Professional Documents

Culture Documents

c3f3 1

Uploaded by

Chandra MohanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

c3f3 1

Uploaded by

Chandra MohanCopyright:

Available Formats

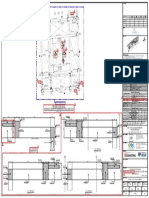

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Project data

Project name C3F3-1

Project number TRA-EXT-CAL-GR-GEN-00090

Author CHECK FOR PLATE

Description

Date 09/06/2019

Design code EN

Material

Steel S 235, S275

Concrete C25/30, C40/50

05/08/2019 15:57:56 PM 1/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

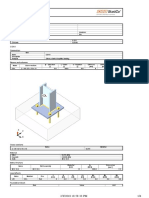

Project item CON1

Design

Name CON1

Description

Analysis Stress, strain/ simplified loading

Beams and columns

β – Direction γ - Pitch α - Rotation Offset ex Offset ey Offset ez

Name Cross-section

[°] [°] [°] [mm] [mm] [mm]

M1 3 - CHS21.3/3.2 90.0 0.0 0.0 90 -60 55

M2 3 - CHS21.3/3.2 -90.0 0.0 0.0 0 60 55

05/08/2019 15:57:56 PM 2/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

05/08/2019 15:57:56 PM 3/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Cross-sections

Name Material

3 - CHS21.3/3.2 S 235

3 - CHS21.3/3.2 S 235

05/08/2019 15:57:56 PM 4/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Cross-sections

Name Material Drawing

3 - CHS21.3/3.2 S 235

3 - CHS21.3/3.2 S 235

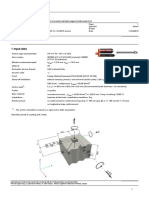

Anchors

Diameter fu Gross area

Name Bolt assembly

[mm] [MPa] [mm2]

M12 8.8 M12 8.8 12 800.0 113

Load effects (equilibrium not required)

X N Vy Vz Mx My Mz

Name Member Pos.

[mm] [kN] [kN] [kN] [kNm] [kNm] [kNm]

LE1 M1 End 0 -6.4 -0.3 -4.0 0.0 0.0 0.0

M2 End 0 -6.4 0.3 -4.0 0.0 0.0 0.0

Foundation block

Item Value Unit

CB 1

Dimensions 420 x 390 mm

Depth 150 mm

Anchor M12 8.8

Anchoring length 100 mm

Shear force transfer Anchors

Check

Summary

Name Value Check status

Analysis 100.0% OK

05/08/2019 15:57:56 PM 5/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Name Value Check status

Plates 0.0 < 5% OK

Anchors 2.7 < 100% OK

Welds 17.4 < 100% OK

Concrete block 7.3 < 100% OK

Buckling Not calculated

Plates

Thickness σEd εPl

Name Material Loads Check status

[mm] [MPa] [1e-4]

M1 S 235 3.2 LE1 235.0 0.8 OK

M2 S 235 3.2 LE1 235.0 0.6 OK

SP1 S275 12.0 LE1 106.5 0.0 OK

SP2 S275 12.0 LE1 87.8 0.0 OK

SP3 S275 12.0 LE1 83.4 0.0 OK

Design data

fy εlim

Material

[MPa] [1e-4]

S 235 235.0 500.0

S275 265.0 500.0

Overall check, LE1

05/08/2019 15:57:56 PM 6/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Strain check, LE1

Equivalent stress, LE1

Anchors

05/08/2019 15:57:56 PM 7/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Ft,Ed V Nrdc Utt Fb,Rd Uts VRd,cp VRd,c

Name Loads Cpf Cef Status

[kN] [kN] [kN] [%] [kN] [%] [kN] [kN]

A1 LE1 0.0 0.3 0.0 0.0 73.7 2.4 41.9 OK 19.2 OK OK

A2 LE1 0.0 0.3 0.0 0.0 123.8 2.7 41.9 OK 19.2 OK OK

Design data

Ft,Rd Bp,Rd Fv,Rd Vrds Stf

Name

[kN] [kN] [kN] [kN] [MN/m]

M12 8.8 - 1 41.1 155.6 26.9 11.8 247

Detailed result for A1

NRk,c

NRd,c = γc ⋅γinst = 0.0 kN

where:

γc = 1.50

γinst = 1.20

0 Ac,N

NRk,c = NRk,c ⋅ 0

Ac,N ⋅ ψs,N ⋅ ψre,N ⋅ ψec,N = 0.0 kN

where:

Ac,N = 0 mm2 Actual area of concrete cone

A0c,N = 0 mm 2

Area of concrete of an individual anchor with large spacing

0

NRk,c = 50.9 kN Characteristic resistance of an anchor placed in cracked concrete

ψs,N = 1.00 Factor of distribution of stresses in the concrete

ψre,N = 1.00 Shell spalling factor

ψec,N = 1.00 Group effect factor

Pull-out failure and splitting failure modes should be guaranteed by a manufacturer

VRk,s

VRd,s = γMS = 11.8 kN

where:

γMS = 1.25 Safety factor

αM ⋅MRk,s

VRk,s = l = 14.8 kN

where:

αM = 2.00

MRk,s = 0.2 kNm

l = 22 mm Lever arm

V

VRd,cp = γRk,cp

MC

= 41.9 kN

VRk,cp = k ⋅ NRk,c = 62.8 kN

where:

NRk,c = 31.4 kN Resistance of an anchor placed in concrete. All anchors in group

k = 2.00 Factor from ETAG 5.2.3.3

γMC = 1.50 Safety factor

05/08/2019 15:57:56 PM 8/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

VRk,c

VRd,c = γMC = 19.2 kN

where:

γMC = 1.50 Safety factor

0 Ac,V

VRk,c = VRk,c ⋅ 0

Ac,V ⋅ ψs,V ⋅ ψh,V ⋅ ψα,V ⋅ ψec,V ⋅ ψre,V = 28.9 kN

where:

0

VRk,c = 43.8 kN Initial value of the characteristic resistance of an anchor

Ac,V = 68625 mm 2

Actual area of concrete cone of anchorage

A0c,V = 137813 mm2 Area of concrete cone of an individual anchor

ψs,V = 1.00 Factor of the distribution of stresses

ψh,V = 1.32 Factor of the decrease of shear resistance

ψα,V = 1.00 Factor of the angle between the load direction and concrete edge

ψec,V = 1.00 Factor of group effect

ψre,V = 1.00 Factor of the type of reinforcement

hef = 100 mm Depth of embedment

Utts = (βN )α + (βV )α = 0.4 %

where:

βN = 0.00 Ratio between design action and design resistance for tension

βV = 0.02 Ratio between design action and design resistance for shear

α = 1.50

Ft,Ed

Utt = min(Ft,Rd ;Bp,Rd ,NRd,c ) = 0.0 %

VEd

Uts = min(Fv,Rd ;Fb,Rd ) = 2.4 %

ck2 fub As

Ft,Rd = γM 2 = 41.1 kN

where:

c = 0.85 Factor

k2 = 0.90 Factor

fub = 800.0 MPa Ultimate tensile strength of the bolt

As = 84 mm2 Tensile stress area of the bolt

γM2 = 1.25 Safety factor

0.6πdm tp fu

Bp,Rd = γM2 = 155.6 kN

where:

dm = 20 mm The mean of the across points and across flats dimensions of the bolt head or the nut, whichever is smaller

tp = 12 mm Thickness

fu = 430.0 MPa Ultimate strength

γM2 = 1.25 Safety factor

05/08/2019 15:57:56 PM 9/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

k1 ab fu dt

Fb,Rd = γM2 = 73.7 kN

where:

k1 = 2.50

ab = 0.60 Factor

fu = 430.0 MPa Ultimate strength

d = 12 mm Nominal diameter of the fastener

t = 12 mm Thickness

γM2 = 1.25 Safety factor

Detailed result for A2

NRk,c

NRd,c = γc ⋅γinst = 0.0 kN

where:

γc = 1.50

γinst = 1.20

0 Ac,N

NRk,c = NRk,c ⋅ 0

Ac,N ⋅ ψs,N ⋅ ψre,N ⋅ ψec,N = 0.0 kN

where:

Ac,N = 0 mm2 Actual area of concrete cone

A0c,N = 0 mm 2

Area of concrete of an individual anchor with large spacing

0

NRk,c = 50.9 kN Characteristic resistance of an anchor placed in cracked concrete

