Professional Documents

Culture Documents

New Modular Gasoline Engine VW

Uploaded by

Pranav SatputeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Modular Gasoline Engine VW

Uploaded by

Pranav SatputeCopyright:

Available Formats

C O V E R S T O R Y GASOLINE ENGINE

NEW MODULAR GASOLINE ENGINE

PLATFORM FROM VOLKSWAGEN

Volkswagen has developed a new generation of three- and four-cylinder in-line gasoline engines. The new en-

gine family, known internally as EA211, has been produced to meet the requirements of the new modular trans-

verse platform design from the Volkswagen Group. In comparison with previous generations, the new engines

will be more compact and up to 30 % lighter in weight. In addition, their fuel consumption will be between 10

and 20 % lower.

24 www.autotechreview.com

24-31_New Modular Gasoline Engine Platform_VW_ATR_Feb'13.indd 24 01-02-2013 17:55:15

AUTHORS

MOTIVATION BASIC ARCHITECTURE

The development of the new engine gen- In order to make full use of the synergy

eration, internally labelled EA211, is potential presented by the modular trans-

closely integrated with the construction of verse platform, the decision was taken to

the Volkswagen Group’s new modular standardise the base engine architecture

transverse platform (MQB in German). within the vehicle. Installation orientation

DR.-ING. RÜDIGER SZENGEL

is Head of Development Gasoline

The MQB covers the A0, A and B passen- plays a major role here. Previously, the

engines at Volkswagen AG in Wolfsburg ger car segments for all brands of Volk- gasoline engines from the EA111 range

(Germany). swagen AG. All of them make use of were tilted forwards with their exhaust

standardised components and modules. side facing towards the radiator. In con-

A major motivating factor for the trast, all other engines, including the die-

development of the modular transverse sel engines, labelled TDI, were tilted back-

platform and thus the new EA211 engine wards with their hot side facing towards

range was the Volkswagen drive and fuel the rear, ➊.

strategy. Its primary aim is the significant Changing the installation orientation

DR.-ING. HERMANN MIDDENDORF reduction of fuel consumption. The group for the EA211 engines presented signifi-

is Head of Development EA111/EA211

Gasoline engines at Volkswagen AG in

already reacted some years ago to this cant challenges. On the one hand, it

Wolfsburg (Germany). demand with its Blue Motion Technology called for the redesign of the engine

strategy. It is within this context that the peripherals such as cooling and exhaust

decision was made to replace the proven system and, on the other, for changeover

EA111 engine range and the TSI engines throughout the Volkswagen Group facto-

based on it with a new design bearing the ries worldwide. However, the new layout

reference EA211. The following objectives delivers substantial synergies, including

were formulated in the design the application of a universal engine/

DIPL.-ING. NIELS MÖLLER specification: transmission flange.

is Technical Project Manager EA211 at :: modular construction to facilitate pro- A further, important objective in the

Volkswagen AG in Wolfsburg (Germany).

duction worldwide, standardisation of development of the EA211 was the com-

installation orientation with other pact layout of the auxiliary units. The air

group engines conditioning compressor and the genera-

:: compact construction in order to real- tor on the new TSI are fixed directly to the

ise short front overhangs on the oil sump and the engine block respec-

vehicle tively without additional supports. In

:: reduction of engine weight by up to order to achieve such a compact layout

DIPL.-ING. HANS BENNECKE

is Test engineer Mechanical Testing 30 % and to run it with a simple toothed belt

EA211 at Volkswagen AG in Wolfsburg :: reduction of fuel consumption and CO2 arrangement, the water pump was posi-

(Germany). emissions by 10 to 20 % fulfilment of tioned on the clutch side of the engine on

the future Euro VI emission standard. the front face of the cylinder head. It is

➊ Unified powertrain-assembly position in the modular transverse platform (MQB)

autotechreview Fe b r u ar y 2 013 Vo lu m e 2 | Is su e 2 25

24-31_New Modular Gasoline Engine Platform_VW_ATR_Feb'13.indd 25 01-02-2013 17:55:19

C O V E R S T O R Y GASOLINE ENGINE

NEDC, the fuel consumption of the engine

has been reduced by 0.4 l/100 km, equat-

ing to a drop in CO2 emissions of 8 g/km.

