Professional Documents

Culture Documents

Bituminous Tack Coat Specs

Uploaded by

shawonscribdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bituminous Tack Coat Specs

Uploaded by

shawonscribdCopyright:

Available Formats

VOLUME 3 TECHNICAL SPECIFICATIONS

DIVISION 3 – PAVEMENT WORKS

3.7 BITUMINOUS TACK COAT

3.7.1 Description

This work shall consist of furnishing and applying bituminous material to a previously

prepared roadbed, in accordance with the Specifications and to the width and area

required by the Engineer.

3.7.2 Materials

Bituminous material shall be either cut back bitumen RC 30, RC 70, or rapid setting

emulsion conforming to the requirements of Section 3.4 of these Specifications. The

bituminous material shall be approved by the Engineer.

3.7.3 Construction Methods

3.7.3.1 Equipment

The Engineer may approve Construction equipment and methods (including labour

intensive methods) other than those specified hereinafter provided that the contractor

can demonstrate his ability to carry out the work to a satisfactory standard using his

proposed equipment and methods to the complete satisfaction of the Engineer. Such

approval shall be in writing and may be withdrawn at any time if the work is found to

be unsatisfactory in any respect. The equipment shall be as specified in Section 3.6,

Bituminous Prime Coat.

3.7.3.2 Cleaning Surface

The full width of surface to be treated shall be cleaned with a power brush to remove

loose dirt, sand, dust and other objectionable material. The surface to be treated

shall be dry.

3.7.3.3 Application of Bituminous Material

Immediately after cleaning the surface, bituminous material shall be applied at the

rate directed by the Engineer, but not to exceed 0.45 litres per square metre and at

the temperature within the range included in Table 3.4-6 for the particular material

being used. The tack coat shall be applied only when the surface is dry.

The tack coat material shall be uniformly distributed over the surface without

streaking. Quantities shall not deviate more than 10% from the quantity prescribed by

the Engineer. Quantities outside the specified tolerances shall be adjusted by the

Contractor at his own expense, to the satisfaction of the Engineer.

The surfaces of structures and trees adjacent to the areas being treated shall be

protected in such manner as to prevent their being splashed or damaged. No

bituminous material shall be discharged into a borrow pit or gutter. The Engineer may

direct that emulsions shall be diluted with clean water in order to control the rate of

spread. This shall be done at the Contractor’s expense.

After the tack coat is applied the Contractor shall protect it from damage until the

surface course is placed. No surfacing layer will be permitted to be placed unless the

tack coat is in a satisfactory condition to receive it and as such the tack coat shall be

applied only so far in advance of surface course placement as is necessary for this to

occur.

MAY 2001 Page

3.32

VOLUME 3 TECHNICAL SPECIFICATIONS

DIVISION 3 – PAVEMENT WORKS

3.7.4 Measurement

The quantity of bituminous material shall be measured for payment in square metres;

however, in the case of plant placed materials a record of the number of Litres of

bituminous material placed will also be kept.

The measured quantity shall be the theoretical required to comply with the Contract,

or shall be the quantity used and accepted. This should be within ± 5% of the

theoretical quantity unless there is a change in the area of coverage.

3.7.5 Payment

This work measured as provided above, shall be paid for at the Contract price per

unit of measurement. The prices and payment shall be full compensation for

furnishing and placing the materials, including all labour, equipment, tools and

incidental necessary to complete the work.

Pay item shall be:

3/7/1 Bituminous Tack Coat (plant work) Square Metre

or

3/7/1 Bituminous Tack Coat (labour intensive work) Square Metre

MAY 2001 Page

3.33

You might also like

- Bituminous Prime Coat PDFDocument3 pagesBituminous Prime Coat PDFMuhammad ArifNo ratings yet

- Section 6. SpecificationsDocument3 pagesSection 6. SpecificationsENGGNo ratings yet

- Highway RehabilitationDocument31 pagesHighway Rehabilitationketh patrickNo ratings yet

- Maintain RoadDocument11 pagesMaintain RoadSarmistha Patowary100% (1)