ψs,N = 1.00 Factor of distribution of stresses in the concrete

ψre,N = 1.00 Shell spalling factor

ψec,N = 1.00 Group effect factor

Pull-out failure and splitting failure modes should be guaranteed by a manufacturer

VRk,s

VRd,s = γMS = 11.8 kN

where:

γMS = 1.25 Safety factor

αM ⋅MRk,s

VRk,s = l = 14.8 kN

where:

αM = 2.00

MRk,s = 0.2 kNm

l = 22 mm Lever arm

V

VRd,cp = γRk,cp

MC

= 41.9 kN

VRk,cp = k ⋅ NRk,c = 62.8 kN

where:

NRk,c = 31.4 kN Resistance of an anchor placed in concrete. All anchors in group

k = 2.00 Factor from ETAG 5.2.3.3

γMC = 1.50 Safety factor

VRk,c

VRd,c = γMC = 19.2 kN

where:

γMC = 1.50 Safety factor

05/08/2019 15:57:56 PM 10/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

0 Ac,V

VRk,c = VRk,c ⋅ 0

Ac,V ⋅ ψs,V ⋅ ψh,V ⋅ ψα,V ⋅ ψec,V ⋅ ψre,V = 28.9 kN

where:

0

VRk,c = 43.8 kN Initial value of the characteristic resistance of an anchor

Ac,V = 68625 mm 2

Actual area of concrete cone of anchorage

A0c,V = 137813 mm2 Area of concrete cone of an individual anchor

ψs,V = 1.00 Factor of the distribution of stresses

ψh,V = 1.32 Factor of the decrease of shear resistance

ψα,V = 1.00 Factor of the angle between the load direction and concrete edge

ψec,V = 1.00 Factor of group effect

ψre,V = 1.00 Factor of the type of reinforcement

hef = 100 mm Depth of embedment

Utts = (βN )α + (βV )α = 0.4 %

where:

βN = 0.00 Ratio between design action and design resistance for tension

βV = 0.03 Ratio between design action and design resistance for shear

α = 1.50

Ft,Ed

Utt = min(Ft,Rd ;Bp,Rd ,NRd,c ) = 0.0 %

VEd

Uts = min(Fv,Rd ;Fb,Rd ) = 2.7 %

ck2 fub As

Ft,Rd = γM 2 = 41.1 kN

where:

c = 0.85 Factor

k2 = 0.90 Factor

fub = 800.0 MPa Ultimate tensile strength of the bolt

As = 84 mm2 Tensile stress area of the bolt

γM2 = 1.25 Safety factor

0.6πdm tp fu

Bp,Rd = γM2 = 155.6 kN

where:

dm = 20 mm The mean of the across points and across flats dimensions of the bolt head or the nut, whichever is smaller

tp = 12 mm Thickness

fu = 430.0 MPa Ultimate strength

γM2 = 1.25 Safety factor

k1 ab fu dt

Fb,Rd = γM2 = 123.8 kN

where:

k1 = 2.50

ab = 1.00 Factor

fu = 430.0 MPa Ultimate strength

d = 12 mm Nominal diameter of the fastener

t = 12 mm Thickness

γM2 = 1.25 Safety factor

Welds (Plastic redistribution)

05/08/2019 15:57:56 PM 11/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Throat th. Length σw,Ed εPl σ⏊ τ|| τ⏊ Ut Utc

Item Edge Loads Status

[mm] [mm] [MPa] [%] [MPa] [MPa] [MPa] [%] [%]

SP1 SP2 12.0 120 LE1 OK

SP1 SP3 ◢4.0◣ 120 LE1 67.4 0.0 -42.7 5.5 -29.6 16.7 13.4 OK

◢4.0◣ 120 LE1 48.2 0.0 33.2 -2.2 -20.0 11.9 10.6 OK

SP3 M1 ◢4.0 57 LE1 63.4 0.0 -28.4 26.0 19.9 15.7 12.4 OK

SP2 M2 ◢4.0 57 LE1 70.2 0.0 -28.3 -29.8 22.1 17.4 12.9 OK

Design data

βw σw,Rd 0.9 σ

[-] [MPa] [MPa]

