Professional Documents

Culture Documents

Check Baseplate and Weld Thicknesses for Steel Structure

Uploaded by

Chandra MohanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check Baseplate and Weld Thicknesses for Steel Structure

Uploaded by

Chandra MohanCopyright:

Available Formats

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Project data

Project name CHECK FOR BASEPLATE & WELD THICK

Project number C3F3-3

Author

Description TRA-EXT-CAL-GR-GEN-00090

Date 08/06/2019

Design code EN

Material

Steel S275

Concrete C25/30, C40/50

08/06/2019 12:02:35 PM 1/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

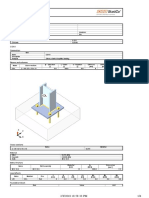

Project item CON1

Design

Name CON1

Description

Analysis Stress, strain/ simplified loading

Beams and columns

β – Direction γ - Pitch α - Rotation Offset ex Offset ey Offset ez

Name Cross-section

[°] [°] [°] [mm] [mm] [mm]

M1 1 - PFC100/50/10 0.0 -90.0 180.0 0 0 0

08/06/2019 12:02:35 PM 2/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

08/06/2019 12:02:35 PM 3/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Cross-sections

Name Material

1 - PFC100/50/10 S275

08/06/2019 12:02:35 PM 4/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

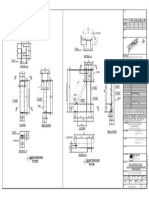

Cross-sections

Name Material Drawing

1 - PFC100/50/10 S275

Anchors

Diameter fu Gross area

Name Bolt assembly

[mm] [MPa] [mm2]

M12 8.8 M12 8.8 12 800.0 113

Load effects (equilibrium not required)

X N Vy Vz Mx My Mz

Name Member Pos.

[mm] [kN] [kN] [kN] [kNm] [kNm] [kNm]

LE1 M1 End 0 0.1 6.1 0.0 0.0 0.0 2.4

Foundation block

Item Value Unit

CB 1

Dimensions 540 x 480 mm

Depth 150 mm

Anchor M12 8.8

Anchoring length 100 mm

Shear force transfer Anchors

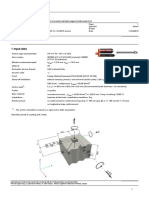

Check

Summary

Name Value Check status

Analysis 100.0% OK

Plates 0.0 < 5% OK

Anchors 60.9 < 100% OK

Welds 70.8 < 100% OK

Concrete block 45.4 < 100% OK

Buckling 39.41

Plates

Thickness σEd εPl

Name Loads Check status

[mm] [MPa] [1e-4]

M1-bfl 1 8.5 LE1 225.2 3.1 OK

M1-tfl 1 8.5 LE1 224.5 4.8 OK

M1-w 1 5.0 LE1 230.2 2.5 OK

SP1 12.0 LE1 117.8 0.0 OK

Design data

08/06/2019 12:02:35 PM 5/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

fy εlim

Material

[MPa] [1e-4]

S275 265.0 500.0

Overall check, LE1

08/06/2019 12:02:35 PM 6/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Strain check, LE1

Equivalent stress, LE1

Anchors

Ft,Ed V Nrdc Utt Fb,Rd Uts VRd,cp VRd,c

Name Loads Cpf Cef Status

[kN] [kN] [kN] [%] [kN] [%] [kN] [kN]

A1 LE1 0.0 1.5 0.0 0.0 123.8 12.9 36.3 OK 19.3 OK OK

A2 LE1 0.0 1.5 0.0 0.0 123.8 12.8 36.3 OK 19.3 OK OK

A3 LE1 13.5 2.1 22.2 60.9 123.8 25.9 36.3 OK 23.1 OK OK

A4 LE1 13.5 2.1 22.2 60.8 123.8 25.7 36.3 OK 23.1 OK OK

Design data

Ft,Rd Bp,Rd Fv,Rd Vrds Stf

Name

[kN] [kN] [kN] [kN] [MN/m]

M12 8.8 - 1 41.1 155.6 26.9 11.8 247

Detailed result for A1

NRk,c

NRd,c = γc ⋅γinst = 0.0 kN

where:

γc = 1.50

γinst = 1.20

08/06/2019 12:02:35 PM 7/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

0 Ac,N

NRk,c = NRk,c ⋅ A0c,N ⋅ ψs,N ⋅ ψre,N ⋅ ψec,N = 0.0 kN

where:

Ac,N = 0 mm2 Actual area of concrete cone

0 2

Ac,N = 0 mm Area of concrete of an individual anchor with large spacing

0

NRk,c = 50.9 kN Characteristic resistance of an anchor placed in cracked concrete

ψs,N = 1.00 Factor of distribution of stresses in the concrete

ψre,N = 1.00 Shell spalling factor

ψec,N = 1.00 Group effect factor

Pull-out failure and splitting failure modes should be guaranteed by a manufacturer

VRk,s

VRd,s = γMS = 11.8 kN

where:

γM S = 1.25 Safety factor

αM ⋅MRk,s

VRk,s = l = 14.8 kN

where:

αM = 2.00

MRk,s = 0.2 kNm

l = 22 mm Lever arm

V

VRd,cp = γRk,cp

MC

= 36.3 kN

VRk,cp = k ⋅ NRk,c = 54.5 kN

where:

NRk,c = 27.3 kN Resistance of an anchor placed in concrete. All anchors in group

k = 2.00 Factor from ETAG 5.2.3.3

γM C = 1.50 Safety factor

VRk,c

VRd,c = γM C = 19.3 kN

where:

γM C = 1.50 Safety factor

0 Ac,V

VRk,c = VRk,c ⋅ A0c,V ⋅ ψs,V ⋅ ψh,V ⋅ ψα,V ⋅ ψec,V ⋅ ψre,V = 28.9 kN

where:

0

VRk,c = 47.2 kN Initial value of the characteristic resistance of an anchor

2

Ac,V = 69375 mm Actual area of concrete cone of anchorage

0

Ac,V = 154013 mm2 Area of concrete cone of an individual anchor

ψs,V = 1.00 Factor of the distribution of stresses

ψh,V = 1.36 Factor of the decrease of shear resistance

ψα,V = 1.00 Factor of the angle between the load direction and concrete edge

ψec,V = 1.00 Factor of group effect

ψre,V = 1.00 Factor of the type of reinforcement

hef = 100 mm Depth of embedment

08/06/2019 12:02:35 PM 8/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Utts = (βN )α + (βV )α = 4.6 %

where:

βN = 0.00 Ratio between design action and design resistance for tension

βV = 0.13 Ratio between design action and design resistance for shear

α = 1.50

Ft,Ed

Utt = min(Ft,Rd ;Bp,Rd ,NRd,c ) = 0.0 %

VEd

Uts = min(Fv,Rd ;Fb,Rd ) = 12.9 %

ck2 fub As

Ft,Rd = γM 2 = 41.1 kN

where:

c = 0.85 Factor

k2 = 0.90 Factor

fub = 800.0 MPa Ultimate tensile strength of the bolt

2

As = 84 mm Tensile stress area of the bolt

γM 2 = 1.25 Safety factor

0.6πdm tp fu

Bp,Rd = γM2 = 155.6 kN

where:

dm = 20 mm The mean of the across points and across flats dimensions of the bolt head or the nut, whichever is smaller

tp = 12 mm Thickness

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

k1 ab fu dt

Fb,Rd = γM 2 = 123.8 kN

where:

k1 = 2.50

ab = 1.00 Factor

fu = 430.0 MPa Ultimate strength

d = 12 mm Nominal diameter of the fastener

t = 12 mm Thickness

γM 2 = 1.25 Safety factor

Detailed result for A2

NRk,c

NRd,c = γc ⋅γinst = 0.0 kN

where:

γc = 1.50

γinst = 1.20

08/06/2019 12:02:35 PM 9/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

0 Ac,N

NRk,c = NRk,c ⋅ A0c,N ⋅ ψs,N ⋅ ψre,N ⋅ ψec,N = 0.0 kN

where:

Ac,N = 0 mm2 Actual area of concrete cone

0 2

Ac,N = 0 mm Area of concrete of an individual anchor with large spacing

0

NRk,c = 50.9 kN Characteristic resistance of an anchor placed in cracked concrete

ψs,N = 1.00 Factor of distribution of stresses in the concrete

ψre,N = 1.00 Shell spalling factor

ψec,N = 1.00 Group effect factor

Pull-out failure and splitting failure modes should be guaranteed by a manufacturer

VRk,s

VRd,s = γMS = 11.8 kN

where:

γM S = 1.25 Safety factor

αM ⋅MRk,s

VRk,s = l = 14.8 kN

where:

αM = 2.00

MRk,s = 0.2 kNm

l = 22 mm Lever arm

V

VRd,cp = γRk,cp

MC

= 36.3 kN

VRk,cp = k ⋅ NRk,c = 54.5 kN

where:

NRk,c = 27.3 kN Resistance of an anchor placed in concrete. All anchors in group

k = 2.00 Factor from ETAG 5.2.3.3

γM C = 1.50 Safety factor

VRk,c

VRd,c = γM C = 19.3 kN

where:

γM C = 1.50 Safety factor

0 Ac,V

VRk,c = VRk,c ⋅ A0c,V ⋅ ψs,V ⋅ ψh,V ⋅ ψα,V ⋅ ψec,V ⋅ ψre,V = 28.9 kN

where:

0

VRk,c = 47.2 kN Initial value of the characteristic resistance of an anchor

2

Ac,V = 69375 mm Actual area of concrete cone of anchorage

0

Ac,V = 154013 mm2 Area of concrete cone of an individual anchor

ψs,V = 1.00 Factor of the distribution of stresses

ψh,V = 1.36 Factor of the decrease of shear resistance

ψα,V = 1.00 Factor of the angle between the load direction and concrete edge

ψec,V = 1.00 Factor of group effect

ψre,V = 1.00 Factor of the type of reinforcement

hef = 100 mm Depth of embedment

08/06/2019 12:02:35 PM 10/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Utts = (βN )α + (βV )α = 4.6 %

where:

βN = 0.00 Ratio between design action and design resistance for tension

βV = 0.13 Ratio between design action and design resistance for shear

α = 1.50

Ft,Ed

Utt = min(Ft,Rd ;Bp,Rd ,NRd,c ) = 0.0 %

VEd

Uts = min(Fv,Rd ;Fb,Rd ) = 12.8 %

ck2 fub As

Ft,Rd = γM 2 = 41.1 kN

where:

c = 0.85 Factor

k2 = 0.90 Factor

fub = 800.0 MPa Ultimate tensile strength of the bolt

2

As = 84 mm Tensile stress area of the bolt

γM 2 = 1.25 Safety factor

0.6πdm tp fu

Bp,Rd = γM2 = 155.6 kN

where:

dm = 20 mm The mean of the across points and across flats dimensions of the bolt head or the nut, whichever is smaller

tp = 12 mm Thickness

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

k1 ab fu dt

Fb,Rd = γM 2 = 123.8 kN

where:

k1 = 2.50

ab = 1.00 Factor

fu = 430.0 MPa Ultimate strength

d = 12 mm Nominal diameter of the fastener

t = 12 mm Thickness

γM 2 = 1.25 Safety factor

Detailed result for A3

NRk,c

NRd,c = γc ⋅γinst = 22.2 kN

where:

γc = 1.50

γinst = 1.20

08/06/2019 12:02:35 PM 11/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

0 Ac,N

NRk,c = NRk,c ⋅ A0c,N ⋅ ψs,N ⋅ ψre,N ⋅ ψec,N = 39.9 kN

where:

Ac,N = 70500 mm2 Actual area of concrete cone

0 2

Ac,N = 90000 mm Area of concrete of an individual anchor with large spacing

0

NRk,c = 50.9 kN Characteristic resistance of an anchor placed in cracked concrete

ψs,N = 1.00 Factor of distribution of stresses in the concrete

ψre,N = 1.00 Shell spalling factor

ψec,N = 1.00 Group effect factor

Pull-out failure and splitting failure modes should be guaranteed by a manufacturer

VRk,s

VRd,s = γMS = 8.3 kN

where:

γM S = 1.25 Safety factor

αM ⋅MRk,s

VRk,s = l = 10.3 kN

where:

αM = 2.00

MRk,s = 0.1 kNm

l = 22 mm Lever arm

V

VRd,cp = γRk,cp

MC

= 36.3 kN

VRk,cp = k ⋅ NRk,c = 54.5 kN

where:

NRk,c = 27.3 kN Resistance of an anchor placed in concrete. All anchors in group

k = 2.00 Factor from ETAG 5.2.3.3

γM C = 1.50 Safety factor

VRk,c

VRd,c = γM C = 23.1 kN

where:

γM C = 1.50 Safety factor

0 Ac,V

VRk,c = VRk,c ⋅ A0c,V ⋅ ψs,V ⋅ ψh,V ⋅ ψα,V ⋅ ψec,V ⋅ ψre,V = 34.7 kN

where:

0

VRk,c = 47.2 kN Initial value of the characteristic resistance of an anchor

2

Ac,V = 83250 mm Actual area of concrete cone of anchorage

0

Ac,V = 154013 mm2 Area of concrete cone of an individual anchor

ψs,V = 1.00 Factor of the distribution of stresses

ψh,V = 1.36 Factor of the decrease of shear resistance

ψα,V = 1.00 Factor of the angle between the load direction and concrete edge

ψec,V = 1.00 Factor of group effect

ψre,V = 1.00 Factor of the type of reinforcement

hef = 100 mm Depth of embedment

08/06/2019 12:02:35 PM 12/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Utts = (βN )α + (βV )α = 60.7 %

where:

βN = 0.61 Ratio between design action and design resistance for tension

βV = 0.26 Ratio between design action and design resistance for shear

α = 1.50

Ft,Ed

Utt = min(Ft,Rd ;Bp,Rd ,NRd,c ) = 60.9 %

VEd

Uts = min(Fv,Rd ;Fb,Rd ) = 25.9 %

ck2 fub As

Ft,Rd = γM 2 = 41.1 kN

where:

c = 0.85 Factor

k2 = 0.90 Factor

fub = 800.0 MPa Ultimate tensile strength of the bolt

2

As = 84 mm Tensile stress area of the bolt

γM 2 = 1.25 Safety factor

0.6πdm tp fu

Bp,Rd = γM2 = 155.6 kN

where:

dm = 20 mm The mean of the across points and across flats dimensions of the bolt head or the nut, whichever is smaller

tp = 12 mm Thickness

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

k1 ab fu dt

Fb,Rd = γM 2 = 123.8 kN

where:

k1 = 2.50

ab = 1.00 Factor

fu = 430.0 MPa Ultimate strength

d = 12 mm Nominal diameter of the fastener

t = 12 mm Thickness

γM 2 = 1.25 Safety factor

Detailed result for A4

NRk,c

NRd,c = γc ⋅γinst = 22.2 kN

where:

γc = 1.50

γinst = 1.20

08/06/2019 12:02:35 PM 13/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

0 Ac,N

NRk,c = NRk,c ⋅ A0c,N ⋅ ψs,N ⋅ ψre,N ⋅ ψec,N = 39.9 kN

where:

Ac,N = 70500 mm2 Actual area of concrete cone

0 2

Ac,N = 90000 mm Area of concrete of an individual anchor with large spacing

0

NRk,c = 50.9 kN Characteristic resistance of an anchor placed in cracked concrete

ψs,N = 1.00 Factor of distribution of stresses in the concrete

ψre,N = 1.00 Shell spalling factor

ψec,N = 1.00 Group effect factor

Pull-out failure and splitting failure modes should be guaranteed by a manufacturer

VRk,s

VRd,s = γMS = 8.3 kN

where:

γM S = 1.25 Safety factor

αM ⋅MRk,s

VRk,s = l = 10.4 kN

where:

αM = 2.00

MRk,s = 0.1 kNm

l = 22 mm Lever arm

V

VRd,cp = γRk,cp

MC

= 36.3 kN

VRk,cp = k ⋅ NRk,c = 54.5 kN

where:

NRk,c = 27.3 kN Resistance of an anchor placed in concrete. All anchors in group

k = 2.00 Factor from ETAG 5.2.3.3

γM C = 1.50 Safety factor

VRk,c

VRd,c = γM C = 23.1 kN

where:

γM C = 1.50 Safety factor

0 Ac,V

VRk,c = VRk,c ⋅ A0c,V ⋅ ψs,V ⋅ ψh,V ⋅ ψα,V ⋅ ψec,V ⋅ ψre,V = 34.7 kN

where:

0

VRk,c = 47.2 kN Initial value of the characteristic resistance of an anchor

2

Ac,V = 83250 mm Actual area of concrete cone of anchorage

0

Ac,V = 154013 mm2 Area of concrete cone of an individual anchor

ψs,V = 1.00 Factor of the distribution of stresses

ψh,V = 1.36 Factor of the decrease of shear resistance

ψα,V = 1.00 Factor of the angle between the load direction and concrete edge

ψec,V = 1.00 Factor of group effect

ψre,V = 1.00 Factor of the type of reinforcement

hef = 100 mm Depth of embedment

08/06/2019 12:02:35 PM 14/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Utts = (βN )α + (βV )α = 60.4 %

where:

βN = 0.61 Ratio between design action and design resistance for tension

βV = 0.26 Ratio between design action and design resistance for shear

α = 1.50

Ft,Ed

Utt = min(Ft,Rd ;Bp,Rd ,NRd,c ) = 60.8 %

VEd

Uts = min(Fv,Rd ;Fb,Rd ) = 25.7 %

ck2 fub As

Ft,Rd = γM 2 = 41.1 kN

where:

c = 0.85 Factor

k2 = 0.90 Factor

fub = 800.0 MPa Ultimate tensile strength of the bolt

2

As = 84 mm Tensile stress area of the bolt

γM 2 = 1.25 Safety factor

0.6πdm tp fu

Bp,Rd = γM2 = 155.6 kN

where:

dm = 20 mm The mean of the across points and across flats dimensions of the bolt head or the nut, whichever is smaller

tp = 12 mm Thickness

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

k1 ab fu dt

Fb,Rd = γM 2 = 123.8 kN

where:

k1 = 2.50

ab = 1.00 Factor

fu = 430.0 MPa Ultimate strength

d = 12 mm Nominal diameter of the fastener

t = 12 mm Thickness

γM 2 = 1.25 Safety factor

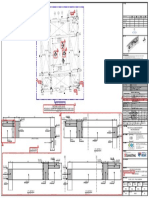

Welds (Plastic redistribution)

Throat th. Length σw,Ed εPl σ⏊ τ|| τ⏊ Ut Utc

Item Edge Loads Status

[mm] [mm] [MPa] [%] [MPa] [MPa] [MPa] [%] [%]

SP1 M1-bfl 1 ◢6.0◣ 48 LE1 264.1 0.0 -91.7 -92.9 -108.6 65.3 45.7 OK

◢6.0◣ 48 LE1 262.4 0.0 -105.3 107.1 88.2 64.8 36.2 OK

SP1 M1-tfl 1 ◢6.0◣ 48 LE1 285.5 0.0 -109.6 -121.5 -91.7 70.5 40.4 OK

◢6.0◣ 48 LE1 286.5 0.0 -95.7 106.8 113.6 70.8 50.9 OK

SP1 M1-w 1 ◢6.0◣ 92 LE1 239.6 0.0 63.7 68.5 114.4 59.2 24.1 OK

◢6.0◣ 92 LE1 135.2 0.0 84.1 38.5 -47.5 33.4 15.1 OK

Design data

βw σw,Rd 0.9 σ

[-] [MPa] [MPa]

