Professional Documents

Culture Documents

Marshall Stability and Flow Test Procedure

Uploaded by

HARIKA DORNALAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marshall Stability and Flow Test Procedure

Uploaded by

HARIKA DORNALACopyright:

Available Formats

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

10. 9 Marshall Stability and Flow

10.9.1 Introduction

The Marshall test method is widely used for the design and control of asphaltic

concrete and hot rolled asphalt materials, it cannot be applied to open textured

materials such as bitumen macadam. Materials containing aggregate sizes larger than

20 mm, are liable to give erratic results.

The full Marshall method is a method of bituminous mix design in addition to being a

quality control test. The details given below related mainly to its use as a quality

control test. The suitability of materials for the design of Marshall asphalt requires that

a numbers of tests are performed on the materials. Tests normally performed are:

1. Asphalt :

(a) Penetration (b) Viscosity (c) Solubility (d) Specific gravity (e) Fire & flash point

(f) Softening point.

2. Aggregates :

(a) Percent wear (b) Unit weight (c) Sieve analysis (d) Specific gravity (e)

Absorption.

The preliminary mix designs, the scheme for analysing aggregate will be

governed, to some extent, by method of producing the gradation during

construction.

10.9.2 Scope

The basic Marshall test consists essentially of crushing a cylinder of bituminous

material between two semi-circular test heads and recording the maximum load

achieved (i.e. the stability) and the deflection at which the maximum load occurs (i.e.

the flow).

In common with many other tests, the bulk of the work is involved in preparing the

samples for testing.

10.9.3 Apparatus

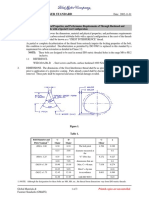

The samples are prepared in 100 mm diameter moulds which are fitted with a base

and collar (Figure 10.9.1) the sample is compacted using a hammer consisting of a

sliding weight which falls onto a circular foot (Figure 10.9.2) during compaction the

mould is held on a hardwood block which is rigidly fixed to a concrete base (Figure

10.9.3).

The sample is removed from the mould using an extraction plate and press (Figure

10.9.1) and heated to the test temperature of 60° C in a water bath.

The cylindrical specimens are tested on their sides between test heads similar to

those shown in Fig. 10.9.4. The flow is measured with a dial gauge and the stability is

measured with a proving ring. A motorised load frame is required for the test.

MAY 2001 Page 10.61

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

∅ 114.3

∅ 38

∅ 101.6± 0.1

R 9.5 spherical seating

63.5

71.5

∅ 99

∅ 12.7 ∅ 106.8±0.1 12.7

Extension collar Extraction plate

∅ 106.4±0.1

∅ 101.6±0.1

12.7

89

12.7 ∅ 114.3

∅ 106.8±0.1

Mould cylinder 12.7

18.25 86

∅ 100.8± 0.1

∅ 104.8

∅ 125.4

5.6 ∅ 114.3

Mould base

Dimensions are in millimetres. Extraction collar

Figure 10.9.1 Marshall Test Compaction and Extraction Equipment

MAY 2001 Page 10.62

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

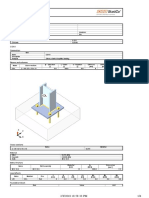

Handle screwed and pinned

457

∅ 55

∅ 15.875

Mandatory requirements

Diameter of foot 98.5 ±0 . 1 2 5

Length of free fall 457

Mass of sliding mass 4.535 kg

(Other dimensions are approximate)

981

Sliding mass 4.535 kg

457 free fall

305 Rod-nut screwed and riveted

on end

25

∅ 45

Finger guard

70

3

Compression spring

Free length 51

Wire diameter 3.175

Mean diameter 27.0 - 28.6

80 Number of coils 4

28

Foot screwed and locked

13 Hard face

∅ 98.5

Figure 10.9.2 Marshall Compaction Hammer

MAY 2001 Page 10.63

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

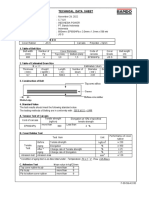

Clamp ring

Hinge post

Guide Post

Sample mould

Spring

Steel plate

300 x 300 x 25 Angle-housing welded to

underface of steel plate

to ensure permanent

Wood block centering of assembly

200 x 200 x 450

Barrel strainers

(Min. Dia. 6.35)

25

Recess in concrete

base of permanent

Concrete centering of timber

block block or angle-housing

bolted to concrete base

200

450 x 450 x 200

450 square

Mould base

locating pegs

NOTE. A suitable framework is

secured to the pedestal to ensure

that the compaction hammer is

kept vertical.