S275 0.85 404.7 309.6

Detailed result for SP1 SP2

Detailed result for SP1 SP3

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 16.7 %

w,Rd σ⊥,Rd

2

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 67.4 MPa

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM2 = 1.25 Safety factor

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 11.9 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 48.2 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM2 = 1.25 Safety factor

Detailed result for SP3 M1

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 15.7 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 63.4 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM2 = 1.25 Safety factor

Detailed result for SP2 M2

σ ∣σ ∣

U T = max( σw,Ed ; ⊥ ) = 17.4 %

w,Rd σ⊥,Rd

σw,Ed = [σ⊥ + 3(τ⊥2 + τ∥2 )]0.5 = 70.2 MPa

2

σw,Rd = fu /(βw γM2 ) = 404.7 MPa

σ⊥,Rd = 0.9fu /γM2 = 309.6 MPa

where:

fu = 430.0 MPa Ultimate strength

γM2 = 1.25 Safety factor

05/08/2019 15:57:56 PM 12/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Concrete block

c Aeff σ Kj Fjd Ut

Item Loads Check status

[mm] [mm2] [MPa] [-] [MPa] [%]

CB 1 LE1 15 2544 3.9 3.00 53.6 7.3 OK

Detailed result for CB 1

U T = Fσjd = 7.3 %

σ = ANeff = 3.9 MPa

Fjd = βj kj fck /γc = 53.6 MPa

where:

N = 10.0 kN Design normal force

Aeff = 2544 mm 2

Effective area, on which the column force N is distributed

βj = 0.67

kj = 3.00 Concentration factor

fck = 40.0 MPa Characteristic compressive concrete strength

γc = 1.50 Safety factor

Buckling

Buckling analysis was not calculated.

Bill of material

Manufacturing operations

Plates Welds Length

Name Shape Nr. Bolts Nr.

[mm] [mm] [mm]

SP1 P12.0x120.0-90.0 (S275) 1 M12 8.8 2

SP2 P12.0x120.0-88.0 (S275) 1

SP3 P12.0x120.0-88.0 (S275) 1

CUT1 Fillet: a = 4.0 56.8

CUT2 Fillet: a = 4.0 56.8

Welds

Throat thickness Leg size Length

Type Material

[mm] [mm] [mm]

Bevel S275 12.0 17.0 120.0

05/08/2019 15:57:56 PM 13/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Throat thickness Leg size Length

Type Material

[mm] [mm] [mm]

Double fillet S275 4.0 5.7 120.0

Fillet S275 4.0 5.7 113.5

Anchors

Length Drill length

Name Count

[mm] [mm]

M12 8.8 122 100 2

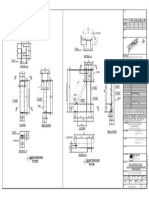

Drawing

SP1

P12.0x90-120 (S275)

05/08/2019 15:57:56 PM 14/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

SP2

P12.0x88-120 (S275)

05/08/2019 15:57:56 PM 15/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

SP3

P12.0x88-120 (S275)

Symbol explanation

Symbol Symbol explanation

εPl Strain

σEd Eq. stress

Ft,Rd Bolt tension resistance EN 1993-1-8 tab. 3.4

Bp,Rd Punching shear resistance

Ft,Ed Tension force

V Resultant of shear forces Vy, Vz in bolt.

Fv,Rd Bolt shear resistance EN_1993-1-8 table 3.4

Vrds Characteristic anchor resistance ETAG 001 Annex C (5.2.3.2)

Fb,Rd Plate bearing resistance EN 1993-1-8 tab. 3.4

Nrk,c Concrete cone breakout resistance

Utt Utilization in tension

Uts Utilization in shear

Vrd,cp Concrete pry-out failure ETAG 001 Annex C (5.2.3.3)

Vrd,c Concrete edge failure ETAG 001 Annex C (5.2.3.4)