S275 0.85 404.7 309.6

Detailed result for SP1 M1-bfl 1

08/06/2019 12:02:35 PM 15/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 65.3 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 264.1 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 64.8 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 262.4 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

Detailed result for SP1 M1-tfl 1

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 70.5 %

w,Rd σ⊥,Rd

2

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 285.5 MPa

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 70.8 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 286.5 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

Detailed result for SP1 M1-w 1

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 59.2 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 239.6 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

08/06/2019 12:02:35 PM 16/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 33.4 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 135.2 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM 2 = 1.25 Safety factor

Concrete block

c Aeff σ Kj Fjd Ut

Item Loads Check status

[mm] [mm2] [MPa] [-] [MPa] [%]

CB 1 LE1 15 1406 24.3 3.00 53.6 45.4 OK

Detailed result for CB 1

U T = Fσjd = 45.4 %

σ = ANeff = 24.3 MPa

Fjd = βj kj fck /γc = 53.6 MPa

where:

N = 34.2 kN Design normal force

Aeff = 1406 mm2 Effective area, on which the column force N is distributed

βj = 0.67

kj = 3.00 Concentration factor

fck = 40.0 MPa Characteristic compressive concrete strength

γc = 1.50 Safety factor

Buckling

Factor

Loads Shape

[-]

LE1 1 39.41

2 40.61

3 46.95

4 47.33

5 70.06

6 70.67

Bill of material

Manufacturing operations

Plates Welds Length

Name Shape Nr. Bolts Nr.

[mm] [mm] [mm]

SP1 P12.0x240.0-180.0 (S275) 1 M12 8.8 4

CUT1 Double fillet: a = 6.0 186.5

Welds

08/06/2019 12:02:35 PM 17/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Throat thickness Leg size Length

Type Material

[mm] [mm] [mm]

Double fillet S275 6.0 8.5 186.5

Anchors

Length Drill length

Name Count

[mm] [mm]

M12 8.8 122 100 4

Drawing

SP1

P12.0x180-240 (S275)

Symbol explanation

Symbol Symbol explanation

εPl Strain

σEd Eq. stress

Ft,Rd Bolt tension resistance EN 1993-1-8 tab. 3.4

Bp,Rd Punching shear resistance

Ft,Ed Tension force

V Resultant of shear forces Vy, Vz in bolt.

Fv,Rd Bolt shear resistance EN_1993-1-8 table 3.4

Vrds Characteristic anchor resistance ETAG 001 Annex C (5.2.3.2)

Fb,Rd Plate bearing resistance EN 1993-1-8 tab. 3.4

Nrk,c Concrete cone breakout resistance

Utt Utilization in tension

08/06/2019 12:02:35 PM 18/32

Project: CHECK FOR BASEPLATE & WELD THICK

Project no: C3F3-3

Author:

Symbol Symbol explanation

Uts Utilization in shear

Vrd,cp Concrete pry-out failure ETAG 001 Annex C (5.2.3.3)

Vrd,c Concrete edge failure ETAG 001 Annex C (5.2.3.4)

σw,Ed Equivalent stress

σw,Rd Equivalent stress resistance

σ⏊ Perpendicular stress

τ|| Shear stress parallel to weld axis

τ⏊ Shear stress perpendicular to weld axis

0.9 σw,Rd Perpendicular stress resistance - 0.9*fu/γM2

βw Corelation factor EN 1993-1-8 tab. 4.1

Ut Utilization

Utc Weld capacity utilization

Aeff Effective area

σ Average stress in concrete

Code settings

Item Value Unit Reference

γM0 1.00 - EN 1993-1-1: 6.1

γM1 1.00 - EN 1993-1-1: 6.1

γM2 1.25 - EN 1993-1-1: 6.1

γM3 1.25 - EN 1993-1-8: 2.2

γC 1.50 - EN 1992-1-1: 2.4.2.4

γInst 1.20 - ETAG 001-C: 3.2.1

Joint coefficient βj 0.67 - EN 1993-1-8: 6.2.5

Effective area - influence of mesh size 0.10 -

Friction coefficient - concrete 0.25 - EN 1993-1-8

Friction coefficient in slip-resistance 0.30 - EN 1993-1-8 tab 3.7

Limit plastic strain 0.05 - EN 1993-1-5

Weld stress evaluation Plastic redistribution

Detailing No

Distance between bolts [d] 2.20 - EN 1993-1-8: tab 3.3

Distance between bolts and edge [d] 1.20 - EN 1993-1-8: tab 3.3

Concrete cone breakout resistance Yes ETAG 001-C

Use calculated αb in bearing check. Yes EN 1993-1-8: tab 3.4

08/06/2019 12:02:35 PM 19/32

You might also like

- 2cdf5ddc 08Document13 pages2cdf5ddc 08Chandra MohanNo ratings yet

- C1 PanelDocument24 pagesC1 PanelChandra MohanNo ratings yet

- c3f3 1Document24 pagesc3f3 1Chandra MohanNo ratings yet

- Base PlateDocument6 pagesBase PlateShaikh ImranNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument14 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument23 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Material: DesignDocument26 pagesMaterial: DesignDavor IlicNo ratings yet