At moderate speeds in city traffic, as well

as cross-country, savings of between 10

and 20 % are possible.

THE NEW ENGINE PLATFORM

Common characteristics of all engines in

the EA211 range are:

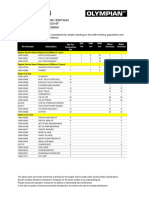

➋ The new EA211 range (top) and engine data for the EA211 TSI platform (bottom) :: four-valve technology

:: aluminium crankcase

1.2-l 1.2-l 1.4-l 1.4-l 1.4-l 110 kw

:: exhaust manifold integrated into the

63 kw TSI 77 kw TSI 90 kw TSI 103 kw TSI TSI HYBRID

cylinder head

TORQUE 160 Nm at 175 Nm at 200 Nm at 250 Nm at 250 Nm at

1400 rpm 1400 rpm 1400 rpm 1500 rpm 1500 rpm :: camshaft drive via toothed belt.

NOM. ENGINE 4800 rpm 5000 rpm 5000 rpm 5000 rpm 5000 rpm The new platform has already celebrated

SPEED its premiere in the Volkswagen model

DISPLACEMENT 1197 cm3 1197 cm3 1395 cm3 1395 cm3 1395 cm3 up! in the shape of the three-cylinder

gasoline engine with a displacement of

BORE 71 mm 71 mm 74.5 mm 74.5 mm 74.5 mm

999 cc and manifold injection. The core

STROKE 75.6 mm 75.6 mm 80 mm 80 mm 80 mm

of the new engine family, however, is

formed by the small, powerful and frugal

COMPRESSION 10.5 10.5 10.5 10.5 10.5 four-cylinder TSI engines with 1.2 l and

RATIO

1.4 l displacements.

FUEL RON95 RON95 RON95 RON95 US / “regular” All engines from the EA211 platform

ENGINE WEIGHT 97 kg

share cylinder spacing of 82 mm. The

97 kg 104 kg 106 kg 93 kg

ideal stroke/bore ratio was selected for

each displacement taking into account

thermodynamics, acoustics and perfor-

driven via toothed belt by the camshaft. developed from a topological standpoint. mance. The most desirable characteristics

As a consequence of the new mount- The respective requirements for cool- are derived from a long-stroke layout. In

ing position tilted 12° rearward and the ing and lubrication were calculated by the case of the 1.2 l engine, bore/stroke is

compact layout of the EA211 engines, means of simulation and testing. The cir- set at 71.0 mm/75.6 mm and, for the 1.4 l

the installed length is shortened by 50 culation of oil and coolant was de-throt- engine, at 74.5 mm/80.0 mm.

mm, equating to 18 % compared with tled with the help of CFD calculations. The spectrum of the new TSI family

the previous engines. In the MQB, this initially covers the well-known perfor-

means the front axle can be positioned mance range of the Volkswagen line-up –

40 mm further forward. The front over- 1.4 L ENGINE WITH ACTIVE CYLIN- it begins with 63 kW and extends to 110

hangs are thus shortened, benefiting DER MANAGEMENT kW for the engine used in the hybrid

impact characteristics, exterior design driveline, ➋. Alongside the TSI engines,

and axle load distribution. The 1.4 l TSI engine with 103 kW in a four-cylinder MPI (multi point injection)

special offer comes with a technical high- variants with 1.4 l and 1.6 l displacements

light that contributes to further reduction will also be derived from the platform for

REDUCTION OF FUEL CONSUMPTION in fuel consumption. Its valve train mod- use on global markets.

