Professional Documents

Culture Documents

Bituminous Prime Coat PDF

Uploaded by

Muhammad ArifOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bituminous Prime Coat PDF

Uploaded by

Muhammad ArifCopyright:

Available Formats

VOLUME 3 TECHNICAL SPECIFICATIONS

DIVISION 3 – PAVEMENT WORKS

3.6 BITUMINOUS PRIME COAT

3.6.1 Description

This work shall consist of the careful cleaning of the surface to be primed and

furnishing and applying bituminous material in accordance with these Specifications to

the area shown on the Drawings or as directed by the Engineer.

3.6.2 Materials

3.6.2.1 Bituminous Materials

Bituminous material shall be a MC 30 or MC 70 cut back bitumen and shall conform to

the requirements of Section 3.4. The bituminous material shall be approved by the

Engineer and may be prepared by cutting back 80/100 penetration bitumen with

kerosene in the ratio of 100 parts by volume of bitumen to 40 – 60 parts by volume of

kerosene depending on the porosity of the surface.

3.6.2.2 Blotting Material

Blotting material shall be approved clean dry sand or stone screenings free from any

cohesive materials or organic matter. Not more than 10 per cent of the sand shall be

finer than the 75 micron sieve.

3.6.3 Construction Methods

3.6.3.1 Weather Limitations

Prime coat shall be applied at a time when the surface to be treated is dry or slightly

damp, when the ambient temperature is above 13ºC and rising, or above 16ºC if

falling, and when the weather is dry.

3.6.3.2 Equipment

The Engineer may approve Construction equipment and methods (including labour

intensive methods) other than those specified hereinafter provided that the contractor

can demonstrate his ability to carry out the work to a satisfactory standard using his

proposed equipment and methods to the complete satisfaction of the Engineer. Such

approval shall be in writing and may be withdrawn at any time if the work is found to

be unsatisfactory in any respect.

The equipment used by the Contractor shall include, unless otherwise approved by

the Engineer, a power brush, a pressure bituminous distributor, and, when necessary,

equipment for heating bituminous material.

The distributor shall have pneumatic tyres and shall be so designed, equipped,

maintained and operated that bituminous material at constant temperature may be

applied uniformly on variable widths of surface up to 4 metres at readily determined

and controlled rates of from 0.2 to 2.0 litres per square metre with uniform pressure,

and with an allowable variation from any specified rate not to exceed 0.1 litre per

square metre. Distribution equipment shall include an instrument for measuring the

speed of travel accurately at low speeds, and the temperature of the contents of the

tank.

The spray bar on the distributor shall be controlled by a man riding at the rear of the

distributor in such a position that operation of all sprays is in his full view.

MAY 2001 Page

3.29

VOLUME 3 TECHNICAL SPECIFICATIONS

DIVISION 3 – PAVEMENT WORKS

The tanks of distributors shall be fitted with accurately calibrated dipsticks or contents

gauges.

All measuring equipment on the distributor shall have been recently calibrated and an

accurate and satisfactory record of such calibration shall be supplied to the Engineer.

If, after beginning the work, the distribution of bituminous material is found to be in

error, the distributor shall be withdrawn from the work and calibrated to the

satisfaction of the Engineer before any further work is undertaken.

The Engineer may require such tests, as he considers necessary to check the

performance of the distributor. As and when directed by the Engineer, the Contractor,

at his own expense, shall make the distributor and its equipment available for field

testing and shall supply any assistance required for this purpose. Any distributor,

which does not operate satisfactorily or conform to the requirements of the

Specifications in all respects, may be rejected by the Engineer for further use on the

Works.

3.6.3.3 Cleaning Surface

Immediately before applying the bituminous material, all loose dirt and other

objectionable material shall be removed from the surface with a power brush. When

so ordered by the Engineer, a light application of water shall be made just before the

application of bituminous material.

3.6.3.4 Application of Bituminous Material

Bituminous material shall be applied at the rate, or rates, either shown in the Contract

Documents or as directed by the Engineer. The rate sprayed can be verified using

STP 10.12. This will usually be from 1.0 to 2.5 litres per square metre, and at a

temperature within the range called for in Table 3.4-6 for the particular material being

used. Any prescribed application shall be divided into two applications when

necessary to prevent bitumen flowing off the surface, and additional bituminous

material shall be applied where surface conditions indicate it to be necessary, if the

Engineer so directs. No further courses shall be applied until the prime coat has dried

and the solvent evaporated.