- Bituminous Surface TreatmentDocument7 pagesBituminous Surface TreatmentSenol KarakayaliNo ratings yet

- Item P-603 Bituminous Tack CoatDocument4 pagesItem P-603 Bituminous Tack CoatMunarwand AhmadNo ratings yet

- Section 02610 - Prime CoatDocument26 pagesSection 02610 - Prime Coatmail3shenNo ratings yet

- 5sec.500 (Base & Surface Courses)Document92 pages5sec.500 (Base & Surface Courses)pankaj_mbmNo ratings yet

- Jatigede Dam Technical SpecificationsDocument14 pagesJatigede Dam Technical SpecificationsJehan BramNo ratings yet

- Site Grading SpecsDocument5 pagesSite Grading SpecsdlloitNo ratings yet

- Bituminous Prime Coat: DescriptionDocument4 pagesBituminous Prime Coat: DescriptionHurriyat AliNo ratings yet

- 30.sec.3000 (Maintenance of Road)Document7 pages30.sec.3000 (Maintenance of Road)aalignup arc & const. pvt ltdNo ratings yet

- ITEM 300 Latest 2004Document75 pagesITEM 300 Latest 2004Avelino De Leon JrNo ratings yet

- Bituminous PavementsDocument13 pagesBituminous PavementsMahesh SuranaNo ratings yet

- DPWH Standard Specifications On Prime Coat, TackDocument8 pagesDPWH Standard Specifications On Prime Coat, TackChesterMercado100% (2)

- 01 02 00 00 48 - Part03 - Sept09Document12 pages01 02 00 00 48 - Part03 - Sept09Safi Zabihullah SafiNo ratings yet

- Tream Paper 2.8.editedDocument5 pagesTream Paper 2.8.editedPartho BasakNo ratings yet

- Bituminous Prime Coat MaterialsDocument4 pagesBituminous Prime Coat MaterialsDevrim Gürsel100% (2)

- Water Proofing SpecificationDocument7 pagesWater Proofing SpecificationjeevanNo ratings yet

- AGGREGATE SURFACE COURSE SPECIFICATIONSDocument75 pagesAGGREGATE SURFACE COURSE SPECIFICATIONSShammir Tabayag MangidaNo ratings yet

- 2021-03-12 - Special ConditionDocument11 pages2021-03-12 - Special ConditionMAULIK RAVALNo ratings yet

- Civil Engineering Document on Soil Improvement WorksDocument18 pagesCivil Engineering Document on Soil Improvement WorksTran Tien DungNo ratings yet

- Water Proofing SpecificationDocument7 pagesWater Proofing SpecificationMohamedNo ratings yet

- Integrated Gas Surface Facilities For RDG Field Project Method Statement For Road WorkDocument7 pagesIntegrated Gas Surface Facilities For RDG Field Project Method Statement For Road WorkfirozNo ratings yet

- Sub BaseDocument4 pagesSub BaseAnonymous Dk3ItoC8MFNo ratings yet

- Section 5008764275514Document99 pagesSection 5008764275514Loganathan PeriyasamiNo ratings yet

- 7 Sc&s7 RoadworkDocument5 pages7 Sc&s7 RoadworkdophongxdNo ratings yet

- Spec Structural IsgDocument98 pagesSpec Structural IsgMoath AlhajiriNo ratings yet

- Technical Specification (Roads)Document8 pagesTechnical Specification (Roads)Richard Westony100% (1)

- WMS (Method Statement For Pouring Concrete On Slab On Grade)Document4 pagesWMS (Method Statement For Pouring Concrete On Slab On Grade)PUI CHEE KHIANNo ratings yet

- Civil specifications for Cut & Bend Processing Building projectDocument10 pagesCivil specifications for Cut & Bend Processing Building projectLuis Gabriel BautistaNo ratings yet

- Method Statement - Concreting WorkDocument4 pagesMethod Statement - Concreting WorkArnold Roy ManaloNo ratings yet

- Annexure-I: Summary For Civil Works - Compound Wall Works (Sez Area)Document7 pagesAnnexure-I: Summary For Civil Works - Compound Wall Works (Sez Area)Ravi Shankar KolluruNo ratings yet