ule with active cylinder management

The reduction in fuel consumption laid (ACT) enables it to switch cylinders 2

down in the specification document – the and 3 on and off in accordance with CRANKCASE

second most important development requirements using electromagnetic actu-

objective – was achieved, on the one ators [1]. The still active cylinders 1 and 4 The crankcase of the EA211 is an ultra-

hand, through the application of new operate at a higher load point and, thus, stiff aluminium pressure die cast con-

technologies and, on the other, through more efficiently. struction with cylinder liners in GJL 250

the painstaking analysis and optimisation The 1.4 l TSI with robust ACT technol- cast iron, ➌. The cylinder liners, which

of all friction sources in the base engines. ogy proves that it is possible, within the are fluid-spray honed in four stages, are

All bearing diameters were reduced to the TSI strategy framework, to combine ambi- fixed to the crankcase using rough-surface

maximum required size, while the width tious consumption targets with high casting. The new crankcase weighs just

and surfaces of the bearings were further power output and high torque. In the 19 kg. Compared to the EA111 with 1.4 l

26 www.autotechreview.com

24-31_New Modular Gasoline Engine Platform_VW_ATR_Feb'13.indd 26 01-02-2013 17:55:20

CRANKSHAFT DRIVE AND

PISTON GROUP

Friction reduction took high priority dur-

ing the development of the EA211. One of

the most important initiatives was the

reduction of the main bearing diameter

from 54 mm on the EA111 to between 42

and 48 mm in the different variants across

the new engine platform. The axial loca-

tion of the con rods is handled by the big-

end bearing in order to facilitate thicker

crank arms. They compensate for the loss

➌ The new alloy crankcase in stiffness caused by the smaller bearing

diameter. The higher elastic deformation

and reduced friction deliver even crank-

displacement, which has a cast iron 120°, with the aim of increasing wear shaft acoustics.

crankcase, this marks a weight reduction resistance – particularly when it comes to As in the preceding engine, the crank-

of 16 kg. the use of alternative fuels and fuels of shaft and conrods are made from forged

Crankcase ventilation is devised as mid-range quality on global markets. The steel. By using the latest FEA and NVH

block ventilation and is conducted largely valve shaft diameter has been reduced to calculation methods, it was possible to

inside the engine. This is an extremely 5 mm to optimise the dynamics of the reduce the weight of the crankshaft by 20

robust layout because external pipe con- valve gear through lower mass and reduce %, ➎, and the weight of the conrods by

nections and transfer points are avoided friction as a result of lower valve spring up to 30 %, ➏. The conrod bearing spin-

almost entirely. In terms of cooling water force. The spark plugs have been specified dles on the crankshaft are hollow bored.

circulation, the block layout is based on with M12 threads to achieve optimum At the small-end bearing, the conrod

the proven two-circuit system from the wall-thickness between the spark plugs does not have the conventional trapezoi-

small TSI engines. Supply to the oil and valve seats. dal shape. Rather, in the forging die, a

cooler, which is screwed onto the side of Intensive finite element analysis work geometry is formed that is optimised for

the crankcase is likewise fully integrated meant that the weight of the cylinder weight in line with component loading.

within the crankcase. head increased by less than 1.2 kg, During the intake stroke, a very slim

despite its considerably more complex upper link pulls the piston downwards,

geometry. The four-valve cylinder head of as the forces at play here are relatively

CYLINDER HEAD the EA211 is produced as an aluminium low. Accordingly, the geometry for trans-

die casting at Volkswagen Group found- ferring the working pressure is more

When it came to the redesign of the cylin- ries using heat-treated AlSi10Mg(Cu) robust in its design.

der head, the focus was on intelligent alloy. The sand cores are made entirely The aluminium pistons have been

thermal management and the expanded from inorganic material using environ- completely redesigned. The piston crown

use of exhaust energy for rapid warm-up. mentally friendly methods. has a virtually flat form, as the wall-guid-

The concept of the four-valve rolling cam

follower head has been retained due to its

low friction characteristics.