When so directed, the prime coat shall be applied in lanes of approximately one-half

or less of the width of the completed surface. A lane of prime coat shall be applied,

allowed to penetrate for not less than 48 hours, then covered with blotting material if

required, and opened to traffic before bituminous material is applied to the adjacent

lane. In covering the first primed lane, a strip at least 200 mm wide shall be left

uncovered where it joins the second traffic lane to permit an overlap of the bituminous

material.

The surface of structures and trees adjacent to the areas being treated shall be

protected in such manner as to prevent their being splashed or damaged. No

bituminous material shall be discharged into a borrow pit or gutter.

3.6.3.5 Maintenance and Opening to Traffic

Traffic shall not be permitted on the primed surface until the material has penetrated

and dried and, in the opinion of the Engineer, will not be picked up by traffic. Where

the Engineer deems it impracticable to detour traffic, the Contractor shall spread the

minimum quantity as determined by the Engineer, of blotting material necessary to

avoid picking up, and traffic shall be allowed to use areas so treated. Any areas

containing an excess or deficiency of priming material shall be corrected by the

addition of sand or bitumen as directed by the Engineer. Such corrections of faulty

work shall be carried out at the Contractor’s expense.

MAY 2001 Page

3.30

VOLUME 3 TECHNICAL SPECIFICATIONS

DIVISION 3 – PAVEMENT WORKS

3.6.4Measurement

The quantity of bituminous material shall be measured for payment in square metres;

however, in the case of plant placed materials a record of the number of Litres of

bituminous material placed will also be kept.

The measured quantity shall be the theoretical required to comply with the Contract,

or shall be the quantity used and accepted. This should be within ± 5% of the

theoretical quantity unless there is a change in the area of coverage.

3.6.5 Payment

This work measured as provided above, shall be paid for at the Contract unit price

per unit of measurement. The prices and payment shall be full compensation for

preparation of the surface and furnishing and placing the materials and application of

blotting materials including all labour, equipment, tools and incidentals necessary to

complete the work prescribed in this Section.

Pay item shall be:

3/6/1 Bituminous Prime Coat (plant placed) Square Metre

or

3/6/1 Bituminous Prime Coat (hand placed) Square Metre

MAY 2001 Page

3.31

You might also like

- Highway RehabilitationDocument31 pagesHighway Rehabilitationketh patrickNo ratings yet

- Is 1514 1990 PDFDocument18 pagesIs 1514 1990 PDFDwijendra ChanumoluNo ratings yet

- Invoice Cum Material Issue Voucher: Miv No. CWC No. CWC Date: Sap Material Document No. Posting DateDocument1 pageInvoice Cum Material Issue Voucher: Miv No. CWC No. CWC Date: Sap Material Document No. Posting Datehimanshu kalraNo ratings yet

- Blasting and Painting ProcedureDocument6 pagesBlasting and Painting Procedureanon_994898767No ratings yet

- Stumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportDocument1 pageStumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportRajkumar KantiwalNo ratings yet

- Astm D4759Document7 pagesAstm D4759EfrilaNo ratings yet

- Concrete Work 1. Standard and Codes of PracticeDocument28 pagesConcrete Work 1. Standard and Codes of PracticeArka ShahRilNo ratings yet

- IS 2185 Part1 2005Document1 pageIS 2185 Part1 2005stoneghoo2618No ratings yet

- EIDS 054 Cafco FENDOLITE MII - Controlling Consistency and Wet Density PDFDocument3 pagesEIDS 054 Cafco FENDOLITE MII - Controlling Consistency and Wet Density PDFcuc nangNo ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- Procedure For Liquid Penetrant ExaminationDocument12 pagesProcedure For Liquid Penetrant ExaminationShashank ParmarNo ratings yet

- Surface Preparation Repair May 2020Document6 pagesSurface Preparation Repair May 2020Mel AnieNo ratings yet