σw,Ed Equivalent stress

σw,Rd Equivalent stress resistance

σ⏊ Perpendicular stress

τ|| Shear stress parallel to weld axis

τ⏊ Shear stress perpendicular to weld axis

0.9 σw,Rd Perpendicular stress resistance - 0.9*fu/γM2

05/08/2019 15:57:56 PM 16/24

Project: C3F3-1

Project no: TRA-EXT-CAL-GR-GEN-00090

Author: CHECK FOR PLATE

Symbol Symbol explanation

βw Corelation factor EN 1993-1-8 tab. 4.1

Ut Utilization

Utc Weld capacity utilization

Aeff Effective area

σ Average stress in concrete

Code settings

Item Value Unit Reference

γM0 1.00 - EN 1993-1-1: 6.1

γM1 1.00 - EN 1993-1-1: 6.1

γM2 1.25 - EN 1993-1-1: 6.1

γM3 1.25 - EN 1993-1-8: 2.2

γC 1.50 - EN 1992-1-1: 2.4.2.4

γInst 1.20 - ETAG 001-C: 3.2.1

Joint coefficient βj 0.67 - EN 1993-1-8: 6.2.5

Effective area - influence of mesh size 0.10 -

Friction coefficient - concrete 0.25 - EN 1993-1-8

Friction coefficient in slip-resistance 0.30 - EN 1993-1-8 tab 3.7

Limit plastic strain 0.05 - EN 1993-1-5

Weld stress evaluation Plastic redistribution

Detailing No

Distance between bolts [d] 2.20 - EN 1993-1-8: tab 3.3

Distance between bolts and edge [d] 1.20 - EN 1993-1-8: tab 3.3

Concrete cone breakout resistance Yes ETAG 001-C

Use calculated αb in bearing check. Yes EN 1993-1-8: tab 3.4

05/08/2019 15:57:56 PM 17/24

05/08/2019 15:57:56 PM 18/24

05/08/2019 15:57:56 PM 19/24

05/08/2019 15:57:56 PM 20/24

05/08/2019 15:57:56 PM 21/24

05/08/2019 15:57:56 PM 22/24

05/08/2019 15:57:56 PM 23/24

05/08/2019 15:57:56 PM 24/24

You might also like

- Design of Steel Structures To EurocodesDocument627 pagesDesign of Steel Structures To Eurocodestekla gom-lua group100% (4)

- Cladding Details PDFDocument144 pagesCladding Details PDFzaki_th00880% (5)

- Dynamic Bearing Capacity of Shallow FoundationDocument31 pagesDynamic Bearing Capacity of Shallow FoundationLingeswarran NumbikannuNo ratings yet

- 8fc63d2f f6Document18 pages8fc63d2f f6Chandra MohanNo ratings yet

- 2cdf5ddc 08Document13 pages2cdf5ddc 08Chandra MohanNo ratings yet

- Check Baseplate and Weld Thicknesses for Steel StructureDocument19 pagesCheck Baseplate and Weld Thicknesses for Steel StructureChandra MohanNo ratings yet

- C1 PanelDocument24 pagesC1 PanelChandra MohanNo ratings yet

- Beam To BeamDocument6 pagesBeam To BeamShaikh ImranNo ratings yet

- Andalusia Canopy Design AnalysisDocument30 pagesAndalusia Canopy Design AnalysisMoustafaNo ratings yet

- Connection - IDEA StatiCa PDFDocument18 pagesConnection - IDEA StatiCa PDFDaniel TuerosNo ratings yet

- Steel connection design check summaryDocument18 pagesSteel connection design check summaryDaniel TuerosNo ratings yet

- Base PlateDocument6 pagesBase PlateShaikh ImranNo ratings yet

- Project Data: Project Name: Project Number Author Description Date 04-09-2023 Design Code AISC 360-16Document29 pagesProject Data: Project Name: Project Number Author Description Date 04-09-2023 Design Code AISC 360-16Pruthviraj JuniNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument23 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Project DataDocument11 pagesProject DataAbdullah NajjarNo ratings yet

- Steel structure design projectDocument16 pagesSteel structure design projectprojelerharunNo ratings yet

- Base PlateDocument15 pagesBase PlateHSY79No ratings yet

- North South Pipe Rack Tee Post DesignDocument30 pagesNorth South Pipe Rack Tee Post DesignPruthviraj JuniNo ratings yet

- Project Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Document49 pagesProject Data: Project Name Project Number Author Description Date 11/23/2020 Design Code AISC 360-16Abdullah NajjarNo ratings yet

