyahNo ratings yet

- BTS3900 External Alarm MonitoringDocument16 pagesBTS3900 External Alarm MonitoringkikirnNo ratings yet

- SJ-20200606171511-001-ZXMW NR8250 (V3.05.02) System Description - 980966Document119 pagesSJ-20200606171511-001-ZXMW NR8250 (V3.05.02) System Description - 980966مهدي مهديNo ratings yet

- 3900 Series Base Station Configuration Principles (SRAN9.0 - 13) (PDF) - enDocument236 pages3900 Series Base Station Configuration Principles (SRAN9.0 - 13) (PDF) - enMd Ataulla100% (2)

- Bellevue Manila-Question ResponseDocument3 pagesBellevue Manila-Question ResponsePatrick Penachos100% (1)

- 2G IP GTMU GBTS SMT User Guide (08) (PDF) 2G GTMU CONFIGUARTION NEW-ENDocument431 pages2G IP GTMU GBTS SMT User Guide (08) (PDF) 2G GTMU CONFIGUARTION NEW-ENAhmed Sharaf100% (1)

- Main - Power System Training Material V1.0-20071012Document26 pagesMain - Power System Training Material V1.0-20071012pr3m4n100% (3)

- ETR+3048 (3000W) Rectifier Module Rev03Document2 pagesETR+3048 (3000W) Rectifier Module Rev03agus saputraNo ratings yet

- Huawei BTS 3900Document5 pagesHuawei BTS 3900FarrukhNo ratings yet

- RTN 310 V100R001C01 Commissioning and Configuration Guide 02 PDFDocument752 pagesRTN 310 V100R001C01 Commissioning and Configuration Guide 02 PDFIssam Ayari100% (3)

- User Manual: TP48600B-N20A1 V500R001C00Document73 pagesUser Manual: TP48600B-N20A1 V500R001C00Mhd M. NooriNo ratings yet

- Huawei GabineteDocument55 pagesHuawei GabineteLuis Angel Padilla PortillaNo ratings yet

- ETP48200 V100R001 Troubleshooting Guide 02Document56 pagesETP48200 V100R001 Troubleshooting Guide 02David ChokaniNo ratings yet

- TP48300B-N04C1 & L04C1 V300R002 User Manual 03Document54 pagesTP48300B-N04C1 & L04C1 V300R002 User Manual 03chien2909No ratings yet

- Tp48200b-L20a5 & N20a5 & N20a6 & n20b1 Engineer ManualDocument50 pagesTp48200b-L20a5 & N20a5 & N20a6 & n20b1 Engineer Manualpatrick vibilaNo ratings yet

- Organizational Behaviour Group Assignment-2Document4 pagesOrganizational Behaviour Group Assignment-2Prateek KurupNo ratings yet

- Victor Mejia ResumeDocument1 pageVictor Mejia Resumeapi-510300922No ratings yet

- ElectricalDocument30 pagesElectricalketerNo ratings yet

- Evolution Packet FinalDocument24 pagesEvolution Packet FinalJoaquinNo ratings yet

- Rotational Equilibrium SimulationDocument3 pagesRotational Equilibrium SimulationCamille ManlongatNo ratings yet

- Moon Fast Schedule 2024Document1 pageMoon Fast Schedule 2024mimiemendoza18No ratings yet

- Organic Facial Remedies Versus Inorganic Facial RemediesDocument13 pagesOrganic Facial Remedies Versus Inorganic Facial Remediesapi-271179911No ratings yet

- Siga-Cc1 12-22-2010Document6 pagesSiga-Cc1 12-22-2010Felipe LozanoNo ratings yet

- Integrating Therapeutic Play Into Nursing and Allied Health PracticeDocument214 pagesIntegrating Therapeutic Play Into Nursing and Allied Health PracticeIbrahim SabraNo ratings yet

- Aerospace Opportunities in SwitzerlandDocument5 pagesAerospace Opportunities in SwitzerlandBojana DekicNo ratings yet

- ??????? ?? ??????Document29 pages??????? ?? ??????Aysha ShahabNo ratings yet

- DCAD OverviewDocument9 pagesDCAD OverviewSue KimNo ratings yet

- Decembermagazine 2009Document20 pagesDecembermagazine 2009maria_diyah4312No ratings yet

- Multivariate Analysis Homework QuestionsDocument2 pagesMultivariate Analysis Homework Questions歐怡君No ratings yet

- KingmakerDocument5 pagesKingmakerIan P RiuttaNo ratings yet

- LNG Vaporizers Using Various Refrigerants As Intermediate FluidDocument15 pagesLNG Vaporizers Using Various Refrigerants As Intermediate FluidFrandhoni UtomoNo ratings yet

- A ULTIMA ReleaseNotesAxiomV PDFDocument38 pagesA ULTIMA ReleaseNotesAxiomV PDFIVANALTAMARNo ratings yet

- Chanel SWOT AnalysisDocument5 pagesChanel SWOT AnalysisJeish KimNo ratings yet

- Appendix 1 Application FormDocument13 pagesAppendix 1 Application FormSharifahrodiah SemaunNo ratings yet

- C11 Strategy DevelopmentDocument30 pagesC11 Strategy DevelopmentPARTI KEADILAN RAKYAT NIBONG TEBALNo ratings yet

- AnhvancDocument108 pagesAnhvancvanchienha7766No ratings yet

- Kennedy 1945 Bibliography of Indonesian Peoples and CulturesDocument12 pagesKennedy 1945 Bibliography of Indonesian Peoples and CulturesJennifer Williams NourseNo ratings yet