Dimensions are in millimetres.

Figure 10.9.3 Marshall Compaction Pedestal

MAY 2001 Page 10.64

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

12.7 Guide pins Upper testing head

Lug for dial gauge and brushes

19 min.

101.6± 0.1

9.5

45 0

9.5

6.35

Dial

gauge

76

Face hardened Base Lower testing head

or plated and

polished

NOTE. Frequent checks on

inner radius of segments and on

alignment of guide posts are

necessary as high loads may

permanently distort the testing

head.

Swinging plate for dial gauge

Dimensions are in millimetres.

Figure 10.9.4 Marshall Testing Heads

MAY 2001 Page 10.65

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

10.9.4 Sampling

Due to the various uses which may be made of Marshall tests, the materials for test

may be obtained in one of the following forms:

a) 100 mm diameter bituminous cores cut from an existing pavement using a core

cutting machine.

b) Ready-mixed bituminous material obtained from a mixing plant or at the point of

laying, and sampled in accordance with Chapter 2.

c) A sample of mixed aggregate obtained from the mixing plant together with a

separate sample of bitumen obtained from the storage tank at the mixing plant in

accordance with Chapter 2.

Note. A sample of mixed aggregate may be obtained from a mixing plant by

batching the specified aggregate weights into the mixer but not allowing

any bitumen to be batched. The aggregate sample is then discharged

into a clean lorry where it may be sampled in accordance with Chapter

2.

d) Samples of the various sized aggregates in use at the mixing plant sampled in

accordance with Chapter 2 together with a separate sample of bitumen sampled

in accordance with Chapter 2.

In the case of a sample of type (a), the core may be tested without further

preparation. It must, however, be of the correct diameter and height. It is doubtful

if samples obtained in this manner give results which are closely comparable to

laboratory compacted specimens; however, the taking of cores is a valuable way

to check the compacted density of the ‘as laid’ material and the small amount of

additional work in determining the stability and flow is justified. If the densities

obtained form cores (or sand replacement tests) are significantly below those of

laboratory compacted specimens, attention should be paid to the methods of

laying and compacting.

For many quality control purposes samples of type (b) are the most useful as

they may be conpacted, after re-heating in an oven to the required temperature.

The delay between initial mixing and compacting should be as short as possible.

With this type of sample separate test on the mixed aggregate will be required to

determine the void content.

It is essential to make frequent checks on the combined aggregate from an

asphalt plant. The most important factors to be checked are the aggregate

temperature at the time of mixing and the grading of the mixed aggregate. It may,

therefore, be convenient to obtain separate samples of aggregate and bitumen

(type (c) sample) and mix them in the required proportions in the laboratory. As

the aggregate will be discharged from the mixer in a dry state, there is

considerable risk of segregation and the greatest care should be taken in

obtaining a representative sample. If there are reasons to suspect that the

bitumen at the mixing plant has been overheated, it may be worth while to check

the penetration as excessive heating hardens the bitumen. One particular use of

this method of sampling is that if some adjustment is required to the bitumen

content, a number of samples may be made at various bitumen contents to

determine which is the most satisfactory.

To maintain the quality of a bituminous material, it is necessary to check, at

regular intervals, the various sizes of aggregate for grading, cleanliness, shape,

strength etc. If it is required to study the effects of varying the aggregate, or

bitumen proportions, it will be necessary to obtain separate samples of each

MAY 2001 Page 10.66

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

aggregate size to be used in addition to a sample of the bitumen (a type (d)

sample).

10.9.5 Sample Preparation

If necessary, the aggregates should be oven-dried at 150°C before testing

commences. (Sample types (c) and (d)).

For samples of type (d) it is first necessary to combine the various sample sizes to

give the required grading for the mixed aggregate. Several different gradings may be

tried if a full Marshall mix design is to be carried out.

When it is required to determine the most satisfactory bitumen content, given a

sample of mixed aggregate, an initial estimate of the required bitumen content can be

made from a knowledge of the compacted density of the Mixed Aggregate (CDMA).

The CDMA is most conveniently determined using a standard 100 mm. diameter

compaction mould and a 2.5 kg compaction hammer. The sample of dry aggregate is

compacted in the mould in four layers, each layer being given 20 blows of the

hammer. The density of the aggregate is then calculated in an identical manner to the

bulk density in a compaction tests. The average of two determinations is taken as the

CDMA, as shown in Form 10.9.1.

