Professional Documents

Culture Documents

R15 REGULAR Manufacturing Technology MAY-JUNE 2017 PDF

R15 REGULAR Manufacturing Technology MAY-JUNE 2017 PDF

Uploaded by

Ramu AmaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R15 REGULAR Manufacturing Technology MAY-JUNE 2017 PDF

R15 REGULAR Manufacturing Technology MAY-JUNE 2017 PDF

Uploaded by

Ramu AmaraCopyright:

Available Formats

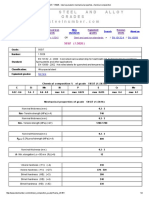

Code: 15A03404

R15

B.Tech II Year II Semester (R15) Regular Examinations May/June 2017

MANUFACTURING TECHNOLOGY

(Mechanical Engineering)

Time: 3 hours Max. Marks: 70

PART – A

(Compulsory Question)

*****

1 Answer the following: (10 X 02 = 20 Marks)

(a) Write the requirements of moulding sand.

(b) Differentiate the terms ‘mould’ and ‘core’.

(c) List the merits and demerits of investment casting.

(d) Name any four types of casting defects.

(e) Give two basic types of AW electrodes.

(f) Write the types of flames in oxy-acetylene gas welding.

(g) List any four applications of TIG welding.

(h) Define brazing process.

(i) Write a short note on surface treatment process.

(j) Give the applications of surface treatment process.

PART – B

(Answer all five units, 5 X 10 = 50 Marks)

UNIT – I

2 Define mould. Explain any two types of mould making process with a neat sketch.

OR

3 Explain the factors which govern the selection of a proper material for pattern making.

UNIT – II

4 Describe investment casting in detail.

OR

5 Elaborate cupola furnace with a neat sketch and list its merits.

UNIT – III

6 Illustrate plasma welding process with a neat sketch.

OR

7 Explain Oxy-Acetylene gas welding process with proper sketch and list its applications.

UNIT – IV

8 Describe laser welding with a neat sketch.

OR

9 List and explain the various types of welding defects.

UNIT – V

10 Explain any two types of surface treatment process.

OR

11 Illustrate diffusion coating process with proper justification.

*****

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 9-Haz, Welding Defecs, Causes and RemdiesDocument24 pages9-Haz, Welding Defecs, Causes and RemdiesRamu Amara100% (1)

- WC-514 - Weld Discontinuities PDFDocument1 pageWC-514 - Weld Discontinuities PDFNathanLaertePiaiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- North Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5Document3 pagesNorth Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5farshid KarpasandNo ratings yet

- Check List PaintingDocument4 pagesCheck List PaintingYash Sharma100% (3)

- Soldering & Brazing: Unit-IvDocument15 pagesSoldering & Brazing: Unit-IvRamu AmaraNo ratings yet

- 4-Gas WeldingDocument23 pages4-Gas WeldingRamu AmaraNo ratings yet

- 10 - Destructive and Non-Destructive Tests Os WeldsDocument20 pages10 - Destructive and Non-Destructive Tests Os WeldsRamu Amara0% (1)

- 1.4-Core, Types of Cores, Core Box, Core PrintsDocument39 pages1.4-Core, Types of Cores, Core Box, Core PrintsRamu AmaraNo ratings yet

- A Comprehensive Guide To Heat Treatment Vol2 - NotesDocument533 pagesA Comprehensive Guide To Heat Treatment Vol2 - NotesRonnie SakaiNo ratings yet

- Adhesives Sealants FOR Panel AssemblyDocument2 pagesAdhesives Sealants FOR Panel AssemblyBhushan VermaNo ratings yet

- Stress-Strain Relations: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsDocument23 pagesStress-Strain Relations: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsRamu AmaraNo ratings yet

- Manufacturing Processes: Prepared BY A.RamanajaneyuluDocument25 pagesManufacturing Processes: Prepared BY A.RamanajaneyuluRamu AmaraNo ratings yet

- 1.2-Introduction To CastingDocument11 pages1.2-Introduction To CastingRamu AmaraNo ratings yet

- 1.4 Stress-Strain Diagram For Mild SteelDocument20 pages1.4 Stress-Strain Diagram For Mild SteelRamu Amara100% (1)

- 3-Design of Welded JointsDocument9 pages3-Design of Welded JointsRamu AmaraNo ratings yet

- Stresses and Strains: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsDocument23 pagesStresses and Strains: Class-Ii-Ii Sem Branch-Mechanical Subject: Echanics F AterialsRamu AmaraNo ratings yet

- 1.5 - GATING SYSTEM, RequirementsDocument38 pages1.5 - GATING SYSTEM, RequirementsRamu AmaraNo ratings yet

- Mechanics of Materials: Class-Ii-Ii Sem Branch-MechanicalDocument13 pagesMechanics of Materials: Class-Ii-Ii Sem Branch-MechanicalRamu AmaraNo ratings yet

- Oxy-Acetylene Cutting: Unit-Iii (B)Document18 pagesOxy-Acetylene Cutting: Unit-Iii (B)Ramu AmaraNo ratings yet

- 8-Thermit WeldingDocument21 pages8-Thermit WeldingRamu AmaraNo ratings yet

- Plasma Arc Welding: Unit-IiiDocument32 pagesPlasma Arc Welding: Unit-IiiRamu AmaraNo ratings yet

- Water Jet Cutting: Unit-Iii (B)Document12 pagesWater Jet Cutting: Unit-Iii (B)Ramu AmaraNo ratings yet