- 410 Tream Paper (Partho Bosak Sagor)Document5 pages410 Tream Paper (Partho Bosak Sagor)Partho BasakNo ratings yet

- Name of Work: Construction of 300 Gallon Vertical Mixer Building No.4 at SprobDocument53 pagesName of Work: Construction of 300 Gallon Vertical Mixer Building No.4 at SprobRavi Sobhan100% (1)

- GSKMotorways - Expressway System - Sect 3 - Sub-Base and Base CourseDocument19 pagesGSKMotorways - Expressway System - Sect 3 - Sub-Base and Base Coursemohamed samirNo ratings yet

- Appendix A - Invitation To Tender - Epoxy Flooring Subcontract WorksDocument22 pagesAppendix A - Invitation To Tender - Epoxy Flooring Subcontract WorksJay GalvanNo ratings yet

- Technical Specification Preliminaries and Preamble ClausesDocument33 pagesTechnical Specification Preliminaries and Preamble ClauseskumaravajiraNo ratings yet

- Blank BOQDocument58 pagesBlank BOQThushan Madu0% (1)

- Premix Bituminous CarpetingDocument5 pagesPremix Bituminous CarpetingNehaSharma100% (1)

- Cellular Concrete Specifications Latest On 4-13Document3 pagesCellular Concrete Specifications Latest On 4-13diracmoutinhoNo ratings yet

- A. Survey WorksDocument7 pagesA. Survey Worksugrasen chaudharyNo ratings yet

- General BoQ Cert 2Document32 pagesGeneral BoQ Cert 2Kiyimba DanielNo ratings yet

- Geotextile Fabric General SpecificationDocument3 pagesGeotextile Fabric General SpecificationjovindhaNo ratings yet

- Exh B2Document163 pagesExh B2Agus SupriadiNo ratings yet

- LAPRIL-C103 enDocument5 pagesLAPRIL-C103 enalpha NEPALNo ratings yet

- Proparation of SubgradeDocument2 pagesProparation of Subgradeemad safaaNo ratings yet

- LAPRIL-C102 enDocument7 pagesLAPRIL-C102 enalpha NEPALNo ratings yet

- SPECIFICATION FOR INSTRUMENTATION AND MONITORING OF RETAINING STRUCTURES AND EXCAVATIONDocument16 pagesSPECIFICATION FOR INSTRUMENTATION AND MONITORING OF RETAINING STRUCTURES AND EXCAVATIONMohammad Hafiz MahadzirNo ratings yet

- Method Statement For Slab On GradeDocument3 pagesMethod Statement For Slab On Grademustafa75% (4)

- Installing Concrete Surface BedDocument3 pagesInstalling Concrete Surface BedAmigowzz Hood100% (1)

- 02 Spec Guniting Works Rev20200610Document8 pages02 Spec Guniting Works Rev20200610Tony JamesNo ratings yet

- Section 8 - Reclamation Technical SpecificationDocument42 pagesSection 8 - Reclamation Technical SpecificationRocky Situmorang100% (1)

- WMS Concrete Repair WorkDocument8 pagesWMS Concrete Repair WorkRepl microsoft, PuneNo ratings yet

- Method Statment - Concrete Pour SoGDocument3 pagesMethod Statment - Concrete Pour SoGMuhammad Zafar IqbalNo ratings yet

- Blinding & Concrete Method StatementDocument5 pagesBlinding & Concrete Method Statementشاز إياسNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Lecture Mod 2Document23 pagesLecture Mod 2amlan sahuNo ratings yet

- AggregatesDocument4 pagesAggregatesSheryn MalayaNo ratings yet

- High Rise Building Fire Safety InspectionDocument28 pagesHigh Rise Building Fire Safety InspectionshawonscribdNo ratings yet

- Thumb RuleDocument13 pagesThumb RuleAtiqur RahmanNo ratings yet

- Chlorine Contact TimeDocument2 pagesChlorine Contact TimeshawonscribdNo ratings yet