The exhaust manifold is fully inte-

grated into the cylinder head, where it

forms a highly effective exhaust heat

exchanger, ➍. It is used to heat the engine

quickly during warm-up, while also pro-

viding plenty of heat for a comfortable

vehicle interior. Under full load, on the

other hand, the exhaust is cooled by

approximately 100 K, which reduces fuel

consumption by up to 2 l/100 km. Com-

pared to conventional, external manifolds,

the exhaust flow paths with an integrated

manifold are considerably shorter, main-

taining heat loss through the walls in the

transient case at an acceptable level.

The valve angle has been increased to ➍ Cylinder head with integrated exhaust manifold

autotechreview Fe b r u ar y 2 013 Vo lu m e 2 | Is su e 2 27

24-31_New Modular Gasoline Engine Platform_VW_ATR_Feb'13.indd 27 01-02-2013 17:55:20

C O V E R S T O R Y GASOLINE ENGINE

tion. Moreover, the entire cooling circuit

has been optimised for throttling losses.

EXHAUST GAS TURBOCHARGER

All versions of the EA211 feature a fully

redeveloped exhaust gas turbocharger

with a single-scroll turbine. The integra-

tion of the exhaust manifold into the cyl-

inder head and the resulting specific air-

flow characteristics represented the most

important development parameters. The

turbocharger has been specifically opti-

mised for low-end torque and good tran-

sient characteristics with well-rounded

torque curves. The 1.4 l TSI with 103 kW

➎ Development in stiffness of the weight-optimised crankshaft output, for instance, has a maximum

torque of 250 Nm available from 1,500

rpm. This marks an improvement of 25

ance for internal mix formation used in circuit. % compared with the previous engine,

previous concepts is not applied here. A further thermostat regulates the ➑. A turbocharger was conceived and

This enabled reduction of piston weight switching of the vehicle radiator. With a optimised for each of the three power

and led to more homogeneous tempera- regulated temperature of 87 °C, it repre- outputs (1.2 l TSI, 1.4 l TSI 90 kW and

tures at the piston crown. The piston sents the best possible compromise 1.4 l TSI 103/110 kW). In all derivatives,

ring package was intensively validated in between friction reduction and efficiency- the mechanism is designed for a maxi-

order to optimise friction and oil con- optimised ignition. The overall efficiency mum exhaust gas temperature of 950 °C

sumption. Installation clearance was of the coolant pump module was and is notable for its small rotor diame-

increased in order to reduce friction. increased to more than 50 %, represent- ter and accordingly low moments of iner-

This also facilitated further improve- ing an improvement of up to 40 % over tia with a high degree of efficiency.

ments to acoustics through a slightly pumps currently found in series produc- The control of the wastegate is oper-

increased piston pin offset and refined ated by a newly developed electric actua-

piston crown geometry. tor. In contrast to conventional excess

pressure control systems, the wastegate

can be adjusted to the desired setting

COOLING CIRCUIT at any time and independently from

the momentary charge pressure. The

All TSI engines in the EA211 engine new actuator functions quickly and pre-

range have a high-temperature circuit cisely, which has a positive effect on the

for engine cooling and a low tempera- acoustics of the turbocharger and on the

ture circuit for indirect charge air cool- responsiveness of the engine. The adjust-

ing, ➐. The low-temperature circuit is ment time between the two end stops is

driven via an electric coolant pump and just 110 milliseconds.

can be controlled completely flexibly in The interface between the turbo-

line with requirements. In trailing throt- charger and the engine periphery is

tle conditions, it also provides cooling identical in all cases, allowing the use

for the turbocharger. of the same cylinder heads, exhaust

Engine cooling is handled by the systems and oil and coolant

high-temperature circuit. It is driven by a lines. Thanks to the integration

mechanical pump configured as a cool- of the exhaust manifold into

ant pump module with integrated cool- the cylinder head, it was possi-

ant temperature regulator. The module is ble to configure the turbine

mounted directly to the cylinder head on casing as a slim and light-

the transmission side of the engine. An weight four-hole flange unit.

expanding-wax thermostat for block Thus, the weight of the turbo-

cooling ensures that the cylinder liners charger has been reduced by

remain at a constantly high temperature more than 2 kg compared with a

independent from the main cooling ➏ The weight-optimised conrod conventional configuration.