- Beam To BeamDocument6 pagesBeam To BeamShaikh ImranNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument13 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Steel connection design check summaryDocument18 pagesSteel connection design check summaryDaniel TuerosNo ratings yet

- Connection - IDEA StatiCa PDFDocument18 pagesConnection - IDEA StatiCa PDFDaniel TuerosNo ratings yet

- Project Data: Project Name: Project Number Author Description Date 04-09-2023 Design Code AISC 360-16Document29 pagesProject Data: Project Name: Project Number Author Description Date 04-09-2023 Design Code AISC 360-16Pruthviraj JuniNo ratings yet

- 8fc63d2f f6Document18 pages8fc63d2f f6Chandra MohanNo ratings yet

- Project Data: MaterialDocument4 pagesProject Data: MaterialsravanNo ratings yet

- Base Plate With ShearDocument7 pagesBase Plate With ShearAman VossNo ratings yet

- Project Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16Document21 pagesProject Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16kheang amgNo ratings yet

- CON1 project stress analysis and design checksDocument7 pagesCON1 project stress analysis and design checksivanNo ratings yet

- North South Pipe Rack Tee Post DesignDocument30 pagesNorth South Pipe Rack Tee Post DesignPruthviraj JuniNo ratings yet

- 2.BP1 T+HDocument14 pages2.BP1 T+Hkheang amgNo ratings yet

- Andalusia Canopy Design AnalysisDocument30 pagesAndalusia Canopy Design AnalysisMoustafaNo ratings yet

- 1.BP1 CDocument13 pages1.BP1 Ckheang amgNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument25 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument13 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Base Plate02Document12 pagesBase Plate02HSY79No ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument20 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Project Data: Project Name Project Number Author Description SS1 Base Connection Date 6/6/2022 Design Code ENDocument11 pagesProject Data: Project Name Project Number Author Description SS1 Base Connection Date 6/6/2022 Design Code ENSyed AbuthahirNo ratings yet

- Project Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Document49 pagesProject Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Abdullah NajjarNo ratings yet

- Yes 1Document56 pagesYes 1Frank Appiah-KusiNo ratings yet

- Base Plate With Tension OnlyDocument7 pagesBase Plate With Tension OnlyAman VossNo ratings yet

- Rabia7 Base 28.02 EmbedDocument7 pagesRabia7 Base 28.02 EmbedvengadNo ratings yet

- 03.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument16 pages03.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- Project DataDocument11 pagesProject DataAbdullah NajjarNo ratings yet

- Attachment 3.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument16 pagesAttachment 3.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- Project Item CON: DesignDocument6 pagesProject Item CON: Designkheang amgNo ratings yet

- Project Data: Project Name Project Number Author Description Date 10/23/2021 Design Code AISC 360-16Document7 pagesProject Data: Project Name Project Number Author Description Date 10/23/2021 Design Code AISC 360-16Ahsan KhanNo ratings yet

- Project data and design of steel structureDocument12 pagesProject data and design of steel structureHSY79No ratings yet

- Stub - temelj Г portalDocument15 pagesStub - temelj Г portalBobanNo ratings yet

- Project Data: Project Name Kamc Project Number Author Description Date 10/13/2021 Design Code AISC 360-16Document27 pagesProject Data: Project Name Kamc Project Number Author Description Date 10/13/2021 Design Code AISC 360-16MoustafaNo ratings yet

- Con 1Document28 pagesCon 1SaifullahNo ratings yet

- Project Data: Project Name Project Number Author Description Date 17/06/2020 Design Code AISC 360-16Document9 pagesProject Data: Project Name Project Number Author Description Date 17/06/2020 Design Code AISC 360-16Pham DuctrungNo ratings yet

- 50NB TUBLER CONNECTIONDocument11 pages50NB TUBLER CONNECTIONDass MNo ratings yet

- Project Data: DesignDocument18 pagesProject Data: DesignEmina HSNo ratings yet

- 1.BP1 CDocument17 pages1.BP1 Ckheang amgNo ratings yet

- 1 BP1Document24 pages1 BP1kheang amgNo ratings yet

- Base PlateDocument15 pagesBase PlateHSY79No ratings yet

- 03.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument17 pages03.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- Project Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Document7 pagesProject Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Abdullah NajjarNo ratings yet

- Base PlateDocument6 pagesBase PlateLangit BumiNo ratings yet

- Steel structure design projectDocument16 pagesSteel structure design projectprojelerharunNo ratings yet