- 1971 Bangladesh Liberation WarDocument2 pages1971 Bangladesh Liberation WarshawonscribdNo ratings yet

- Bangladesh Concrete CodeDocument34 pagesBangladesh Concrete CodeXaid IbrahimNo ratings yet

- Water Bidhimala 2018Document92 pagesWater Bidhimala 2018shawonscribdNo ratings yet

- Amp 16906 P 19Document14 pagesAmp 16906 P 19Hoque AnamulNo ratings yet

- FS TrainingDocument1 pageFS TrainingshawonscribdNo ratings yet

- Engineering FirmDocument5 pagesEngineering FirmshawonscribdNo ratings yet

- Dhaka Imarat Nirman Bidhimala-2008Document142 pagesDhaka Imarat Nirman Bidhimala-2008sazeda67% (3)

- 170kVA Generator Risk AssessmentDocument4 pages170kVA Generator Risk AssessmentshawonscribdNo ratings yet

- Underground Water Assessment: PNG (BD) LimitedDocument8 pagesUnderground Water Assessment: PNG (BD) LimitedshawonscribdNo ratings yet

- BRTC Test Rate - 2015-2016 - 22.11.15Document1 pageBRTC Test Rate - 2015-2016 - 22.11.15shawonscribdNo ratings yet

- PVC Pipes Price List 2017Document2 pagesPVC Pipes Price List 2017Christopher Joshua MartinezNo ratings yet

- Turbo Nozzle 95Document1 pageTurbo Nozzle 95shawonscribdNo ratings yet

- BRTC Test Rate - 2015-2016 - 22.11.15Document5 pagesBRTC Test Rate - 2015-2016 - 22.11.15Jahirul QuaimNo ratings yet

- Passport MRP Online Form Fillup InstructionDocument14 pagesPassport MRP Online Form Fillup InstructionRahmatullah RonNo ratings yet

- BCC Report Pipe Costs OH Cities Feb 25 2016Document11 pagesBCC Report Pipe Costs OH Cities Feb 25 2016shawonscribdNo ratings yet

- BRTC Test Rate - 2015-2016 - 22.11.15Document5 pagesBRTC Test Rate - 2015-2016 - 22.11.15Jahirul QuaimNo ratings yet

- Fire Alarm Design SubmissionDocument5 pagesFire Alarm Design SubmissionshawonscribdNo ratings yet

- NTPA-Guidelines Final PDFDocument116 pagesNTPA-Guidelines Final PDFshawonscribd0% (1)

- Csicjrlw PDFDocument2 pagesCsicjrlw PDFshawonscribdNo ratings yet

- 11 18 13 The Need Apparels Factory AssessmentDocument5 pages11 18 13 The Need Apparels Factory AssessmentshawonscribdNo ratings yet

- Alliance Fire Audit ReportDocument16 pagesAlliance Fire Audit ReportshawonscribdNo ratings yet

- PLC Training Class Start Notice - 4517Document1 pagePLC Training Class Start Notice - 4517shawonscribdNo ratings yet

- Mikro - Power Factor RegulatorDocument6 pagesMikro - Power Factor Regulatorshawonscribd67% (3)

- Fire Service Training Complex Admission FormDocument1 pageFire Service Training Complex Admission FormshawonscribdNo ratings yet

- Construction of Cement Concrete Pavement - Advantages, Drawbacks & JointsDocument21 pagesConstruction of Cement Concrete Pavement - Advantages, Drawbacks & JointsZahid RahmanNo ratings yet

- Safe Work ManualDocument176 pagesSafe Work ManualAsim JavedNo ratings yet

- Glo Brochure Sikagard 555 W ElasticDocument4 pagesGlo Brochure Sikagard 555 W ElasticYasndra AbeygunewardhaneNo ratings yet

- Design and Build of Six-Storey MEZ Administration Office BuildingDocument89 pagesDesign and Build of Six-Storey MEZ Administration Office BuildingKarl MoralejoNo ratings yet

- SPP 204 A Fulltime Supervision ServicesDocument3 pagesSPP 204 A Fulltime Supervision ServicesmonNo ratings yet