28 www.autotechreview.com

24-31_New Modular Gasoline Engine Platform_VW_ATR_Feb'13.indd 28 01-02-2013 17:55:21

DEVELOPMENT OF THE

INTAKE PORTS

The so-called Automatic Component Opti-

misation from Volkswagen proved to be

the perfect tool for the development of the

intake ports. The starting point for port

development was the intake port on the

1.4 l TSI EA111. Based on this, the flow

coefficient and tumble value for the EA211

TSI were derived using CFD calculations,

with the objective of finding the best com-

promise between high flow rate and

intensive charge movement. From the

mathematical models, five ports were

selected and evaluated using 3D simula-

tions. Three of these ports were cast as

physical models. Their measurement on

the flow test rig confirmed the initial

selection and they were subsequently

tested on the full engine on the engine

test stand. The optimum port variant ➐ The cooling circuit with separate head/block cooling

delivered the best results in terms of fuel

consumption, running smoothness and

emissions. Its tumble value is considera- bustion process for the EA211 range, simulation methods used, it was possible

bly higher than that of the EA111 TSI, which was aided by CFD. A major focal to optimise in detail the MOV spray pat-

while its flow coefficient is only insignifi- point was the matching of the spray pat- tern and injector timing, as well as their

cantly lower. tern to the flow within the cylinder. adaptation for flow inside the cylinder.

Due to the high specific loads of a Up to three injections per cycle are

small-displacement TSI engine, the opti- possible. These multiple injections occur

OPTIMISATION OF THE mum compromise for mixture formation from idle all the way to full load in the rev

COMBUSTION PROCESS with the smallest quantities of fuel, as range up to 4,000 rpm. Injection pressure

well as under full load, is a multi-orifice is up to 200 bar. The stable tumble flow

This optimum port variant formed the valve (MOV) in combination with generated by the new intake port in com-

basis for the optimisation of the TSI com- increased injection pressure. With the bination with the non rotationally sym-

➑ Torque increase for the EA211 TSI engines

autotechreview Fe b r u ar y 2 013 Vo lu m e 2 | Is su e 2 29

24-31_New Modular Gasoline Engine Platform_VW_ATR_Feb'13.indd 29 01-02-2013 17:55:22

C O V E R S T O R Y GASOLINE ENGINE

metrical five-orifice spray meant that a all, the specific consumption of the SUMMARY

piston recess for mix formation under low EA211 under full load was reduced by

load and special conditions like catalyst up to 20 %, ➒. With the new EA211 series of gasoline

heating was not necessary. Under partial load, too, the combus- engines, the demanding targets for the

Moving outwards from the spark plug, tion process leads to a reduction in con- Volkswagen Group’s future high-volume

the flame front is able to expand evenly, sumption. The main contributing factors engines have been successfully realised.

ensuring that no voids that might induce in this instance are the higher compres- Through the shortening of the block by

knock form at the edges. The compact sion ratio and increased residual gas tol- up to 18 % and the modular construction,

combustion chamber design with con- erance. Because wall wetting is largely the new engines are ideally suited for use

sistently short flame paths and a avoided, the mix can also be run leaner in the Volkswagen Group’s new modular

recessed spark position, as well as the even when the engine is very cold. transverse platform (MQB). They are also

increased turbulent kinetic energy in the fully suitable for implementation in its

combustion chamber, result in improved other vehicles.