It is also necessary to carry out separate determinations of the specific gravity of the

mixed aggregate (SGMA), and the specific gravity of bitumen.

The voids in mixed aggregate VMA are then determined from the formula:

(SGMA − CDMA

VMA = X 100%

SGMA

The VMA should normally be between 17 and 20% for a satisfactory mix. An initial

estimate of the optimum bitumen content (B) is obtained from the formulae :

( VMA − VIM ) x S. G . Bitumen

B100 =

CDMA

Where, B100 is expressed in parts per 100 parts of mixed aggregate (p.h.a) and

VIM = the specified percentage of air voids in the compacted mix.

Note. In bitumen calculations, it is usual to express all densities and specific

gravities in gram/ml; gram/cc or Mg/cu.m.

Having completed the required tests on the mixed aggregates, the bituminous

material is then produced by mixing the aggregates with the bitumen in the correct

proportions.

For each test specimen, the required weight of mixed aggregate is weighed out and

place in an oven at the temperature shown in the following Table 10.9.1 (Column 2) :

MAY 2001 Page 10.67

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

MAY 2001 Page 10.68

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

Table 10.9.1 Temperatures required in the preparation of moulded specimens

1 2 3 4 5

Binder Temperature

grade pen

(in mm) Heated Heated On Completion of Immediately

aggregate binder mixing (approx.) prior to

bitumen compaction

(max. - min.)

°C °C °C °C

80 - 100 155 150 140 136 - 132

60 - 70 160 155 145 141 - 137

40 - 50 165 160 150 146 - 142

The amount of aggregate required for each specimen is in the region of 1000 - 1500

grams, but the exact amount must be determined by an initial trial.

There specimens are required for each bitumen content and the aggregate should be

heated in the oven for at least 2 hours.

The weight of bitumen required for each specimen should be weighed out into a small

metal container, and heated to the temperature shown in the Table 10.9.1 (Column

3), using an oven or a hot plate. When using a hot plate, the bitumen should be

stirred whenever possible to prevent local overheating and heating should not

continue for longer than 30 minutes. The temperature should be maintained for at

least 10 minutes. When pouring a sample of bitumen it is inevitable that some bitumen

adheres to the sides of the container, to account for this, it is useful to beat a sample

of bitumen in the container and pour this away, thus coating the sides of the container

before adding the exact weight of bitumen required for the specimen, the weight of

bitumen adhering to the sides of the container will vary only slightly each time it is

emptied. To establish the exact weight of bitumen used, the weight of the container

should be taken before heating and after pouring.

The heated aggregate and bitumen should be thoroughly mixed together as quickly

as possible. Mixing may be by hand or in a mechanical mixer. In either case the mixing

pan and tools should be heated prior to use so that the temperature of the sample is

maintained. When all the aggregate is evenly coated with the bitumen, the sample

should be removed from the mixing pan and compacted as quickly as possible.

When using a sample of mixed bituminous material (type (b)), this should be divided

into the required specimen weights as quickly as possible after sampling and then

brought back to the required mixing temperature by heating in an oven. The time of

heating will depend on the initial temperature of the sample and should not exceed

one hour. On removal from the oven, the sample should be compacted as soon as

possible.

The compaction moulds, collars and bases should be cleaned, lightly oiled and

placed in an oven, at the temperature shown in column 5 of the Table 10.9.1, for a

period of at least one hour. The hammer base should also be heated in a similar

manner.

The base, mould and collar should then be assembled and a 100 mm. diameter disc

of tough non-absorbent paper (such as greaseproof) placed in the base of the mould.

The whole of the mixed material is then transferred into the mould as quickly as

possible and levelled by prodding with a spatula 15 times round the perimeter and 10

times over the interior of the sample. At the end of this process, the upper surface of

MAY 2001 Page 10.69

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

the sample should be slightly domed. At this stage the temperature should be

checked, using a previously warmed thermometer, to save time, and must be within

the range shown in column 5, Table 10.9.1.

A disc of non-absorbent paper is then placed on the top of the sample, the mould

assembly is placed on the compaction pedestal and located in the mould clamp.

Compaction is then given to the top of the sample using 50 blows of the hammer. The

hammer must be maintained perfectly vertical during this operation and the rate of

compaction should be about 60 - 70 blows per minute.