- CCC CompanyDocument48 pagesCCC CompanyUSERNo ratings yet

- Checklist For UPS & Accessories InstallationDocument1 pageChecklist For UPS & Accessories InstallationguspriyNo ratings yet

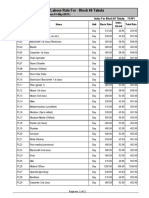

- Labour Rates Block 66Document2 pagesLabour Rates Block 66ManojNo ratings yet

- IR Unified Standard Schedule of Rates - 2021Document10 pagesIR Unified Standard Schedule of Rates - 2021Vinod KumarNo ratings yet

- Can/Csa-CSA S157-17 Strength Design in Aluminum Welding RequirementsDocument2 pagesCan/Csa-CSA S157-17 Strength Design in Aluminum Welding RequirementsChris MedeirosNo ratings yet

- Specification Estimation and ValuationDocument71 pagesSpecification Estimation and ValuationRitika RituNo ratings yet

- Nagpur Metro Rail Project S T R U C T U R E B01: Systra-Aecom-Egis-RitesDocument2 pagesNagpur Metro Rail Project S T R U C T U R E B01: Systra-Aecom-Egis-RitesAniket WaghmareNo ratings yet

- Small, Medium and Large Construction CompanyDocument21 pagesSmall, Medium and Large Construction CompanyCho ToeNo ratings yet

- Desktop Guide To Aggregate Pier Ground ImprovementDocument17 pagesDesktop Guide To Aggregate Pier Ground ImprovementJohn SeversonNo ratings yet

- Star Al Madina1pq Full SubmittalDocument45 pagesStar Al Madina1pq Full Submittalthribin sathyababuNo ratings yet

- QA-QC Work PlanDocument11 pagesQA-QC Work PlanWilliam l. Cabato100% (1)

- 0924 Part B DCHB Hardoi PDFDocument424 pages0924 Part B DCHB Hardoi PDFArushi SinghNo ratings yet

- Tile Specification Guide 2016 2017 Master Specifications PDFDocument21 pagesTile Specification Guide 2016 2017 Master Specifications PDFRoland James ArimadoNo ratings yet

- Sanli Environmental IPO ProspectusDocument282 pagesSanli Environmental IPO ProspectusTony LeongNo ratings yet

- KUORO Allan - BBLD4 Monthly Report FinalisedDocument24 pagesKUORO Allan - BBLD4 Monthly Report Finalisedallan kuoroNo ratings yet

- Project Work Presentation Phase 1-1Document19 pagesProject Work Presentation Phase 1-1Manoj NagarkondNo ratings yet

- ch.5 Pile Foundations-GeneralDocument4 pagesch.5 Pile Foundations-GeneralManuela Orrego CardonaNo ratings yet

- Providing BIM Management for Alveo CERCA PHASE 3 ProjectDocument4 pagesProviding BIM Management for Alveo CERCA PHASE 3 ProjectBEN CLADONo ratings yet

- Awadhy The GreatDocument19 pagesAwadhy The GreatAwadhiNo ratings yet

- MOS For RoofingDocument4 pagesMOS For RoofingYe YintNo ratings yet

- Persimmon Ar18Document152 pagesPersimmon Ar18Srividhya GirishNo ratings yet

- Ecoply Bracing EP2 Specification Tech Note April 2016Document2 pagesEcoply Bracing EP2 Specification Tech Note April 2016郭骥No ratings yet

- CVX4446 SynopsisDocument3 pagesCVX4446 SynopsisHansika RuwanthiNo ratings yet

- Standard Operating Procedure: Indus Pharma (PVT.) LTDDocument4 pagesStandard Operating Procedure: Indus Pharma (PVT.) LTDUmair ShekhaniNo ratings yet

- Case Study: Comparative Analysis of Larsen & Toubro Ltd. With Its Peers & IndustryDocument14 pagesCase Study: Comparative Analysis of Larsen & Toubro Ltd. With Its Peers & IndustrySALONI JaiswalNo ratings yet