tolerance to residual gas under partial FUEL CONSUMPTION, EMISSIONS Fuel consumption in the NEDC drops

load reduced knocking tendency by up to 10 % with the new EA211 TSI

increased combustion efficiency. With the new EA211 engines, it has been engines, and by as much as 20 % in com-

possible to achieve a further impressive bination with the new active cylinder

reduction in fuel consumption. In the management. And similar consumption

INFLUENCE ON CONSUMPTION OF NEDC, consumption figures for the 1.4 l benefits can be expected in real-life cus-

KNOCK LIMIT AND COMBUSTION TSI engines have been reduced in com- tomer usage. Customers, who drive their

SPEED parison with the EA111 engines by vehicles largely over short distances and

around 8 to 10 %. In combination with at low temperatures, will profit from the

The combustion process developed for extensive optimisation of the MQB vehi- new intelligent thermal management.

the EA211 TSI with its high combustion cle, the average consumption in the com- Sporty customers and regular motorway

speed and resulting reduced knock ten- pact class (Golf or Audi A3) will lie in drivers, who frequently run the engine at

dency has a very positive effect on fuel the ballpark of around 5.0 to 5.2 l/100 high load experience, will particularly get

consumption. Across the entire full-load km, which equates to CO2 emissions of substantial benefits from the reduced full-

curve, combustion duration has been around 120 to 125 g/km. For the 1.4 l TSI load consumption resulting from the

shortened by circa 10° of crank angle, with 103 kW and cylinder deactivation, exhaust manifold being integrated into the

enabling mixture enrichment to be sig- the reduction measures up to 20 %. The cylinder head. A further effect of this new

nificantly reduced. Despite an increase new active cylinder management (ACT) concept is significantly improved heating

in compression from 10.0 to 10.5 (in a alone reduces consumption by circa 0.4 of the occupant cabin.

configuration with super grade RON 95 l/100 km or around 8 g CO2 /km. Under Last but not least, the new solutions

gasoline), the combustion point is ear- low loads and at low vehicle speeds in for the EA211 range also have a very posi-

lier. Peak pressure is likewise earlier and particular, the potential for fuel savings tive impact on conventional mixed opera-

is also higher than for the EA111. Over- is even greater. tion. The smaller bearing diameters, the

developments to the pistons and valve

train, the new toothed belt and the regu-

lated oil pump reduce base friction by up

to 30 %. The painstaking weight optimi-

sation of the engine design also delivers a

major contribution within the overall

vehicle to the achievement of weight and

CO2 targets.

REFERENCE

[1] Middendorf, H.; Theobald, J.; Lang, L.; Hartel,

K.: Der 1,4-l-TSI-Ottomotor mit Zylinderabschal-

tung. In: MTZ 73 (2012), No. 3, pp. 186-197

Read this article on

➒ Fuel consumption at full load www.autotechreview.com

30 www.autotechreview.com

24-31_New Modular Gasoline Engine Platform_VW_ATR_Feb'13.indd 30 01-02-2013 17:55:23

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ea288 1Document76 pagesEa288 1api-393155663100% (2)

- MG330Document20 pagesMG330Bipin Kumar75% (4)

- Manual de Partes QSK 23 (PALA 207) PDFDocument121 pagesManual de Partes QSK 23 (PALA 207) PDFKionss Kions100% (4)

- A8 - Feb 09Document62 pagesA8 - Feb 09Sean WilsonNo ratings yet

- 11 - CheyenneIIXL-Reference Manual - Rev 0 PDFDocument236 pages11 - CheyenneIIXL-Reference Manual - Rev 0 PDFwillianverling32hotmail.comNo ratings yet

- Matchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionDocument60 pagesMatchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionBhavesh Hathiwala67% (3)

- Na Presentation Lenovo Docking SolutionsDocument26 pagesNa Presentation Lenovo Docking SolutionsPranav SatputeNo ratings yet

- Docking Station GuideDocument64 pagesDocking Station GuidePranav SatputeNo ratings yet