- Project DataDocument23 pagesProject DataAbdul basithNo ratings yet

- Yes 1Document56 pagesYes 1Frank Appiah-KusiNo ratings yet

- 03.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument16 pages03.1 - Inclined Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- 50NB TUBLER CONNECTIONDocument11 pages50NB TUBLER CONNECTIONDass MNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument25 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1BHL6PNMMMVATF7Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1BHL6PNMMMVATF7Anonymous 6R10dB2RNNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument14 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Base PlateDocument6 pagesBase PlateLangit BumiNo ratings yet

- B237 Option1 (20 10 2022)Document41 pagesB237 Option1 (20 10 2022)Abdullah AhamedNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument13 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Sambungan Atap Dan BaseplateDocument36 pagesSambungan Atap Dan Baseplatedinal031No ratings yet

- Con 1Document28 pagesCon 1SaifullahNo ratings yet

- Base Plate02Document12 pagesBase Plate02HSY79No ratings yet

- Project Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16Document21 pagesProject Data: Project Name Project Number Author Description Date 26-Dec-23 Design Code AISC 360-16kheang amgNo ratings yet

- Project Data: Project Name Project Number Author Description Date 10/23/2021 Design Code AISC 360-16Document7 pagesProject Data: Project Name Project Number Author Description Date 10/23/2021 Design Code AISC 360-16Ahsan KhanNo ratings yet

- Project design data and analysisDocument3 pagesProject design data and analysisfilipbarisic4No ratings yet

- Sambungan Atap 2Document6 pagesSambungan Atap 2dinal031No ratings yet

- Material: DesignDocument26 pagesMaterial: DesignDavor IlicNo ratings yet

- BracingDocument5 pagesBracingإبراهيم طلعتNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-08 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-08 Column Section DesignAlpha ScimathNo ratings yet

- 01 PDFDocument2 pages01 PDFAlpha ScimathNo ratings yet

- Project Data: Project Name Kamc Project Number Author Description Date 10/13/2021 Design Code AISC 360-16Document27 pagesProject Data: Project Name Kamc Project Number Author Description Date 10/13/2021 Design Code AISC 360-16MoustafaNo ratings yet

- Project Data: DesignDocument18 pagesProject Data: DesignEmina HSNo ratings yet

- Project Data: MaterialDocument4 pagesProject Data: MaterialsravanNo ratings yet

- Project data and design of steel structureDocument12 pagesProject data and design of steel structureHSY79No ratings yet

- Weld ClaculationDocument6 pagesWeld ClaculationUdhaya sankarNo ratings yet

- Rabia7 Base 28.02 EmbedDocument7 pagesRabia7 Base 28.02 EmbedvengadNo ratings yet

- SHS250 SHS200 To ConcBeam Rev01 Alter 021122Document104 pagesSHS250 SHS200 To ConcBeam Rev01 Alter 021122HongducBuiNo ratings yet

- BASEPLATEDocument8 pagesBASEPLATEfrancis sebastian lagamayoNo ratings yet

- Project Item CON: DesignDocument6 pagesProject Item CON: Designkheang amgNo ratings yet

- RAM Connection - Report12.8Document8 pagesRAM Connection - Report12.8ahmed fathiNo ratings yet

- 03.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C VerificationDocument17 pages03.2 - Horizontal Member For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- Base Plate With ShearDocument7 pagesBase Plate With ShearAman VossNo ratings yet

- Stub - temelj Т portalDocument15 pagesStub - temelj Т portalBobanNo ratings yet

- 03.4 - Connection of Purlin For Supporting of Grating Between Grid 03 and 2C VerificationDocument13 pages03.4 - Connection of Purlin For Supporting of Grating Between Grid 03 and 2C Verificationkheang amgNo ratings yet

- Sambungan Atap 1Document6 pagesSambungan Atap 1dinal031No ratings yet

- Jack Portal ConnectionDocument24 pagesJack Portal ConnectionAfsal JhNo ratings yet

- Project: Project No: AuthorDocument31 pagesProject: Project No: Authorabdullah_23320666No ratings yet

- Connection Type - 4Document10 pagesConnection Type - 4Abdul basithNo ratings yet

- Conn 1Document5 pagesConn 1إبراهيم طلعتNo ratings yet

- Project Data: Project Name Project Number Author Description Date 6/11/2020 Design Code ENDocument12 pagesProject Data: Project Name Project Number Author Description Date 6/11/2020 Design Code ENWaqar FaziNo ratings yet