- PipingDocument8 pagesPipingRajkumar ANo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- A223 6 44 0074Document15 pagesA223 6 44 0074mishtinilNo ratings yet

- Water Soluble Penetrant Test ProcedureDocument7 pagesWater Soluble Penetrant Test ProcedureTahseen Ahmed100% (1)

- SH 7-83-Soil Suitability For Earthworks-MCV PDFDocument53 pagesSH 7-83-Soil Suitability For Earthworks-MCV PDFADF3000No ratings yet

- Al-Jazeera Epo-Rich Primer12 PDFDocument2 pagesAl-Jazeera Epo-Rich Primer12 PDFAmer Y K100% (1)

- Blasting PaintingDocument3 pagesBlasting PaintingAthirah AkhmaNo ratings yet

- Contractor IOT Infrastructure & Energy Services LTDDocument38 pagesContractor IOT Infrastructure & Energy Services LTDNaveen KurupNo ratings yet

- Micrasil TDSDocument2 pagesMicrasil TDSAmmarNo ratings yet

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- ASTM D4541 and ISO 4624: ?/sup InstrumentsDocument2 pagesASTM D4541 and ISO 4624: ?/sup InstrumentsTeguh SilaNo ratings yet

- Sand Content - Mud TestingDocument1 pageSand Content - Mud TestingYougchu Luan100% (2)

- Apron Concrete Repair Method R01Document19 pagesApron Concrete Repair Method R01ayhanarmanNo ratings yet

- Italian-Thai Density Test ResultsDocument9 pagesItalian-Thai Density Test ResultsJovanni RodriguezNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- Mastic Asphalt Laying ChecklistDocument1 pageMastic Asphalt Laying ChecklistRayudu VVSNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedNo ratings yet

- Gabion Wall Installation GuideDocument5 pagesGabion Wall Installation GuideJoel KomaNo ratings yet

- D. Specs For Field & Shop PaintingDocument10 pagesD. Specs For Field & Shop PaintingrajeshNo ratings yet

- Concresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarDocument4 pagesConcresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarFrancois-No ratings yet

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinNo ratings yet

- Sieve Analysis and Materials Finer Than 75 μm (No. 200) by WashingDocument24 pagesSieve Analysis and Materials Finer Than 75 μm (No. 200) by Washingalsami67No ratings yet

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- NCR Flow Chart: Inspector QC EngineerDocument1 pageNCR Flow Chart: Inspector QC Engineerrty2No ratings yet

- Daily structural concrete reportDocument2 pagesDaily structural concrete reportAli RazaNo ratings yet

- Precast Concrete Manhole Installation GuidelinesDocument68 pagesPrecast Concrete Manhole Installation GuidelinesAhmadNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetajuhaseenNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Surface Preparation & Paint Inspection ReportDocument2 pagesSurface Preparation & Paint Inspection ReportFatih DemircanNo ratings yet

- EmbankmentDocument5 pagesEmbankmentAmila Priyadarshana Dissanayake100% (1)

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDocument14 pagesMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliNo ratings yet

- Non-Destructive Testing RequirementsDocument7 pagesNon-Destructive Testing RequirementsWill SmithNo ratings yet

- ASTM D2104-03 Tubo de Plástico de PE, Cédula 40Document7 pagesASTM D2104-03 Tubo de Plástico de PE, Cédula 40Marlon TurnerNo ratings yet

- Method Statement Asphalt PavingDocument3 pagesMethod Statement Asphalt PavingHussam WaleedNo ratings yet

- 04 - TDS - Concresive 2200Document3 pages04 - TDS - Concresive 2200aahtagoNo ratings yet

- Aggregate Impact ValueDocument5 pagesAggregate Impact Valueonline researchNo ratings yet

- After How Much Time Concrete Should Be RejectedDocument7 pagesAfter How Much Time Concrete Should Be RejectedDEBOPRASAD BISWAS100% (1)

- Painting ReportDocument1 pagePainting Reportbaidu1980No ratings yet

- Corrective and Preventive Action On High Rejection RateDocument1 pageCorrective and Preventive Action On High Rejection RateRakeshNo ratings yet

