Professional Documents

Culture Documents

Tayyaba Assignment 1

Uploaded by

TAYYABA AMJAD L1F16MBAM02210 ratings0% found this document useful (0 votes)

9 views2 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesTayyaba Assignment 1

Uploaded by

TAYYABA AMJAD L1F16MBAM0221Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Summary

The Triple-A Supply Chain

Traditionally companies aim for- greater speed and cost effectiveness. So the companies couldn’t

sustain that competitive advantage. But Wal-Mart, Dell, and Amazon were successful to maintain

a competitive advantage through supply chain management

Top-performing supply chains possess three very different qualities Agile, Adaptable, and

Aligned

Agile means respond quickly to sudden changes in supply or demand. They handle unexpected

cost-efficiently. And recovers the company from natural disasters, epidemics, and computer

viruses. The lack of an agile supply chain caused Compaq to lose PC market share throughout the

decade. Smart companies use agile supply chains to differentiate themselves from rivals.

For instance, H&M, Mango, and Zara. In September 1999, an earthquake in Taiwan delayed

shipments of computer components to the United States by weeks and, in some cases, by months.

Most PC manufacturers, such as Compaq, Apple, and Gateway, couldn’t deliver products to

customers on time. Dell could do that because it got data on the earthquake damage early, sized

up the extent of vendors’ problems quickly, and implemented the plans it had drawn up to cope

with such condition.

Adaptable evolve over time as economic progress, political shifts, demographic trends, and

technological advances reshape markets. Great companies don’t stick to the same supply networks

when markets or strategies change. To identify future patterns, it’s necessary to follow some

guidelines. Track economic changes, especially in developing countries, because as nations open

up their economies to global competition, the costs, skills, and risks of global supply chain

operations change. They must develop new suppliers that complement existing ones.

Aligned means interests of all participating firms in the supply chain with their own. As each

player maximizes its own interests, it optimizes the chain's performance as well. Establish

incentives for supply chain partners to improve performance of the entire chain.

In the late 1980s, HP’s integrated circuit (IC) division tried to carry as little inventory as possible,

partly because that was one of its key success factors. Lack of alignment causes the failure of many

supply chain practices. For example, several high-tech companies, including Flextronics,

Solectron, Cisco, and 3Com, have set up supplier hubs close to their assembly plants. Vendors

maintain just enough stock at the hubs to support manufacturers’ needs, and they replenish the

hubs without waiting for orders.

The problem starts with the fact that suppliers own components until they physically enter the

manufacturers’ assembly plants and therefore bear the costs of inventories for longer periods than

they used to. Thus, manufacturers have reduced costs by shifting the ownership of inventories to

vendors, but supply chains bear higher costs because vendors’ costs have risen. In fact, some VMI

systems have generated friction because manufacturers have refused to share costs with vendors.

Seven-Eleven Japan (SEJ) is an example of how a company that builds its supply chain on agility,

adaptability, and alignment stays ahead of its rivals. The $21 billion convenience store chain has

remarkably low stock out rates and in 2004 had an inventory turnover of 55. With gross profit

margins of 30%. The company has designed its supply chain to respond to quick changes in

demand not to focus on fast or cheap deliveries. Some years ago, the company decided to

concentrate stores in key locations instead of building outlets all over the country.

The incentives and disincentives are clear: Make Seven-Eleven Japan successful, and share the

rewards. Fail to deliver on time, and pay a penalty. When Seven-Eleven Japan spots business

opportunities, it works with suppliers to develop products and shares revenues with them.

When I describe the triple-A supply chain to companies, most of them immediately assume it will

require more technology and investment. Most firms already have the infrastructure in place to

create triple-A supply chains. What they need is a fresh attitude and a new culture to get their

supply chains to deliver triple-A performance. This can be challenging for companies because

there are no technologies that can do those things only managers can make them happen.