- 2-Mig Welding MFTDocument28 pages2-Mig Welding MFTRamu AmaraNo ratings yet

- 12-Plasma Arc CuttingDocument9 pages12-Plasma Arc CuttingRamu AmaraNo ratings yet

- 3-Friction Welding MFTDocument14 pages3-Friction Welding MFTRamu AmaraNo ratings yet

- 6,7-Forge Welding, Resistance WeldingDocument13 pages6,7-Forge Welding, Resistance WeldingRamu AmaraNo ratings yet

- 5-Explosion WeldingDocument13 pages5-Explosion WeldingRamu AmaraNo ratings yet

- 4 - Induction Welding MFTDocument10 pages4 - Induction Welding MFTRamu AmaraNo ratings yet

- Objective: On The Completion of This Period, You Would Able To KnowDocument23 pagesObjective: On The Completion of This Period, You Would Able To KnowRamu AmaraNo ratings yet

- Objectives: On Completion of This Period, You Would Be Able To KnowDocument26 pagesObjectives: On Completion of This Period, You Would Be Able To KnowRamu AmaraNo ratings yet

- 8-Adhesive BondingDocument13 pages8-Adhesive BondingRamu Amara100% (1)

- 6-Laser Beam Welding MFTDocument11 pages6-Laser Beam Welding MFTRamu AmaraNo ratings yet

- AssignmentDocument1 pageAssignmentRamu AmaraNo ratings yet

- Objectives:: On The Completion of This Period, You Would Be Able To KnowDocument17 pagesObjectives:: On The Completion of This Period, You Would Be Able To KnowRamu AmaraNo ratings yet

- Basics of GrindingDocument15 pagesBasics of Grindingmaulikgadara100% (1)

- Corrosion Control of Reinforcement BarsDocument6 pagesCorrosion Control of Reinforcement BarsBhaskar ReddyNo ratings yet

- Processing of Ceramics, Glass, and SuperconductorsDocument17 pagesProcessing of Ceramics, Glass, and SuperconductorsQuốc HoàngNo ratings yet

- Premier Engineering Industries: List of WPS/PQRDocument1 pagePremier Engineering Industries: List of WPS/PQRBalkishan DyavanapellyNo ratings yet

- Components and Assemblies: Explaining and Assessing Manufacturing TechniquesDocument5 pagesComponents and Assemblies: Explaining and Assessing Manufacturing TechniquesOsmar AlíNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4 EN 10089farshid KarpasandNo ratings yet

- Article Xiv Brazing Data: QB-400 VariablesDocument26 pagesArticle Xiv Brazing Data: QB-400 VariablesCarlinho TipianmNo ratings yet

- Mastershield Coatings Guide For SURFACE PREPARATION - ODcwMDDocument18 pagesMastershield Coatings Guide For SURFACE PREPARATION - ODcwMDVincent LecoursNo ratings yet

- Electrode Booklet F Web 120Document1 pageElectrode Booklet F Web 120satnamNo ratings yet

- Form PenetrantDocument2 pagesForm PenetrantEko Adi PutraNo ratings yet

- Assignment No.1 SolutionDocument4 pagesAssignment No.1 SolutionHazem AhmedNo ratings yet

- Metal Coating - Marine CorossionDocument16 pagesMetal Coating - Marine CorossionSARANG saNo ratings yet

- Welding Guidelines For Section ADocument6 pagesWelding Guidelines For Section AemadabdelsattarNo ratings yet

- Paints and VarnishesDocument10 pagesPaints and VarnishesSwapna PandeNo ratings yet

- Manufacturing Engineering: Basics of Manufacturing EngineeringDocument3 pagesManufacturing Engineering: Basics of Manufacturing EngineeringPrincess GinezNo ratings yet

- COMPILATION OF QUIZ WorkshopDocument15 pagesCOMPILATION OF QUIZ WorkshopCamille RazalanNo ratings yet

- Non Traditional Method IntroductionDocument7 pagesNon Traditional Method IntroductionAjay KumarNo ratings yet

- Fabrication of Multi-Axis Welding Robot With Grinding Machine (Phase 1)Document15 pagesFabrication of Multi-Axis Welding Robot With Grinding Machine (Phase 1)bhuvaneshNo ratings yet

- Full Time MBA Brochure - Melbourne Business SchoolDocument19 pagesFull Time MBA Brochure - Melbourne Business Schoolvishnupremnair02No ratings yet

- Kalp Chap 27 Advanced Machining ProcessesDocument40 pagesKalp Chap 27 Advanced Machining ProcessesJohan NicholasNo ratings yet

- GDA Aluminium in The Packaging IndustryDocument13 pagesGDA Aluminium in The Packaging IndustryDuy PhamNo ratings yet

- Solidification Process (Metal Casting: Expendable Mold Casting: Sand Casting)Document29 pagesSolidification Process (Metal Casting: Expendable Mold Casting: Sand Casting)The NoobNo ratings yet

- Chemical Processes: Engr. Concordia C. Bacalso M. Eng'g (Education)Document21 pagesChemical Processes: Engr. Concordia C. Bacalso M. Eng'g (Education)Ivan AlcomendrasNo ratings yet

- E92 M3 Clutch ServiceDocument52 pagesE92 M3 Clutch ServiceJonas Alberto Ochoa CastilloNo ratings yet

- SERVO Cut S - PDSDocument1 pageSERVO Cut S - PDSVENKATNo ratings yet