On completion of 50 blows, the collar and base are carefully removed, the mould is

turned over and the base and collar re-fixed so the bottom of the sample is now

facing upwards. The assembly is re-fixed in the pedestal mould holder and given

another 50 blows of the hammer.

On completion of compaction, the collar is removed and the mould and base are

immersed in cold water for at least 15 minutes.

When completely cool the base is removed and the sample ejected from the mould

using the extraction apparatus. The specimen must be extracted from the mould

without shock or distortion. Any burrs may be removed with a spatula or sharp knife.

The specimen should be placed on a flat surface and the average height measured,

preferably with a dial gauge, the height must be between 62.0 and 65.0 mm. (2.7/16”

- 2.9/16) otherwise the sample should be discarded.

The specimen is then dried with a cloth and stored on a piece of absorbent paper on

a flat surface for at least 16 hours. Ensure the different specimens are clearly

marked.

The mould, base and collar should be thoroughly cleaned before re-use or storage.

10.9.6 Measurement of Density

Prior to testing, it is necessary to determine the density of the density of the

specimen, this is done by weighing in water.

The weight of the dry specimen is first determined to an accuracy of 0.1 grams.

Weight C.

The specimen is then weighed in water, weight d, using a wire basket suspended from

a suitable balance. Care should be taken to ensure that there are no air bubbles

attached to the wire basket or the specimen prior to weighing.

These weights are recorded on the data sheet Form 10.9.2 and the calculations

relating to volume and voids in the mix may then be completed.

MAY 2001 Page 10.70

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

MAY 2001 Page 10.71

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

From the weight of bitumen and aggregates used in the mix, the proportion of binder is

calculated as follows:

Weight of bitumen

Proportion of binder, B = x 100...(a)

Weight of mixed

aggregate

Where B is expressed in parts of bitumen per 100 parts of aggregate (p.h.a) . This is

the most convenient method of expressing binder content.

The binder content as a true percentage of the mixed material, is given by:

Weight of bitumen

B' = x 100%

(Weight of mixed aggregate) + (Weight of bitumen)

Note that

100

B' = B x % ............... ( b)

(100 + B)

Where, B is in p.h.a.

From the weight in air and weight in water :

Total Volume of specimen, V = (Weight c - Weight d) x S.G. water

= (Weight c - Weight d) ml .......... (f)

The density of the compacted specimen is then given by, Compacted density of mix,

Weight C

CDM = gram / ml ....................... (g)

V

The maximum theoretical density of the specimen if there were no air voids would be:

Max. theoretical specimen density,

100

' X' =

% Bitumen % Aggregate

+

S.G . Bitumen S. G . M .A

100

or, ' X' = gram / ml..................(h)

B' (100 − B')

+

S.B.Bitumen S.G.M.A

From the above results it is possible to derive a number of factors concerning the

volumetric proportions of the mix and the void content:

B' x CDM

Volume of binder, Vb = % .............. (i)

S.G. Bitumen

(as % of total volume)

MAY 2001 Page 10.72

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

(100 − B') x CDM

Volumeof aggregate, Vagg = % ..............( j)

S. G. M. A

Volumeof air voids, VIM = (100 − Vb − Vagg ) % ..................(k)

(as % of total volume)

The voids in the mixed aggregate are given by :

VMA = (100 - Vagg) % ............... (l)

and this value may be compared with that calculated previously using the CDMA.

The percentage of voids filled with bitumen are given by :

Vb

VFB = 100 x % ....................................................... (m)

VMA

and the percentage of air voids in the compacted mix,

CDM

VIM = 100 x ( 1 - ) % ........ (n)

' X'

This alternative method of calculating VIM may be used as a check. The values of VIM

achieved should be compared with the specified value.

If the test is being repeated using a number of different bitumen contents, it is usual

to plot, graphs of compacted density of mix, CDM, Voids in Mix, VIM, and Voids filled

with bitumen, VFB, against binder content, B.

10.9.7 Test procedure

On completion of density measurements, the specimens are heated in a

thermostatically controlled water bath at a temperature of 60 ± 0.5°C for a period of

60 minutes the specimens should be completely immersed in the water.

The inside faces of the testing heads should be thoroughly cleaned and the guide

rods lightly oiled, so that the upper head slides freely. The heads should then be

immersed in the water bath at 60 ± 0.5°C so they are heated to the correct test

temperature.

It is important that the test is carried out quickly and efficiently such that the total time

between removing the specimen from the water bath and completion of the test

should not exceed 40 seconds. It is, therefore, essential that the test machine,

gauges etc., are all prepared ready for use before removing the specimens from the

water bath.