- ASSHTODocument3 pagesASSHTOmiguelangelNo ratings yet

- BOLT Torquing ReportDocument4 pagesBOLT Torquing ReportSumith Kumar S MNo ratings yet

- Msbte Concrete Lab Manual-9021Document13 pagesMsbte Concrete Lab Manual-9021Mohammed Faiz67% (3)

- Hamburg Wheel Track Test Requirements NCHRP - w219Document88 pagesHamburg Wheel Track Test Requirements NCHRP - w219Max Cedeño De LeónNo ratings yet

- Bituminous Tack Coat SpecsDocument2 pagesBituminous Tack Coat SpecsshawonscribdNo ratings yet

- Section 02610 - Prime CoatDocument26 pagesSection 02610 - Prime Coatmail3shenNo ratings yet

- ٽيون وجود - امر جليل PDFDocument164 pagesٽيون وجود - امر جليل PDFMuhammad Arif0% (1)

- Astm d790 PDFDocument11 pagesAstm d790 PDFMuhammad ArifNo ratings yet

- D 6 - 95 R00 RdyDocument3 pagesD 6 - 95 R00 RdyJosé Ramón GutierrezNo ratings yet

- Prospectus 2021Document242 pagesProspectus 2021Sufyan MaharNo ratings yet

- Ch2part2 PDFDocument98 pagesCh2part2 PDFনীল জোছনাNo ratings yet

- J - Acid Sulfate Soil Borehole LogsDocument7 pagesJ - Acid Sulfate Soil Borehole LogsRoshan MalhotraNo ratings yet

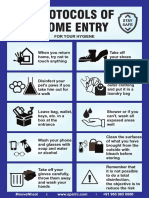

- Protocols For Your Hygiene PDFDocument3 pagesProtocols For Your Hygiene PDFHoussam ChNo ratings yet

- Komposisi Standar Semen PutihDocument104 pagesKomposisi Standar Semen PutihmichelleNo ratings yet

- MIX Proportioning: Designing Concrete MixturesDocument18 pagesMIX Proportioning: Designing Concrete MixturesSmookers HeavenNo ratings yet

- Field Sampling and Testing Manual Section 400 Bituminous PavementsDocument56 pagesField Sampling and Testing Manual Section 400 Bituminous PavementsFaruk AtalarNo ratings yet

- Company Profile: PLE InternationalDocument28 pagesCompany Profile: PLE InternationalMuhammad ArifNo ratings yet

- HM 33 Table of ContentsDocument59 pagesHM 33 Table of Contentsoscort027No ratings yet

- جيئن جيئن پرين پسن - نور احمد ميمڻ PDFDocument200 pagesجيئن جيئن پرين پسن - نور احمد ميمڻ PDFChirbat Raja SameNo ratings yet

- Developing a Conceptual Framework for Construction Constraint ManagementDocument3 pagesDeveloping a Conceptual Framework for Construction Constraint ManagementramszlaiNo ratings yet

- Bituminous Prime Coat PDFDocument3 pagesBituminous Prime Coat PDFMuhammad ArifNo ratings yet

- Setting Up and Managing A Test Lab: Ruth@keys-Consult - deDocument11 pagesSetting Up and Managing A Test Lab: Ruth@keys-Consult - deNaqiNaziruddinNo ratings yet

- 14.3332013AtterbergLimitsData BlankDocument2 pages14.3332013AtterbergLimitsData BlankMuhammad ArifNo ratings yet

- Bs Steel CodeDocument14 pagesBs Steel CodeA.K.A. HajiNo ratings yet

- Theoretical Maximum Specific Gravity (G) and Density of Hot Mix Asphalt (Hma) Paving Mixtures Fop For Aashto T 209 ScopeDocument10 pagesTheoretical Maximum Specific Gravity (G) and Density of Hot Mix Asphalt (Hma) Paving Mixtures Fop For Aashto T 209 ScopeAshish Walia100% (1)

- Tube 2018 MAKLADA SA Paper Witu2018.2565651 3qbMLicwQLavC11TAtb5gwDocument7 pagesTube 2018 MAKLADA SA Paper Witu2018.2565651 3qbMLicwQLavC11TAtb5gwMuhammad ArifNo ratings yet