- VolkswagenEA EnginesDocument34 pagesVolkswagenEA EnginesPranav SatputeNo ratings yet

- Titan 1MDocument1 pageTitan 1MPranav SatputeNo ratings yet

- Ata Chapters 100 MemorizeDocument3 pagesAta Chapters 100 MemorizeFranswa TebelinNo ratings yet

- Dorman BrakeDocument281 pagesDorman BrakeFAKESIGNUPACCOUNTNo ratings yet

- Carburetion Troubleshooting Detail Reference GuideDocument10 pagesCarburetion Troubleshooting Detail Reference GuideyskidmoreNo ratings yet

- Diesel Power Plant (Principle, Component, Layout, Applications)Document17 pagesDiesel Power Plant (Principle, Component, Layout, Applications)Daniel EspinaNo ratings yet

- Specification Sheet of S6R2-T2MPTK Marine Diesel Engine: Item No. M0209-0012E Date April 2013Document4 pagesSpecification Sheet of S6R2-T2MPTK Marine Diesel Engine: Item No. M0209-0012E Date April 2013Nguyễn Văn CảnhNo ratings yet

- E2842E - V12 Gas Engine For CHPDocument4 pagesE2842E - V12 Gas Engine For CHPFlo MarineNo ratings yet

- Car PartsDocument12 pagesCar PartsSemir Nadzakovic100% (1)

- Cooling SystemDocument26 pagesCooling Systemdoreen ann montanoNo ratings yet

- 2006 Nissan X Trail 52433Document80 pages2006 Nissan X Trail 52433Andres Choque100% (1)

- Cat c6.6 Torques SpecsDocument8 pagesCat c6.6 Torques SpecsKedson Martins100% (2)

- PA 32R 301 301T SaratogaDocument6 pagesPA 32R 301 301T SaratogaZawy Alkazawy100% (1)

- 04 BrakesDocument94 pages04 BrakesIonut Valentin VladNo ratings yet

- Service Data Tools Construction Disassembly and ReassemblyDocument16 pagesService Data Tools Construction Disassembly and Reassemblyhanafi yusufNo ratings yet

- Technical Data - Engine 400/520 SX, MXC, Exc Racing 2001Document2 pagesTechnical Data - Engine 400/520 SX, MXC, Exc Racing 2001RostilsavNo ratings yet

- Disc Brake Pads, Caliper Spares & Brake DiscsDocument13 pagesDisc Brake Pads, Caliper Spares & Brake DiscsBW MechanicalNo ratings yet

- Technical Specification: Engine Front AxleDocument2 pagesTechnical Specification: Engine Front AxleÇağrı Fatih AYNo ratings yet

- 2015 Kawasaki kx450f 52462Document204 pages2015 Kawasaki kx450f 52462Armando ConstandaNo ratings yet

- Introduction To Ic EngineDocument57 pagesIntroduction To Ic EnginejhpandiNo ratings yet

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDocument11 pagesDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshNo ratings yet

- Why Do Airplanes With Turbofan Engines Have To Fly Higher Than The Ones With Turboprop - QuoraDocument4 pagesWhy Do Airplanes With Turbofan Engines Have To Fly Higher Than The Ones With Turboprop - QuoraAmir BahramiNo ratings yet

- Hypro D30 Dia PumpDocument1 pageHypro D30 Dia PumpJorge MartinezNo ratings yet

- 2009 BBM Service ManualDocument43 pages2009 BBM Service ManualjgokeyNo ratings yet

- Engine Model 1106C-E66TAG4 Alternator Model LL5014F Engine Build PK38659Document2 pagesEngine Model 1106C-E66TAG4 Alternator Model LL5014F Engine Build PK38659TadeleNo ratings yet

- Linde H16DDocument2 pagesLinde H16Dfox mulderNo ratings yet

- 2003 Model Year: PDF Service ManualDocument96 pages2003 Model Year: PDF Service ManualFrancisco Talavera100% (1)