On completion of the heating period, the specimen and heads should be quickly

removed from the bath and the specimen placed on its side centrally in the lower test

head, the upper head is then located on the slides and brought into contact with the

specimen. The whole assembly is then placed on the test machine directly below the

plunger.

The deformation dial gauge should be placed into position and either zeroed or the

initial reading taken. The load ring dial gauge should previously have been zeroed.

The load is then applied to the specimen by the machine at a rate of 50.8 mm/minute

± 5%. The reading on the load ring gauge should be observed and the instant the

load stops increasing, the machine should be switched off. The maximum load gauge

MAY 2001 Page 10.73

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

reading should be taken. The corresponding reading on the deformation (flow) gauge

may then be taken.

The heads should be wiped clean before testing further specimens.

10.9.8 Calculation

The calculations concerned with densities and voids have already been described in

section 10.9.6

From the maximum load gauge reading, the maximum load applied may be

determined using a calibration chart or proving ring factor. This is the measured

stability.

It will be noted that the height of the specimen may vary somewhat and the measured

stability will tend to increase as the height of the specimen increases. To reduce all

measurements to a common height of 63.5 mm. (21/2 ins.) a stability correction factor

is applied to the measured value such that:

Corrected stability = ( Measured stability ) x (Adjustment factor)

The adjustment factor is determined from the specimen volume in accordance with

Figure 10.9.5. The stability is expressed in kN (or 1bf).

The flow value is simply the reading on the deformation gauge at the point of

maximum load, and is expressed in mm. (or 0.01 inch).

A useful factor in the assessment of mix quality is the stability to flow ration which is

given by :

Corrected stability

Stability flow ratio =

Flow

The stability to flow is expressed in kN/mm or lb/(0.01 inch). The average value of the

three specimens should be quoted.

As mentioned previously the Marshall test is often carried out as a mix design

procedure and specimens will be made at various bitumen contents to determine

which is the most satisfactory (i.e. the optimum binder content).

To determine the optimum binder content graphs of CDM, VIM, VFB, Stability and

Flow against binder content are normally plotted as shown in Figure 10.9.6.

The values of some these factors may be specified and the most satisfactory values

for the other factors are generally known; it is, therefore, possible to obtain the most

desirable bitumen content relating to each of these factors from the relevant graph.

These values are not likely to be exactly the same, but are generally fairly close. The

optimum bitumen content may than be determined by taking an average of these

different values.

MAY 2001 Page 10.74

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

10.9.9 Reporting of results

The stability should be reported to the nearest 0.1 kN (20 lbsf) and the flow should be

reported to the nearest 0.5 mm. (0.01inch).

The bitumen content of the specimen, the grade of bitumen and the proportions of the

various aggregate sizes used should be given.

Height of specimen, Volume of specimen, Stability correction

ml factor

mm

62 502 - 503 1.04

504 - 506 1.03

507 - 509 1.02

510 - 512 1.01

63.5 513 - 517 1.00

515 - 520 0.99

512 - 523 0.98

524 - 526 0.97

65 527 - 528 0.96

Figure 10.9.5 Correction factors for stability values with variations in height or volume

MAY 2001 Page 10.75

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

Density (CDM)

2000

Stability (Lbs)

2.3 1500

2.2 1000

2.1 500

4.5 5.0 5.5 6.0 6.5 7.0 7.5 4.5 5.0 5.5 6.0 6.5 7.0 7.5

Binder Content (pha) Binder Content (pha)

90

Voids In Mix (V.I.M.) Voids Filled with Bitumen (V.F.B.)

8

7 80

5 70

60

4.5 5.0 5.5 6.0 6.5 7.0 7.5 4.5 5.0 5.5 6.0 6.5 7.0 7.5

Binder Content (pha) Binder Content (pha)

30

Flow (0.01)

25

20

15

10

4.5 5.0 5.5 6.0 6.5 7.0 7.5

Binder Content (pha)

Figure 10.9.6 (10.9.8) Marshall Test Results

Binder Content

(p.h.a.)

Max CDM 6.4

Max Stab 6.6 Hence optimum binder

VIM - 5% 6.3 content = 6.6 p.h.a.

VFB - 80% 7.1

Flow II 6.4

Mean 6.6 p.h.a.