- 03.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument25 pages03.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- Stub - temelj П portalDocument15 pagesStub - temelj П portalBobanNo ratings yet

- SHS250 SHS200 To ConcBeam Rev01 Alter 021122Document104 pagesSHS250 SHS200 To ConcBeam Rev01 Alter 021122HongducBuiNo ratings yet

- Project Data: Project Name Project Number Author Description Date 6/11/2020 Design Code ENDocument12 pagesProject Data: Project Name Project Number Author Description Date 6/11/2020 Design Code ENWaqar FaziNo ratings yet

- Sambungan Atap Dan BaseplateDocument36 pagesSambungan Atap Dan Baseplatedinal031No ratings yet

- Attachment 3.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument15 pagesAttachment 3.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- Project 01: Base Circular Support StructureDocument7 pagesProject 01: Base Circular Support StructureFlavio SNo ratings yet

- Stub - temelj Т portalDocument15 pagesStub - temelj Т portalBobanNo ratings yet

- 2.BP1 T+HDocument31 pages2.BP1 T+Hkheang amgNo ratings yet

- Project Data: DesignDocument35 pagesProject Data: DesignEmina HSNo ratings yet

- Material submittal review and variation proceduresDocument5 pagesMaterial submittal review and variation proceduresChandra MohanNo ratings yet

- RS7 Pro STD 001Document1 pageRS7 Pro STD 001Chandra MohanNo ratings yet

- Elegent Resume Design in Ms Word 2019Document3 pagesElegent Resume Design in Ms Word 2019Chandra MohanNo ratings yet

- Tra Ext Qor GR RS5 00077 00 - 2Document5 pagesTra Ext Qor GR RS5 00077 00 - 2Chandra MohanNo ratings yet

- En Midas Design Catalog LowDocument6 pagesEn Midas Design Catalog LowArnoldoAyalaSalamancaNo ratings yet

- Tra Ext Qor GR RB5 00084Document1 pageTra Ext Qor GR RB5 00084Chandra MohanNo ratings yet

- Tra Ext Qor GR HS6 00090Document4 pagesTra Ext Qor GR HS6 00090Chandra MohanNo ratings yet

- Sick Leave CertificateDocument1 pageSick Leave CertificateChandra MohanNo ratings yet

- Program Download Link PDFDocument1 pageProgram Download Link PDFChandra MohanNo ratings yet

- PowerPadSampleOutput PDFDocument56 pagesPowerPadSampleOutput PDFChandra MohanNo ratings yet

- Tra Ext Pla GR Gen 00002 00Document1 pageTra Ext Pla GR Gen 00002 00Chandra MohanNo ratings yet

- Program Download Link PDFDocument1 pageProgram Download Link PDFChandra MohanNo ratings yet

- Sick Leave CertificateDocument1 pageSick Leave CertificateChandra MohanNo ratings yet

- Design of Steel Structures To EurocodesDocument627 pagesDesign of Steel Structures To Eurocodestekla gom-lua group100% (4)

- Znm-Int-st-ss-mual-sdw-113419 (r00) b01 - SHT 5 - Seismic & Normal Support DetailsDocument1 pageZnm-Int-st-ss-mual-sdw-113419 (r00) b01 - SHT 5 - Seismic & Normal Support DetailsChandra MohanNo ratings yet

- Drafts - EXT-CTI-TOW-FC-CA-0073 AnchorDocument7 pagesDrafts - EXT-CTI-TOW-FC-CA-0073 AnchorChandra MohanNo ratings yet

- Ysd P02 0208 Ar SJF CD F0005 BDocument47 pagesYsd P02 0208 Ar SJF CD F0005 BChandra MohanNo ratings yet

- Amr Rashad: EducationDocument3 pagesAmr Rashad: EducationChandra MohanNo ratings yet

- Second Floor Level Residence Drop Off Concrete Structure PlanDocument1 pageSecond Floor Level Residence Drop Off Concrete Structure PlanChandra MohanNo ratings yet

- Status-B Approved With Comments:-: 1-The Proposed System Is Subject To Architectural and Shop Drawings ApprovalsDocument60 pagesStatus-B Approved With Comments:-: 1-The Proposed System Is Subject To Architectural and Shop Drawings ApprovalsChandra MohanNo ratings yet

- Base Plate Templete - BP4-ADocument153 pagesBase Plate Templete - BP4-AChandra MohanNo ratings yet

- AnvrrgrgwerherherherherehDocument55 pagesAnvrrgrgwerherherherherehChandra MohanNo ratings yet

- Cladding Details PDFDocument144 pagesCladding Details PDFzaki_th00880% (5)

- ASCE7‐10 Components & Cladding Wind Load ProvisionsDocument83 pagesASCE7‐10 Components & Cladding Wind Load ProvisionsGonzalo Rodriguez GuzmanNo ratings yet

- EC3 GB - WeldingDocument7 pagesEC3 GB - WeldingRancor82No ratings yet

- 01-A32!00!35 - Residential Porte CochereDocument1 page01-A32!00!35 - Residential Porte CochereChandra MohanNo ratings yet