- ETABS 2016 column design summaryDocument2 pagesETABS 2016 column design summaryjccajamarcaNo ratings yet

- Project: PIPE RACK - 9 Connections DesignDocument16 pagesProject: PIPE RACK - 9 Connections DesignAbdul basithNo ratings yet

- Tra Ext Qor GR HS6 00090Document4 pagesTra Ext Qor GR HS6 00090Chandra MohanNo ratings yet

- En Midas Design Catalog LowDocument6 pagesEn Midas Design Catalog LowArnoldoAyalaSalamancaNo ratings yet

- Tra Ext Qor GR RS5 00077 00 - 2Document5 pagesTra Ext Qor GR RS5 00077 00 - 2Chandra MohanNo ratings yet

- Material submittal review and variation proceduresDocument5 pagesMaterial submittal review and variation proceduresChandra MohanNo ratings yet

- Tra Ext Qor GR RB5 00084Document1 pageTra Ext Qor GR RB5 00084Chandra MohanNo ratings yet

- Elegent Resume Design in Ms Word 2019Document3 pagesElegent Resume Design in Ms Word 2019Chandra MohanNo ratings yet

- Drafts - EXT-CTI-TOW-FC-CA-0073 AnchorDocument7 pagesDrafts - EXT-CTI-TOW-FC-CA-0073 AnchorChandra MohanNo ratings yet

- Sick Leave CertificateDocument1 pageSick Leave CertificateChandra MohanNo ratings yet

- RS7 Pro STD 001Document1 pageRS7 Pro STD 001Chandra MohanNo ratings yet

- Program Download Link PDFDocument1 pageProgram Download Link PDFChandra MohanNo ratings yet

- Sick Leave CertificateDocument1 pageSick Leave CertificateChandra MohanNo ratings yet

- Status-B Approved With Comments:-: 1-The Proposed System Is Subject To Architectural and Shop Drawings ApprovalsDocument60 pagesStatus-B Approved With Comments:-: 1-The Proposed System Is Subject To Architectural and Shop Drawings ApprovalsChandra MohanNo ratings yet

- PowerPadSampleOutput PDFDocument56 pagesPowerPadSampleOutput PDFChandra MohanNo ratings yet

- Tra Ext Pla GR Gen 00002 00Document1 pageTra Ext Pla GR Gen 00002 00Chandra MohanNo ratings yet

- Znm-Int-st-ss-mual-sdw-113419 (r00) b01 - SHT 5 - Seismic & Normal Support DetailsDocument1 pageZnm-Int-st-ss-mual-sdw-113419 (r00) b01 - SHT 5 - Seismic & Normal Support DetailsChandra MohanNo ratings yet

- AnvrrgrgwerherherherherehDocument55 pagesAnvrrgrgwerherherherherehChandra MohanNo ratings yet

- Program Download Link PDFDocument1 pageProgram Download Link PDFChandra MohanNo ratings yet

- Amr Rashad: EducationDocument3 pagesAmr Rashad: EducationChandra MohanNo ratings yet

- Ysd P02 0208 Ar SJF CD F0005 BDocument47 pagesYsd P02 0208 Ar SJF CD F0005 BChandra MohanNo ratings yet

- ASCE7‐10 Components & Cladding Wind Load ProvisionsDocument83 pagesASCE7‐10 Components & Cladding Wind Load ProvisionsGonzalo Rodriguez GuzmanNo ratings yet

- 01-A32!00!35 - Residential Porte CochereDocument1 page01-A32!00!35 - Residential Porte CochereChandra MohanNo ratings yet

- Base Plate Templete - BP4-ADocument153 pagesBase Plate Templete - BP4-AChandra MohanNo ratings yet

- C3-C4b - Open NCR's As of 30th September 2019Document12 pagesC3-C4b - Open NCR's As of 30th September 2019Chandra MohanNo ratings yet

- Second Floor Level Residence Drop Off Concrete Structure PlanDocument1 pageSecond Floor Level Residence Drop Off Concrete Structure PlanChandra MohanNo ratings yet

- EC3 GB - WeldingDocument7 pagesEC3 GB - WeldingRancor82No ratings yet

- Idea Statica Connection: Theoretical BackgroundDocument52 pagesIdea Statica Connection: Theoretical BackgroundChandra MohanNo ratings yet