MAY 2001 Page 10.76

You might also like

- A Working Guide To Process Equipment ContentDocument13 pagesA Working Guide To Process Equipment ContentMichael Cabalfin100% (1)

- Foundation Designs.Document26 pagesFoundation Designs.Shijumon KpNo ratings yet

- Work Methodology, Road WorksDocument14 pagesWork Methodology, Road WorksFRANCIS KAGUANYUNo ratings yet

- Tensile TestDocument4 pagesTensile TestHarsha Vardhana50% (8)

- Weld Length and Plate DesignDocument6 pagesWeld Length and Plate DesignSantosh ZunjarNo ratings yet

- Collings, David - Steel Concrete Composite Bridges (2005, Thomas Telford Publishing) PDFDocument195 pagesCollings, David - Steel Concrete Composite Bridges (2005, Thomas Telford Publishing) PDFjasmina100% (2)

- Method Statement For Chamber Construction of TSE Line Ev ManagerDocument20 pagesMethod Statement For Chamber Construction of TSE Line Ev ManagerBleep News100% (1)

- CBR TEST DETERMINES SOIL STRENGTHDocument11 pagesCBR TEST DETERMINES SOIL STRENGTHFazrul Amin50% (2)

- Flexible Pavement RectificationDocument11 pagesFlexible Pavement RectificationIfkar AzmiNo ratings yet

- Materials Technology - Soil and Soil AggregatesDocument17 pagesMaterials Technology - Soil and Soil AggregatesBrian PaulNo ratings yet

- Data Sheet AluminaDocument10 pagesData Sheet AluminaXin EnNo ratings yet

- Distillation of Cut-Back Asphaltic Products PDFDocument8 pagesDistillation of Cut-Back Asphaltic Products PDFKevin TangNo ratings yet

- 4.2 Bolt DesignDocument14 pages4.2 Bolt DesignbernabasNo ratings yet

- Ume 1312 Som Lab Ese QP - A2 Batch PDFDocument19 pagesUme 1312 Som Lab Ese QP - A2 Batch PDFDhanush NatesanNo ratings yet

- 10.rarebay Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesDocument5 pages10.rarebay Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesAbi DemeNo ratings yet

- Ford Wa 971-2002Document3 pagesFord Wa 971-2002DanielMaNo ratings yet

- Ijmet 09 03 102Document16 pagesIjmet 09 03 102Tessema ShbruNo ratings yet

- 9.irresa Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesDocument5 pages9.irresa Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesAbi DemeNo ratings yet

- 6.guraja Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesDocument5 pages6.guraja Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesAbi DemeNo ratings yet

- CONCRETE AGGREGATES QUALITY TESTSDocument37 pagesCONCRETE AGGREGATES QUALITY TESTSDanao ErickNo ratings yet

- EN 1057 Standard Product For Copper TubingDocument9 pagesEN 1057 Standard Product For Copper TubingcakhokheNo ratings yet

- Inspection tk-101 2Document1 pageInspection tk-101 2Mohammed YoussefNo ratings yet

- Fineness Modulus of SandDocument7 pagesFineness Modulus of SandJalal Uddin PaponNo ratings yet

- CMT Lab Report #1Document5 pagesCMT Lab Report #1jae periasNo ratings yet

- Cold Rolling and Tensile Testing Effects on MetalsDocument14 pagesCold Rolling and Tensile Testing Effects on MetalsSean BiseNo ratings yet

- (PDF) Metal Casting Processes QUALITATIVE PROBLEMS Trien Nguyen - Academia - EduDocument1 page(PDF) Metal Casting Processes QUALITATIVE PROBLEMS Trien Nguyen - Academia - EduAlii AlliNo ratings yet

- Check Baseplate and Weld Thicknesses for Steel StructureDocument19 pagesCheck Baseplate and Weld Thicknesses for Steel StructureChandra MohanNo ratings yet

- Shear PropertiesDocument1 pageShear PropertiesSh.nasirpurNo ratings yet

- The Tension TestDocument8 pagesThe Tension TestAditya agrawalNo ratings yet

- Impact Toughness Testing: THABIT KHALIFA (0218307) Group MembersDocument8 pagesImpact Toughness Testing: THABIT KHALIFA (0218307) Group MembersRafiHunJianNo ratings yet

- Float Test Determines Bitumen Material Buoyancy Under 40 CharactersDocument3 pagesFloat Test Determines Bitumen Material Buoyancy Under 40 CharactersanbertjonathanNo ratings yet