- C3-C4b - Open NCR's As of 30th September 2019Document12 pagesC3-C4b - Open NCR's As of 30th September 2019Chandra MohanNo ratings yet

- Idea Statica Connection: Theoretical BackgroundDocument52 pagesIdea Statica Connection: Theoretical BackgroundChandra MohanNo ratings yet

- Design of Strap FootingDocument6 pagesDesign of Strap FootingEdgar Arana JNo ratings yet

- Physics Project Work On Hooke's Law and Stress-Strain RelationshipDocument17 pagesPhysics Project Work On Hooke's Law and Stress-Strain RelationshipAbhisek Adhikari100% (2)

- Drilling OverpressureDocument78 pagesDrilling OverpressuresrpadronNo ratings yet

- Seminar On MramDocument28 pagesSeminar On MramShibojyoti BhattacharjeeNo ratings yet

- VPFR Data Sheet - Final (APAC)Document1 pageVPFR Data Sheet - Final (APAC)NoorAhmadNo ratings yet

- MaterialExam1 SolutionsDocument4 pagesMaterialExam1 SolutionslarasmoyoNo ratings yet

- Muntinlupa City Ordinance 10-109Document7 pagesMuntinlupa City Ordinance 10-109Joy Dawis-Asuncion0% (1)

- As 2400.18-1983 Packaging Use of Desiccants in PackagingDocument6 pagesAs 2400.18-1983 Packaging Use of Desiccants in PackagingSAI Global - APAC100% (1)

- Welding Procedure - A - PDFDocument60 pagesWelding Procedure - A - PDFMade Agus BudiarthaNo ratings yet

- Assessment: Directions: Choose The Letter of The Correct Answer. Write Your Answers On A Separate Sheet of PaperDocument5 pagesAssessment: Directions: Choose The Letter of The Correct Answer. Write Your Answers On A Separate Sheet of Paperkim aaron marcelinoNo ratings yet

- Leader Test Series / Joint Package Course: Distance Learning ProgrammeDocument7 pagesLeader Test Series / Joint Package Course: Distance Learning Programmekhushal_bhavsar26No ratings yet

- Synthesis of Potassium Tris (Oxalato) Ferrate (III)Document7 pagesSynthesis of Potassium Tris (Oxalato) Ferrate (III)Timothy Tan83% (36)

- HydroprocessingDocument18 pagesHydroprocessinghala mrayanNo ratings yet

- Chemistry Notes 7 DIAGRAMSDocument9 pagesChemistry Notes 7 DIAGRAMSvravisankarNo ratings yet

- DPT ProcedureDocument3 pagesDPT ProcedureAmit HasanNo ratings yet

- Concrete Bridge Code 2014 - 6Document124 pagesConcrete Bridge Code 2014 - 6Anonymous YHcvra8Xw693% (15)

- ISI 7272 Labour OutputDocument9 pagesISI 7272 Labour Outputniraj rai100% (2)

- DIB Testing & Commissioning BOQ Schedule BuildingDocument1 pageDIB Testing & Commissioning BOQ Schedule BuildingArmaghan ShahidNo ratings yet

- Aromaticdiazocom031270mbp PDFDocument463 pagesAromaticdiazocom031270mbp PDFSatriya Baskara PutraNo ratings yet

- Thesis Huifei JinDocument170 pagesThesis Huifei Jintaufiqishak09No ratings yet

- TechnicalDocument71 pagesTechnicalPelayanan AnggotaNo ratings yet

- Design and Validation of Bellows As Per EJMA-FEA (White Paper) PDFDocument5 pagesDesign and Validation of Bellows As Per EJMA-FEA (White Paper) PDFJaveed A. KhanNo ratings yet

- Catalogo Graphenano Dental Octubre 2018 - en WebDocument16 pagesCatalogo Graphenano Dental Octubre 2018 - en WebAndrew ThomsonNo ratings yet

- Gr. 7 Science LM (Q1 To 4) PDFDocument270 pagesGr. 7 Science LM (Q1 To 4) PDFMary Jane84% (45)

- Jiang - 21: Et AlDocument4 pagesJiang - 21: Et AlvisvisvisvisNo ratings yet

- Piping Material Classes GuideDocument98 pagesPiping Material Classes GuideLuis Pottozen VillanuevaNo ratings yet

- STGB 7 H 60 DFDocument25 pagesSTGB 7 H 60 DFFernando MadeiraNo ratings yet

- Sika Ferrogard 901: Corrosion Inhibiting Liquid AdmixtureDocument0 pagesSika Ferrogard 901: Corrosion Inhibiting Liquid AdmixtureGeorges Abi SaadNo ratings yet

- STC FittingDocument32 pagesSTC Fittingdj22500No ratings yet

- 17.0 Hydroxy CompoundsDocument19 pages17.0 Hydroxy CompoundsKudzayi TusaumweNo ratings yet