You might also like

- File 2Document1 pageFile 2TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Pakistan: Land, People, SocietyDocument1 pagePakistan: Land, People, SocietyTAYYABA AMJAD L1F16MBAM0221No ratings yet

- File 1Document1 pageFile 1TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Assignment 2 Supply ChainDocument2 pagesAssignment 2 Supply ChainTAYYABA AMJAD L1F16MBAM0221No ratings yet

- File 4Document1 pageFile 4TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Zain Assignment 2Document1 pageZain Assignment 2TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Assignment 3 Supply ChainDocument2 pagesAssignment 3 Supply ChainTAYYABA AMJAD L1F16MBAM0221No ratings yet

- File 3Document1 pageFile 3TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Mcdonald: SR# Year Slogan Target Audience Ad Success Factor Effectiveness Improvement LinkDocument2 pagesMcdonald: SR# Year Slogan Target Audience Ad Success Factor Effectiveness Improvement LinkTAYYABA AMJAD L1F16MBAM0221No ratings yet

- ME417 Final Project PacketDocument40 pagesME417 Final Project PacketTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Supply Chain Assignment 5Document3 pagesSupply Chain Assignment 5TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Front Page Taiba SPDocument1 pageFront Page Taiba SPTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Supply Chain Assignment 4Document3 pagesSupply Chain Assignment 4TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Tayyaba Assignment 1Document2 pagesTayyaba Assignment 1TAYYABA AMJAD L1F16MBAM0221No ratings yet

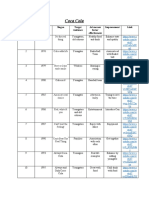

- Coca Cola: SR# Year Slogan Target Audience Ad Success Factor Effectiveness Improvement LinkDocument2 pagesCoca Cola: SR# Year Slogan Target Audience Ad Success Factor Effectiveness Improvement LinkTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Zain SP Assignment 5Document3 pagesZain SP Assignment 5TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Supply Chain Assignment 4 ZainDocument3 pagesSupply Chain Assignment 4 ZainTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Zain Advertising Assignemnt 18 NovDocument2 pagesZain Advertising Assignemnt 18 NovTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Summary 2 TayyabaDocument2 pagesSummary 2 TayyabaTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Zain Assignment 1 Supply ChainDocument2 pagesZain Assignment 1 Supply ChainTAYYABA AMJAD L1F16MBAM0221No ratings yet

- BFChap 1Document29 pagesBFChap 1TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Taiba Assignment 10Document2 pagesTaiba Assignment 10TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Tayyaba Amjad Advertising Assignemnt 18 NovDocument2 pagesTayyaba Amjad Advertising Assignemnt 18 NovTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Zain Assignment Advertising and PromotionDocument2 pagesZain Assignment Advertising and PromotionTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Supply Chain Management Assignment on Jilltronics Security SystemsDocument2 pagesSupply Chain Management Assignment on Jilltronics Security SystemsTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Taiba Assignment 10Document2 pagesTaiba Assignment 10TAYYABA AMJAD L1F16MBAM0221No ratings yet

- Supply Chain Management Assignment on Jilltronics Security SystemsDocument2 pagesSupply Chain Management Assignment on Jilltronics Security SystemsTAYYABA AMJAD L1F16MBAM0221No ratings yet

- 26 Nov Taiba Supply ChainDocument3 pages26 Nov Taiba Supply ChainTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Taiba and ZainDocument3 pagesTaiba and ZainTAYYABA AMJAD L1F16MBAM0221No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CH 03Document67 pagesCH 03Joshua GibsonNo ratings yet

- A Storage and Material Handling Ballou11Document19 pagesA Storage and Material Handling Ballou11Uttkarsh JaiswalNo ratings yet

- Planning and StocksDocument26 pagesPlanning and StocksLara SilveraNo ratings yet

- Komparasi Metode Ecomomic Order Quantity Dan Just in Time Terhadap Efisiensi Biaya Persediaan Putri Lestari Dedi Darwis DamayantiDocument15 pagesKomparasi Metode Ecomomic Order Quantity Dan Just in Time Terhadap Efisiensi Biaya Persediaan Putri Lestari Dedi Darwis DamayantinofitaNo ratings yet