- 3Document11 pages3ahmad albabNo ratings yet

- 2000 CWP - Full Port - Threaded Ends: Materials of ConstructionDocument1 page2000 CWP - Full Port - Threaded Ends: Materials of ConstructionAxel BernabeNo ratings yet

- Magnetic Impelled Arc ButtDocument32 pagesMagnetic Impelled Arc ButtPrasanna VenkatNo ratings yet

- 2.1.6 Tickness of Glass FabricDocument1 page2.1.6 Tickness of Glass FabricAndres RojasNo ratings yet

- Annexure-10 Dropper SpecificationDocument1 pageAnnexure-10 Dropper SpecificationAnkit AgarwalNo ratings yet

- MiscellaneousDocument49 pagesMiscellaneousjrsvalenzuelaNo ratings yet

- Wide Width Tensile StrengthDocument4 pagesWide Width Tensile StrengthMohit SharmaNo ratings yet

- Project Data: MaterialDocument4 pagesProject Data: MaterialsravanNo ratings yet

- Design and Fabrication of Wear Testing MachineDocument18 pagesDesign and Fabrication of Wear Testing Machinekush Budihal67% (3)

- X32016X Y32016X MetricDocument5 pagesX32016X Y32016X MetricПавел ПосканныйNo ratings yet

- RS 5Document21 pagesRS 5AbdallahNo ratings yet

- Basic Civil Engineering - 8Document1 pageBasic Civil Engineering - 8visanuNo ratings yet

- Refrigerant Tray Sizing CalculatorDocument1 pageRefrigerant Tray Sizing Calculatormilindskulkarni2005@yahoo.co.inNo ratings yet

- CE 3410 - Construction Materials Laboratory: Record BookDocument7 pagesCE 3410 - Construction Materials Laboratory: Record Bookvamsi siddelaNo ratings yet

- Brochure KuterlexDocument8 pagesBrochure KuterlexT KelvinNo ratings yet

- A Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Document3 pagesA Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Velmurugan Siva KamarajNo ratings yet

- Sieve analysis and compaction test resultsDocument8 pagesSieve analysis and compaction test resultsamit singhNo ratings yet

- Data Collection and AnalysisDocument10 pagesData Collection and AnalysisChris ArtecoNo ratings yet

- GRADING OF SPLIT 10-20MM 29 Agust 2019Document2 pagesGRADING OF SPLIT 10-20MM 29 Agust 2019Zulhan90No ratings yet

- Belt Conveyor Preliminary Power Estimate: (Graphic Method, CEMA 5TH Edition)Document5 pagesBelt Conveyor Preliminary Power Estimate: (Graphic Method, CEMA 5TH Edition)eccmaNo ratings yet

- Hanging and Bracing Guidelines for System PipingDocument3 pagesHanging and Bracing Guidelines for System PipingAhmed AliNo ratings yet

- Masonry Structural Behaviour at Different Scales Under Compressive LoadingDocument8 pagesMasonry Structural Behaviour at Different Scales Under Compressive LoadingOyeniyi Samuel KehindeNo ratings yet

- Experiment Lab Sheet j2020Document8 pagesExperiment Lab Sheet j2020nur nazatul najwaNo ratings yet

- Tds Wikon Ip. C 7&8Document1 pageTds Wikon Ip. C 7&8deni prastikoNo ratings yet

- Quasi-Static Indentation Test On Composite Sandwich Panels With Foam Core (Advanced Materials Research, Vol. 718-720) (2013)Document6 pagesQuasi-Static Indentation Test On Composite Sandwich Panels With Foam Core (Advanced Materials Research, Vol. 718-720) (2013)bacedNo ratings yet

- Mitutoyo - Twardościomierze Shore'a HH-300 - E4137-811 - 2009 ENDocument6 pagesMitutoyo - Twardościomierze Shore'a HH-300 - E4137-811 - 2009 END.T.No ratings yet

- Concrete Core TestDocument1 pageConcrete Core Testhariom singh chaudharyNo ratings yet

- Block and Bleed Gauge Valves - M25 and M251: Product OverviewDocument5 pagesBlock and Bleed Gauge Valves - M25 and M251: Product OverviewFercomil S.A.SNo ratings yet

- Part A: Tensile Testing of Mild Steel As Received SampleDocument7 pagesPart A: Tensile Testing of Mild Steel As Received SampleAdarsh BujadeNo ratings yet

- Aggregate Sieve Analysis TestDocument52 pagesAggregate Sieve Analysis TestikaNo ratings yet

- Reinforcement MasterDocument12 pagesReinforcement MasterMonal RajNo ratings yet