- The Importance of Earth Loop ImpedanceDocument4 pagesThe Importance of Earth Loop ImpedanceKarim Amer100% (1)

- Tempt Me, Marry MeDocument832 pagesTempt Me, Marry MeCharlotte Selin BautistaNo ratings yet

- Hydraulic Fluids in Mobile Application Re98128 - 2015-06 - Online PDFDocument13 pagesHydraulic Fluids in Mobile Application Re98128 - 2015-06 - Online PDFDennis Huanuco CcamaNo ratings yet

- AmoniacoDocument2 pagesAmoniacoAlejandra Morales0% (1)

- Theories of AgingDocument6 pagesTheories of AgingBamba FloresNo ratings yet

- Bio-Diesel Production From Waste Cooking OilDocument51 pagesBio-Diesel Production From Waste Cooking OilDemostenes DeceoNo ratings yet

- Astm E1973 - 1 (En)Document4 pagesAstm E1973 - 1 (En)Dinesh SaiNo ratings yet

- 2.2.5 Respiration WorksheetDocument7 pages2.2.5 Respiration WorksheeterikabeltranNo ratings yet

- Journey by Night EssayDocument2 pagesJourney by Night Essaystillwakingsleep100% (2)

- Gang Violence in Jamaica: Causes, Effects and SolutionsDocument20 pagesGang Violence in Jamaica: Causes, Effects and SolutionsRicardoMoody50% (2)

- Math ProjectDocument18 pagesMath ProjectChar LotteNo ratings yet

- Pharmacy CUM L IIIDocument78 pagesPharmacy CUM L IIIashagrie100% (1)

- 1Document7 pages1mmNo ratings yet

- Procedures For Analysis of Citrus Products PDFDocument193 pagesProcedures For Analysis of Citrus Products PDFluis100% (2)

- GPAT Pharmaceutical Chemistry SyllabusDocument4 pagesGPAT Pharmaceutical Chemistry Syllabuskumar HarshNo ratings yet

- Psychosocial Support Activity Pack PSAP FINAL - 20211123Document108 pagesPsychosocial Support Activity Pack PSAP FINAL - 20211123Ruben HatamosaNo ratings yet

- CALIMOVEDocument46 pagesCALIMOVERasheedAladdinNGuiomala0% (1)

- En - Ineos Bichlor ElectrolyserDocument8 pagesEn - Ineos Bichlor Electrolyserbarun1977No ratings yet

- CattabrigaF45 90 120Document21 pagesCattabrigaF45 90 120Fernando William Rivera CuadrosNo ratings yet

- Design calculations for 5 ton capacity steel tankDocument26 pagesDesign calculations for 5 ton capacity steel tankhgagselim2012No ratings yet

- TDS - Zettex MS Polymer 72 - ENDocument2 pagesTDS - Zettex MS Polymer 72 - ENsasidharkanthetiNo ratings yet

- KalasarpaDosha RemedyDocument28 pagesKalasarpaDosha RemedyAnita Kadavergu100% (1)

- Hvac Ducting System - BoqDocument6 pagesHvac Ducting System - BoqBeò FhathastNo ratings yet

- Maritime Business Environment AssignmentDocument4 pagesMaritime Business Environment AssignmentsivaNo ratings yet

- Appendix 6Document4 pagesAppendix 6Vlad OlariuNo ratings yet

- SAMSUNG LCD Service Manual (Internal) - ES15UDocument81 pagesSAMSUNG LCD Service Manual (Internal) - ES15Umeng798651No ratings yet

- Continuity of Education in the New NormalDocument2 pagesContinuity of Education in the New NormalMon Agulto LomedaNo ratings yet

- Thuja's Effectiveness Against SmallpoxDocument361 pagesThuja's Effectiveness Against SmallpoxFrank NavaNo ratings yet

- Interstate Standard: Gost 10444.1-84Document17 pagesInterstate Standard: Gost 10444.1-84giannina cabanillas100% (1)

- Final Duct Wraps Brochure 98-0213-4600-6rrDocument8 pagesFinal Duct Wraps Brochure 98-0213-4600-6rrDiego Armando Martinez GutierrezNo ratings yet