- Chapter 2. COST IDocument8 pagesChapter 2. COST IyebegashetNo ratings yet

- Sbi KukkatpallyDocument2 pagesSbi KukkatpallyRavi Babu KonkatiNo ratings yet

- (Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Document3 pages(Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Hoai Ngoc NguyenNo ratings yet

- Improving PerformanceDocument2 pagesImproving PerformanceYidne MasreshaNo ratings yet

- Easy Eight's Battleground World War II Normandy NightmareDocument97 pagesEasy Eight's Battleground World War II Normandy NightmareAdolfo JoseNo ratings yet

- Complicaciones en La Tracción Ortodóntica Del Canino Superior Izquierdo. Retratamiento.Document7 pagesComplicaciones en La Tracción Ortodóntica Del Canino Superior Izquierdo. Retratamiento.Miltonfcc100% (1)

- Nouveau Document TexteDocument6 pagesNouveau Document Texteamal mallouliNo ratings yet

- Island Arc: LocationDocument7 pagesIsland Arc: LocationBlessing NgonidzasheNo ratings yet

- Jurnal SinusitisDocument49 pagesJurnal SinusitisAramanda Dian100% (1)

- Knowledge (2) Comprehension (3) Application (4) Analysis (5) Synthesis (6) EvaluationDocument5 pagesKnowledge (2) Comprehension (3) Application (4) Analysis (5) Synthesis (6) EvaluationxtinNo ratings yet

- 2020 FMGT 1013 - Financial Management RevisedDocument9 pages2020 FMGT 1013 - Financial Management RevisedYANIII12345No ratings yet

- Barcelona Conferences Abstracts December 2016Document82 pagesBarcelona Conferences Abstracts December 2016Bahadır AkbalNo ratings yet

- Tecnolatinas en PDF 170116Document45 pagesTecnolatinas en PDF 170116AaronUrdanetaNo ratings yet

- Application of CFD To Debottleneck Production SepaDocument14 pagesApplication of CFD To Debottleneck Production SepaFernando AmoresNo ratings yet

- School Canteen Satisfaction Survey ResultsDocument2 pagesSchool Canteen Satisfaction Survey ResultsElla PastorinNo ratings yet

- Epimastic 7200: Product DescriptionDocument2 pagesEpimastic 7200: Product DescriptionSu KaNo ratings yet

- Weak Downlink Data for Multiple TRX Indices Over TimeDocument3,643 pagesWeak Downlink Data for Multiple TRX Indices Over TimeSK Basak BDNo ratings yet

- ISC 2023 English Language Question PaperDocument5 pagesISC 2023 English Language Question PaperMohit JoshiNo ratings yet

- CPO Science Foundations of Physics: Unit 7, Chapter 24Document47 pagesCPO Science Foundations of Physics: Unit 7, Chapter 24dheerajbhagwatNo ratings yet

- DCM300E Clamp Meter Measures Earth Leakage CurrentDocument2 pagesDCM300E Clamp Meter Measures Earth Leakage CurrentKatamba RogersNo ratings yet

- MVC PaperDocument14 pagesMVC PaperManal MkNo ratings yet

- Bindura University of Science Education March - August 2015 Admissions PDFDocument12 pagesBindura University of Science Education March - August 2015 Admissions PDFLuke MadzikotoNo ratings yet

- ADVANCED ANALOG IC DESIGN Lab ManualDocument27 pagesADVANCED ANALOG IC DESIGN Lab ManualJahnavi Ratnam0% (1)

- Specialty Fibers: Select SheetDocument4 pagesSpecialty Fibers: Select SheetсергейNo ratings yet

- HypertensionDocument26 pagesHypertensionAbdalrhman Zaqqa100% (1)

- Quiz 10Document6 pagesQuiz 10Kath RiveraNo ratings yet

- 2.1 Conditional Logic: Ladder ProgrammingDocument10 pages2.1 Conditional Logic: Ladder ProgrammingLuka NikitovicNo ratings yet

- Troubleshooting Guide: Multifunctional Digital SystemsDocument132 pagesTroubleshooting Guide: Multifunctional Digital SystemsnguyenhieuproNo ratings yet

- Spread footing design calculationDocument6 pagesSpread footing design calculationFrancklinMeunierM'ondoNo ratings yet