- Lightherm - Compressive Strength Test ReportDocument11 pagesLightherm - Compressive Strength Test ReportRafael Obusan IINo ratings yet

- Construction Materials Lab Test Manual Sieve AnalysisDocument10 pagesConstruction Materials Lab Test Manual Sieve AnalysisHeril JainNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- 1.0 Description: Specifications For Supplying and Placing BackfillDocument7 pages1.0 Description: Specifications For Supplying and Placing BackfillbilalNo ratings yet

- Civil Polytechnic Engineering-Transportation Engineering Semester 4 Text BooksDocument226 pagesCivil Polytechnic Engineering-Transportation Engineering Semester 4 Text BooksROHITHNo ratings yet

- Mashal TestDocument13 pagesMashal TestPhemmy JibadeNo ratings yet

- Exhibit A - Scope of Works For TE#04 & TE#09 Wellpad ConstructionDocument5 pagesExhibit A - Scope of Works For TE#04 & TE#09 Wellpad ConstructionAsep FirmansyahNo ratings yet

- Is 2720 14 1983Document19 pagesIs 2720 14 1983nehaNo ratings yet

- Soil Properties For Earthen Building ConstructionDocument14 pagesSoil Properties For Earthen Building ConstructionRaksmey SangNo ratings yet

- Strengthening Methods For Subsoil Under Existing Railway LinesDocument11 pagesStrengthening Methods For Subsoil Under Existing Railway LinesValerioNo ratings yet

- New empirical formula based on dynamic probing test results in fine cohesive soilsDocument10 pagesNew empirical formula based on dynamic probing test results in fine cohesive soilsReagan MulumbaNo ratings yet

- Interlocking Concrete Paver SpecsDocument6 pagesInterlocking Concrete Paver Specscarolinetrippin100% (1)

- ACI229Document18 pagesACI229Francisco CalderónNo ratings yet

- CBR Practicum Report - Basic Soil MechanicsDocument18 pagesCBR Practicum Report - Basic Soil MechanicsShiela Ariesta EfendiNo ratings yet

- Soil mechanics: Sieve analysisDocument16 pagesSoil mechanics: Sieve analysisHengchhorn PhaiNo ratings yet

- Soil Mechanics: Economical Choice of Borrow Pits for Earth Dam ConstructionDocument20 pagesSoil Mechanics: Economical Choice of Borrow Pits for Earth Dam ConstructionMemo LyNo ratings yet

- Effect of Nanomaterials on Black Cotton Soil PropertiesDocument32 pagesEffect of Nanomaterials on Black Cotton Soil PropertieskrupaNo ratings yet

- Soil Stabilization Using Sawdust & LimeDocument21 pagesSoil Stabilization Using Sawdust & LimeManas Ranjan Dash100% (1)

- SD-180 Vibratory Soil Compactor PRO-PAC™Document2 pagesSD-180 Vibratory Soil Compactor PRO-PAC™KasidinNo ratings yet

- Proposed three-storey commercial/residential building bid proposalDocument11 pagesProposed three-storey commercial/residential building bid proposalKurama BasketNo ratings yet

- 4.1 Soil Compaction 1Document35 pages4.1 Soil Compaction 1Musfiqur RahmanNo ratings yet

- Tex 113 eDocument15 pagesTex 113 eDayner M Sanchez GarciaNo ratings yet

- Diamond Sons Pty LTD: Geotechnical AssessmentDocument47 pagesDiamond Sons Pty LTD: Geotechnical AssessmentTarek AbulailNo ratings yet

- Geotechnical Report DraftDocument41 pagesGeotechnical Report DraftMichelle PaninopoulosNo ratings yet

- NEW DSR (Effective From 01-07-2023)Document1 pageNEW DSR (Effective From 01-07-2023)rahul pardeshiNo ratings yet

- Constructing Soil-Based RoadbedsDocument23 pagesConstructing Soil-Based RoadbedsRommel Carlo LargadoNo ratings yet

- Astm d5030Document13 pagesAstm d5030Roberto Rodriguez0% (1)

- REVIEW PAPER ON INTERGRANULAR VOID RATIO AND ITS RELATION WITH COMPACTION PARAMETERS AND SOIL STRENGTHDocument12 pagesREVIEW PAPER ON INTERGRANULAR VOID RATIO AND ITS RELATION WITH COMPACTION PARAMETERS AND SOIL STRENGTHSyeda L RNo ratings yet