- RFL ElictronicsDocument14 pagesRFL ElictronicsAntora HoqueNo ratings yet

- Director of Purchasing or Purchasing Manager or Director of MateDocument4 pagesDirector of Purchasing or Purchasing Manager or Director of Mateapi-77587911No ratings yet

- Financial Analysis Project - Rite Aid CorporationDocument15 pagesFinancial Analysis Project - Rite Aid Corporationapi-302665852No ratings yet

- Activity/ Asessment 3: Activity: Home Inventory: How Globalized Is Your Home? Points 20 Pts. InstructionsDocument3 pagesActivity/ Asessment 3: Activity: Home Inventory: How Globalized Is Your Home? Points 20 Pts. InstructionsPrecious Mae Cuerquis BarbosaNo ratings yet

- Jan-Feb Cost of Sales, Purchases, CollectionsDocument1 pageJan-Feb Cost of Sales, Purchases, CollectionsVinabie PunoNo ratings yet

- Standard Costs and Operating Performance MeasuresDocument50 pagesStandard Costs and Operating Performance MeasuresJadeNo ratings yet

- The Importance of Budgets in Financial Planning ClassDocument33 pagesThe Importance of Budgets in Financial Planning ClassMonkey2111No ratings yet

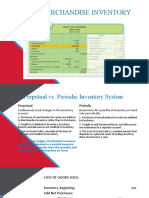

- Merchandise Inventory System and CostingDocument13 pagesMerchandise Inventory System and CostingJade PielNo ratings yet

- Business MathematicsDocument21 pagesBusiness MathematicsAhmer A. NadeemNo ratings yet

- Tugas IndividuDocument6 pagesTugas IndividuMuhammad Fauzan H FauzanNo ratings yet

- Exam 3 001 A FALL 008 SolutionsDocument7 pagesExam 3 001 A FALL 008 SolutionsmounicasrungaNo ratings yet

- Quiz Finman Invty MNGTDocument4 pagesQuiz Finman Invty MNGTZoey Alvin EstarejaNo ratings yet

- Operations Management Processes and Supply Chains 11th Edition Krajewski Test BankDocument71 pagesOperations Management Processes and Supply Chains 11th Edition Krajewski Test Bankglycerolcentry.r8oi100% (24)

- Intelligent Solutions for High Productivity: The Bossard Group's Fastener ExpertiseDocument18 pagesIntelligent Solutions for High Productivity: The Bossard Group's Fastener ExpertiseDavid JendraNo ratings yet

- DocxDocument11 pagesDocx?????No ratings yet

- Sop For Warehouse Inventory Management 140119Document9 pagesSop For Warehouse Inventory Management 140119baabdullah100% (2)

- CVHimanshu MishraDocument8 pagesCVHimanshu Mishrak1969No ratings yet

- Merchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaDocument29 pagesMerchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaSanghamitra KalitaNo ratings yet

- Beginners Guide to Implementing Oracle ASCPDocument21 pagesBeginners Guide to Implementing Oracle ASCPNavin SidanaNo ratings yet

- Data Dictionary For Inventory SchemaDocument6 pagesData Dictionary For Inventory SchemaUsama Bin Alam0% (1)

- Inventory Valuation ProblemsDocument12 pagesInventory Valuation Problemspranay raj rathoreNo ratings yet

- An Introduction To Cost Terms and PurposesDocument22 pagesAn Introduction To Cost Terms and PurposesMohammed Al-baitiNo ratings yet

- CatalogDocument16 pagesCatalogclucian2000No ratings yet

- 4 Inventory Planning and ControlDocument55 pages4 Inventory Planning and ControlSandeep SonawaneNo ratings yet

- Importance of Human Resource PlanningDocument9 pagesImportance of Human Resource PlanningZeUsNo ratings yet

- Yunita Pangala (A031191177) - Akuntansi Manajemen (Tugas Mandiri)Document4 pagesYunita Pangala (A031191177) - Akuntansi Manajemen (Tugas Mandiri)elvienNo ratings yet